ASTM D7344-07

(Test Method)Standard Test Method for Distillation of Petroleum Products at Atmospheric Pressure (Mini Method)

Standard Test Method for Distillation of Petroleum Products at Atmospheric Pressure (Mini Method)

SIGNIFICANCE AND USE

The distillation (volatility) characteristics of hydrocarbons have an important effect on their safety and performance, especially in the case of fuels and solvents. The boiling range gives information on the composition, the properties, and the behavior of the fuel during storage and use. Volatility is the major determinant of the tendency of a hydrocarbon mixture to produce potentially explosive vapors.

The distillation characteristics are equally important for both automotive and aviation gasolines, affecting starting, warm-up, and tendency to vapor lock at high operating temperatures or high altitude, or both. The presence of high boiling point components in these and other fuels can significantly affect the degree of formation of solid combustion deposits.

Volatility, as it affects the rate of evaporation, is an important factor in the application of many solvents, particularly those used in paints.

Distillation limits are often included in petroleum product specifications, in commercial contract agreements, process refinery/control applications, and for compliance to regulatory rules.

SCOPE

1.1 This test method covers the procedure for the determination of the distillation characteristics of petroleum products in the range of 20 to 400C (68 to 752F) using miniaturized automatic distillation apparatus.

1.2 This test method is applicable to such products as: light and middle distillates, automotive spark-ignition engine fuels, aviation gasolines, aviation turbine fuels, regular and low sulfur diesel fuels, biodiesel fuels, special petroleum spirits, naphthas, white spirits, kerosines, burner fuels, and marine fuels.

1.3 This test method is designed for the analysis of distillate products; it is not applicable to products containing appreciable quantities of residual material.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D7344–07

Standard Test Method for

Distillation of Petroleum Products at Atmospheric Pressure

(Mini Method)

This standard is issued under the fixed designation D 7344; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 5190 Test Method for Vapor Pressure of Petroleum Prod-

ucts (Automatic Method)

1.1 This test method covers the procedure for the determi-

D 5191 Test Method for Vapor Pressure of Petroleum Prod-

nation of the distillation characteristics of petroleum products

ucts (Mini Method)

in the range of 20 to 400°C (68 to 752°F) using miniaturized

D 5482 Test Method for Vapor Pressure of Petroleum Prod-

automatic distillation apparatus.

ucts (Mini Method—Atmospheric)

1.2 This test method is applicable to such products as: light

D 6300 Practice for Determination of Precision and Bias

and middle distillates, automotive spark-ignition engine fuels,

Data for Use in Test Methods for Petroleum Products and

aviation gasolines, aviation turbine fuels, regular and low

Lubricants

sulfur diesel fuels, biodiesel fuels, special petroleum spirits,

D 6708 Practice for Statistical Assessment and Improve-

naphthas, white spirits, kerosines, burner fuels, and marine

ment of Expected Agreement Between Two Test Methods

fuels.

that Purport to Measure the Same Property of a Material

1.3 This test method is designed for the analysis of distillate

2.2 Energy Institute Standards:

products;itisnotapplicabletoproductscontainingappreciable

IP 69 Determination of Vapour Pressure—Reid Method

quantities of residual material.

IP 394 Determination of Air Saturated Vapour Pressure

1.4 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

3. Terminology

only.

3.1 Definitions:

1.5 This standard does not purport to address all of the

3.1.1 charge volume, n—in petroleum products, in distilla-

safety concerns, if any, associated with its use. It is the

tion, volume of the liquid sample transferred to the specimen

responsibility of the user of this standard to establish appro-

container.

priate safety and health practices and determine the applica-

3.1.2 decomposition, n—of a hydrocarbon, pyrolysis or

bility of regulatory limitations prior to use.

cracking of a molecule yielding smaller molecules with lower

2. Referenced Documents boiling points than the original molecule.

3.1.2.1 decomposition point, n—corrected thermometer

2.1 ASTM Standards:

reading that coincides with the first indications of thermal

D86 Test Method for Distillation of Petroleum Products at

decomposition of the liquid in the specimen container.

Atmospheric Pressure

3.1.2.2 Discussion—Characteristic indications of thermal

D 323 Test Method for Vapor Pressure of Petroleum Prod-

decomposition are evolution of fumes and erratic, typically

ucts (Reid Method)

decreasing, temperature readings that occur during the final

D 4057 Practice for Manual Sampling of Petroleum and

stages of the distillation.

Petroleum Products

3.1.2.3 Discussion—The decomposition point, as deter-

D 4177 Practice for Automatic Sampling of Petroleum and

mined under the conditions of this test method, does not

Petroleum Products

necessarily correspond to the decomposition temperature in

D 4953 Test Method for Vapor Pressure of Gasoline and

other applications.

Gasoline-Oxygenate Blends (Dry Method)

3.1.3 dynamic holdup, n—amount of material present in the

distillationcolumn,andinthecondenserduringthedistillation.

3.1.4 end point (EP) or final boiling point (FBP),

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

n—maximum corrected temperature reading obtained during

D02.08 on Volatility.

the test.

Current edition approved July 15, 2007. Published August 2007.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Energy Institute, 61 New Cavendish St., London, WIG 7AR,

the ASTM website. U.K., http://www.energyinst.org.uk.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7344–07

3.1.5 initial boiling point (IBP), n—corrected temperature 5. Significance and Use

reading at the instant of the first detection of condensate in the

5.1 The distillation (volatility) characteristics of hydrocar-

receiver.

bons have an important effect on their safety and performance,

3.1.6 percent evaporated, n—sum of the percent recovered

especially in the case of fuels and solvents. The boiling range

and the percent loss.

gives information on the composition, the properties, and the

3.1.7 percent loss, n—one hundred minus the percent total behavior of the fuel during storage and use. Volatility is the

major determinant of the tendency of a hydrocarbon mixture to

recovery.

produce potentially explosive vapors.

3.1.7.1 corrected loss, n—percent loss corrected for baro-

5.2 The distillation characteristics are equally important for

metric pressure.

both automotive and aviation gasolines, affecting starting,

3.1.8 percent recovered, n—volume of condensate observed

warm-up, and tendency to vapor lock at high operating

inthereceiver,expressedasapercentageofthechargevolume,

temperatures or high altitude, or both. The presence of high

associated with a simultaneous temperature reading.

boiling point components in these and other fuels can signifi-

3.1.9 percent recovery, n—maximum percent recovered.

cantly affect the degree of formation of solid combustion

3.1.9.1 corrected percent recovery, n—percent recovery,

deposits.

adjusted for the difference between the corrected loss and the

5.3 Volatility, as it affects the rate of evaporation, is an

observed loss.

important factor in the application of many solvents, particu-

3.1.9.2 percent total recovery, n—combined percent recov-

larly those used in paints.

ery and percent residue.

5.4 Distillation limits are often included in petroleum prod-

uct specifications, in commercial contract agreements, process

3.1.10 percent residue, n—volume of residue in the speci-

refinery/control applications, and for compliance to regulatory

mencontainer,expressedasapercentageofthechargevolume.

rules.

3.1.11 vapor temperature reading, n—temperature of the

saturated vapor measured in the distillation column below the

6. Apparatus

vapor tube, as determined by the prescribed conditions of the

6.1 Automatic Distillation Apparatus—The type of appara-

test.

tus suitable for this test method employs a heat source, a

3.1.11.1 corrected vapor temperature reading,

specimen cup, a stainless steel distillation column, a tempera-

n—temperature reading, as described in 3.1.11, corrected for

ture measuring device, a thermoelectrically controlled con-

barometric pressure.

denser and receiver system, a thermoelectrically controlled

sample introduction and dosing system, and a system to

4. Summary of Test Method

measure and automatically record the vapor temperature, the

4.1 Based on its composition, vapor pressure, expected IBP

associated percent recovered volume in the receiver, the

orexpectedFBP,oracombinationthereof,thesampleisplaced 4

condenser temperature, and the barometric pressure.

in one of four groups. Condenser temperature and other

6.2 A description of the apparatus is given in Annex A1.

operational variables are defined by the group in which the

6.3 Sample Introduction and Dosing System—A system

sample falls.

capable to automatically draw sample from a sample container

4.2 A specimen of the sample is distilled under prescribed

and fill the specimen container cup with a specimen of 6 6

conditions for the group in which the sample falls. The

0.05 mL or 5.5 6 0.05 mL.

specimen volume for distillation Groups 1 to 3 is 6 mL. For

6.4 Temperature Measuring Device—A thermocouple

Group 4, the specimen volume is 5.5 mL. The distillation is

(NiCr-Ni or similar) in stainless steel tube of 1 6 0.02 mm

performed in an automatic, miniaturized distillation apparatus

diameter with a response time of t(90) = 3 6 1 s shall be used

at ambient pressure under conditions that are designed to

for measuring the temperature of the vapor. The minimum

provide approximately one theoretical plate fractionation. The

resolution shall be 0.1°C (0.2°F), and the minimum accuracy

vapor temperature readings and volumes of condensate are

60.1°C (0.2°F).

monitored continuously. After the test, specimen losses and

6.5 Pressure Transducer—A pressure transducer with a

residue are recorded.

minimum range of 0 to 120 kPa with a minimum resolution of

0.1 kPa shall be used. The minimum accuracy shall be 60.1

4.3 After conclusion of the test, the temperatures are auto-

kPa.

matically corrected for barometric pressure, using the pressure

6.6 Balance, with a minimum range of 25 g and a minimum

readingofabuilt-inpressuretransducer.Thedataareexamined

accuracy of 63 mg.

for conformance to procedural requirements, such as distilla-

6.7 Pressure Measuring Device for Calibration, capable of

tion rates.The test has to be repeated if any specified condition

measuring local station pressure with an accuracy and a

has not been met.

4.4 Test results are commonly expressed as percent volume

evaporated or percent volume recovered versus corresponding

vapor temperature, either in a table or graphically, as a plot of The sole source of supply of the apparatus known to the committee at this time

is Grabner Instruments,A-1220Vienna, Dr. Otto Neurathgasse 1,Austria. If you are

the distillation curve.

aware of alternative suppliers, please provide this information to ASTM Interna-

4.5 This test method uses a small specimen volume and

tional Headquarters.Your comments will receive careful consideration at a meeting

miniaturized apparatus which can be portable for field testing. of the responsible technical committee, which you may attend.

D7344–07

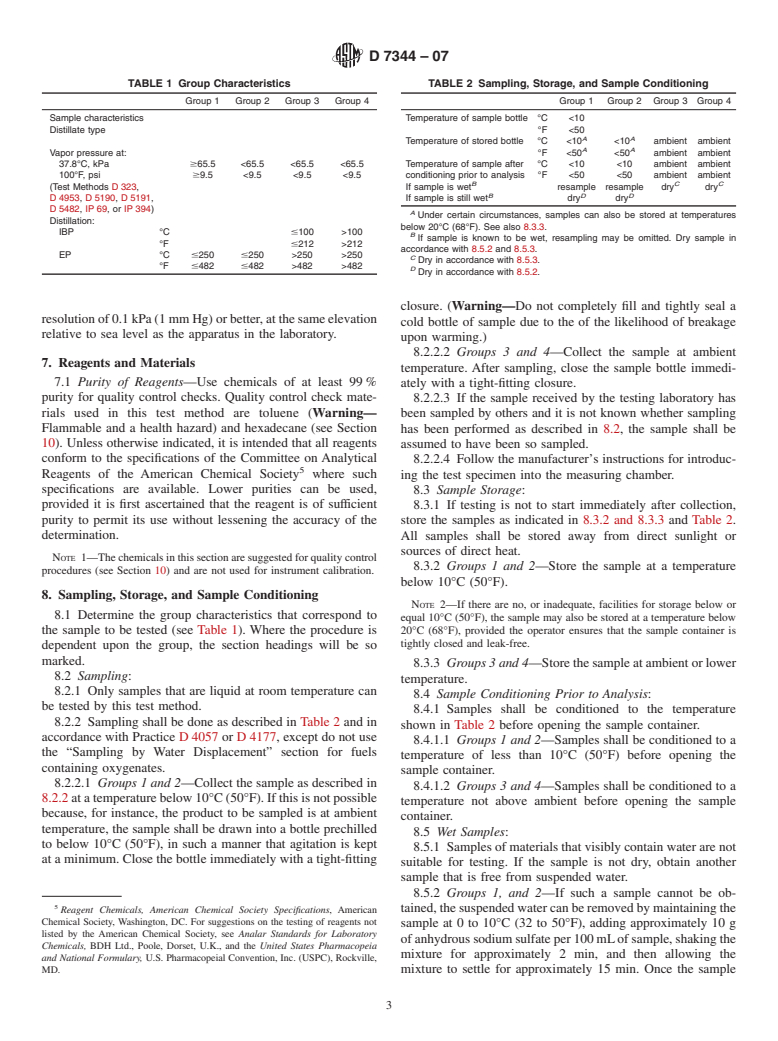

TABLE 1 Group Characteristics TABLE 2 Sampling, Storage, and Sample Conditioning

Group 1 Group 2 Group 3 Group 4 Group 1 Group 2 Group 3 Group 4

Sample characteristics Temperature of sample bottle °C <10

Distillate type °F <50

A A

Temperature of stored bottle °C <10 <10 ambient ambient

A A

Vapor pressure at: °F <50 <50 ambient ambient

37.8°C, kPa $65.5 <65.5 <65.5 <65.5 Temperature of sample after °C <10 <10 ambient ambient

100°F, psi $9.5 <9.5 <9.5 <9.5 conditioning prior to analysis °F <50 <50 ambient ambient

B C C

(Test Methods D 323, If sample is wet resample resample dry dry

B D D

D 4953, D 5190, D 5191, If sample is still wet dry dry

D 5482, IP 69,or IP 394)

A

Under certain circumstances, samples can also be stored at temperatures

Distillation:

below 20°C (68°F). See also 8.3.3.

IBP °C #100 >100

B

If sample is known to be wet, resampling may be omitted. Dry sample in

°F #212 >212

accordance with 8.5.2 and 8.5.3.

EP °C #250 #250 >250 >250

C

Dry in accordance with 8.5.3.

°F #482 #482 >482 >482

D

Dry in accordance with 8.5.2.

closure. (Warning—Do not completely fill and tightly seal a

resolutionof0.1kPa(1mmHg)orbetter,atthesameelevation

cold bottle of sample due to the of the likelihood of breakage

relative to sea level as the apparatus in the laboratory.

upon warming.)

8.2.2.2 Groups 3 and 4—Collect the sample at ambient

7. Reagents and Materials

temperature. After sampling, close the sample bottle immedi-

7.1 Purity of Reagents—Use chemicals of at least 99 %

ately with a tight-fitting closure.

purity for quality control checks. Quality control check mate-

8.2.2.3 If the sample received by the testing laboratory has

rials used in this test method are toluene (Warning—

been sampled by others and it is not known whether sampling

Flammable and a health hazard) and hexadecane (see Section has been performed as described in 8.2, the sample shall be

10). Unless otherwise indicated, it is intended that all reagents

assumed to have been so sampled.

conform to the specifications of the Committee on Analytical 8.2.2.4 Follow the manufacturer’s instructions for introduc-

Reagents of the American Chemical Society where such

ing the test specimen into the measuring chamber.

specifications are available. Lower purities can be used, 8.3 Sample Storage:

provided it is first ascertained that the reagent is of sufficient

8.3.1 If testing is not to start immediately after collection,

purity to permit its use without lessening the accuracy of the store the samples as indicated in 8.3.2 and 8.3.3 and Table 2.

determination.

All samples shall be stored away from direct sunlight or

sources of direct heat.

NOTE 1—Thechemicalsinthissectionaresuggestedforqualitycontrol

8.3.2 Groups 1 and 2—Store the sample at a temperature

procedures (see Section 10) and are not used for instrument calibration.

below 10°C (50°F).

8. Sampling, Storage, and Sample Conditioning

NOTE 2—If there are no, or inadequate, facilities for storage below or

8.1 Determine the group characteristics that correspond to

equal 10°C (50°F), the sample may also be stored at a temperature below

the sample to be tested (see Table 1). Where the procedure is 20°C (68°F), provided the operator ensures that the sample container is

tightly closed and leak-free.

dependent upon the group, the section headings will be so

marked.

8.3.3 Groups 3 and 4—Storethesampleatambientorlower

8.2 Sampling:

temperature.

8.2.1 Only samples that are liquid at room temperature can

8.4 Sample Conditioning Prior to Analysis:

be tested by this test method.

8.4.1 Samples shall be conditioned to the temperature

8.2.2 Sampling shall be done as described in Table 2 and in

shown in Table 2 before opening the sample container.

accordance with Practice D 4057 or D 4177, except do not use

8.4.1.1 Groups 1 and 2—Samples shall be conditioned to a

the “Sampling by Water Displacement” section for fuels

temperature of less than 10°C (50°F) before opening the

containing oxygenates.

sample container.

8.2.2.1 Groups 1 and 2—Collect the sample as described in

8.4.1.2 Groups 3 and 4—Samples shall be conditioned to a

8.2.2atatemperaturebelow10°C(50°F).Ifthisisnotpossible

temperature not above ambient before opening the sample

because, for instance, the product to be sampled is at ambient

container.

temperature, the sample shall be drawn into a bottle prechilled

8.5 Wet Samples:

to below 10°C (50°F), in such a manner that agitation is kept

8.5.1 Samples of materi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.