ASTM D7855/D7855M-13(2021)

(Test Method)Standard Test Method for Determination of Mold Growth on Coated Building Products Designed for Interior Applications Using an Environmental Chamber and Indirect Inoculation

Standard Test Method for Determination of Mold Growth on Coated Building Products Designed for Interior Applications Using an Environmental Chamber and Indirect Inoculation

SIGNIFICANCE AND USE

5.1 An accelerated test for determining the resistance of interior coated building products to mold growth is useful in estimating the relative performance for use in interior environments under conditions favorable to fungal growth.

5.2 Static or environmental chambers provide controlled laboratory micro-environment conditions. These chambers are not intended to duplicate room conditions, and care must be taken when interpreting the results. Static chambers are not a substitute for dynamic chambers or field studies.

SCOPE

1.1 This test method covers an environmental chamber and the conditions of operation to evaluate in a 4-week period the relative resistance to mold growth and microbial surface defacement on coated building products designed for interior application using an indirect inoculation method. The apparatus is designed so it can be easily built or obtained by any interested party.

1.2 This test method can be used to evaluate the comparative resistance of coated building products to accelerated mold growth. Ratings do not imply a specific time period that the coated building product will be free of fungal growth during installation in an interior environment.

1.3 This test method is not intended for use in the evaluation of public health claims.

1.4 The test method is intended for the accelerated evaluation of mold growth on a coated building product designed for interior use. This method is not intended for evaluation of surfaces designed for exterior applications or uncoated surfaces. Use of this test method for evaluating exterior performance has not been validated, nor have the limitations for such use been determined.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7855/D7855M − 13 (Reapproved 2021)

Standard Test Method for

Determination of Mold Growth on Coated Building Products

Designed for Interior Applications Using an Environmental

Chamber and Indirect Inoculation

This standard is issued under the fixed designation D7855/D7855M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This test method covers an environmental chamber and

ization established in the Decision on Principles for the

the conditions of operation to evaluate in a 4-week period the

Development of International Standards, Guides and Recom-

relative resistance to mold growth and microbial surface

mendations issued by the World Trade Organization Technical

defacement on coated building products designed for interior

Barriers to Trade (TBT) Committee.

application using an indirect inoculation method. The appara-

tus is designed so it can be easily built or obtained by any

2. Referenced Documents

interested party.

2.1 ASTM Standards:

1.2 This test method can be used to evaluate the compara-

D16TerminologyforPaint,RelatedCoatings,Materials,and

tive resistance of coated building products to accelerated mold

Applications

growth. Ratings do not imply a specific time period that the

D1193Specification for Reagent Water

coated building product will be free of fungal growth during

D6329Guide for Developing Methodology for Evaluating

installation in an interior environment.

the Ability of Indoor Materials to Support Microbial

1.3 Thistestmethodisnotintendedforuseintheevaluation

Growth Using Static Environmental Chambers

of public health claims.

E177Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.4 The test method is intended for the accelerated evalua-

E691Practice for Conducting an Interlaboratory Study to

tion of mold growth on a coated building product designed for

Determine the Precision of a Test Method

interior use. This method is not intended for evaluation of

surfaces designed for exterior applications or uncoated sur-

3. Terminology

faces. Use of this test method for evaluating exterior perfor-

mancehasnotbeenvalidated,norhavethelimitationsforsuch 3.1 Definitions—For definitions of terms refer to Terminol-

ogy D16.

use been determined.

1.5 The values stated in either SI units or inch-pound units 3.2 Definitions of Terms Specific to This Standard:

3.2.1 chamber control, n—openPetridishcontainingappro-

are to be regarded separately as standard. The values stated in

each system may not be exact equivalents; therefore, each priate agar to demonstrate viability of fungal organisms within

the environmental chamber.

system shall be used independently of the other. Combining

values from the two systems may result in non-conformance

3.2.2 coated building product, n—a building material hav-

with the standard.

ingaliquid,liquefiableormasticcompositionthatisconverted

1.6 This standard does not purport to address all of the to a solid protective, decorative, or functional adherent film

after application as a thin layer onto a building fabric.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.2.3 interior, n—any surface not exposed to exterior envi-

priate safety, health, and environmental practices and deter-

ronments in end use.

mine the applicability of regulatory limitations prior to use.

3.2.4 interior finish, n—interior wall and ceiling finish and

interior floor finish.

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.28 on Biodeterioration. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2021. Published November 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2013. Last previous edition approved in 2017 as D7855/D7855M–13 Standards volume information, refer to the standard’s Document Summary page on

(2017). DOI: 10.1520/D7855_D7855M-13R21. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7855/D7855M − 13 (2021)

3.2.5 material control, n—untreated representative sub- nineteenlitercontainermeasuringapproximately460mmlong

strate. by 300 mm wide by 230 mm high [18 in. long by 12 in. wide

by 9 in. high] can accommodate fifteen 75 by 100 mm [3 by 4

3.2.6 sample, n—a portion of material taken from a larger

in.] test specimens suspended from rods using cable ties.

quantity for the purpose of estimating properties or composi-

Opaque chambers shall have a viewing port that permits

tion of the larger quantity.

observation of chamber controls. Chamber shall permit tem-

3.2.7 sample tests, n—a group of samples (one or more).

perature and humidity monitoring without opening the cham-

3.2.8 test run, n—theevaluationofcoatedbuildingproducts

ber lid. Examples would include wireless or wired probes.

in accordance with the procedure outlined in this test method.

7.1.1 The test chamber shall be designed so that no conden-

3.2.9 test specimen, n—a portion of a test unit needed to sate forming on the top interior surface will drip onto the test

specimens. For stand-alone chambers, this can be accom-

obtain a single test determination.

plished by designing the top so that the interior surface is at an

4. Summary of Test Method

angle of at least 30 degrees, relative to the plane of the bottom

of the chamber. A sheet of polycarbonate secured at an angle,

4.1 This test method is an indirect inoculation to a coated

or hinged or joined sheets of polycarbonate attached to the

interior building product of two fungal organisms, Aspergillus

underside of the lid will direct the condensation away from the

nigerand Penicillium citrinum.Testspecimensareplacedinan

test samples. Condensation inside the test chamber is not a

environmentalchambermaintainedat30 62°C[86 63.6°F]

concern as it indicates that humidity is being maintained.

and at greater than 90 % relative humidity for four weeks.

7.1.1.1 Anon-corrosive open grid is placed at the bottom of

Humidity is maintained by adding sufficient sterile DI water to

the test chamber above the water level supporting 100 by 15

the bottom of the covered test chamber. A continuous fungal

mm [4 by ⁄8 in.] sterile Petri dishes alternating the two fungal

inoculation is provided by open Petri dishes supporting seven

organisms. See Fig. 1 for non-corroding open grid example.

day cultures of the two test organisms placed on a rack below

Place sufficient Petri dishes on the rack to fill the grid. The

the test pieces. Test specimens are removed from the chamber

plastic grid designed to cover recessed ceiling fixtures or

after four weeks exposure and examined for fungal growth.

similar works well.

The evaluation is a macroscopic inspection of the test pieces

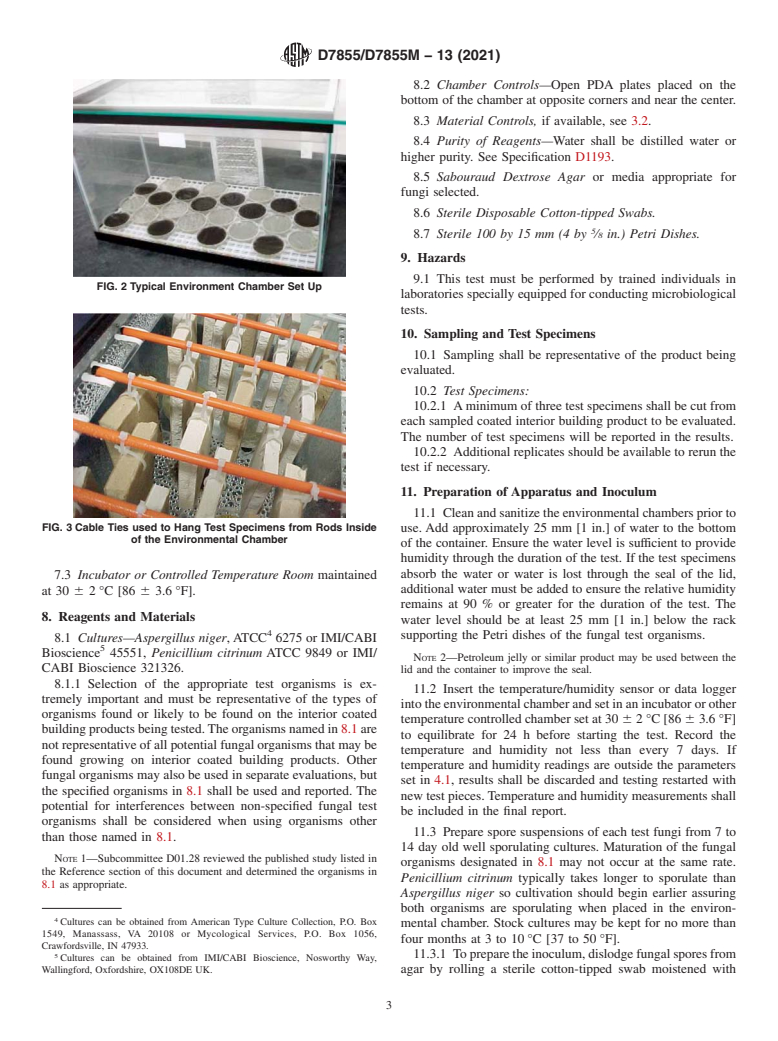

7.1.1.2 Position test specimens by suspending them from

with indirect lighting.

rodsusingplasticcableties.Samplesmustbe50to100mm[2

5. Significance and Use to 4 in.] above the inoculated Petri dishes. The minimum

distance between adjacent specimens and between test speci-

5.1 An accelerated test for determining the resistance of

mens and chamber walls shall be at least 25 mm [1 in.].

interior coated building products to mold growth is useful in

Materials used as the rods or mounting racks shall be non-

estimating the relative performance for use in interior environ-

corroding and of sufficient strength to support specimens

ments under conditions favorable to fungal growth.

throughout the duration of the test. Use of engineered plastics

5.2 Static or environmental chambers provide controlled

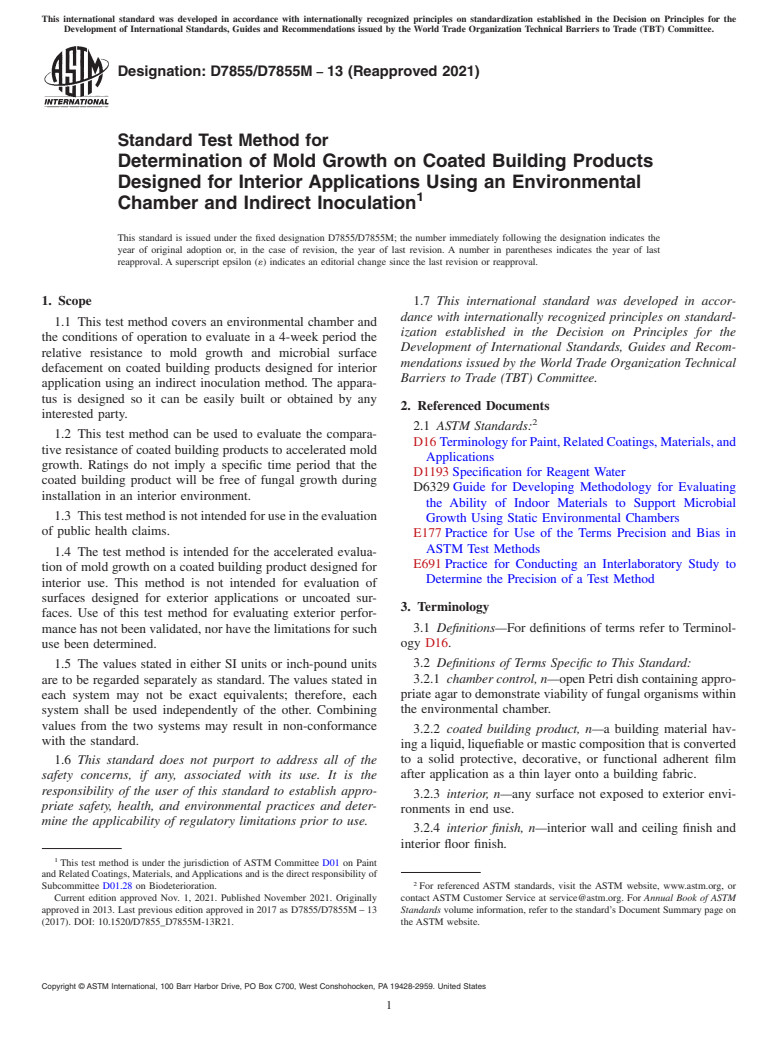

such as polycarbonate has been found suitable. Fig. 2 shows a

laboratory micro-environment conditions. These chambers are

photo of typical chamber construction. Fig. 3 illustrates use of

not intended to duplicate room conditions, and care must be

cable ties to hang test specimens from rods.

taken when interpreting the results. Static chambers are not a

7.2 Measurement Instruments, capable of accurate and pre-

substitute for dynamic chambers or field studies.

cise measures of temperature and humidity. See Section 12.

6. Interferences

6.1 Proper lab ventilation, hygiene, and aseptic technique

must be followed to ensure fungal cultures are pure and no

cross contamination of fungal strains or growth media occurs.

6.2 The exposure of test specimens to environmental con-

ditions including temperature, humidity, and light can impact

test results. To minimize variability of test results consistent

handling and storage of test specimens is important.

7. Apparatus

7.1 Environmental Chamber—Anon-corrosive covered box

containing standing water placed in an incubator at 30 62°C

[86 6 3.6°F] will expose the test specimens to a controlled

environment of temperature and humidity. Containers found

suitable include glass, polycarbonate or other plastic storage

containers which are generally available. For example a

The 5.0 Gallon Rectangular Food Storage Containers from various suppliers FIG. 1 Non-corroding Open Grid for Placement in Bottom of the

have been found to work well. Environmental Chamber

D7855/D7855M − 13 (2021)

8.2 Chamber Controls—Open PDA plates placed on the

bottom of the chamber at opposite corners and near the center.

8.3 Material Controls, if available, see 3.2.

8.4 Purity of Reagents—Water shall be distilled water or

higher purity. See Specification D1193.

8.5 Sabouraud Dextrose Agar or media appropriate for

fungi selected.

8.6 Sterile Disposable Cotton-tipped Swabs.

8.7 Sterile 100 by 15 mm (4 by ⁄8 in.) Petri Dishes.

9. Hazards

9.1 This test must be performed by trained individuals in

FIG. 2 Typical Environment Chamber Set Up

laboratories specially equipped for conducting microbiological

tests.

10. Sampling and Test Specimens

10.1 Sampling shall be representative of the product being

evaluated.

10.2 Test Specimens:

10.2.1 Aminimumofthreetestspecimensshallbecutfrom

each sampled coated interior building product to be evaluated.

The number of test specimens will be reported in the results.

10.2.2 Additional replicates should be available to rerun the

test if necessary.

11. Preparation of Apparatus and Inoculum

11.1 Cleanandsanitizetheenvironmentalchamberspriorto

FIG. 3 Cable Ties used to Hang Test Specimens from Rods Inside

use. Add approximately 25 mm [1 in.] of water to the bottom

of the Environmental Chamber

of the container. Ensure the water level is sufficient to provide

humidity through the duration of the test. If the test specimens

absorb the water or water is lost through the seal of the lid,

7.3 Incubator or Controlled Temperature Room maintained

additional water must be added to ensure the relative humidity

at 30 6 2°C [86 6 3.6°F].

remains at 90 % or greater for the duration of the test. The

8. Reagents and Materials

water level should be at least 25 mm [1 in.] below the rack

supporting the Petri dishes of the fungal test organisms.

8.1 Cultures—Aspergillus niger,ATCC 6275 or IMI/CABI

Bioscience 45551, Penicillium citrinum ATCC 9849 or IMI/

NOTE 2—Petroleum jelly or similar product may be used between the

CABI Bioscience 321326.

lid and the container to improve the seal.

8.1.1 Selection of the appropriate test organisms is ex-

11.2 Insert the temperature/humidity sensor or data logger

tremely important and must be representative of the types of

intotheenvironmentalchamberandsetinanincubatororother

organisms found or likely to be found on the interior coated

temperaturecontrolledchambersetat30 62°C[86 63.6°F]

buildingproductsbeingtested.Theorganismsnamedin8.1are

to equilibrate for 24 h before starting the test. Record the

notrepresentativeofallpotentialfungalorganismsthatmaybe

temperature and humidity not less than every 7 days. If

found growing on interior coated building products. Other

temperature and humidity readings are outside the parameters

fungalorganismsmayalsobeusedinseparateevaluations,but

set in 4.1, results shall be discarded and testing restarted with

the specified organisms in 8.1 shall be used and reported. The

newtestpieces.Temperatureandhumiditymeasurementsshall

potential for interferences between non-specified fungal test

be included in the final report.

organisms shall be considered when using organisms other

11.3 Prepare spore suspensions of each test fungi from 7 to

than those named in 8.1.

14 day old well sporulating cultures. Maturation of the fungal

NOTE 1—Subcommittee D01.28 reviewed the published study listed in

organisms designated in 8.1 may not occur at the same rate.

the Reference section of this document and determined the organisms in

Penicillium citrinum typically takes longer to sporulate than

8.1 as appropriate.

Aspergillus niger so cultivation should begin earlier assuring

both organisms are sporulating when placed in the environ-

Cultures can be obtained from American Type Culture Collection, P.O. Box

mental chamber. Stock cultures may be kept for no more than

1549, Manassass, VA 20108 or Mycological Services, P.O. Box 1056,

four months at 3 to 10°C [37 to 50°F].

Crawfordsville, IN 47933.

11.3.1 Topreparetheinoculum,dislodgefungalsporesfrom

Cultures can be obtained from IMI/CABI Bioscience, Nosworthy Way,

Wallingford, Oxfordshire, OX108DE UK. agar by rolling a sterile cotton-tipped swab moistened with

D7855/D7855M − 13 (2021)

FIG. 4 Example of Sporulating Fungal Plates Arranged in an Alternating Pattern in the Environmental Chamber

sterile distilled water across the sporulating fungi.Transfer the 12.2 Instruments for humidity measurement shall measure

spores from the cotton tipped swab to a test tube containing 5 with a precision of 65%RHat95%RH.

mL of sterile distilled water and a nontoxic wetting agent for

12.3 Both types of measurement instruments shall be cali-

each test organism. Blend the fungal spore suspension on the

brated no less than annually by a laboratory using standards

vortex mixer for 10 s to liberate spores from hyphae and to

that are documented traceable to NIST standards.

break up spore clumps. Repeat this

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.