ASTM F793-93(2004)

(Classification)Standard Classification of Wallcovering by Durability Characteristics

Standard Classification of Wallcovering by Durability Characteristics

SCOPE

1.1 This classification covers the classification of wallcovering by durability characteristics, that is, according to its serviceability in use, recognizing that certain wallcovering is designed primarily for decorative effect, while other wallcovering is also designed to achieve a high degree of serviceability.

1.2 The values stated in inch-pound units are to be regarded as the standard. The metric values given in parentheses are provided for information only.

1.3 The flammability test in this classification should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire risk assessment that takes into account all of the factors that are pertinent to an assessment of the fire hazard of a particular end use

This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 793 – 93 (Reapproved 2004)

Standard Classification of

Wallcovering by Durability Characteristics

This standard is issued under the fixed designation F793; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E84 Test Method for Surface Burning Characteristics of

Building Materials

1.1 This classification covers the classification of wallcov-

G21 Practice for Determining Resistance of Synthetic

ering by durability characteristics, that is, according to its

Polymeric Materials to Fungi

serviceability in use, recognizing that certain wallcovering is

2.2 Federal Standards:

designed primarily for decorative effect, while other wallcov-

Fed. Std. No. 191 Textile Test Methods

ering is also designed to achieve a high degree of serviceabil-

Fed. Spec. CCCW-408C Wallcoverings and Vinyl Coated

ity.

2.3 Other Documents:

1.2 The values stated in inch-pound units are to be regarded

NFPA 101 Life Safety Code

as the standard. The metric values given in parentheses are

NFPA255 TestofSurfaceBurningCharacteristicsofBuild-

provided for information only.

ing Materials

1.3 The flammability test in this classification should be

UL 723 Test for Surface Burning Characteristics of Build-

used to measure and describe the properties of materials,

ing Materials

products, or assemblies in response to heat and flame under

controlled laboratory conditions and should not be used to

3. Terminology

describe or appraise the fire hazard or fire risk of materials,

3.1 Definitions of Terms Specific to This Standard:

products, or assemblies under actual fire conditions. However,

3.1.1 abrasion resistance—the ability to withstand me-

results of this test may be used as elements of a fire risk

chanical action such as rubbing, scraping, or scrubbing that

assessment that takes into account all of the factors that are

may progressively tend to remove material from the surface of

pertinent to an assessment of the fire hazard of a particular end

a wallcovering.

use.

3.1.2 blocking resistance—the ability to resist adhesion or

1.4 This standard does not purport to address all of the

sticking between two surfaces of a wallcovering that touch

safety problems, if any, associated with its use. It is the

under uniform loading and temperature conditions for a speci-

responsibility of the user of this standard to establish appro-

fied time.

priate safety and health practices and determine the applica-

3.1.3 breaking strength—the ability of a wallcovering to

bility of regulatory limitations prior to use.

withstand a pulling force in the plane of the web.

2. Referenced Documents 3.1.4 coating adhesion—a measure of the strength of the

2 bond between the surface coating and the backing or substrate

2.1 ASTM Standards:

of a wallcovering.

D685 Practice for Conditioning Paper and Paper Products

3.1.5 cold cracking resistance—theabilitytoresistcracking

for Testing

of the coated or decorative surface when a wallcovering is

D751 Test Methods for Coated Fabrics

folded during exposure to low temperatures.

D1308 Test Method for Effect of Household Chemicals on

3.1.6 colorfastness—the ability to resist change or loss of

Clear and Pigmented Organic Finishes

color resulting from exposure to light.

D2486 Test Method for Scrub Resistance of Wall Paints

3.1.7 crocking resistance—the ability to resist transfer of

color from a wallcovering surface when rubbed.

This classification is under the jurisdiction of ASTM Committee F15 on

Consumer Products and is the direct responsibility of Subcommittee F15.15 on

Wallcoverings.

Current edition approved Jan. 1, 2004. Published January 2004. Originally AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

approved in 1982. Last previous edition approved in 1998 as F793–93 (1998). Robbins Ave., Philadelphia, PA 19111-5094, ATTN: NPODS.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from National Fire Protection Association (NFPA), 1 Batterymarch

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Park, Quincy, MA 02269-9101.

Standards volume information, refer to the standard’s Document Summary page on Available from Underwriters Laboratories (UL), Corporate Progress, 333

the ASTM website. Pfingsten Rd., Northbrook, IL 60062.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 793 – 93 (2004)

3.1.8 flammability—a measure of the ability of a wallcov- 4. Significance and Use

eringtoresistthepropagationofflameandthedevelopmentof

4.1 This classification provides criteria by which wallcov-

smoke under prescribed test conditions. (See 1.2.)

eringofappropriatedurabilitycharacteristicscanbechosenfor

3.1.9 heat aging resistance—the ability to resist deteriora- particular residential and commercial decorating applications.

tion of the coated or decorative surface when a wallcovering is

5. Basis of Classification

exposed to elevated temperatures over an extended period.

3.1.10 mildew-resistant wallcovering—a wallcovering that 5.1 Wallcovering is classified based on its durability in tests

for:

has been treated to deter the growth of fungi (mildew) on the

decorative surface.

Abrasion resistance

Blocking resistance

3.1.11 peelable wallcovering—a wallcovering from which

Breaking strength

the decorative surface may be dry-peeled from the substrate, Coating adhesion

Cold cracking resistance

leaving a continuous layer of the substrate on the wall, when

Colorfastness

the wallcovering has been installed and peeled in accordance

Crocking resistance

with the manufacturer’s instructions. Heat aging resistance

Maximum Flame Spread

3.1.12 scrubbability—the ability of a wallcovering to with-

Maximum Shrinkage

stand scrubbing with a brush and a prescribed detergent Maximum Smoke Development

Scrubbability

solution.

Stain resistance

3.1.13 shrinkability—the change in the dimension of the Tear resistance

Washability

wallcovering after wetting it and drying it.

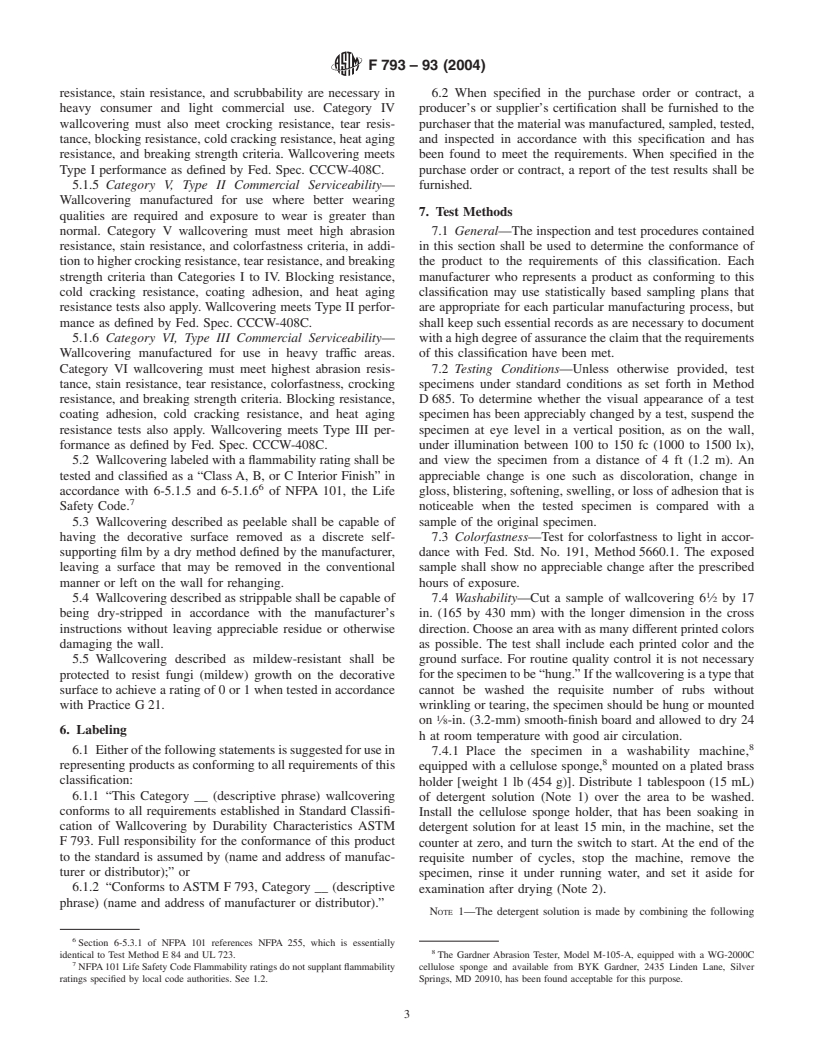

Wallcovering shall be classified in accordance with the

3.1.14 stain resistance—the ability of a wallcovering to

performance criteria listed in Table 1 when tested in accor-

show no appreciable change in appearance after application

dance with the appropriate test methods in Section 7.

and removal of specified reagents.

5.1.1 Category I, Decorative Only—Wallcoveringmanufac-

3.1.15 strippable wallcovering—a wallcovering that can be

turedfordecorativepurposesthatcanbehungwithoutdamage

dry-stripped from the wall after having been installed and

in accordance with the manufacturer’s instructions.

stripped in accordance with the manufacturer’s instructions,

5.1.2 Category II, Decorative with Medium Serviceability—

leaving a minimum of product residue on the wall and without

Wallcovering primarily decorative but more washable and

damage to the wall surface.

colorfast than Category I wallcovering.

3.1.16 tear strength—the ability of a wallcovering to resist

5.1.3 Category III, Decorative with High Serviceability—

the propagation of an existing tear.

Wallcovering manufactured for medium use, where abrasion

3.1.17 wallcovering—a flexible product designed to cover

resistance, stain resistance, scrubbability, and increased color-

walls and ceilings for decorative or functional purposes, or

fastness are necessary. Category III wallcovering must also

both.

meet breaking strength and crocking resistance criteria.

3.1.18 washability—the ability of a wallcovering to with- 5.1.4 Category IV, Type I Commercial Serviceability—

standoccasionalspongingwithaprescribeddetergentsolution. Wallcovering manufactured for use where higher abrasion

TABLE 1 Classification Criteria

Category II Category III Category IV Category V Category VI

Category I

Section Decorative Decorative Type I Type II Type III

Property Decorative

Reference with Medium with High Commercial Commercial Commercial

Only

Serviceability Serviceability Serviceability Serviceability Serviceability

Minimum colorfastness 7.3 23 h 46 h 200 h 200 h 200 h

Minimum washability 7.4 100 cycles 100 cycles 100 cycles 100 cycles 100 cycles

Minimum scrubbability 7.7 50 cycles 200 cycles 300 cycles 500 cycles

Minimum abrasion resistance 7.8 200 cycles 300 cycles 1000 cycles

(220 grit) (220 grit) (220 grit)

Minimum breaking strength 7.9 40 lb 50 lb 100 lb

MD (machine direction) 30 lb 55 lb 95 lb

CMD (cross machine direction)

Minimum crocking resistance 7.6 good good good good

Minimum stain resistance 7.5 Reagents 1 to 9 Reagents 1 to 9 Reagents 1 to 12 Reagents 1 to 12

Minimum tear resistance 7.10 12 25 50

Maximum blocking resistance 7.11 2 2 2

Minimum coating adhesion 7.12 2 lb/in 3 lb/in. 3 lb/in.

Minimum cold cracking resistance 7.13 no change no change no change

Minimum heat aging resistance 7.14 pass pass pass

Maximum flame spread 7.15 25 25 25 25 25

Maximum smoke development 7.15 50 50 50 50 50

Maximum shrinkage 7.19

MD (machine direction) 2 2 2

CMD (cross machine direction) 1 1 1.5

F 793 – 93 (2004)

resistance, stain resistance, and scrubbability are necessary in 6.2 When specified in the purchase order or contract, a

heavy consumer and light commercial use. Category IV producer’s or supplier’s certification shall be furnished to the

wallcovering must also meet crocking resistance, tear resis- purchaser that the material was manufactured, sampled, tested,

tance, blocking resistance, cold cracking resistance, heat aging and inspected in accordance with this specification and has

resistance, and breaking strength criteria. Wallcovering meets been found to meet the requirements. When specified in the

Type I performance as defined by Fed. Spec. CCCW-408C. purchase order or contract, a report of the test results shall be

5.1.5 Category V, Type II Commercial Serviceability— furnished.

Wallcovering manufactured for use where better wearing

7. Test Methods

qualities are required and exposure to wear is greater than

normal. Category V wallcovering must meet high abrasion 7.1 General—The inspection and test procedures contained

resistance, stain resistance, and colorfastness criteria, in addi- in this section shall be used to determine the conformance of

tiontohighercrockingresistance,tearresistance,andbreaking the product to the requirements of this classification. Each

strength criteria than Categories I to IV. Blocking resistance, manufacturer who represents a product as conforming to this

cold cracking resistance, coating adhesion, and heat aging classification may use statistically based sampling plans that

resistance tests also apply. Wallcovering meets Type II perfor- are appropriate for each particular manufacturing process, but

mance as defined by Fed. Spec. CCCW-408C. shall keep such essential records as are necessary to document

5.1.6 Category VI, Type III Commercial Serviceability— withahighdegreeofassurancetheclaimthattherequirements

Wallcovering manufactured for use in heavy traffic areas. of this classification have been met.

Category VI wallcovering must meet highest abrasion resis- 7.2 Testing Conditions—Unless otherwise provided, test

tance, stain resistance, tear resistance, colorfastness, crocking specimens under standard conditions as set forth in Method

resistance, and breaking strength criteria. Blocking resistance, D685. To determine whether the visual appearance of a test

coating adhesion, cold cracking resistance, and heat aging specimen has been appreciably changed by a test, suspend the

resistance tests also apply. Wallcovering meets Type III per- specimen at eye level in a vertical position, as on the wall,

formance as defined by Fed. Spec. CCCW-408C. under illumination between 100 to 150 fc (1000 to 1500 lx),

5.2 Wallcoveringlabeledwithaflammabilityratingshallbe and view the specimen from a distance of 4 ft (1.2 m). An

tested and classified as a “Class A, B, or C Interior Finish” in appreciable change is one such as discoloration, change in

accordance with 6-5.1.5 and 6-5.1.6 of NFPA 101, the Life gloss,blistering,softening,swelling,orlossofadhesionthatis

Safety Code. noticeable when the tested specimen is compared with a

5.3 Wallcovering described as peelable shall be capable of sample of the original specimen.

having the decorative surface removed as a discrete self- 7.3 Colorfastness—Test for colorfastness to light in accor-

supporting film by a dry method defined by the manufacturer, dance with Fed. Std. No. 191, Method5660.1. The exposed

leaving a surface that may be removed in the conventional sample shall show no appreciable change after the prescribed

manner or left on the wall for rehanging. hours of exposure.

5.4 Wallcovering described as strippable shall be capable of 7.4 Washability—Cut a sample of wallcovering 6 ⁄2 by 17

being dry-stripped in accordance with the manufacturer’s in. (165 by 430 mm) with the longer dimension in the cross

instructions without leaving appreciable residue or otherwise direction.Chooseanareawithasmanydifferentprintedcolors

damaging the wall. as possible. The test shall include each printed color and the

5.5 Wallcovering described as mildew-resistant shall be ground surface. For routine quality control it is not necessary

protected to resist fungi (mildew) growth on the decorative forthespecimentobe“hung.”Ifthewallcoveringisatypethat

surface to achieve a rating of 0 or 1 when tested in accordance cannot be washed the requisite number of rubs without

with Practice G21. wrinkling or tearing, the specimen should be hung or mounted

on ⁄8-in. (3.2-mm) smooth-finish board and allowed to dry 24

6. Labeling

h at room temperature with good air circulation.

6.1 Eitherofthefollowingstatementsissuggestedforusein

7.4.1 Place the specimen in a washability machine,

representingproductsasconformingtoallrequirementsofthis

equipped with a cellulose sponge, mounted on a plated brass

classification:

holder [weight 1 lb (454 g)]. Distribute 1 tablespoon (15 mL)

6.1.1 “This Category __ (descriptive phrase) wallcovering

of detergent solution (Note 1) over the area to be washed.

conforms to all requirements established in Standard Classifi-

Install the cellulose sponge holder, that has been soaking in

cation of Wallcovering by Durability Characteristics ASTM

detergent solution for at least 15 min, in the machine, set the

F793. Full responsibility for the conformance of this product

counter at zero, and turn the switch to start. At the end of the

to the standard is assumed by (name and address of manufac-

requisite number of cycles, stop the machine, remove the

turer or distributor);” or

spe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.