ASTM A758/A758M-09

(Specification)Standard Specification for Wrought-Carbon Steel Butt-Welding Piping Fittings with Improved Notch Toughness

Standard Specification for Wrought-Carbon Steel Butt-Welding Piping Fittings with Improved Notch Toughness

ABSTRACT

This guide covers standard specification for wrought-carbon steel butt-welding seamless or welded fittings specially processed to ensure better notch toughness. Heat treatment shall be required for all types of fittings. Fittings with mandatory radiographic examination of welds shall be included. Cast fittings and fittings formed from all weld metal, shall not be included. Heat or cast analysis shall be conducted wherein the material shall conform to the required chemical components for carbon, manganese, phosphorus, sulfur, silicon, vanadium, chromium, nickel, molybdenum, copper, and lead. The fittings, as represented by tensile test specimens taken subsequent to final heat treatment, shall conform to the specified values of tensile strength, yield strength, and elongation for the applicable grades of steel. Mechanical tests such as tension test and transverse guided weld bend test shall be performed on the fittings.

SCOPE

1.1 This specification covers wrought-carbon steel butt-welding seamless or welded fittings specially processed to ensure better notch toughness than that to be expected in fittings manufactured to the requirements of Specification A234/A234M.

1.1.1 Included are elbows, caps, tees, reducers, and other type fittings covered by ASME B 16.9.

1.1.2 Heat treatment is required for all fittings.

1.1.3 Fittings with mandatory radiographic examination of welds are included.

1.1.4 Supplementary requirements are provided for use when additional testing or examination is desired.

1.1.5 Cast fittings, and fittings formed from all weld metal, are not included.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A758/A758M – 09

Standard Specification for

Wrought-Carbon Steel Butt-Welding Piping Fittings with

1

Improved Notch Toughness

This standard is issued under the fixed designationA758/A758M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* SI units are shown in brackets. The values stated in each

system may not be exact equivalents; therefore, each system

1.1 This specification covers wrought-carbon steel butt-

shall be used independently of the other. Combining values

welding seamless or welded fittings specially processed to

from the two systems may result in non-conformance with the

ensure better notch toughness than that to be expected in

standard.

fittings manufactured to the requirements of Specification

A234/A234M.

2. Referenced Documents

1.1.1 Included are elbows, caps, tees, reducers, and other

2.1 In addition to those reference documents listed in

type fittings covered by ASME B 16.9.

Specification A960/A960M, the following list of standards

1.1.2 Heat treatment is required for all fittings.

apply to this specification:

1.1.3 Fittings with mandatory radiographic examination of

2

2.2 ASTM Standards:

welds are included.

A234/A234M Specification for Piping Fittings of Wrought

1.1.4 Supplementary requirements are provided for use

Carbon Steel and Alloy Steel for Moderate and High

when additional testing or examination is desired.

Temperature Service

1.1.5 Cast fittings, and fittings formed from all weld metal,

A275/A275M Practice for Magnetic Particle Examination

are not included.

of Steel Forgings

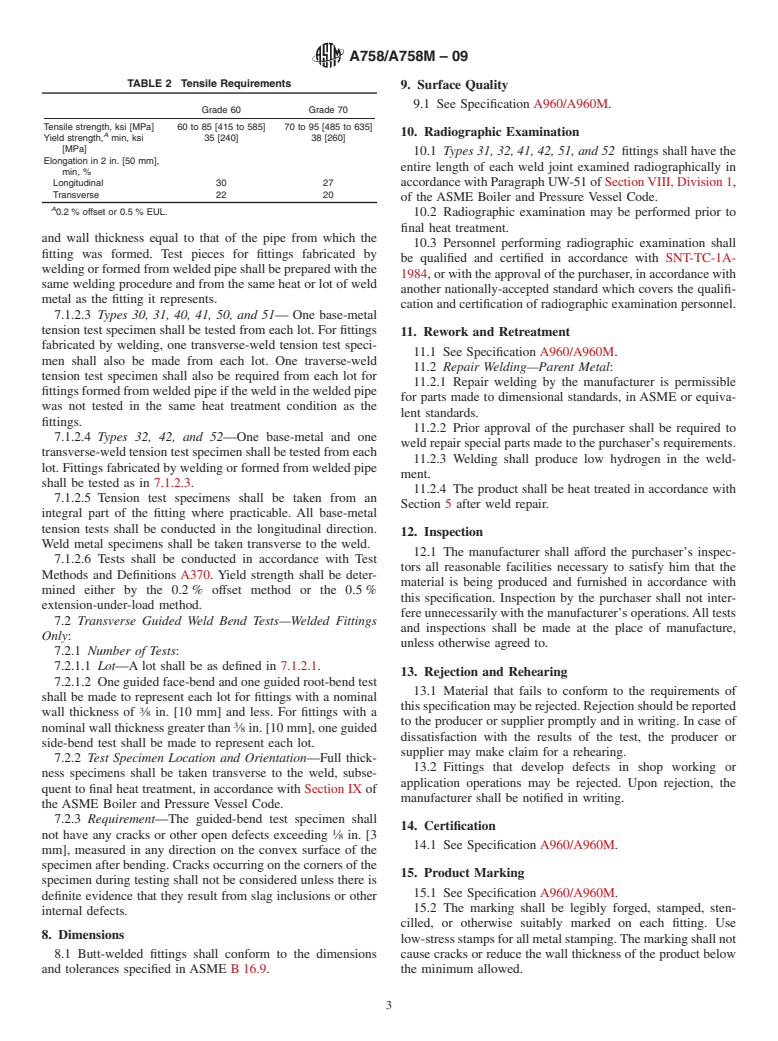

1.2 Several type of fittings are provided, as follows:

A370 Test Methods and Definitions for Mechanical Testing

Heat Treatment Weld Seam Radiography

of Steel Products

Type Required Finish (5.3.2) Required?

A960/A960M Specification for Common Requirements for

30 normalize UW-35 no

Wrought Steel Piping Fittings

31 normalize UW-35 yes

E165 PracticeforLiquidPenetrantExaminationforGeneral

32 normalize UW-35 and ground flush yes

40 normalize and temper UW-35 no

Industry

41 normalize and temper UW-35 yes

E709 Guide for Magnetic Particle Testing

42 normalize and temper UW-35 and ground flush yes

3

2.3 ASMEBoilerandPressureVesselCode(ASMECode):

50 quench and temper UW-35 no

51 quench and temper UW-35 yes

Section VIII, Division 1 Pressure Vessels

52 quench and temper UW-35 and ground flush yes

Section IX , Welding and Brazing Qualifications

1.3 It shall be the responsibility of the purchaser to deter-

2.4 ASME Standard:

3

mine whether material meeting the requirements of this speci- B 16.9 Standards for Steel Butt-Welding Fittings

fication is satisfactory for the service application.

2.5 ASNT Standard:

1.4 This specification is expressed in both inch-pound units SNT-TC-1A Practice for Nondestructive Examination Per-

4

and SI units. However, unless the order specifies the applicable

sonnel Qualification and Certification

“M” specification designation (SI units), the material shall be

3. Ordering Information

furnished to inch-pound units.

1.5 The values stated in either SI units or inch-pound units 3.1 See Specification A960/A960M.

are to be regarded separately as standard. Within the text, the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Standards volume information, refer to the standard’s Document Summary page on

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee the ASTM website.

3

A01.22 on Steel Forgings andWrought Fittings for PipingApplications and Bolting Available from American Society of Mechanical Engineers (ASME), ASME

Materials for Piping and Special Purpose Applications. International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

Current edition approved Oct. 1, 2009. Published November 2009. Originally www.asme.org.

4

approved in 1978. Last previous edition approved in 2005 as A758/ AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

A758M – 00(2005). DOI: 10.1520/A0758_A0758M-09. 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A758/A758M – 09

4. General Requirements 6. Chemical Composition

6.1 HeatorCastAnalysis—Theresultsshallconformtothe

4.1 Product furnished to this specification shall confo

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A758/A758M–00 (Reapproved 2005) Designation: A758/A758M – 09

Standard Specification for

Wrought-Carbon Steel Butt-Welding Piping Fittings with

1

Improved Notch Toughness

This standard is issued under the fixed designationA758/A758M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers wrought-carbon steel butt-welding seamless or welded fittings specially processed to ensure better

notch toughness than that to be expected in fittings manufactured to the requirements of Specification A234/A234M.

1.1.1 Included are elbows, caps, tees, reducers, and other type fittings covered by ASME B 16.9.

1.1.2 Heat treatment is required for all fittings.

1.1.3 Fittings with mandatory radiographic examination of welds are included.

1.1.4 Supplementary requirements are provided for use when additional testing or examination is desired.

1.1.5 Cast fittings, and fittings formed from all weld metal, are not included.

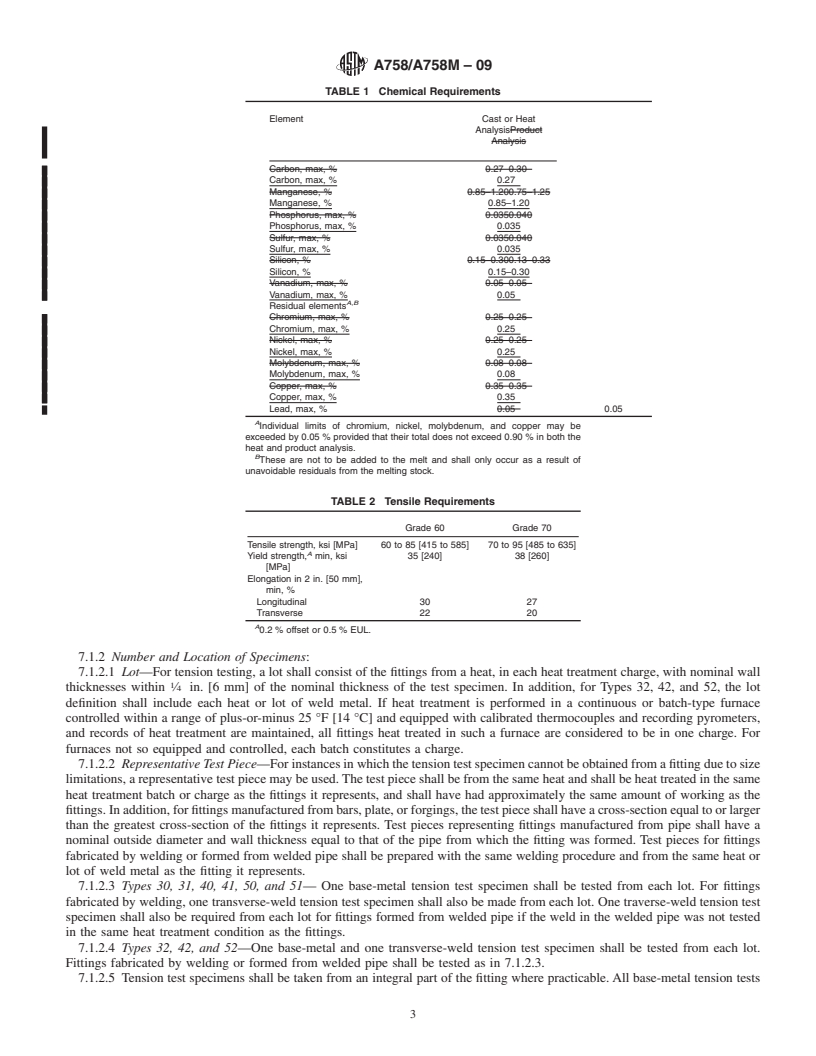

1.2 Several type of fittings are provided, as follows:

Heat Treatment Weld Seam Radiography

Type Required Finish (5.3.2) Required?

30 normalize UW-35 no

31 normalize UW-35 yes

32 normalize UW-35 and ground flush yes

40 normalize and temper UW-35 no

41 normalize and temper UW-35 yes

42 normalize and temper UW-35 and ground flush yes

50 quench and temper UW-35 no

51 quench and temper UW-35 yes

52 quench and temper UW-35 and ground flush yes

1.3 It shall be the responsibility of the purchaser to determine whether material meeting the requirements of this specification

is satisfactory for the service application.

1.4 Thisspecificationisexpressedinbothinch-poundunitsandSIunits.However,unlesstheorderspecifiestheapplicable“M”

specification designation (SI units), the material shall be furnished to inch-pound units.

1.5 The values stated in either inch-poundSI units or SIinch-pound units are to be regarded separately as standard. Within the

text, the SI units are shown in brackets. The values stated in each system aremay not be exact equivalents; therefore, each system

mustshall be used independently of the other. Combining values from the two systems may result in non-conformance with the

specification. standard.

2. Referenced Documents

2.1 In addition to those reference documents listed in Specification A960/A960M, the following list of standards apply to this

specification:

2

2.2 ASTM Standards:

A234/A234M Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature

Service

A275/A275M Practice for Magnetic Particle Examination of Steel Forgings

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A960/A960M Specification for Common Requirements for Wrought Steel Piping Fittings

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel,Steel and Related Alloys,Alloys and is the direct responsibility of

Subcommittee A01.22 on Steel Forgings and Wrought Fittings for Piping Applications and Bolting Materials for Piping and Special Purpose Applications.

Current edition approved Sept. 10, 2000. Published December 2000. Originally approved in 1978. Last previous edition approved in 1998 as A758/A758M–98. DOI:

10.1520/A0758_A0758M-00R05.

Current edition approved Oct. 1, 2009. Published November 2009. Originally approved in 1978. Last previous edition approved in 2005 asA758/A758M – 00(2005). DOI:

10.1520/A0758_A0758M-09.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A758/A758M – 09

E165 Practice for Liquid Penetrant Examination for General Industry

E709 Guide for Magnetic Particle Testing

3

2.3 ASME Boiler and Pressure Vessel Code (ASME Code):

Section VIII, Division 1 Pressure Vessels

Section IX , Welding and Brazing Qualifications

2.4 ASME Standard:

3

B 16.9 Standards for Steel Butt-Welding Fittings

2.5 ASNT Standard:

4

SNT-TC-1A Practice for Nondestructive Examination Personnel Qualification

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.