ASTM F38-00

(Test Method)Standard Test Methods for Creep Relaxation of a Gasket Material

Standard Test Methods for Creep Relaxation of a Gasket Material

SCOPE

1.1 These test methods provide a means of measuring the amount of creep relaxation of a gasket material at a stated time after a compressive stress has been applied.

1.1.1 Test Method A -Creep relaxation measured by means of a calibrated strain gage on a bolt.

1.1.2 Test Method B -Creep relaxation measured by means of a calibrated bolt with dial indicator.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F38–00

Standard Test Methods for

Creep Relaxation of a Gasket Material

ThisstandardisissuedunderthefixeddesignationF 38;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Summary of Test Methods

1.1 These test methods provide a means of measuring the 3.1 In both test methods the specimen is subjected to a

amount of creep relaxation of a gasket material at a predeter- compressive stress between two platens, with the stress applied

mined time after a compressive stress has been applied. by a nut and bolt.

1.1.1 Test MethodA— Creep relaxation measured by means 3.2 InTestMethodA,normallyrunatroomtemperature,the

of a calibrated strain gage on a bolt. stress is measured by a calibrated strain gage on the bolt. In

1.1.2 Test Method B— Creep relaxation measured by means running the test, strain indicator readings are taken at intervals

of a calibrated bolt with dial indicator. of time, beginning at the loading time, to the end of the test.

1.2 The values stated in SI units are to be regarded as the The strain indicator readings are converted to percentages of

standard. the initial stress which are then plotted against the log of time

1.3 This standard does not purport to address all of the in hours. The percentage of initial stress loss or relaxation can

safety concerns, if any, associated with its use. It is the be read off the curve at any given time, within the limits of the

responsibility of the user of this standard to establish appro- total test time.

priate safety and health practices and determine the applica- 3.3 InTest Method B, run at room or elevated temperatures,

bility of regulatory limitations prior to use. the stress is determined by measuring the change in length of

the calibrated bolt with a dial indicator. The bolt length is

2. Referenced Documents

measured at the beginning of the test and at the end of the test;

2.1 ASTM Standards: from this the percentage of relaxation is calculated.

A 193 Specification for Alloy Steel and Stainless Steel

4. Significance and Use

Bolting Materials for High-Temperature Service

B 637 Specification for Precipitation-Hardening Nickel Al- 4.1 These test methods are designed to compare related

loy Bars, Forgings, and Forging Stock for High Tempera- materials under controlled conditions and their ability to

ture Services maintain a given compressive stress as a function of time. A

D 3040 Practice for Preparing Precision Statements for portion of the torque loss on the bolted flange is a result of

Standards Related to Rubber and Rubber Testing creep relaxation. Torque loss can also be caused by elongation

F 104 Classification System for Nonmetallic Gasket Mate- of the bolts, distortion of the flanges, and vibration; therefore,

rials the results obtained should be correlated with field results.

2.2 ASTM Adjuncts: These test methods may be used as a routine test when agreed

Relaxometer, Method A (F 38) upon between the consumer and the producer.

Relaxometer, Method B (F 38)

NOTE 1—TestMethodBwasdevelopedusingasbestosgasketmaterials

and at issuance substantiating data were not available for other gasket

materials.

These test methods are under the jurisdiction of ASTM Committee F03 on

Gaskets and are the direct responsibility of Subcommittee F03.20 on Methods of

5. Apparatus

Test.

Current edition approved Apr. 10, 2000. Published May 2000. Originally issued

5.1 Test Method A:

1962 as D 2139. Redesignated in 1963. Last previous edition F 38 – 95.

5.1.1 Strain Indicator.

Annual Book of ASTM Standards, Vol 01.01.

3 5.1.2 Timer.

Annual Book of ASTM Standards, Vol 02.04.

Discontinued—see 1986 Annual Book of ASTM Standards, Vols 09.01 and

09.02.

Annual Book of ASTM Standards, Vol 09.02.

A print of this apparatus is available at a nominal cost from ASTM, 100 Barr

Harbor Drive, Conshohocken, PA 19428. Request Adjunct No. ADJF003801.

Detailed working drawings of this apparatus are available from ASTM. Order

Adjunct No. ADJF003802.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F38–00

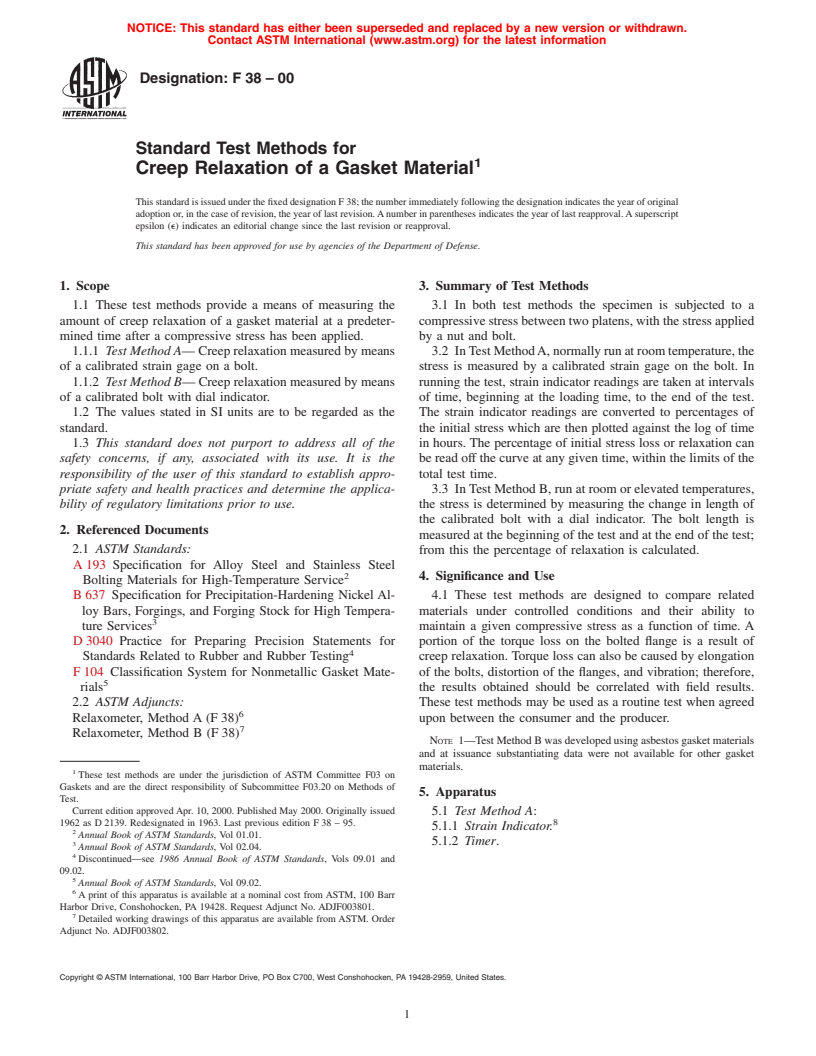

FIG. 1 Relaxometer, Test Method A

5.1.3 Relaxometer, composed of two platens, upper and 6.2.3 For Type 4 Class 2 materials, specimen size shall be

lower; a bolt, with mounted strain gage; and a thrust bearing as one continuous length of 152.4 mm (6.0 in.).

shown in Fig. 1. 6.3 A minimum of three tests shall be conducted.

5.1.4 Strain Gages, 120 V resistance with a gage factor of 6.4 Nominal thickness of specimen shall be 0.8 mm (0.03

2.0 6 0.10 %. The gages shall be mounted to indicate tensile in.) unless otherwise agreed upon between the consumer and

strain and positioned to compensate for torque, temperature, the producer. ForType 4 materials the nominal thickness of the

andbending.Thegagesshallbemountedonthesmalldiameter specimen shall be no greater than 1.78 mm (0.07 in.).

of the bolt about 50.8 mm (2 in.) from the head. The bolt with

7. Conditioning

mounted strain gages must be calibrated.

5.2 Test Method B: 7.1 Condition cut specimens in accordance with their clas-

,

7 10

5.2.1 Relaxometer, composed of two platens, special sification as required in Classification F 104.

drilled and calibrated bolt, washer and nut composed of

8. Procedure

Specification A 193 Grade B7 or ASTM B 637 Grade UNS

N07718 or other alloys of construction that would satisfy the 8.1 Test Method A:

calibration procedure (see Annex) for the test temperature 8.1.1 Clean all surfaces, platens, and specimen free of wax,

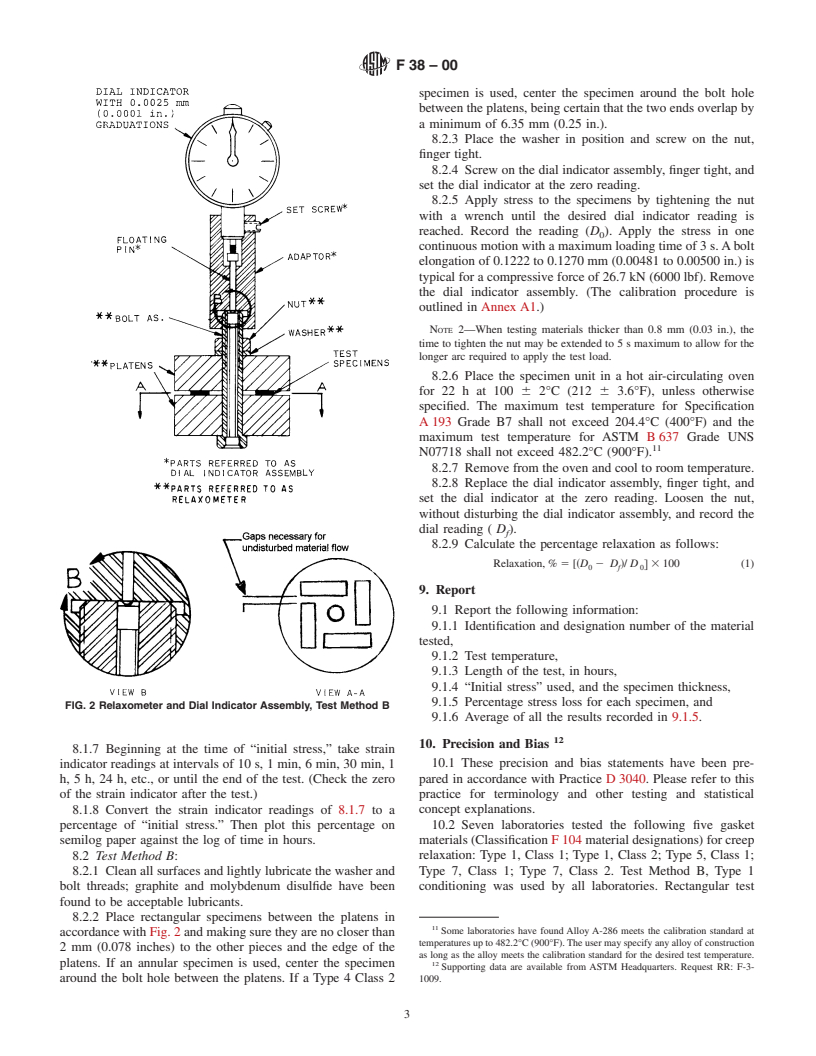

specified, and a dial indicator assembly as shown in Fig. 2. mold release, and oils. (Remove with isooctane or other

5.2.2 Box End Wrench. suitable solvent.) Lubricate bolt threads.

8.1.2 Use an initial stress of 13.8 6 0.3 MPa (2000 6 50

6. Test Specimen

psi) unless otherwise specified.

6.1 Test Method A— The sample size shall be 33.02 6 0.05 8.1.3 Conduct the test at 20 to 30°C (70 to 85°F) unless

mm (1.300 6 0.002 in.) in inside diameter and 52.32 6 0.05

otherwise specified.

mm (2.0606 0.002 in.) in outside diameter. 8.1.4 Disassemble the relaxometer and place the specimen

6.2 Test Method B:

between platens. The inside diameter of the specimen should

6.2.1 Specimen size shall be 10.16 6 0.381 mm (0.400 6 be nearly concentric with the inside diameter of the platens.

0.015in.)wideby31.75 60.381mm(1.250 60.015in.)long.

Screw on the nut and thrust bearing and tighten very slightly,

Four specimens are required per test.

by hand, or just enough to hold the specimen in place during

2 2

6.2.2 An annular specimen with 1290-mm (2.0-in. )

subsequent handling. Mount the head of the bolt in a clamp.

surface area may also be used.Asize of 15.62-mm (0.615-in.)

8.1.5 Hook up and balance the strain indicator. Record the

inside diameter by 43.56-mm (1.715-in.) outside diameter is

reading. Then set the reading on the strain indicator for the

recommended.

specified initial stress. (The microinches that are added to the

above reading will vary the stress and the strain gage bolt

calibration.)

A strain recorder such as the Leeds & Northrup Type G is preferred for this

8.1.6 Apply stress to the gasket by tightening the nut with a

purpose; however, SR-4 strain indicator Models L, K, and N from Baldwin-Lima-

solid wrench until the strain indicator reaches a balance. A

Hamilton; HW-1 portable strain indicator from the Budd Co.; and BridgeAmplifier

and Meter BAM-1 from Ellis Associates have been found satisfactory.

torque of approximately 30 N·m (22 lbf·ft) is required for a

Baldwin-Lima-Hamilton TypeAB-7 strain gages have been found satisfactory.

compressive force of 17.8 kN (4000 lbf). The stress should be

Dario P. Bernasconi, 40 Farrington St., Stoughton, MA 02072 and Donald G.

applied at uniform rate such that at the end of 10 6 2 s the

Johnson, Metal Samples, Route 1, Box 152, Munford,AL36268 are suppliers of the

relaxometer. specified stress is reached. This is called the “initial stress.”

F38–00

specimen is used, center the specimen around the bolt hole

between the platens, being certain that the two ends overlap by

a minimum of 6.35 mm (0.25 in.).

8.2.3 Place the washer in position and screw on the nut,

finger tight.

8.2.4 Screw on the dial indicator assembly, finger tight, and

set the dial indicator at the zero reading.

8.2.5 Apply stress to the specimens by tightening the nut

with a wrench until the desired dial indicator reading is

reached. Record the reading (D ). Apply the stress in one

continuous motion with a maximum loading time of 3 s.Abolt

elongation of 0.1222 to 0.1270 mm (0.00481 to 0.00500 in.) is

typical for a compressive force of 26.7 kN (6000 lbf). Remove

the dial indicator assembly. (The calibration procedure is

outlined in Annex A1.)

NOTE 2—When testing materials thicker than 0.8 mm (0.03 in.), the

time to tighten the nut may be extended to 5 s maximum to allow for the

longer arc required to apply the test load.

8.2.6 Place the specimen unit in a hot air-circulating oven

for 22 h at 100 6 2°C (212 6 3.6°F), unless otherwise

specified. The maximum test temperature for Specification

A 193 Grade B7 shall not exceed 204.4°C (400°F) and the

maximum test temperature for ASTM B 637 Grade UNS

N07718 shall not exceed 482.2°C (900°F).

8.2.7 Remove from the oven and cool to room temperature.

8.2.8 Replace the dial indicator assembly, finger tight, and

set the dial indicator at the zero reading. Loosen the nut,

without disturbing the dial indicator assembly, and record the

dial reading ( D).

f

8.2.9 Calculate the percentage relaxation as follows:

Relaxation, % 5 [~D 2 D !/ D # 3 100 (1)

0 f 0

9. Report

9.1 Report the following information:

9.1.1 Identification and designation number of the material

tested,

9.1.2 Test temperature,

9.1.3 Length of the test, in hours,

9.1.4 “Initial stress” used, and the specimen thickness,

9.1.5 Percentage stress loss for each specimen, and

FIG. 2 Relaxometer and Dial Indicator Assembly, Test Method B

9.1.6 Average of all the results recorded in 9.1.5.

10. Precision and Bias

8.1.7 Beginning at the time of “initial stress,” take strain

indicator readings at intervals of 10 s, 1 min, 6 min, 30 min, 1 10.1 These precision and bias statements have been pre-

h, 5 h, 24 h, etc., or until the end of the test. (Check the zero pared in accordance with Practice D 3040. Please refer to this

of the strain indicator after the test.) practice for terminology and other testing and statistical

8.1.8 Convert the strain indicator readings of 8.1.7 to a concept explanations.

percentage of “initial stress.” Then plot this percentag

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.