ASTM A1120/A1120M-21

(Specification)Standard Specification for Electric-Resistance-Welded Carbon Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes with Textured Surface

Standard Specification for Electric-Resistance-Welded Carbon Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes with Textured Surface

SCOPE

1.1 This specification covers average or minimum wall thickness electric resistance welded (ERW) tubing to be used for boilers, heat exchangers, condensers, and similar heat-transfer apparatus.

1.2 The tubing sizes and thicknesses usually furnished to the specification are 0.375 in. [9.5 mm] inside diameter (ID) to 1.5 in. [38 mm] outside diameter (OD) and 0.020 to 0.079 in. [0.5 to 2 mm], inclusive, in wall thickness. Tubing having other dimensions may be furnished provided such tubes comply with all other requirements of this specification.

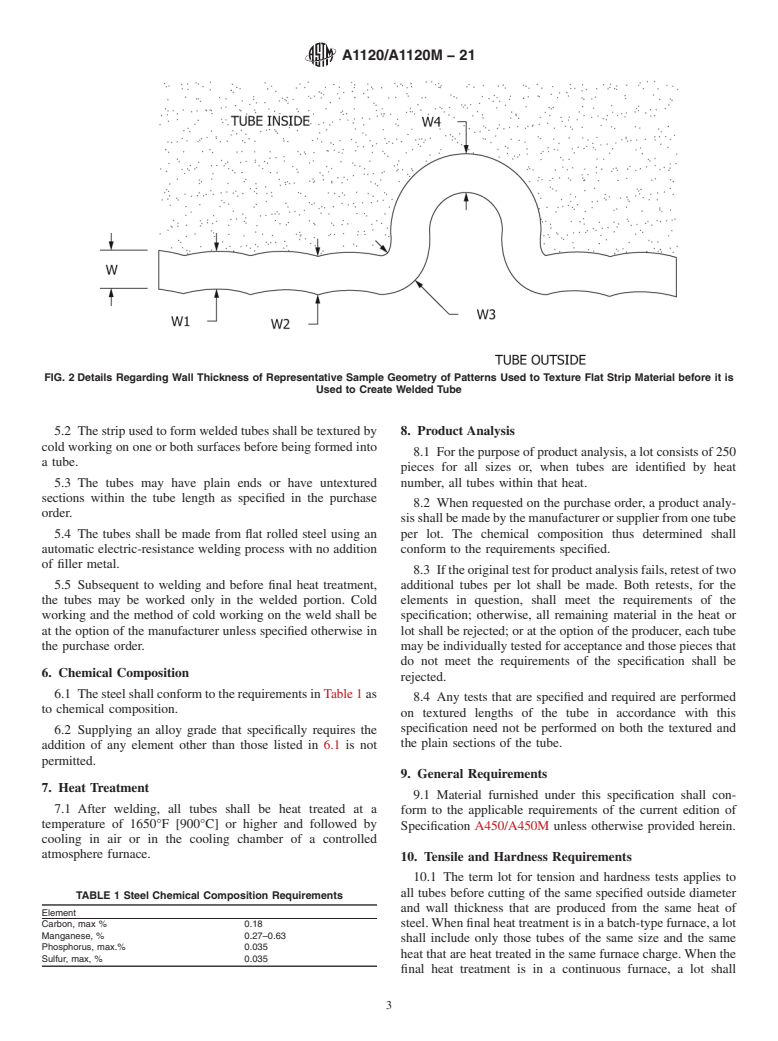

1.3 The steel materials shall have the (1) external tube surface, (2) internal tube surface, or (3) both internal and external tube surfaces textured to improve heat transfer or fluid flow or both. Textured surface(s) are produced by cold forming a specified configuration on the surface(s) of base strip material before welding.

1.4 Optional supplementary requirements are provided and, when desired, shall be so stated on the purchase order.

1.5 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard. The inch-pound units shall apply unless the “M” designation (SI) of the product specification is specified in the order.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A1120/A1120M −21

Standard Specification for

Electric-Resistance-Welded Carbon Steel Boiler,

Superheater, Heat-Exchanger, and Condenser Tubes with

1

Textured Surface

This standard is issued under the fixed designation A1120/A1120M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This specification covers average or minimum wall

ization established in the Decision on Principles for the

thickness electric resistance welded (ERW) tubing to be used

Development of International Standards, Guides and Recom-

for boilers, heat exchangers, condensers, and similar heat-

mendations issued by the World Trade Organization Technical

transfer apparatus.

Barriers to Trade (TBT) Committee.

1.2 Thetubingsizesandthicknessesusuallyfurnishedtothe

specification are 0.375 in. [9.5 mm] inside diameter (ID) to 1.5

2. Referenced Documents

in. [38 mm] outside diameter (OD) and 0.020 to 0.079 in. [0.5

2

2.1 ASTM Standards:

to 2 mm], inclusive, in wall thickness. Tubing having other

A450/A450M Specification for General Requirements for

dimensions may be furnished provided such tubes comply with

Carbon and Low Alloy Steel Tubes

all other requirements of this specification.

A941 TerminologyRelatingtoSteel,StainlessSteel,Related

1.3 The steel materials shall have the (1) external tube

Alloys, and Ferroalloys

surface, (2) internal tube surface, or (3) both internal and

E140 Hardness Conversion Tables for Metals Relationship

external tube surfaces textured to improve heat transfer or fluid

Among Brinell Hardness, Vickers Hardness, Rockwell

flow or both.Textured surface(s) are produced by cold forming

Hardness, Superficial Hardness, Knoop Hardness, Sclero-

aspecifiedconfigurationonthesurface(s)ofbasestripmaterial

scope Hardness, and Leeb Hardness

before welding.

E213 Practice for Ultrasonic Testing of Metal Pipe and

1.4 Optional supplementary requirements are provided and, Tubing

E273 Practice for Ultrasonic Testing of the Weld Zone of

when desired, shall be so stated on the purchase order.

Welded Pipe and Tubing

1.5 Units—The values stated in either SI units or inch-

E384 Test Method for Microindentation Hardness of Mate-

pound units are to be regarded separately as standard. Within

rials

the text, the SI units are shown in brackets. The values stated

3

2.2 ASME Standard:

in each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining Section VIII Para UW-51

values from the two systems may result in nonconformance

with the standard. The inch-pound units shall apply unless the 3. Terminology

“M”designation(SI)oftheproductspecificationisspecifiedin

3.1 Definitions—Fordefinitionsofgeneraltermsusedinthis

the order.

specification, refer to Terminology A941.

1.6 This standard does not purport to address all of the

3.2 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

3.2.1 plain cylindrical ring gauges, n—cylindrical metal

responsibility of the user of this standard to establish appro-

ring whose inside diameter is furnished to gauge tolerance.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Standards volume information, refer to the standard’s Document Summary page on

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee the ASTM website.

3

A01.09 on Carbon Steel Tubular Products. Available from American Society of Mechanical Engineers (ASME), ASME

Current edition approved Nov. 1, 2021. Published December 2021. DOI: International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

10.1520/A1120_A1120M-21. www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A1120/A1120M−21

3.2.2 plain ending, n—portion of the tube that has no 3.3.15 S —Secondary character diameter.

d

surface texture.

3.3.16 S —Secondary character height (inside).

hi

3.2.3 primary character, n—largest texture i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.