ASTM E570-97

(Practice)Standard Practice for Flux Leakage Examination of Ferromagnetic Steel Tubular Products

Standard Practice for Flux Leakage Examination of Ferromagnetic Steel Tubular Products

SCOPE

1.1 This practice covers the application and calibration of equipment using the flux leakage test method for detection of outer surface, inner surface, and subsurface discontinuities in ferromagnetic steel tubular products (Note 1) of uniform cross section such as seamless and welded tubing.

Note 1-The term "tube" or "tubular product" will be used to refer to both pipe and tubing.

1.2 This practice is intended for use on tubular products having outside diameters from approximately 1/2 to 24 in. (12.7 to 610 mm) with wall thicknesses to 1/2 in. These techniques have been used for other sizes, however, and may be so specified upon contractual agreement between the purchaser and the supplier.

1.3 This practice does not establish acceptance criteria; they must be specified by the using parties.

1.4 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 570 – 97

Standard Practice for

Flux Leakage Examination of Ferromagnetic Steel Tubular

Products

This standard is issued under the fixed designation E 570; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope MIL-STD-410 Nondestructive Testing Personnel Qualifica-

tion

1.1 This practice covers the application and calibration of

equipment using the flux leakage test method for detection of

3. Terminology

outer surface, inner surface, and subsurface discontinuities in

3.1 Definitions of terms relating to flux leakage examination

ferromagnetic steel tubular products (Note 1) of uniform cross

are provided in Terminology E 1316.

section such as seamless and welded tubing.

4. Summary of Practice

NOTE 1—The term “tube” or “tubular product” will be used to refer to

both pipe and tubing.

4.1 This method consists of the following steps:

1.2 This practice is intended for use on tubular products 4.1.1 The tube wall is magnetized at the area under test to a

having outside diameters from approximately ⁄2 to 24 in. (12.7

proper level approaching magnetic saturation.

to 610 mm) with wall thicknesses to ⁄2 in (12.7 mm). These

NOTE 2—Tubes subjected to magnetic inspections can retain various

techniques have been used for other sizes, however, and may

strengths and configuration of residual magnetic fields depending upon the

be so specified upon contractual agreement between the

magnetization technique. If the residual field resulting from a given

purchaser and the supplier.

technique can interfere with subsequent applications of the tube, then a

supplemental demagnetization process may be required.

1.3 This practice does not establish acceptance criteria; they

must be specified by the using parties.

4.1.2 A flux sensor containing magnetic transducers is

1.4 This standard does not purport to address the safety

placed on or above the outside surface of the tube in the

concerns, if any, associated with its use. It is the responsibility

magnetized area.

of the user of this standard to establish appropriate safety and

4.1.3 Either the tube or the flux sensor is moved at a

health practices and determine the applicability of regulatory

constant speed in the direction of the magnetic field so that the

limitations prior to use.

sensor scans the entire surface of the tube.

4.1.4 Each magnetic transducer in the flux sensor is con-

2. Referenced Documents

nected to an electronic console which amplifies, filters, and

2.1 ASTM Standards:

electronically processes the signals such that significant dis-

E 543 Practice for Evaluating Agencies that Perform Non-

continuities are indicated (visually, audibly), and marked with

destructive Testing

paint, or automatically removed from the production line, or

E 1316 Terminology for Nondestructive Examinations

both.

2.2 Other Documents:

4.1.5 A suitable means for assuring near magnetic saturation

SNT-TC-1A Recommended for Personnel Qualification and

of the product (subject to periodic check or calibration) must be

Certification of Nondestructive Testing Personnel

provided as part of the test to verify the capability of detection

ANSI/ASNT CP-189 ASNT Standard for Qualification and

of outside diameter and inside diameter discontinuities.

Certification of Nondestructive Testing Personnel

5. Significance and Use

5.1 This practice outlines a procedure for examining ferro-

This practice is under the jurisdiction of ASTM Committee E-7 on Nonde-

magnetic tubular products using the flux leakage method. If

structive Testing and is the direct responsibility of Subcommittee E07.07 on

Electromagnetic Method. properly applied, this method is capable of detecting the

Current edition approved May 10, 1997. Published February 1998. Originally

published as E 570–76. Last previous edition E 570–91.

Annual Book of ASTM Standards, Vol 03.03.

3 4

Available from American Society for Nondestructive Testing, 1711 Arlingate Available from Standardization Documents Order Desk, Building 4 Section D,

Plaza, PO Box 28518, Columbus, Ohio 43228-0518. 700 Robbins Avenue, Philadelphia, PA 19111-5904, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E570–97

presence and location of significant longitudinally or trans- DETECTION OF LONGITUDINAL

versely oriented discontinuities such as pits, scabs, slivers, DISCONTINUITIES

gouges, roll-ins, laps, seams, cracks, holes, and improper welds

8. Apparatus

in ferromagnetic tubes under inspection. In addition, the

8.1 Rotary Mechanism—The rotary mechanism shall be

severity of a discontinuity may be estimated and a rejection

capable of rotating a magnetizing system or flux leakage

level set with respect to the magnitude of the electromagnetic

sensors, or both, in unison around tubing that is being

indication produced by the discontinuity.

translated axially through the mechanism, thereby producing a

5.2 The response from natural discontinuities can be signifi-

helical scan over the surface. Good examination practices

cantly different from the response for artificial discontinuities

require that the pole pieces of the magnetizing system rotate

such as drilled holes or notches of equivalent depth. For this

uniformly about the tube and that the flux sensor ride on the

reason, sufficient work should be done to determine the

tube or be spaced uniformly above the surface of the tube

conditions necessary to detect and mark natural discontinuities

during rotation.

whose characteristics will adversely affect the serviceability of

8.2 Spin Feed Mechanism—The spin feed mechanism shall

the tube, in order to establish acceptance criteria between the

be capable of positioning a magnetizing system or flux leakage

supplier and purchaser.

sensors, or both, on or near the surface of a translating rotating

tube such that there is a uniform spacing between the pole

6. Basis of Application

pieces of the magnetizing system and the tube. The flux

6.1 The following criteria may be specified in the purchase

leakage sensors shall ride on the surface of the tube or be held

specification, contractual agreement, or elsewhere, and may

uniformly from the surface of the tube during test.

require agreement between the purchaser and supplier:

8.3 Magnetizing System:

6.1.1 Acceptance criteria.

8.3.1 An active field magnetizing system consists of a

6.1.2 Type, dimensions, location, and number of artificial

suitable means of applying a strong adjustable transverse

discontinuities to be placed on the reference standard.

magnetic field to the region of the tube under the flux sensors

6.1.3 Size and type of tubing to be examined.

and shall be capable of bringing that region of the tube to near

6.1.4 Extent of examination (that is, full length, weld zone

saturation. Typical systems employ either permanent magnets

only if welded, etc.).

or controllable electromagnets. If permanent magnets are used,

6.1.5 Disposition of material with discontinuity indications.

a means shall be provided to adjust the spacing of the pole

6.1.6 Methods of verifying dimensions of artificial discon-

pieces in order to reach the proper magnetization level. Refer

tinuities and allowable tolerances.

to Section 13 for application of longitudinal magnetic fields.

6.1.7 Time of inspection, that is, the point(s) in the manu-

8.3.2 A residual field magnetizing system consists of a

facturing process at which the material will be inspected.

means of applying a circular residual magnetic field to an entire

6.1.8 Nondestructive testing (NDT) personnel shall be

tube before the tube is inspected. Typical systems employ a

qualified in accordance with a nationally recognized NDT

centrally positioned conducting rod through which a high

personnel qualification practice or standard such as ANSI/

direct current is passed; alternatively, the current may be

ASNT CP-189, SNT-TC-1A, MIL-STD-410 or a similar docu-

conducted through the tube itself. The current produces a

ment. The practice or standard used and its applicable revision

circular active magnetic field which is concentric with the

shall be specified in the purchase specification or contractural

current distribution. When the current ceases, there remains a

agreement between the using parties.

residual magnetic field which is circular, concentric with the

6.1.9 If specified in the purchase specification or contractual

tube, and wholly contained within the tube wall.

agreement, NDT agencies shall be evaluated and qualified as

8.4 Flux Leakage Sensors:

described in Practice E 543. The applicable edition of Practice

8.4.1 The flux sensor shall consist of magnetic field trans-

E 543 shall be identified in the purchase specification or

ducers that respond to variations in magnetic flux density.

contractual agreement between the using parties.

These sensors generally consist of one of the following types:

electromagnetic coils, Hall probes, magneto diodes, magnis-

7. Interferences

tors, or magnetoresistors. These sensors are normally used to

7.1 There are some manufacturing processes that produce detect the flux leakage directly from the discontinuity in the

tubing with surface conditions that could interfere with or

tube; however, they may also be used to detect flux leakage

obscure signals related to inner surface discontinuities. In the patterns that have been transferred from the tube to a strip of

examination of heavy-walled tubing having these conditions,

magnetic tape. The flux sensors should be of sufficient number

the ability to test reliably for inner surface discontinuities may and length so as to provide 100 % coverage while scanning the

be affected.

tube surface to be tested at the desired examination speed.

7.2 When examining tubes with large rapid surface varia- Their location (with respect to the magnetic pole pieces and the

tions, false signals may be caused by the sensors bouncing tubular product) should result in maximum response to the

along the surface of the tubes. leakage field caused by a discontinuity in the tubular product.

7.3 For active pole magnetizing systems, a small air gap 8.4.2 The depth and orientation of a discontinuity below the

between the magnetizing system and material under test could outside surface will affect the magnitude of the signal received

cause a heavy accumulation of scale buildup on the pole from it. Sensitivity decreases significantly as the distance

pieces. between the flux leakage sensor and the tube under test is

E570–97

increased. Therefore, the sensors should remain clean and have the tube through the inspection apparatus at constant speed and

uniform contact with the tube surface, or if air riding the concentric with the inspection apparatus. As required, the

sensors should be held at a uniform distance above the surface driving mechanism shall be capable of rotating and advancing,

of the tube. or just advancing the tube with a constant speed.

8.5 Electronic Instrumentation—The electronic apparatus

9. Principles of Examination

shall be capable of amplifying signals from the flux sensors and

processing them for the operation of alarms. Multiple probes 9.1 Conduct the examination of tubular products for longi-

may be used to increase the speed of test. The signals may be tudinal discontinuities employing a transverse magnetic field

processed in two separate channels to result in a differentiation and flux leakage detectors using one or more of the following

between inner and outer surface discontinuities. Each of the techniques:

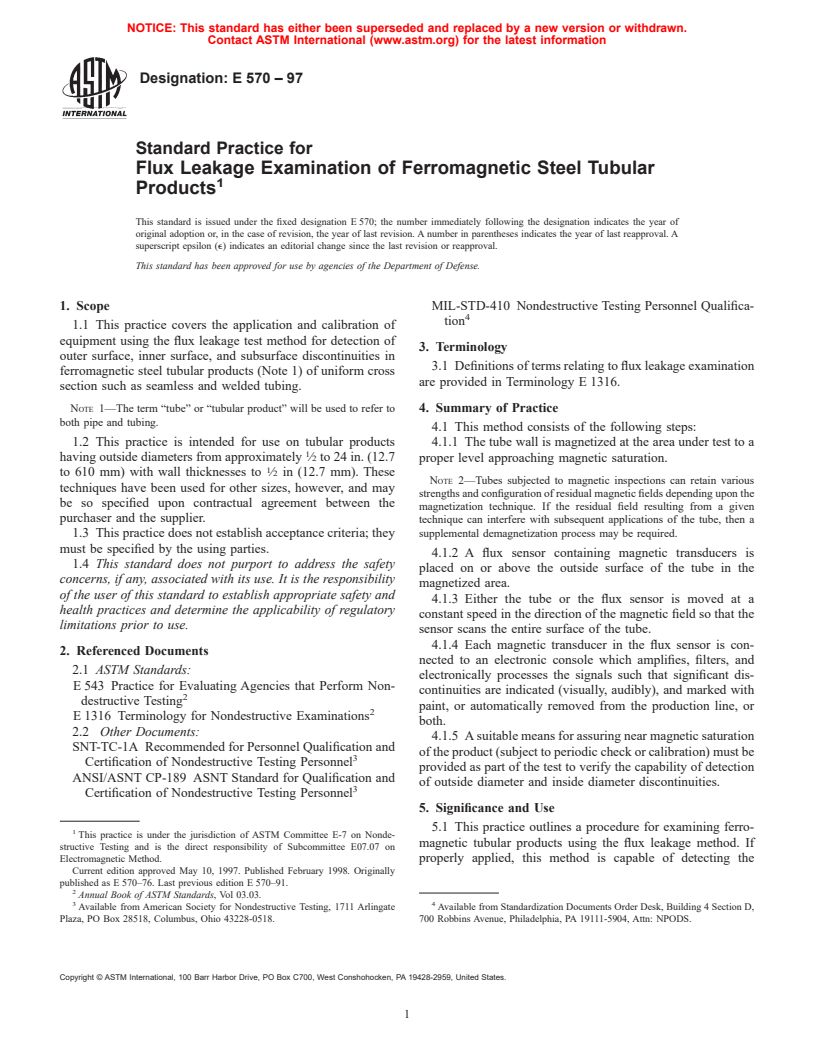

two sets of electronic channels should contain its own sensi- 9.1.1 Obtain a transverse magnetic field by either (1)

tivity and threshold triggering controls for independent setting positioning north and south poles of a magnet on opposite sides

of percentage of wall rejection levels. of a tube on a diameter or chord as shown in Fig. 1(a) and 1(b);

8.6 Driving Mechanism—A mechanical drive mechanism or (2) passing a high direct current through a conducting rod

shall be used which is capable of rigidly holding and passing centrally positioned in the tube under test.

(a)

(b)

FIG. 1 Transverse Magnetization

E570–97

9.1.2 Position a flux sensor (or sensors) containing magnetic voltage generated by the sensor is generally indicative of the

field transducers on or near the tube surface and move at a severity of the discontinuity when all other factors are constant.

uniform speed over the area being magnetized. The flux leakage field measured at the outside surface of the

9.1.3 At a discontinuity in the tube wall, the flux lines are tube resulting from an inside surface discontinuity is much

distorted, producing a leakage field. The maximum flux leak- broader than the leakage field from a discontinuity of equal

age for a discontinuity normally occurs when magnetization is severity located on the outer surface of the tube, resulting in a

perpendicular to the discontinuity. lower signal frequency for the inner surface discontinuity (Fig.

9.1.4 For active pole magnetization, rotation of the magne- 3(a) and 3(b)). Several types of equipment utilize this infor-

tizing system about the tube results in transverse magnetization mation to determine whether the discontinuity is located on the

of the tube wall that is periodically perpendicular to all radii of inner or outer surface of the tube.

the tube (Fig. 2(a)). Rotation of the tube with the magnetizing 9.1.6 Near saturation is required to provide repeatable and

poles held stationary will also produce the same effect (Fig. reliable indications for the presence of outer surface, inner

2(b)). surface, or subsurface discontinuities. A suitable measuring

9.1.5 Relative motion between the flux sensor and the flux means or reference samples or both are required to properly

leakage field caused by the discontinuity is generally utilized to adjust the equipment for operation at the required sensitivity

generate a voltage in the flux sensor. The amplitude of the and magnetization level.

FIG. 2 Rotational Transverse Magnetization

E570–97

(a) Outer Surface Defect

(b) Inner Surface Defect

FIG. 3 External Flux Leakage for O.D. and I.D. Discontinuities

9.2 The examination of tubular products for transverse specified based on factors involving intended service or other

discontinuities utilizing a longitudinal magnetic field is dis- appropriate criteria. Typical

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.