ASTM C1153-97

(Practice)Standard Practice for Location of Wet Insulation in Roofing Systems Using Infrared Imaging

Standard Practice for Location of Wet Insulation in Roofing Systems Using Infrared Imaging

SCOPE

1.1 This practice applies to techniques that employ infrared imaging at night to determine the location of wet insulation in roofing systems that have insulation above the deck in contact with the waterproofing. This practice includes ground-based and aerial inspections.

1.2 This practice addresses criteria for infrared equipment such as minimum resolvable temperature difference, spectral range, instantaneous field of view, and field of view.

1.3 This practice addresses meteorological conditions under which infrared inspections should be performed.

1.4 This practice addresses the effect of roof construction, material differences, and roof conditions on infrared inspections.

1.5 This practice addresses operating procedures, operator qualifications, and operating practices.

1.6 This practice also addresses verification of infrared data using invasive test methods.

1.7 The values stated in SI units are to be regarded as standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Notes 1, 2, and 3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: C 1153 – 97

Standard Practice for

Location of Wet Insulation in Roofing Systems Using

Infrared Imaging

This standard is issued under the fixed designation C 1153; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C 168 Terminology Relating to Thermal Insulating Materi-

als

1.1 This practice applies to techniques that employ infrared

D 1079 Terminology Relating to Roofing, Waterproofing,

imaging at night to determine the location of wet insulation in

and Bituminous Materials

roofing systems that have insulation above the deck in contact

E 1149 Definitions of Terms Relating to NDT by Infrared

with the waterproofing. This practice includes ground-based

Thermography

and aerial inspections.

E 1213 Test Method for Minimum Resolvable Temperature

1.2 This practice addresses criteria for infrared equipment

Difference for Thermal Imaging Systems

such as minimum resolvable temperature difference, spectral

2.2 ANSI-ASHRAE Standard:

range, instantaneous field of view, and field of view.

ANSI-ASHRAE Standard 101—Application of Infrared

1.3 This practice addresses meteorological conditions under

Sensing Devices to theAssessment of Building Heat Loss

which infrared inspections should be performed.

Characteristics

1.4 This practice addresses the effect of roof construction,

2.3 ISO Standard:

material differences, and roof conditions on infrared inspec-

ISO/DP 6781.3E—Thermal Insulation—Qualitative Detec-

tions.

tion of Thermal Irregularities in Building Envelopes—

1.5 This practice addresses operating procedures, operator

Infrared Method

qualifications, and operating practices.

1.6 This practice also addresses verification of infrared data

3. Terminology

using invasive test methods.

3.1 Definitions:

1.7 The values stated in SI units are to be regarded as

3.1.1 blackbody, n—the ideal, perfect emitter and absorber

standard.

ofthermalradiation.Itemitsradiantenergyateachwavelength

1.8 This standard does not purport to address all of the

at the maximum rate possible as a consequence of its tempera-

safety concerns, if any, associated with its use. It is the

ture, and absorbs all incident radiance. (See Terminology

responsibility of the user of this standard to establish appro-

C 168.)

priate safety and health practices and determine the applica-

3.1.2 core, n—a small sample encompassing at least 13

bility of regulatory limitations prior to use. Specific precau-

cm of the roof surface area taken by cutting through the roof

tionary statements are given in Notes 1-3.

membrane and insulation and removing the insulation to

NOTE 1—Warning: Caution should be taken in handling any cryogenic

determine its composition, condition, and moisture content.

liquids and pressurized gases required for use in this practice.

3.1.3 detection, n—the condition at which there is a consis-

NOTE 2—Warning: Extreme caution should be taken when accessing

tent indication that a thermal difference is present on the

or walking on roof surfaces and when operating aircraft at low altitudes,

surface of the roof. Detection of thermal anomalies can be

especially at night.

accomplished when they are large enough and close enough to

NOTE 3—Precaution: Itisagoodsafetypracticeforatleasttwopeople

to be present on the roof surface at all times when ground-based

be within the spatial resolution capabilities of the imaging

inspections are being conducted.

system; that is, when their width is at least two times the

product of the instantaneous field of view (IFOV) (see 3.1.10)

2. Referenced Documents

2.1 ASTM Standards:

Annual Book of ASTM Standards, Vol 04.06.

1 3

This practice is under the jurisdiction of ASTM Committee C-16 on Thermal Annual Book of ASTM Standards, Vol 04.04.

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal Discontinued; replaced by E 1316.

Measurement. Annual Book of ASTM Standards, Vol 03.03.

Current edition approved May 10, 1997. Published August 1997. Originally Available from American National Standards Institute, 11 W. 42nd St., 13th

published as C 1153 – 90. Last previous edition C 1153 – 90. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

C1153–97

of the system and the distance from the system to the surface 3.1.18 roofing system, n—an assembly of interacting com-

of the roof divided by 1000. ponents designed to weatherproof, and normally to insulate, a

building’s top surface. (See Terminology D 1079.)

3.1.4 emittance, e,n—theratiooftheradiantfluxemittedby

a specimen to that emitted by a blackbody at the same 3.1.19 survey window, n—the time period during which

temperature and under the same conditions. (See Terminology roof moisture surveys can be successfully conducted according

C 168.) to the requirements of Section 10.

3.1.20 thermal anomaly, n—a thermal pattern of a surface

3.1.5 expansion joint, n—a structural separation or flexible

connection between two building elements that allows free that varies from a uniform color or tone when viewed with an

infrared imaging system.Thermal anomalies may be caused by

movementbetweentheelementswithoutdamagetotheroofing

or waterproofing system. (See Terminology D 1079.) wet insulation.

3.1.6 field-of-view, (FOV), n—the total angular dimensions, 3.1.21 thermogram, n—a recorded visual image that maps

the apparent temperature pattern of an object or scene into a

expressed in radians, within which objects can be imaged,

displayed and recorded by a stationary imaging device. corresponding contrast or color pattern. (See Terminology

E 1149 with the word “recorded” added.)

3.1.7 infrared imaging line scanner, n—an apparatus that

scans along a single line for variations in infrared radiance and

is moved perpendicular to that line to produce a two- 4. Significance and Use

dimensional image of the region scanned.

4.1 This practice should be used to outline the minimum

3.1.8 infrared imaging system, n—an apparatus that con-

necessary elements and conditions to obtain an accurate

verts the spatial variations in infrared radiance from a surface

determination of the location of wet insulation in roofing

into a two-dimensional image, in which variations in radiance

systems using infrared imaging.

are displayed as a range of colors or tones.

4.2 This practice is not meant to be an instructional docu-

3.1.9 infrared thermography, n—the process of generating

ment or to provide all the knowledge and background neces-

imagesthatrepresentvariationsininfraredradianceofsurfaces

sary to provide an accurate analysis. For further information,

of objects.

see ANSI-ASHRAE Standard 101 and ISO/DP 6781.3E.

3.1.10 instantaneous field of view, (IFOV), n—the smallest

4.3 This practice does not provide methods to determine the

angle, in milliradians, that can be instantaneously resolved by

cause of moisture or its point of entry. It does not address the

a particular infrared imaging system.

suitability of any particular system to function capably as

3.1.11 line scanner, n—an apparatus that scans along a

waterproofing.

single line of a scene to provide a one-dimensional thermal

profile of the scene. (See Terminology E 1149.)

5. Infrared Survey Techniques

3.1.12 membrane, n—a flexible or semiflexible roof cover-

5.1 Ground-Based:

ing or waterproofing whose primary function is the exclusion

5.1.1 Walk-Over—Walking on a roof using an infrared

of water. (See Terminology D 1079.)

imaging system. The system may be hand-carried or mounted

3.1.13 minimum resolvable temperature difference (MRTD),

on a cart. Thermograms are taken of areas of interest. Areas

n—a measure of the ability of operators of an infrared imaging

that appear to contain wet insulation are identified and marked

systemtodiscerntemperaturedifferenceswiththatsystem.The

for verification.

MRTD is the minimum temperature difference between a four

5.1.2 Elevated Vantage Point—Use of an infrared imaging

slot test pattern of defined shape and size and its blackbody

system from an elevated vantage point may provide an

background at which an average observer can discern the

improved view of the roof.

pattern with that infrared imaging system at a defined distance.

5.2 Aerial:

3.1.14 moisture meter probe, n—an invasive (electrical

5.2.1 Real-Time Imaging—Use of an infrared imaging sys-

resistance or galvanometric type) test that entails the insertion

tem from an aircraft. Thermograms are obtained for the entire

of a meter probe(s) through the roof membrane to indicate the

roof.

presence of moisture within the roofing system.

5.2.2 Line Scanner Imaging—Use of a line scanner from an

3.1.15 radiance, n—the rate of radiant emission per unit

aircraft to record thermal imagery for the entire roof.

solid angle and per unit projected area of a source in a stated

angular direction from the surface (usually the normal). (See

6. Instrument Requirements

Terminology C 168.)

6.1 General:

3.1.16 recognition, n—the ability to differentiate between

6.1.1 Objective—Instrument requirements have been estab-

different types of thermal patterns such as board-stock, picture-

lished in order to permit location of insulation that has lost as

framed and amorphous. Recognition of thermal anomalies can

little as 20 % of its insulating ability because it contains

be accomplished when their width is at least eight times the

moisture.

product of the IFOV of the infrared imaging system and the

6.1.2 Spectral Range—The infrared imaging system shall

distance from the system to the surface of the roof divided by

1000. operate within a spectral range from 2 to 14 µm. A spot

radiometer or nonimaging line scanner is not sufficient.

3.1.17 roof section, n—a portion of a roof that is separated

from adjacent portions by walls or expansion joints and in 6.1.3 Minimum Resolvable Temperature Difference

which there are no major changes in the components. (MRTD)—The MRTD at 20°C shall be 0.3°C.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

C1153–97

6.1.3.1 The survey shall be conducted with the thermal 6.3.1 Anomaly Size—Instrument requirements have been

imaging system only on sensitivity settings that meet this established to permit recognition of areas of wet insulation as

requirement. small as 0.15 m on a side.

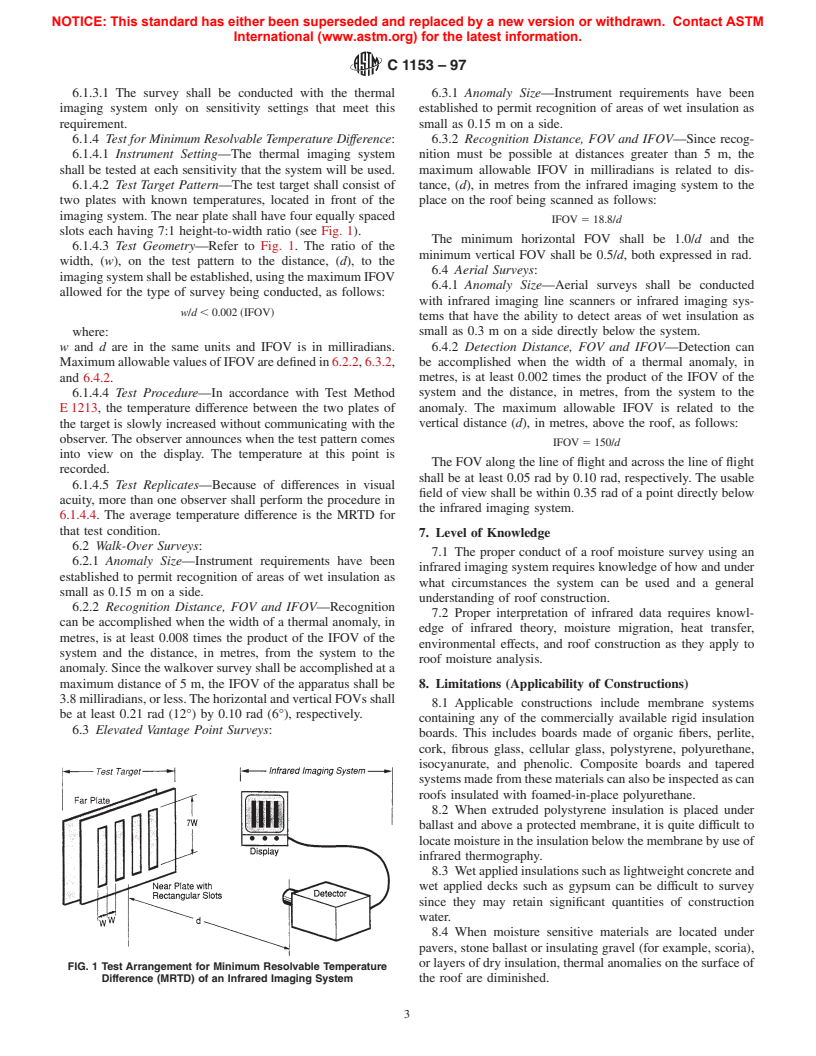

6.1.4 Test for Minimum Resolvable Temperature Difference: 6.3.2 Recognition Distance, FOV and IFOV—Since recog-

6.1.4.1 Instrument Setting—The thermal imaging system nition must be possible at distances greater than 5 m, the

shall be tested at each sensitivity that the system will be used. maximum allowable IFOV in milliradians is related to dis-

6.1.4.2 Test Target Pattern—The test target shall consist of tance, (d), in metres from the infrared imaging system to the

two plates with known temperatures, located in front of the place on the roof being scanned as follows:

imaging system. The near plate shall have four equally spaced

IFOV 5 18.8/d

slots each having 7:1 height-to-width ratio (see Fig. 1).

The minimum horizontal FOV shall be 1.0/d and the

6.1.4.3 Test Geometry—Refer to Fig. 1. The ratio of the

minimum vertical FOV shall be 0.5/d, both expressed in rad.

width, (w), on the test pattern to the distance, (d), to the

6.4 Aerial Surveys:

imagingsystemshallbeestablished,usingthemaximumIFOV

6.4.1 Anomaly Size—Aerial surveys shall be conducted

allowed for the type of survey being conducted, as follows:

with infrared imaging line scanners or infrared imaging sys-

w/d , 0.002 ~IFOV!

tems that have the ability to detect areas of wet insulation as

where: small as 0.3 m on a side directly below the system.

6.4.2 Detection Distance, FOV and IFOV—Detection can

w and d are in the same units and IFOV is in milliradians.

MaximumallowablevaluesofIFOVaredefinedin6.2.2,6.3.2, be accomplished when the width of a thermal anomaly, in

metres, is at least 0.002 times the product of the IFOV of the

and 6.4.2.

6.1.4.4 Test Procedure—In accordance with Test Method system and the distance, in metres, from the system to the

anomaly. The maximum allowable IFOV is related to the

E 1213, the temperature difference between the two plates of

the target is slowly increased without communicating with the vertical distance (d), in metres, above the roof, as follows:

observer. The observer announces when the test pattern comes

IFOV 5 150/d

into view on the display. The temperature at this point is

The FOV along the line of flight and across the line of flight

recorded.

shall be at least 0.05 rad by 0.10 rad, respectively. The usable

6.1.4.5 Test Replicates—Because of differences in visual

field of view shall be within 0.35 rad of a point directly below

acuity, more than one observer shall perform the procedure in

the infrared imaging system.

6.1.4.4. The average temperature difference is the MRTD for

that test condition.

7. Level of Knowledge

6.2 Walk-Over Surveys:

7.1 The proper conduct of a roof moisture survey using an

6.2.1 Anomaly Size—Instrument requirements have been

infrared imaging system requires knowledge of how and under

established to permit recognition of areas of wet insulation as

what circumstances the system can be used and a general

small as 0.15 m on a side.

understanding of roof construction.

6.2.2 Recognition Distance, FOV and IFOV—Recognition

7.2 Proper interpretation of infrared data requires knowl-

can be accomplished when the width of a thermal anomaly, in

edge of infrared theory, moisture migration, heat transfer,

metres, is at least 0.008 times the product of the IFOV of the

environmental effects, and roof construction as they apply to

system and the distance, in metres, from the system to the

roof moisture analysis.

anomaly. Since the walkover survey shall be accomplished at a

maximum distance of 5 m, the IFOV of the apparatus shall be 8. Limitations (Applicability of Constructions)

3.8milliradians,orless.ThehorizontalandverticalFOVsshall

8.1 Applicable constructions include membrane systems

be at least 0.21 rad (12°) by 0.10 rad (6°), respectively.

containing any of the commercially available rigid insulation

6.3 Elevated Vantage Point Surveys:

boards. This includes boards made of organic fibers, perlite,

cork, fibrous glass, cellular glass, polystyrene, polyurethane,

isocyanurate, and phenoli

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.