ASTM C301-18(2022)

(Test Method)Standard Test Methods for Vitrified Clay Pipe

Standard Test Methods for Vitrified Clay Pipe

SIGNIFICANCE AND USE

4.1 Meaning and Suitability—The tests called for herein, from their results, indicate the suitability and acceptability of vitrified clay pipe for specifications acceptance, design purposes, regulatory statutes, manufacturing control, and research.

SCOPE

1.1 These test methods cover the equipment for, and the techniques of, testing vitrified clay pipe prior to installation. Tests using whole pipe determines the resistance to crushing and hydrostatic forces. Tests using pipe fragments measure the amount of water absorption of the pipe body and the quantity of acid-soluble material that may be extracted from it.

Note 1: The following standards also apply to clay pipe and can be referenced for further information: Practice C12 and Test Method C828; Specifications C425 and C700.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C301 −18 (Reapproved 2022)

Standard Test Methods for

Vitrified Clay Pipe

This standard is issued under the fixed designation C301; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope C828 Test Method for Low-Pressure Air Test of Vitrified

Clay Pipe Lines

1.1 These test methods cover the equipment for, and the

C896 Terminology Relating to Clay Products

techniques of, testing vitrified clay pipe prior to installation.

E6 Terminology Relating to Methods of Mechanical Testing

Tests using whole pipe determines the resistance to crushing

and hydrostatic forces. Tests using pipe fragments measure the

3. Terminology

amount of water absorption of the pipe body and the quantity

of acid-soluble material that may be extracted from it.

3.1 Definitions:

NOTE 1—The following standards also apply to clay pipe and can be

3.1.1 For definitions of terms used in these test methods,

referenced for further information: Practice C12 and Test Method C828;

refer to Terminology E6 and Terminology C896.

Specifications C425 and C700.

1.2 The values stated in inch-pound units are to be regarded

4. Significance and Use

as standard. The values given in parentheses are mathematical

4.1 Meaning and Suitability—The tests called for herein,

conversions to SI units that are provided for information only

from their results, indicate the suitability and acceptability of

and are not considered standard.

vitrified clay pipe for specifications acceptance, design

1.3 This standard does not purport to address all of the

purposes, regulatory statutes, manufacturing control, and re-

safety concerns, if any, associated with its use. It is the

search.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

5. Bearing Strength

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

5.1 Test Specimens:

dance with internationally recognized principles on standard-

5.1.1 The test specimens shall be sound, full-size pipe and

ization established in the Decision on Principles for the

shall be selected by the purchaser, or his representative, at

Development of International Standards, Guides and Recom-

points he designates when placing the order.

mendations issued by the World Trade Organization Technical

5.1.2 The number of specimens to be tested shall not exceed

Barriers to Trade (TBT) Committee.

0.5 % of the number of pipe of each size furnished, except that

no less than two specimens shall be tested.

2. Referenced Documents

5.2 Measurement and Inspection of Specimens:

2.1 ASTM Standards:

5.2.1 The specimens shall be free of all visible moisture and

C12 Practice for Installing Vitrified Clay Pipe Lines

frost. These specimens shall be inspected and measured for

C425 Specification for Compression Joints forVitrified Clay

conformance with the applicable specifications. The results of

Pipe and Fittings

these observations shall be recorded.

C700 Specification for Vitrified Clay Pipe, Extra Strength,

5.2.2 Specimens that are observed to have defects in excess

Standard Strength, and Perforated

of the limits permitted in the applicable specifications shall be

discarded and replaced with additional specimens from the lot

These test methods are under the jurisdiction of ASTM Committee C04 on

to be tested.

Vitrified Clay Pipe and is the direct responsibility of Subcommittee C04.20 on

Methods of Test and Specifications.

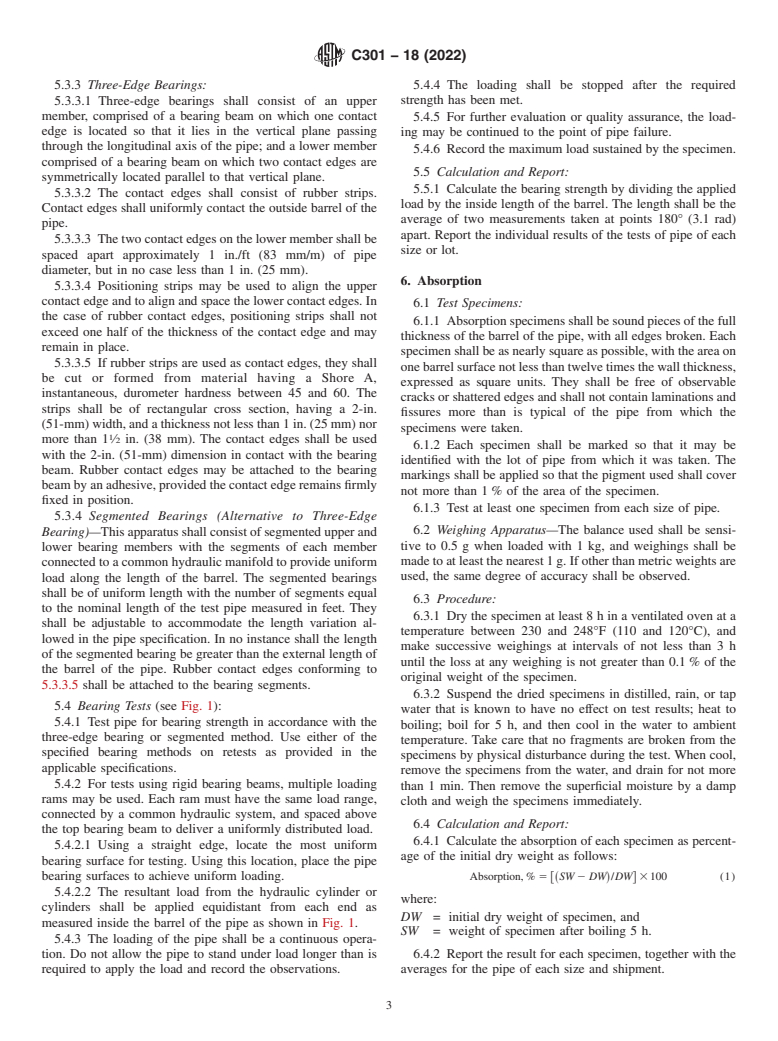

5.3 Loading Apparatus (see Fig. 1):

Current edition approved Sept. 1, 2022. Published September 2022. Originally

5.3.1 Testing Machine:

approved in 1952. Last previous edition approved in 2018 as C301 – 18. DOI:

10.1520/C0301-18R22.

5.3.1.1 The loading apparatus shall consist of a testing

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

machine capable of applying loads, with upper and lower

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

bearings capable of transmitting these loads to the pipe. The

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. bearings shall be bearing beams and contact edges.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C301 − 18 (2022)

FIG. 1 Three-Edge Bearing Testing (see 5.3.4 for Segmented Testing)

5.3.1.2 Any motor driven testing machine that is capable of vibration or shock. The upper bearing shall be free to rotate in

applying a load at a uniform rate of 2000 6 500 lbf/min·linear averticalplanethroughthelongitudinalaxisofthebearingand

ft (29.2 6 7.3 kN/min·linear m) of pipe length, shall be used

the pipe.

for making the test.

5.3.2 Bearing Beams—Bearingbeamsshallnotdeflectmore

5.3.1.3 The load may be applied at a rapid rate until 50 % of than a 14 by 8-in. (355 by 205-mm), 53-lb/linear ft (73-kg/

the required bearing strength is reached. Subsequently, the load

linear m), wide flange beam as specified by the American

shall be applied to the pipe at a uniform rate of 2000 6 500 Institute of Steel Construction. Under no circumstances shall

lbf/min·linear ft (29.2 6 7.3 kN/min·linear m) of pipe length

the deflection in inches or millimetres under maximum load

without vibration or shock.

exceed that given by the ratio L/720 in which L is the beam

length in inches or millimetres. The length of the bearing

5.3.1.4 Thetestingmachineshallbesufficientlyrigidsothat

beams shall be no less than the full length of the outside barrel

the load distribution will not be appreciably affected by the

deformation or yielding of any part. The machine and bearings of the pipe. Built-up bearing beams may be used, provided

their deflection does not exceed that specified. In order for the

shall be constructed to transmit the load in a vertical plane

through the longitudinal axes of the bearings and pipe. The bell or socket of the pipe to clear the bearing beams, it is

bearings shall be attached to the machine so as to receive and recommended that the bearing beams be faced with a metal or

uniformly transmit the loads required in the tests, without hardwood member for affixing the contact edges.

C301 − 18 (2022)

5.3.3 Three-Edge Bearings: 5.4.4 The loading shall be stopped after the required

5.3.3.1 Three-edge bearings shall consist of an upper strength has been met.

member, comprised of a bearing beam on which one contact

5.4.5 For further evaluation or quality assurance, the load-

edge is located so that it lies in the vertical plane passing

ing may be continued to the point of pipe failure.

through the longitudinal axis of the pipe; and a lower member

5.4.6 Record the maximum load sustained by the specimen.

comprised of a bearing beam on which two contact edges are

5.5 Calculation and Report:

symmetrically located parallel to that vertical plane.

5.5.1 Calculate the bearing strength by dividing the applied

5.3.3.2 The contact edges shall consist of rubber strips.

load by the inside length of the barrel. The length shall be the

Contact edges shall uniformly contact the outside barrel of the

average of two measurements taken at points 180° (3.1 rad)

pipe.

apart. Report the individual results of the tests of pipe of each

5.3.3.3 The two contact edges on the lower member shall be

size or lot.

spaced apart approximately 1 in./ft (83 mm/m) of pipe

diameter, but in no case less than 1 in. (25 mm).

6. Absorption

5.3.3.4 Positioning strips may be used to align the upper

contact edge and to align and space the lower contact edges. In

6.1 Test Specimens:

the case of rubber contact edges, positioning strips shall not

6.1.1 Absorption specimens shall be sound pieces of the full

exceed one half of the thickness of the contact edge and may

thickness of the barrel of the pipe, with all edges broken. Each

remain in place.

specimen shall be as nearly square as possible, with the area on

5.3.3.5 If rubber strips are used as contact edges, they shall

onebarrelsurfacenotlessthantwelvetimesthewallthickness,

be cut or formed from material having a Shore A,

expressed as square units. They shall be free of observable

instantaneous, durometer hardness between 45 and 60. The

cracks or shattered edges and shall not contain laminations and

strips shall be of rectangular cross se

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.