ASTM G62-87(1998)e1

(Test Method)Standard Test Methods for Holiday Detection in Pipeline Coatings (Withdrawn 2007)

Standard Test Methods for Holiday Detection in Pipeline Coatings (Withdrawn 2007)

SCOPE

1.1 These test methods cover the apparatus and procedure for detecting holidays in pipeline type coatings.

1.2 Method A is designed to detect holidays such as pinholes and voids in thin-film coatings from 0.0254 to 0.254 mm (1 to 10 mils) in thickness using ordinary tap water and an applied voltage of less than 100 V d-c. It is effective on films up to 0.508 mm (20 mils) thickness if a wetting agent is used with the water. It should be noted, however, that this method will not detect thin spots in the coating, even those as thin as 0.635 mm (0.025 mils). This may be considered to be a nondestructive test because of the relatively low voltage.

1.3 Method B is designed to detect holidays such as pinholes and voids in pipeline coatings; but because of the higher applied voltages, it can also be used to detect thin spots in the coating. This method can be used on any thickness of pipeline coating and utilizes applied voltages between 900 and 20 000 V d-c. This method is considered destructive because the high voltages involved generally destroy the coating at thin spots.

1.4 The values stated in SI units to three significant decimals are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

These test methods cover the apparatus and procedure for detecting holidays in pipeline type coatings. Method A is designed to detect holidays such as pinholes and voids in thin-film coatings from 0.0254 to 0.254 mm (1 to 10 mils) in thickness using ordinary tap water and an applied voltage of less than 100 V d-c. Method B is designed to detect holidays such as pinholes and voids in pipeline coatings; but because of the higher applied voltages, it can also be used to detect thin spots in the coating.

Formerly under the jurisdiction of Committee D01 on Paint and Related Coatings, Materials, and Applications, this test method was withdrawn in March 2007 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:G62–87 (Reapproved 1998)

Standard Test Methods for

Holiday Detection in Pipeline Coatings

ThisstandardisissuedunderthefixeddesignationG 62;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Unit of measurement in section 1.2 was corrected editorially in July 2002.

1. Scope A 742/A 742M Specification for Steel Sheet, Metallic

Coated and Polymer Precoated for Corrugated Steel Pipe

1.1 These test methods cover the apparatus and procedure

for detecting holidays in pipeline type coatings.

3. Terminology

1.2 Method A is designed to detect holidays such as pin-

3.1 Definitions:

holes and voids in thin-film coatings from 0.0254 to 0.254 mm

3.1.1 holiday—small faults or pinholes that permit current

(1 to 10 mils) in thickness using ordinary tap water and an

drainagethroughprotectivecoatingsonsteelpipeorpolymeric

applied voltage of less than 100 V d-c. It is effective on films

precoated corrugated steel pipe.

up to 0.508 mm (20 mils) thickness if a wetting agent is used

3.1.2 mil—0.001 in.

with the water. It should be noted, however, that this method

3.2 Definitions of Terms Specific to This Standard:

will not detect thin spots in the coating, even those as thin as

3.2.1 holiday detector—A highly sensitive electrical device

0.635 mm (25 mils). This may be considered to be a nonde-

designed to locate holidays such as pinholes, voids, and thin

structive test because of the relatively low voltage.

spotsinthecoating,noteasilyseenbythenakedeye.Theseare

1.3 Method B is designed to detect holidays such as

used on the coatings of relatively high-electrical resistance

pinholes and voids in pipeline coatings; but because of the

when such coatings are applied to the surface of materials of

higher applied voltages, it can also be used to detect thin spots

low-electrical resistance, such as steel pipe.

in the coating. This method can be used on any thickness of

3.2.2 pipeline type coating—Coatings of relatively high-

pipeline coating and utilizes applied voltages between 900 and

electrical resistance applied to surfaces of relatively low-

20 000 V d-c. This method is considered destructive because

electrical resistance, such as steel pipe.

the high voltages involved generally destroy the coating at thin

spots.

4. Summary of Test Methods

1.4 The values stated in SI units to three significant deci-

4.1 Both methods rely on electrical contact being made

mals are to be regarded as the standard. The values given in

through the pipeline coating because of a holiday or a

parentheses are for information only.

low-resistance path created by metal particles, or thin spots in

1.5 This standard does not purport to address all of the

the coating. This electrical contact will activate an alarm

safety concerns, if any, associated with its use. It is the

alerting the operator of the incidence of a holiday.

responsibility of the user of this standard to establish appro-

4.2 In Method A, the applied voltage is 100 V d-c or less.

priate safety and health practices and determine the applica-

4.3 In Method B, the applied voltage is 900 to 20 000

bility of regulatory limitations prior to use.

V d-c.

2. Referenced Documents

5. Significance and Use

2.1 ASTM Standards:

5.1 Method A—Method A describes a quick, safe method

for determining if pinholes, voids, or metal particles are

protruding through the coating.This method will not, however,

These test methods are under the jurisdiction of ASTM Committee D01 on

Paint and Related Coatings, Materials, and Applications and are the direct

find any thin spots in the coating. This method will determine

responsibility of Subcommittee D01.48 on Durability of Pipeline Coating and

the existence of any gross faults in thin-film pipeline coatings.

Linings.

5.2 Method B—Method B describes a method for determin-

Current edition approved Sept. 25, 1987. Published November 1987. Originally

published as G 62 – 79. Last previous edition G 62 – 85. ing if pinholes, voids, or metal particles are protruding through

This was taken from the pamphlet “Operating Instructions forTinker and Rasor

Model EP Holiday Detector.” Other manufacturers’ holiday detectors can be

expected to have similar voltage specifications. Annual Book of ASTM Standards, Vol 01.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

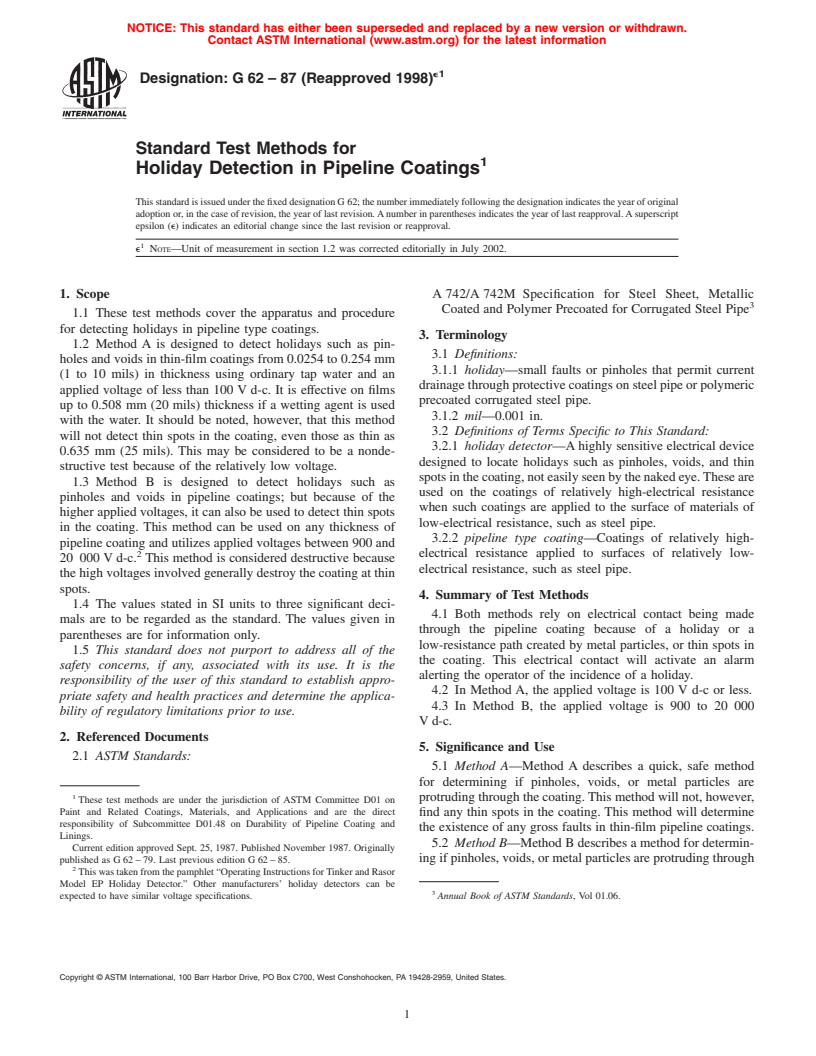

G62

the coating, and thin spots in pipeline coatings. This method 10.2 Assemble the wand and electrode according to the

can be used to verify minimum coating thicknesses as well as manufacturer’s instructions and attach the ground wire to the

voids in quality-control applications. metal surface.

10.3 Attach the electrode clamps to the end of the wand,

6. Apparatus

dampen the sponge electrode with tap water, and place it

6.1 Low-Voltage Holiday Detector—A holiday detector

between the clamps. Then tighten the clamps with the screw

tester having an electrical energy source of less than 100Vd-c,

until they are well down into the sponge electrode. Attach the

such as a battery; an exploring electrode having a cellulose

ground wire (lead with battery clamp) and the wand to the

sponge dampened with an electrically conductive liquid such

terminals. Clip the ground wire to some point where the metal

as tap water; and an audio indicator to signal a defect in a

surface is bare. Now touch the electrode to a second point

high-electrical resistance coating on a metal substrate. A

where the surface is bare and note that the audible signal will

ground wire connects the detector with the low-resistance

be activated. The detector is now ready to operate by passing

metal surface.

the damp sponge over the coated surface. When a holiday is

6.2 High-Voltage Holiday Detector—A holiday detector

picked up by the audible alarm, the electrode can be turned on

tester having an electrical energy source of 900 to 20 000 V

endandtheexactspotoffailurecanbenotedbysearchingwith

d-c; an exploring electrode consisting of wire brush, coil-

the tip of the electrode.

spring, or conductive silicon electrode capable of moving

10.4 The voltage between the electrode (sponge) and the

along the pipeline coating; and an audio indicator to signal a

metal surface upon which the coating lies shall not exceed 100

defect in a high-electrical resistance coating on a metal

V d-c, measured between the electrode sponge and the coated

substrate. A ground wire connects the detector with the

metal when the detector is in its normal operating position.

low-resistance metal surface.

10.5 Prior to making the inspection, ensure that the coated

6.3 Peak or Crest Reading Voltmeter—A kilovoltmeter

surface is dry. This is particularly important if formed surfaces

capable of detecting a single pulse and holding it long enough

are to be inspected. If the surface is in an environment where

for the meter circuits to indicate.

electrolytes might form on the surface, such as salt spray, wash

the coated surface with fresh water and allow to dry before

7. Reagents and Materials

testing. Take care to keep the electrolyte at least 12.7 mm ( ⁄2

7.1 Tap Water, plain or with a w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.