ASTM C1208/C1208M-11

(Specification)Standard Specification for Vitrified Clay Pipe and Joints for Use in Microtunneling, Sliplining, Pipe Bursting, and Tunnels

Standard Specification for Vitrified Clay Pipe and Joints for Use in Microtunneling, Sliplining, Pipe Bursting, and Tunnels

ABSTRACT

This specification establishes the criteria for the manufacture, quality assurance testing, inspection, installation, field acceptance testing, inspection, installation, field acceptance testing, and product marking of vitrified clay pipe to be used in microtunneling, pilot tube microtunneling, sliplining, pipe bursting, and in casings and tunnels for the conveyance of sewage, industrial wastes, and storm water. Vitrified clay pipe shall be manufactured from fire clay, shale, surface clay, or a combination of these materials that, when formed into pipe and fired to suitable temperatures, yields a product that conforms to this specification. Pipes of nominal diameters shall meet the prescribed bearing strength requirements. The clay pipe shall undergo the following tests: compressive strength test; hydrostatic pressure test; absorption test; and acid resistance test. The pipe shall conform to the required sizes and dimensions. The pipe shall not deviate from straight by more than a specified value when the maximum offset is measured from the concave side of the pipe. The pipe wall thickness shall be a suitable dimension to adequately distribute the field jacking forces. There shall be no fractures or cracks passing through the carrel, visible to the unaided eye. Chips, fractures, or blisters on the pipe shall not exceed a specified value in any surface dimension and shall not exceed a required depth of the minimum thickness of the barrel. Principles of joint design, test requirements, and test methods for assembled joints shall also be indicated.

SCOPE

1.1 This specification establishes the criteria for the manufacture, quality assurance testing, inspection, installation, field acceptance testing, and product marking of vitrified clay pipe to be used in microtunneling, pilot tube microtunneling, sliplining, pipe bursting, and in casings and tunnels for the conveyance of sewage, industrial wastes, and storm water.

1.1.1 Sections 3 through 7 and 9 of this specification contain manufacturing, quality assurance testing, inspection, and product marking criteria which are applicable to vitrified clay pipe prior to installation.

1.1.2 Section 8 of this specification contains criteria for the installation and field acceptance testing of vitrified clay pipe.

1.2 This specification also covers materials and test requirements for jointing of the pipe.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1208/C1208M −11

StandardSpecification for

Vitrified Clay Pipe and Joints for Use in Microtunneling,

1

Sliplining, Pipe Bursting, and Tunnels

This standard is issued under the fixed designation C1208/C1208M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C828 Test Method for Low-Pressure Air Test of Vitrified

Clay Pipe Lines

1.1 This specification establishes the criteria for the

C896 Terminology Relating to Clay Products

manufacture, quality assurance testing, inspection, installation,

C1091 Test Method for Hydrostatic Infiltration Testing of

field acceptance testing, and product marking of vitrified clay

Vitrified Clay Pipe Lines

pipe to be used in microtunneling, pilot tube microtunneling,

D395 Test Methods for Rubber Property—Compression Set

sliplining, pipe bursting, and in casings and tunnels for the

D412 Test Methods forVulcanized Rubber andThermoplas-

conveyance of sewage, industrial wastes, and storm water.

tic Elastomers—Tension

1.1.1 Sections3through7and9ofthisspecificationcontain

D471 Test Method for Rubber Property—Effect of Liquids

manufacturing, quality assurance testing, inspection, and prod-

D518 Test Method for Rubber Deterioration—Surface

uct marking criteria which are applicable to vitrified clay pipe

3

Cracking (Withdrawn 2007)

prior to installation.

D543 Practices for Evaluating the Resistance of Plastics to

1.1.2 Section 8 of this specification contains criteria for the

Chemical Reagents

installation and field acceptance testing of vitrified clay pipe.

D573 Test Method for Rubber—Deterioration in an Air

1.2 This specification also covers materials and test require-

Oven

ments for jointing of the pipe.

D1149 Test Methods for Rubber Deterioration—Cracking in

1.3 The values stated in either SI units or inch-pound units an Ozone Controlled Environment

D2240 Test Method for Rubber Property—Durometer Hard-

are to be regarded separately as standard. The values stated in

each system may not be exact equivalents; therefore, each ness

system shall be used independently of the other. Combining

3. Terminology

values from the two systems may result in non-conformance

with the standard.

3.1 Definitions—Terminology C896 can be used for clarifi-

cation of terminology in this specification.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

PIPE

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Materials and Manufacture

bility of regulatory limitations prior to use.

4.1 Vitrified clay pipe shall be manufactured from fire clay,

2. Referenced Documents shale, surface clay, or a combination of these materials that,

2 when formed into pipe and fired to suitable temperatures,

2.1 ASTM Standards:

yields a product that conforms to this specification.

C67 Test Methods for Sampling and Testing Brick and

Structural Clay Tile 4.2 Test Requirements for Pipe:

C301 Test Methods for Vitrified Clay Pipe 4.2.1 Test Samples:

4.2.1.1 When requested, test samples representative of the

pipe to be used shall be selected by the purchaser or his

1

This specification is under the jurisdiction of ASTM Committee C04 on

representative from the supplier’s stock.

Vitrified Clay Pipe and is the direct responsibility of Subcommittee C04.20 on

Methods of Test and Specifications. 4.2.1.2 The number of samples to be tested shall not exceed

Current edition approved Jan. 1, 2011. Published January 2011. Originally

0.5 % of the number of pipe of each size furnished, except that

approved in 1991. Last previous edition approved in 2008 as C1208/C1208M – 08.

no less than three samples shall be tested.

DOI: 10.1520/C1208_C1208M-11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

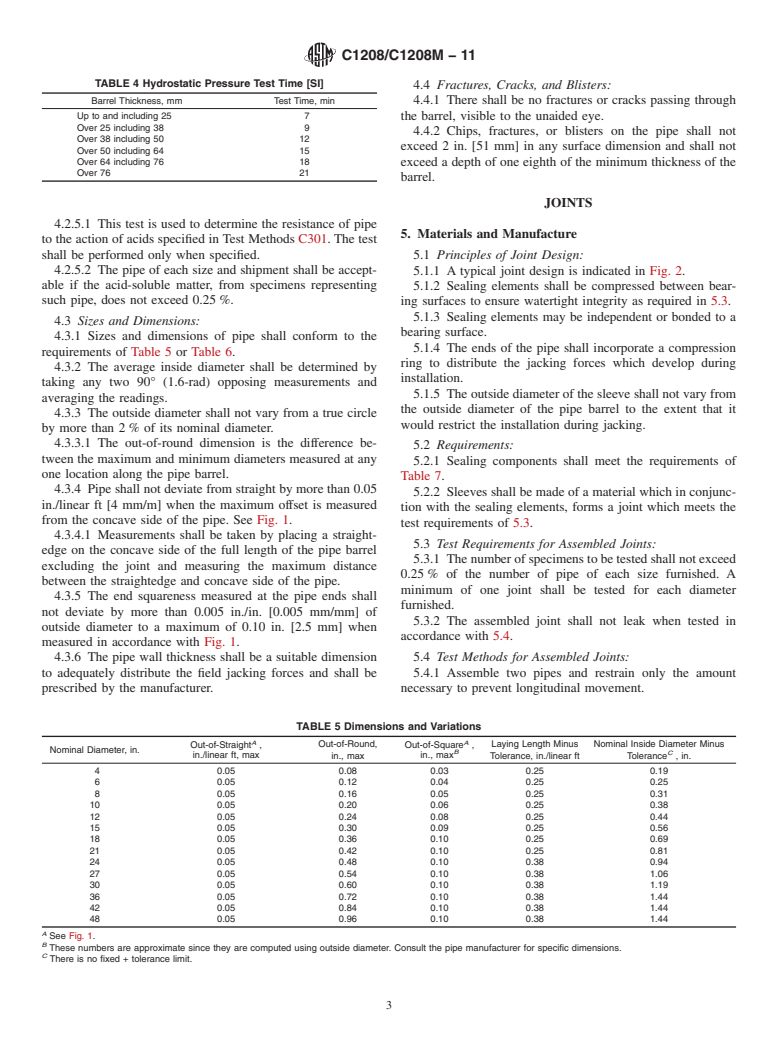

C1208/C1208M−11

TABLE 1 Three Edge Bearing Strength

minimum diameter of 0.75 in. [19 mm] for pipe wall thick-

1

Nominal Diameter, in. Bearing Strength, lb/linear ft nesses through 2 ⁄2 in. [64 mm] and 2 in. [51 mm] for greater

4 2000 wall thicknesses and a diameter to length ratio of 1:1. The

6 2000

tolerance of the diameter and length shall be +10 % –0 %.

8 2200

Meas

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1208/C1208M–08 Designation: C1208/C1208M – 11

Standard Specification for

Vitrified Clay Pipe and Joints for Use in Microtunneling,

1

Sliplining, Pipe Bursting, and Tunnels

This standard is issued under the fixed designation C1208/C1208M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification establishes the criteria for the manufacture, quality assurance testing, inspection, installation, field

acceptance testing, and product marking of vitrified clay pipe to be used in microtunneling, pilot tube microtunneling, sliplining,

pipe bursting, and in casings and tunnels for the conveyance of sewage, industrial wastes, and storm water.

1.1.1 Sections 3 through 7 and 9 of this specification contain manufacturing, quality assurance testing, inspection, and product

marking criteria which are applicable to vitrified clay pipe prior to installation.

1.1.2 Section 8 of this specification contains criteria for the installation and field acceptance testing of vitrified clay pipe.

1.2 This specification also covers materials and test requirements for jointing of the pipe.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C67 Test Methods for Sampling and Testing Brick and Structural Clay Tile

C301 Test Methods for Vitrified Clay Pipe

C828 Test Method for Low-Pressure Air Test of Vitrified Clay Pipe Lines

C896 Terminology Relating to Clay Products

C1091 Test Method for Hydrostatic Infiltration Testing of Vitrified Clay Pipe Lines

D395 Test Methods for Rubber PropertyCompression Set

D412 Test Methods for Vulcanized Rubber and Thermoplastic ElastomersTension

D471 Test Method for Rubber PropertyEffect of Liquids

D518 Test Method for Rubber DeteriorationSurface Cracking

D543 Practices for Evaluating the Resistance of Plastics to Chemical Reagents

D573 Test Method for RubberDeterioration in an Air Oven

D1149 Test Methods for Rubber DeteriorationCracking in an Ozone Controlled Environment

D2240 Test Method for Rubber PropertyDurometer Hardness

3. Terminology

3.1 Definitions—Terminology C896 can be used for clarification of terminology in this specification.

PIPE

4. Materials and Manufacture

4.1 Vitrified clay pipe shall be manufactured from fire clay, shale, surface clay, or a combination of these materials that, when

formed into pipe and fired to suitable temperatures, yields a product that conforms to this specification.

1

This specification is under the jurisdiction ofASTM Committee C04 on Vitrified Clay Pipe and is the direct responsibility of Subcommittee C04.20 on Methods of Test

and Specifications.

Current edition approved Nov.Jan. 1, 2008.2011. Published November 2008.January 2011. Originally approved in 1991. Last previous edition approved in 20042008 as

C1208/C1208M – 048. DOI: 10.1520/C1208_C1208M-0811.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

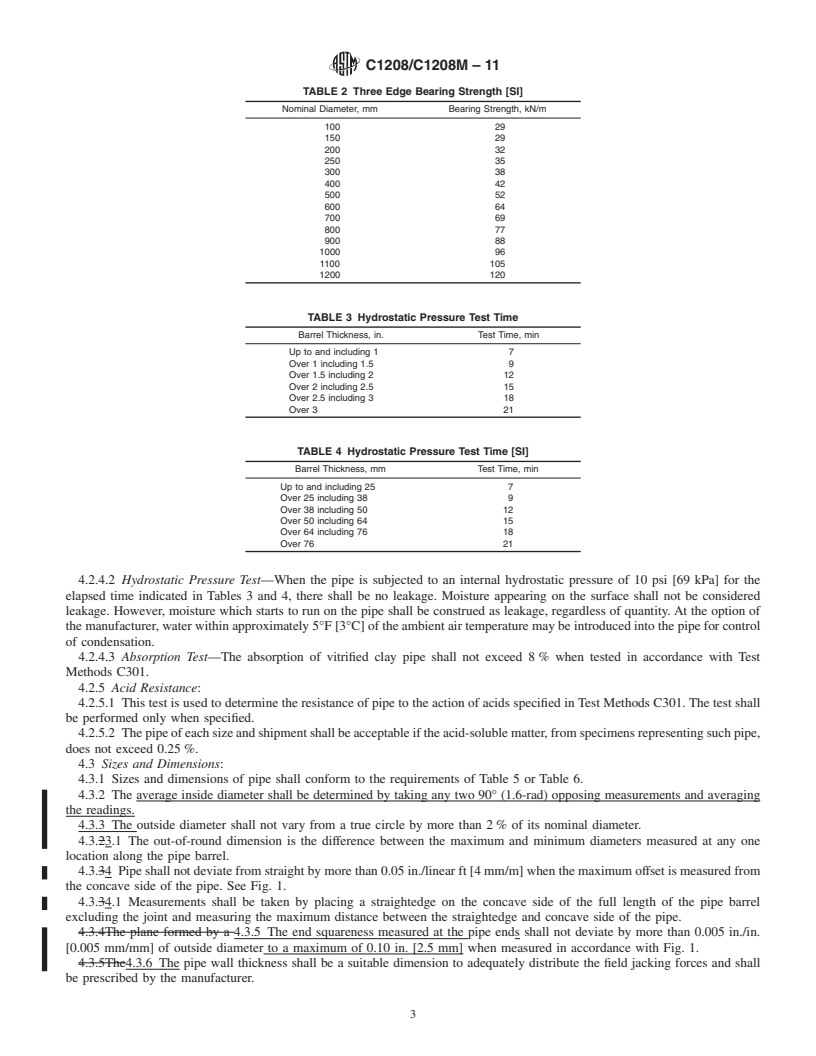

C1208/C1208M – 11

4.2 Test Requirements for Pipe:

4.2.1 Test Samples:

4.2.1.1 Whenrequested,testsamplesrepresentativeofthepipetobeusedshallbeselectedbythepurchaserorhisrepresentative

from the supplier’s stock.

4.2.1.2 The number of samples to be tested shall not exceed 0.5 % of the number of pipe of each size furnished, except that

no less than three samples shall be tested.

4.2.1.3 If any of the test samples fail to meet the requirements of 4.2.2 through 4.2.5, the manufacturer will be allowed to retest

two additional sam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.