ASTM E82-91(2007)

(Test Method)Standard Test Method for Determining the Orientation of a Metal Crystal

Standard Test Method for Determining the Orientation of a Metal Crystal

SIGNIFICANCE AND USE

Metals and other materials are not always isotropic in their physical properties. For example, Young’modulus will vary in different crystallographic directions. Therefore, it is desirable or necessary to determine the orientation of a single crystal undergoing tests in order to ascertain the relation of any property to different directions in the material.

This test method can be used commercially as a quality control test in production situations where a desired orientation, within prescribed limits, is required.

With the use of an adjustable fixed holder that can later be mounted on a saw, lathe, or other machine, a single crystal material can be moved to a preferred orientation, and subsequently sectioned, ground, or processed otherwise.

If grains of a polycrystalline material are large enough, this test method can be used to determine their orientations and differences in orientation.

SCOPE

1.1 This test method covers the back-reflection Laue procedure for determining the orientation of a metal crystal. The back-reflection Laue method for determining crystal orientation (1, 2) may be applied to macrograins (3) (0.5-mm diameter or larger) within polycrystalline aggregates, as well as to single crystals of any size. The method is described with reference to cubic crystals; it can be applied equally well to hexagonal, tetragonal, or orthorhombic crystals.

1.2 Most natural crystals have well developed external faces, and the orientation of such crystals can usually be determined from inspection. The orientation of a crystal having poorly developed faces, or no faces at all (for example, a metal crystal prepared in the laboratory) must be determined by more elaborate methods. The most convenient and accurate of these involves the use of X-ray diffraction. The "orientation of a metal crystal" is known when the positions in space of the crystallographic axes of the unit cell have been located with reference to the surface geometry of the crystal specimen. This relation between unit cell position and surface geometry is most conveniently expressed by stereographic or gnomonic projection.

1.3 The values stated in inch-pound units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 82 – 91 (Reapproved 2007)

Standard Test Method for

Determining the Orientation of a Metal Crystal

ThisstandardisissuedunderthefixeddesignationE82;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Adjunct:

HyberbolicchartforsolvingbackreflectionLauepatterns(1

1.1 This test method covers the back-reflection Laue proce-

film positive)

dure for determining the orientation of a metal crystal. The

back-reflection Laue method for determining crystal orienta-

3. Summary of Test Method

tion (1, 2) may be applied to macrograins (3) (0.5-mm

3.1 Thearrangementoftheapparatusissimilartothatofthe

diameterorlarger)withinpolycrystallineaggregates,aswellas

transmission Laue method for crystal structure determination

to single crystals of any size. The method is described with

except that the photographic film is located between the X-ray

reference to cubic crystals; it can be applied equally well to

sourceandthespecimen.ThebeamofwhiteXradiationpasses

hexagonal, tetragonal, or orthorhombic crystals.

through a pinhole system and through a hole in the photo-

1.2 Most natural crystals have well developed external

graphic film, strikes the crystal, and is diffracted back onto the

faces, and the orientation of such crystals can usually be

film. Dark spots, which represent X-ray beams “reflected” by

determinedfrominspection.Theorientationofacrystalhaving

the atomic planes within the specimen, appear on the devel-

poorlydevelopedfaces,ornofacesatall(forexample,ametal

oped film. The atomic planes these spots represent are identi-

crystalpreparedinthelaboratory)mustbedeterminedbymore

fied by crystallographic procedures and the orientation of the

elaborate methods. The most convenient and accurate of these

metal crystal is determined.

involves the use of X-ray diffraction. The “orientation of a

metal crystal” is known when the positions in space of the

4. Significance and Use

crystallographic axes of the unit cell have been located with

4.1 Metals and other materials are not always isotropic in

referencetothesurfacegeometryofthecrystalspecimen.This

their physical properties. For example, Young’s modulus will

relation between unit cell position and surface geometry is

vary in different crystallographic directions. Therefore, it is

most conveniently expressed by stereographic or gnomonic

desirable or necessary to determine the orientation of a single

projection.

crystalundergoingtestsinordertoascertaintherelationofany

1.3 The values stated in inch-pound units are to be regarded

property to different directions in the material.

as the standard.

4.2 This test method can be used commercially as a quality

1.4 This standard does not purport to address all of the

control test in production situations where a desired orienta-

safety concerns, if any, associated with its use. It is the

tion, within prescribed limits, is required.

responsibility of the user of this standard to establish appro-

4.3 With the use of an adjustable fixed holder that can later

priate safety and health practices and determine the applica-

be mounted on a saw, lathe, or other machine, a single crystal

bility of regulatory limitations prior to use.

material can be moved to a preferred orientation, and subse-

quently sectioned, ground, or processed otherwise.

2. Referenced Documents

3 4.4 If grains of a polycrystalline material are large enough,

2.1 ASTM Standards:

thistestmethodcanbeusedtodeterminetheirorientationsand

E3 Guide for Preparation of Metallographic Specimens

differences in orientation.

5. Apparatus

This test method is under the jurisdiction of ASTM Committee E04 on

5.1 X-Ray Tube—Inorderthatexposuretimesbereducedto

Metallography and is the direct responsibility of Subcommittee E04.11 on X-Ray

and Electron Metallography. aminimum,theX-raytubeshallhaveatargetthatgivesahigh

Current edition approved May 1, 2007. Published May 2007. Originally

yield of white X-radiation. The tube voltage shall be near 50

approved in 1949. Replaces E82– 49. Last previous edition approved in 2001 as

kVp.

E82–91(2001).

5.2 Back-Reflection Laue X-Ray Camera—The X-ray cam-

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

this method.

era shall have (1) a pinhole system about 6 cm in length with

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Plate I is available from ASTM Headquarters. Order Adjunct: ADJE0082.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 82 – 91 (2007)

openings of ⁄4 to 1 mm, (2) a flat, light-tight film holder (the

hole in the center of the film should be as small as possible,

preferably about ⁄8 in. (3.2 mm) in diameter), (3) a specimen

holder,and( 4)meansforsettingthecrystal-to-filmdistanceat

3.00 cm. These parts may be assembled in various ways

depending upon the type of specimen being studied and upon

theaccuracydesired.Themainrequirementforaccurateresults

is that the pinhole system shall be precisely perpendicular to

thefilmholderandthustothefilm.Analuminumsheetmaybe

placed between the specimen and the film, preferably in close

contact with the film, in order to filter much of the secondary

X-radiation emitted by the crystal.

NOTE 1—Fig. 1 illustrates a back-reflection Laue camera constructed

forusewithmetallicsheetspecimenshavinggrainswithadiameterof0.5

mm or larger. The specimen-to-film distance is fixed at 3 cm and the

specimen surface is maintained perpendicular to the incident beam and

parallel to the film.

NOTE 2—Fig. 2 illustrates a universal camera with a goniometer head,

as adapted for back-reflection Laue studies. With this camera the inter-

pretation of an unsymmetrical pattern may be verified rapidly by rotating

the specimen to an angle for which a prominent pole is perpendicular to

the film, so that a pattern of recognized symmetry is obtained. FIG. 2 Universal Camera With Goniometer Head for Back-

Reflection Laue Studies

6. Test Specimen

6.1 The test specimen may be of any convenient size or

of metals such as tin and zinc (or their solid solutions), which

shape. Normally, the orientation will be determined with

twin readily on being plastically deformed.

reference to a prepared surface and a line on this surface.

NOTE 3—Reference may be made to MethodsE3, for procedures for

Surfaces on metal crystals may be prepared by methods

polishing specimens.

ordinarily used in preparing metallographic specimens (Note

3). After final polishing, the specimen shall be etched deeply

PROCEDURE

enoughtoremoveallpolishingdistortion.Thissurfaceshallbe

examined microscopically to make sure that the etch has

7. Orientation of Specimen and Film

removedallscratchesordistortedmetal.Strain-freesurfacesof

7.1 It is necessary that the orientation relationships between

aluminum, iron, copper, brass, tungsten, nickel, etc., are easily

the specimen and film be fixed at the outset (a sketch of this

prepared. Great care is needed in preparing surfaces on cystals

relationship should be made) and be preserved throughout the

determinations.Forexample,thisrelationshipisfixedif(1)the

exposed specimen surface is parallel to the plane of the film,

(2) a vertical line inscribed on the specimen surface is parallel

to a vertical line on the film, (3) the “top” of the film

corresponds with the “top” of the specimen, and ( 4) the

exposed surface of the film facing the specimen is definitely

marked.

8. Back-Reflection Laue Pattern

8.1 The back-reflection Laue pattern, properly prepared,

will contain a hundred or more diffraction spots. These spots

represent “reflections” of the X-ray beam from all important

lattice planes of the crystal that are in position for diffraction.

With the crystal-to-film distance of 3 cm and a photographic

film5in.(127mm)indiameteror4by5in.(102by127mm),

this will include all important lattice planes that make an angle

of less than about 35° with the film; the reflections from all

other planes in the crystal will not be intercepted by the film.

The diffraction spots form a pattern consisting of many

hyperbolic curves; these curves represent crystallographic

zones (1, 2). Some of these hyperbolic curves are more

prominent (more thickly populated with spots) than others, as

they represent crystallographic zones having a higher popula-

FIG. 1 Back-Reflection Laue Camera for Metallic Sheet

Specimens tion of low-indices planes.

E 82 – 91 (2007)

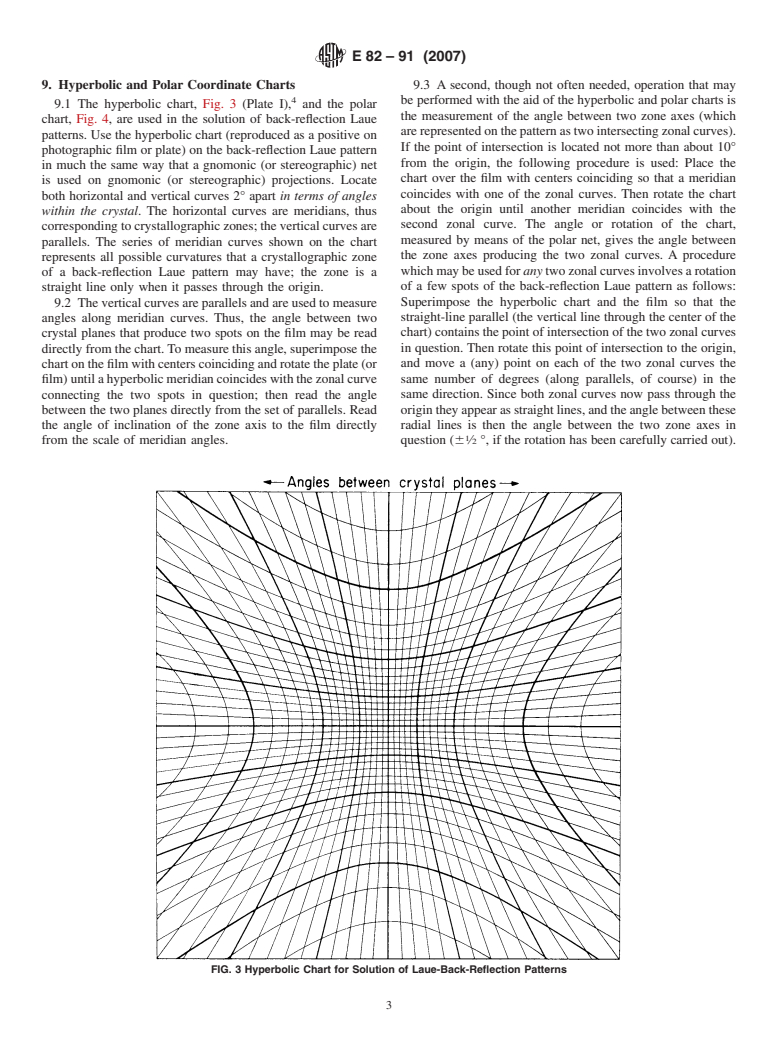

9. Hyperbolic and Polar Coordinate Charts 9.3 A second, though not often needed, operation that may

be performed with the aid of the hyperbolic and polar charts is

9.1 The hyperbolic chart, Fig. 3 (Plate I), and the polar

the measurement of the angle between two zone axes (which

chart, Fig. 4, are used in the solution of back-reflection Laue

arerepresentedonthepatternastwointersectingzonalcurves).

patterns. Use the hyperbolic chart (reproduced as a positive on

If the point of intersection is located not more than about 10°

photographic film or plate) on the back-reflection Laue pattern

from the origin, the following procedure is used: Place the

in much the same way that a gnomonic (or stereographic) net

chart over the film with centers coinciding so that a meridian

is used on gnomonic (or stereographic) projections. Locate

coincides with one of the zonal curves. Then rotate the chart

both horizontal and vertical curves 2° apart in terms of angles

about the origin until another meridian coincides with the

within the crystal. The horizontal curves are meridians, thus

second zonal curve. The angle or rotation of the chart,

correspondingtocrystallographiczones;theverticalcurvesare

measured by means of the polar net, gives the angle between

parallels. The series of meridian curves shown on the chart

the zone axes producing the two zonal curves. A procedure

represents all possible curvatures that a crystallographic zone

whichmaybeusedfor anytwozonalcurvesinvolvesarotation

of a back-reflection Laue pattern may have; the zone is a

of a few spots of the back-reflection Laue pattern as follows:

straight line only when it passes through the origin.

Superimpose the hyperbolic chart and the film so that the

9.2 Theverticalcurvesareparallelsandareusedtomeasure

angles along meridian curves. Thus, the angle between two straight-line parallel (the vertical line through the center of the

chart)containsthepointofintersectionofthetwozonalcurves

crystal planes that produce two spots on the film may be read

directlyfromthechart.Tomeasurethisangle,superimposethe in question. Then rotate this point of intersection to the origin,

and move a (any) point on each of the two zonal curves the

chartonthefilmwithcenterscoincidingandrotatetheplate(or

film)untilahyperbolicmeridiancoincideswiththezonalcurve same number of degrees (along parallels, of course) in the

connecting the two spots in question; then read the angle same direction. Since both zonal curves now pass through the

between the two planes directly from the set of parallels. Read origintheyappearasstraightlines,andtheanglebetweenthese

the angle of inclination of the zone axis to the film directly radial lines is then the angle between the two zone axes in

from the scale of meridian angles. question (6 ⁄2 °, if the rotation has been carefully carried out).

FIG. 3 Hyperbolic Chart for Solution of Laue-Back-Reflection Patterns

E 82 – 91 (2007)

FIG. 4 Polar Chart for Solution of Laue Back-Reflection Patterns

Thisoperationisthesameastheoperationrequiredtomeasure central spot and parallel to a prominent direction in the

the angle between any two intersecting great circles on a specimen, and measure all azimuth angles with respect to this

stereographic projection. line. Methods for plotting the projections are described by

Barrett (4).Methodsforidentifyingprominentspotsandzones

10. Interpretation of Unsymmetrical Back-Reflection

are summarized in 10.2 to 10.6, inclusive.

Laue Patterns

10.2 After some experience has been gained, it will be

10.1 The most rigorous method for solving an unsymmetri- found that back-reflection Laue patterns may be solved by

cal pattern is by preparing a stereographic projection with its inspection alone. The following remarks should be of assis-

plane parallel to the plane of the film. Read the film from the tanceinthedevelopmentofasystematicapproach:Atleastone

side opposite that of incident radiation, so that the projection standard stereographic projection (5) of the lattice being

corresponds to viewing the crystal from the position of the studied shall be prepared. This projection shall include ^100&,

X-ray tube. Inscribe a reference line on the film through the ^110&,and ^111&zones,andifthecrystalisface-centeredcubic,

E 82 – 91 (2007)

the projection shall include all the poles of the forms {100}, cubic crystals, these important spots are {111}, {100}, and

{110}, {111}, and {113}; if body-centered cubic, the projec- {110}, for body-centered cubic, they are {110}, {100}, and

tion shall include {100}, {110}, {111}, and {112}. This {112}. The above-listed planes and zones are all that need be

standard projection shall be studied until one has become considered in the solution of patterns, because every unsym-

familiar with the relative positions of poles and their angular metrical back-reflection Laue pattern will contain at least two

separations, the symmetry characteristics of each pole, the ofthelisteddiffractionspots,andinordertoobtainacomplete

important zonal curves passing through each pole, etc. solution of a pattern it is necessary only to identify two

10.3 In Figs. 5-8 are reproduced standard stereographic important diffraction spots, or one important spot and a zonal

projections of a cubic crystal with the {100}, {111}, {110}, curve.Animportantspotonaback-reflectionLauepatternmay

and {112} poles at the center. These projections illustrate be recognized easily because (1) it is (comparatively) isolated

orientations having four-fold, three-fold, and two-fold axes of from its neighbors, (2) it is a point of intersection of a large

symmetry and a plane of symmetry, respectively. Note that the number of zonal curves, and (3) it is of rather high intensity.A

standard cubic, or {100}, projection is made of 24 identical spot is identified by the angles between the important zonal

triangular areas. curvesthati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.