ASTM D7736-12(2018)

(Test Method)Standard Test Method for Determination of Acids and Glycol Esters in Ethylene Glycol

Standard Test Method for Determination of Acids and Glycol Esters in Ethylene Glycol

SIGNIFICANCE AND USE

5.1 The presence of acids or glycol esters in the ethylene glycol used to produce engine coolant is undesirable. Under conditions in an engine cooling system, the esters can hydrolyze to form glycol and an acid. The acid will react with the corrosion inhibitors, thereby reducing the useful life of the coolant. This method can determine the amount of acid and glycol ester present in the ethylene glycol.

SCOPE

1.1 This test method covers the determination of free acids and glycol esters in ethylene glycol by titration.

1.2 This test method is for used on ethylene glycol used for the manufacture of engine coolant. It can not be used on formulated engine coolant. The inhibitors will interfere with the determination.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7736 − 12 (Reapproved 2018)

Standard Test Method for

Determination of Acids and Glycol Esters in Ethylene

Glycol

This standard is issued under the fixed designation D7736; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Determine the Precision of a Test Method

1.1 This test method covers the determination of free acids

3. Terminology

and glycol esters in ethylene glycol by titration.

3.1 Definitions:

1.2 This test method is for used on ethylene glycol used for

3.1.1 For definitions of terms used in this test method, refer

the manufacture of engine coolant. It can not be used on

to Terminology D4725.

formulated engine coolant. The inhibitors will interfere with

the determination.

4. Summary of Test Method

1.3 The values stated in SI units are to be regarded as

4.1 This test method is used to determine the acid and ester

standard. No other units of measurement are included in this

content of ethylene glycol by titration.The sample is titrated to

standard.

the phenolphthalein end point with 0.02 N NaOH to determine

1.4 This standard does not purport to address all of the

the acidity. Then a known amount of base is added and the

safety concerns, if any, associated with its use. It is the

sample is heated at 100 °C to hydrolyze the esters. It is then

responsibility of the user of this standard to establish appro-

back-titrated with 0.02 N sulfuric acid to determine the ester

priate safety, health, and environmental practices and deter-

content.

mine the applicability of regulatory limitations prior to use.

5. Significance and Use

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

5.1 The presence of acids or glycol esters in the ethylene

ization established in the Decision on Principles for the

glycol used to produce engine coolant is undesirable. Under

Development of International Standards, Guides and Recom-

conditions in an engine cooling system, the esters can hydro-

mendations issued by the World Trade Organization Technical

lyze to form glycol and an acid. The acid will react with the

Barriers to Trade (TBT) Committee.

corrosion inhibitors, thereby reducing the useful life of the

coolant. This method can determine the amount of acid and

2. Referenced Documents

glycol ester present in the ethylene glycol.

2.1 ASTM Standards:

D1176 Practice for Sampling and Preparing Aqueous Solu- 6. Interferences

tions of Engine Coolants orAntirusts forTesting Purposes

6.1 This test method is based on a color change titration.

D1193 Specification for Reagent Water

Glycol with a strong color could interfere with the results of

D4725 Terminology for Engine Coolants and Related Fluids

this method.

E177 Practice for Use of the Terms Precision and Bias in

6.2 High pH recycled glycols streams will affect the results

ASTM Test Methods

of this test method.

E691 Practice for Conducting an Interlaboratory Study to

7. Apparatus

This test method is under the jurisdiction ofASTM Committee D15 on Engine

7.1 250 mL Borosilicate Glass Bottles, with screw caps.

Coolants and Related Fluids and is the direct responsibility of Subcommittee

D15.04 on Chemical Properties.

8. Reagents and Materials

Current edition approved March 1, 2018. Published March 2018. Originally

approved in 2011. Last previous edition approved in 2012 as D7736 - 12. DOI:

8.1 Phenolphthalein Solution—Dissolve 0.5 g of phenol-

10.1520/D7736-12R18.

phthalein in methanol or ethanol and dilute to 100 mL.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

8.2 Sodium Hydroxide (NaOH), 0.02 N in water.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 8.3 Sulfuric Acid (H SO ), 0.02 N in water.

2 4

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

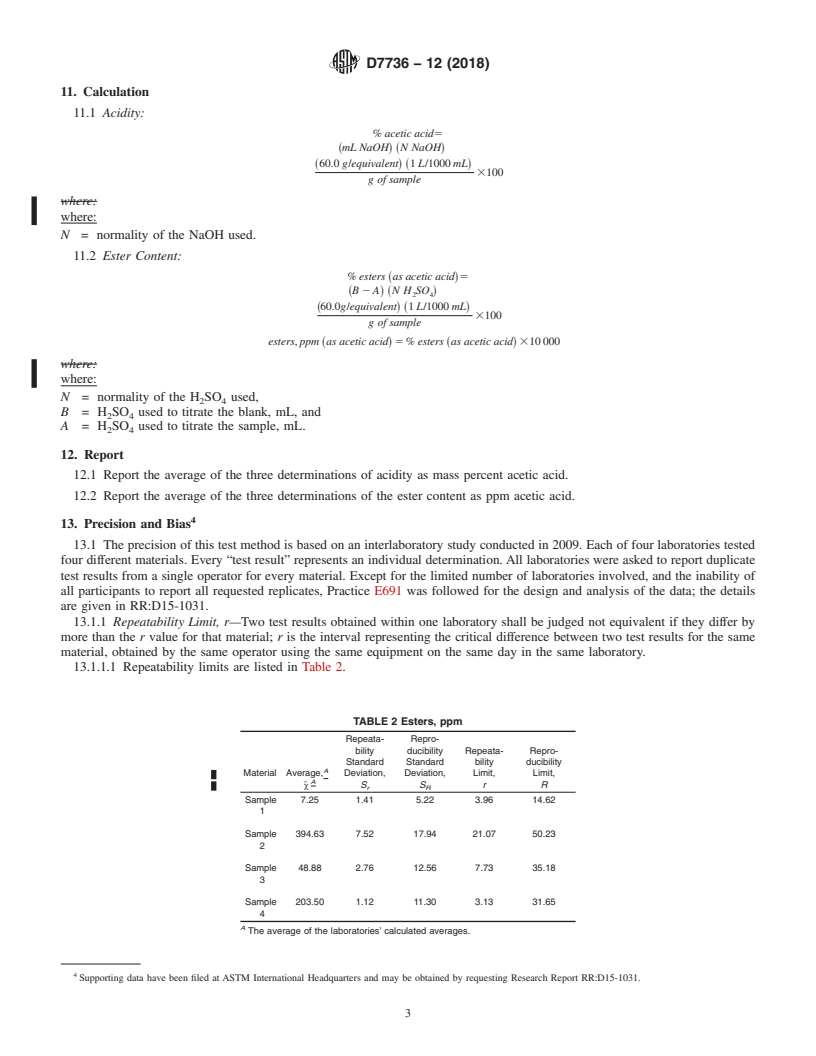

D7736 − 12 (2018)

TABLE 1 Recommended Sample Sizes

10.2.2 Determination of the Ester Content—Remove bottles

Estimated Ester from the bath and cool to room temperature. When cool, add 3

Sample Size, g Sample Method

Content, wt %

drops of phenolphthalein solution to each and titrate with 0.02

< 0.10 25.0 Weigh the sample to the

NH SO until disappearance of pink color.

0.10 to 0.20 10.0 nearest 0.1 g into the 2 4

A

0.20 to 0.50 5.0 bottle

of water prepared in 11. Calculation

10.1.1

11.1 Acidity:

A

Report as “>0.50 wt %” if the titration determination exceeds 0.50 %.

% acetic acid5

mL NaOH N NaOH

~ !~ !

60.0 g/equivalent 1 L/1000 mL

~ !~ !

8.4 Purity of Water—Unless otherwise indicated, references

g of sample

to water shall be understood to mean reagent water as defined

by Type II or III of Specification D1193.

where:

N = normality of the NaOH used.

8.5 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

11.2 Ester Content:

all reagents shall conform to the specifications of the Commit-

% esters as acetic acid 5

~ !

tee onAnalytical Reagents of theAmerican Chemical Society,

3 ~B 2 A!~NH SO !

2 4

where such specifications are available. Other grades may be

60.0g/equivalent 1 L/1000 mL

~ !~ !

used, provided it is first ascertained that the reagent is of

g of sample

sufficiently high purity to permit its use without lessening the

esters, ppm as acetic acid 5 % esters as acetic acid 310 000

accuracy of the determination. ~ ! ~ !

where:

9. Sampling

N = normality of the H SO used,

2 4

9.1 Sample the material in accordance with Practice D1176.

B =H SO used to titrate the blank, mL, and

2 4

A =H SO used to titrate the sample, mL.

2 4

10. Procedure

12. Report

10.1 Acid Content:

10.1.1 Adjustment of pH—Pipet 25.00 mL of deionized

12.1 Report the average of the three determinations of

water into each of three 250 mL bottles. Add 3 drops of

acidity as mass percent acetic acid.

phenolphthalein solution to each. Titrate with 0.02 N sodium

12.2 Report the average of the three determinations of the

hydroxidetothefirstpinkendpointpermanentforatleast15 s.

ester content as ppm acetic acid.

Do not record this volume of titrant. Repeat for each bottle.

10.1.2 Determination of Sample Acidit

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7736 − 12 D7736 − 12 (Reapproved 2018)

Standard Test Method for

Determination of Acids and Glycol Esters in Ethylene

Glycol

This standard is issued under the fixed designation D7736; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of free acids and glycol esters in ethylene glycol by titration.

1.2 This test method is for used on ethylene glycol used for the manufacture of engine coolant. It can not be used on formulated

engine coolant. The inhibitors will interfere with the determination.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D1176 Practice for Sampling and Preparing Aqueous Solutions of Engine Coolants or Antirusts for Testing Purposes

D1193 Specification for Reagent Water

D4725 Terminology for Engine Coolants and Related Fluids

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, refer to Terminology D4725.

4. Summary of Test Method

4.1 This test method is used to determine the acid and ester content of ethylene glycol by titration. The sample is titrated to the

phenolphthalein end point with 0.02 N NaOH to determine the acidity. Then a known amount of base is added and the sample is

heated at 100°C100 °C to hydrolyze the esters. It is then back-titrated with 0.02 N sulfuric acid to determine the ester content.

5. Significance and Use

5.1 The presence of acids or glycol esters in the ethylene glycol used to produce engine coolant is undesirable. Under conditions

in an engine cooling system, the esters can hydrolyze to form glycol and an acid. The acid will react with the corrosion inhibitors,

thereby reducing the useful life of the coolant. This method can determine the amount of acid and glycol ester present in the

ethylene glycol.

This test method is under the jurisdiction of ASTM Committee D15 on Engine Coolants and Related Fluids and is the direct responsibility of Subcommittee D15.04 on

Chemical Properties.

Current edition approved April 1, 2012March 1, 2018. Published June 2012March 2018. Originally approved in 2011. Last previous edition approved in 20112012 as

D7736 - 11.D7736 - 12. DOI: 10.1520/D7736–12.10.1520/D7736-12R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7736 − 12 (2018)

6. Interferences

6.1 This test method is based on a color change titration. Glycol with a strong color could interfere with the results of this

method.

6.2 High pH recycled glycols streams will affect the results of this test method.

7. Apparatus

7.1 250 mL Borosilicate Glass Bottles, with screw caps.

8. Reagents and Materials

8.1 Phenolphthalein Solution—Dissolve 0.5 g of phenolphthalein in methanol or ethanol and dilute to 100 mL.

8.2 Sodium Hydroxide (NaOH), 0.02 N in water.

8.3 Sulfuric Acid (H SO ), 0.02 N in water.

2 4

8.4 Purity of Water—Unless otherwise indicated, references to water shall be understood to mean reagent water as defined by

Type II or III of Specification D1193.

8.5 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

9. Sampling

9.1 Sample the material in accordance with Practice D1176.

10. Procedure

10.1 Acid Content:

10.1.1 Adjustment of pH—Pipet 25.00 mL of deionized water into each of three 250 mL bottles. Add 3 drops of phenolphthalein

solution to each. Titrate with 0.02 N sodium hydroxide to the first pink end point permanent for at least 15 seconds. 15 s. Do not

record this volume of titrant. Repeat for each bottle.

10.1.2 Determination of Sample Acidity:

10.1.2.1 Add an amount of sample as indicated in Table 1 to the nearest 0.1 g into the bottle of deionized water prepared in

10.1.1.

10.1.2.2 Titrate each sample with 0.02 N sodium hydroxide to the first pink end point permanent for at least 15 s. This volume

of titrant is used to calculate the percent acid.

NOTE 1—If the ester content is completely unknown, a trial titration beginning with 25 g of sample may be conducted to develop a preliminary estimate

before the actual test titration is performed. If the trial suggests concentration of over 0.10 wt % (1000 ppm) then reduce the sample to 10 g and repeat.

The second trial should provide enough information to direct an appropriate choice of the sample quantity to be used.

10.2 Total Ester Content:

10.2.1 Hydrolysis of the Esters—Pipet 25.00 mL of 0.02 N sodium hydroxide into each bottle used in 10.1.2. Prepare a blank

for each sample by pipetting 25.00 mL of 0.02 N sodium hydroxide into three clean, 250 mL bottles. Immerse the pairs of bottles

in a boiling water bath for 1 h. (Tap water is suitable.) The weight of the bottl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.