ASTM E1010-16

(Practice)Standard Practice for Preparation of Disk Specimens of Steel and Iron by Remelting for Spectrochemical Analysis (Withdrawn 2022)

Standard Practice for Preparation of Disk Specimens of Steel and Iron by Remelting for Spectrochemical Analysis (Withdrawn 2022)

SIGNIFICANCE AND USE

5.1 Most spectrochemical instruments employed for analyzing steel and iron require a solid specimen with a flat surface large enough for analytical excitation and measurement procedures. This practice describes a procedure for converting unusual types of steel and iron samples to satisfactory spectrochemical specimens.

SCOPE

1.1 This practice describes the preparation of disk specimens of steel and iron by melting chunks, chips, drillings, turnings, wire, or powder briquets with an electric arc in an argon atmosphere. Solidification of the specimen takes place in the crucible in an argon atmosphere. The disk obtained is suitable for quantitative spectrochemical analysis.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use. Specific warning statements are given in 6.2.1, Section 8, and 10.1.2.1.

WITHDRAWN RATIONALE

This practice describes the preparation of disk specimens of steel and iron by melting chunks, chips, drillings, turnings, wire, or powder briquets with an electric arc in an argon atmosphere. Solidification of the specimen takes place in the crucible in an argon atmosphere. The disk obtained is suitable for quantitative spectrochemical analysis.

Formerly under the jurisdiction of Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials, this practice was withdrawn in June 2022 and replaced by Practice E1306 for Preparation of Metal and Alloy Samples for Chemical Analysis by Electric Arc Remelting.1

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1010 − 16

Standard Practice for

Preparation of Disk Specimens of Steel and Iron by

1

Remelting for Spectrochemical Analysis

This standard is issued under the fixed designation E1010; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope controlled rate of flow. An arc is struck between the electrode

and the sample material and is maintained until the melting is

1.1 This practice describes the preparation of disk speci-

complete. The molten specimen is allowed to solidify in the

mens of steel and iron by melting chunks, chips, drillings,

crucible in an argon atmosphere. After solidification, the

turnings, wire, or powder briquets with an electric arc in an

specimen is removed from the crucible and prepared for

argon atmosphere. Solidification of the specimen takes place in

spectrochemical analysis.

the crucible in an argon atmosphere. The disk obtained is

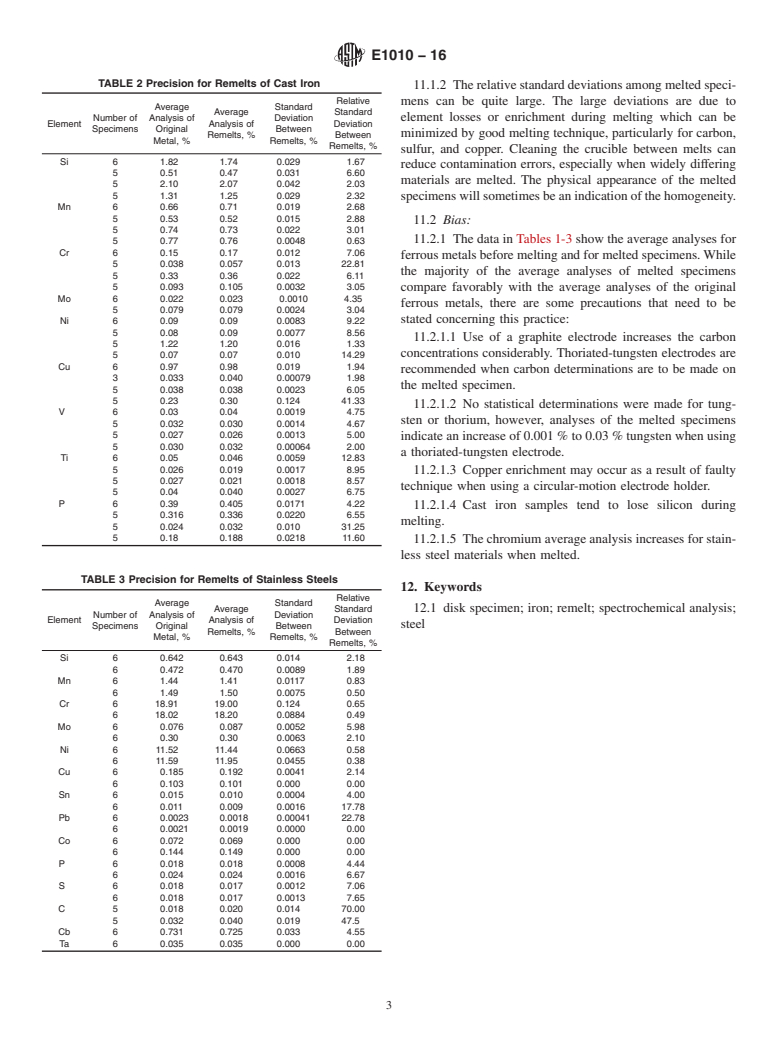

suitable for quantitative spectrochemical analysis. 4.2 Partial losses of some elements may be experienced

during the melting of the disk specimen. This procedure, if

1.2 The values stated in SI units are to be regarded as

carefully followed, will provide consistent losses. Elemental

standard. No other units of measurement are included in this

losses can be determined by correlating the analysis of the

standard.

charge material with the spectrochemical analysis of the

1.3 This standard does not purport to address all of the

remelted specimen.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices, and determine the applica-

5.1 Most spectrochemical instruments employed for analyz-

bility of regulatory limitations prior to use. Specific warning

ing steel and iron require a solid specimen with a flat surface

statements are given in 6.2.1, Section 8, and 10.1.2.1.

large enough for analytical excitation and measurement proce-

dures. This practice describes a procedure for converting

2. Referenced Documents

unusual types of steel and iron samples to satisfactory spec-

2

2.1 ASTM Standards:

trochemical specimens.

E135 Terminology Relating to Analytical Chemistry for

Metals, Ores, and Related Materials

6. Apparatus

E876 Practice for Use of Statistics in the Evaluation of

4

6.1 Melting Furnace, consisting of a chamber that contains

3

Spectrometric Data (Withdrawn 2003)

the following:

6.1.1 Crucible, of copper and water-cooled, in which

3. Terminology

samples of steel or iron are melted, then solidified to form

3.1 For definitions of terms used in this procedure, refer to

specimens for spectrochemical analysis.

Terminology E135.

6.1.2 Electrode Holder, water-cooled and of negative

polarity, that can be moved up and down easily, and may have

4. Summary of Practice

provisions for circular motion and adjusting the arc gap to a

4.1 The sample of steel or iron is placed in a water-cooled

fixed spacing.

copper crucible. The furnace is flushed with argon at a

6.1.3 Viewing Window, composed of dark welding-type

glass with an inner-protective glass that is impervious to heat

1

This practice is under the jurisdiction of ASTM Committee E01 on Analytical

and splatter from the molten metal.

Chemistry for Metals, Ores, and Related Materials and is the direct responsibility of

Subcommittee E01.01 on Iron, Steel, and Ferroalloys. 6.2 DC Electric Power Generator, to supply electric current

Current edition approved Jan. 15, 2016. Published March 2016. Originally

and voltage equivalent to that required for electric arc welding.

approved in 1984. Last previous edition approved in 2009 as E1010 – 09. DOI:

It may be a rotating dc generator or a static rectifier with

10.1520/E1010-16.

2

provisions to adjust the current in the 0 A to 600 A range.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

4

the ASTM website. Melting furnaces, manufactured by Cianflone Scientific, 228 RIDC Park West

3

The last approved version of this historical standard is referenced on Drive, Pittsburgh, PA 15275, http://www.cianflone.com, have been found suitable

www.astm.org. for this purpose.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1010 − 16

TABLE 1 Precision for Remelts of Low-Alloy Steels

6.2.1 Warning—A safety interlock shall be provided to

prevent electrical shock

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.