ASTM C878-95a

(Test Method)Standard Test Method for Restrained Expansion of Shrinkage-Compensating Concrete

Standard Test Method for Restrained Expansion of Shrinkage-Compensating Concrete

SCOPE

1.1 This test method covers the determination of expansion of concrete made with shrinkage-compensating cement.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information purposes only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation:C878–95a

Standard Test Method for

Restrained Expansion of Shrinkage-Compensating

Concrete

This standard is issued under the fixed designation C 878; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

1. Scope 223-83 Standard Practice for the Use of Shrinkage-

Compensating Concrete

1.1 This test method covers the determination of expansion

of concrete made with shrinkage-compensating cement.

3. Terminology

1.2 The values stated in inch-pound units are to be regarded

3.1 Terms used in this test method are defined in Terminol-

as the standard. The values in parentheses are for information

ogy C 219C 219, Terminology C 125C 125, and ACI 116-R-

purposes only.

90.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

4.1 Since the potential for expansion, under conditions of

priate safety and health practices and determine the applica-

controlled restraint, of concrete made with shrinkage-

bility of regulatory limitations prior to use.

compensating cement cannot always be satisfactorily predicted

2. Referenced Documents from tests of mortars made in accordance with Test Method

C 806C 806, a need has been recognized for a test method in

2.1 ASTM Standards:

which concrete specimens are tested.

C 125 Terminology Relating to Concrete and Concrete

2 4.2 This test method can also be adapted readily to studies

Aggregates

of expansion involving degrees of restraint, comparisons of

C 157 Test Method for Length Change of Hardened Hy-

2 cements, effects of cement contents, mixture proportions,

draulic Cement Mortar and Concrete

schedules, or environmental treatments that differ from the

C 192 Practice for Making and Curing Concrete Test Speci-

2 standard procedures prescribed by this test method.

mens in the Laboratory

C 219 Terminology Relating to Hydraulic Cement

5. Apparatus

C 403 Test Method for Time of Setting of Concrete Mix-

2 5.1 Molds, for casting test specimens, when used in con-

tures by Penetration Resistance

junction with the restraining cage described in 4.2, shall

C 490 Practice for Use of Apparatus for the Determination

provide for forming prisms 3 in. (76 mm) square with a gage

of Length Change of Hardened Cement Paste, Mortar, and

length of 10 in. (254 mm). The molds shall otherwise conform

Concrete

to the requirements of Practice C 490C 490, except that the

C 670 Practice for Preparing Precision and Bias Statements

stud holder, gage studs, and spacer screws described in that

for Test Methods for Construction Materials

specification will not be used.

C 806 Test Method for Restrained Expansion of Expansive

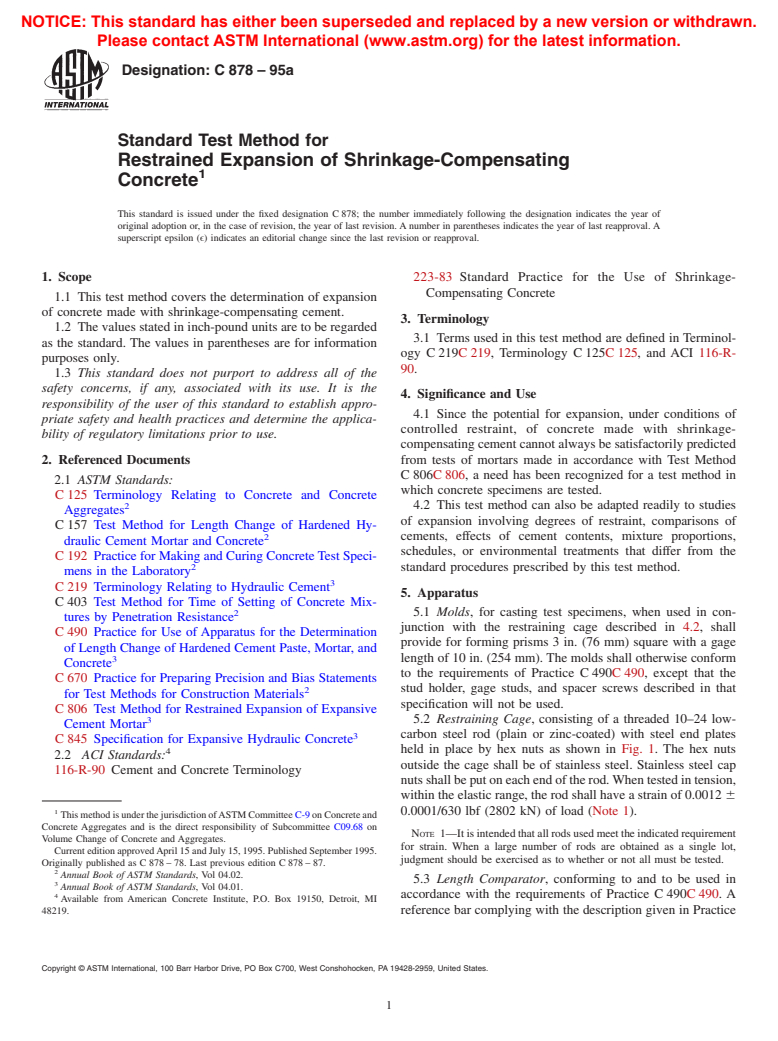

5.2 Restraining Cage, consisting of a threaded 10–24 low-

Cement Mortar

3 carbon steel rod (plain or zinc-coated) with steel end plates

C 845 Specification for Expansive Hydraulic Concrete

4 held in place by hex nuts as shown in Fig. 1. The hex nuts

2.2 ACI Standards:

outside the cage shall be of stainless steel. Stainless steel cap

116-R-90 Cement and Concrete Terminology

nutsshallbeputoneachendoftherod.Whentestedintension,

within the elastic range, the rod shall have a strain of 0.0012 6

1 0.0001/630 lbf (2802 kN) of load (Note 1).

ThismethodisunderthejurisdictionofASTMCommitteeC-9onConcreteand

Concrete Aggregates and is the direct responsibility of Subcommittee C09.68 on

NOTE 1—Itisintendedthatallrodsusedmeettheindicatedrequirement

Volume Change of Concrete and Aggregates.

for strain. When a large number of rods are obtained as a single lot,

Current edition approvedApril 15 and July 15, 1995. Published September 1995.

judgment should be exercised as to whether or not all must be tested.

Originally published as C 878 – 78. Last previous edition C 878 – 87.

Annual Book of ASTM Standards, Vol 04.02.

5.3 Length Comparator, conforming to and to be used in

Annual Book of ASTM Standards, Vol 04.01.

accordance with the requirements of Practice C 490C 490.A

Available from American Concrete Institute, P.O. Box 19150, Detroit, MI

48219. reference bar complying with the description given in Practice

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

C878–95a

Dimensions

Measurement

in. mm

9 1

A11 ⁄16 6 ⁄16 294 6 1.6

B 10 254 (gage length)

C3 76

31 1

D2 ⁄32 6 ⁄32 75 6 1

E1 ⁄2 38

F1 ⁄64 37.7

G ⁄8 10

H ⁄16 5

NOTE 1—All material is mild steel, except for stainless steel cap nuts.

FIG. 1 Restraining Cage

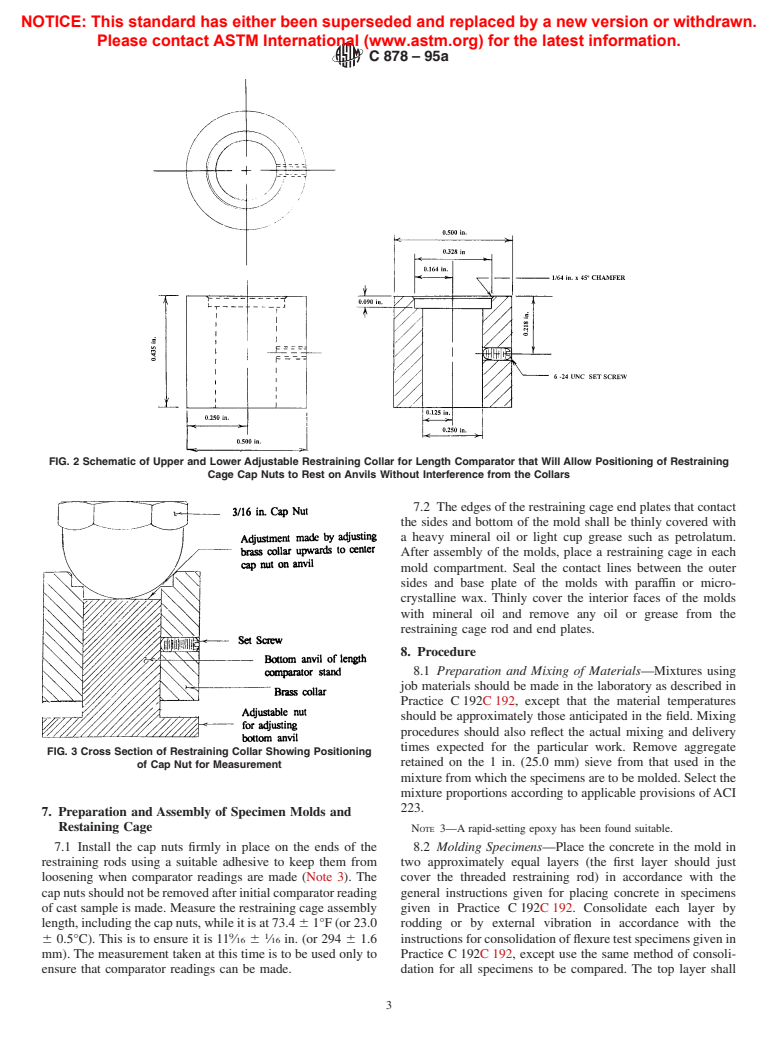

C 490C 490 shall be used. If the terminals of the comparator 6. Test Specimens

are fitted with collars, they shall be such that the cap nuts on

6.1 The test specimen shall be a prism: 3 in. (76 mm) square

the ends of the threaded rod of the specimen do not rest on the

with a gage length of 10 in. (254 mm) and an overall length

collar during the measuring (see Figs. 2 and 3).

(including the length of the rod and cap nuts) of approximately

5.4 Tamping Rod—The tamping rod shall be a straight steel

11 ⁄2 in. (292 mm). At least three specimens shall be prepared

rod, ⁄8 in. or 10 mm in diameter, and no less than 10 in. or 250

for each test.

mm in length, having at least the tamping end rounded to a

hemispherical tip of the same diameter.

NOTE 2—Caution: Aggregate sizes greater than 1 in. may adversely

5.5 Vibrators, conforming to the requirements for external

affect the test results.

vibrators prescribed in Practice C 192C 192.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

C878–95a

FIG. 2 Schematic of Upper and Lower Adjustable Restraining Collar for Length Comparator that Will Allow Positioning of Restraining

Cage Cap Nuts to Rest on Anvils Without Interference from the Collars

7.2 The edges of the restraining cage end plates that contact

the sides and bottom of the mold shall be thinly covered with

a heavy mineral oil or light cup grease such as petrolatum.

After assembly of the molds, place a restraining cage in each

mold compartment. Seal the contact lines between the outer

sides and base plate of the molds with paraffin or micro-

crystalline wax. Thinly cover the interior faces of the molds

with mineral oil and remove any oil or grease from the

restraining cage rod and end plates.

8. Procedure

8.1 Preparation and Mixing of Materials—Mixtures using

job materials should be made in the laboratory as described in

Practice C 192C 192, except that the material temperatures

should be approximately those anticipated in the field. Mixing

procedures should also reflect the actual mixing and delivery

times expected for the particular work. Remove aggregate

FIG. 3 Cross Section of Restraining Collar Showing Positioning

retained on the 1 in. (25.0 mm) sieve from that used in the

of Cap Nut for Measurement

mixture from which the specim

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.