ASTM E2551-07

(Test Method)Standard Test Method for Humidity Calibration (or Conformation) of Humidity Generators for Use with Thermogravimetric Analyzers

Standard Test Method for Humidity Calibration (or Conformation) of Humidity Generators for Use with Thermogravimetric Analyzers

SIGNIFICANCE AND USE

This test method calibrates or demonstrates conformity of the humidity level in a purge gas generated by a humidity generator at a fixed temperature. Such calibration or demonstration of conformity may be required by quality initiatives.

Conformance demonstrates that the humidified purge gas is within some established limits.

Calibration provides an offset and or slope value that may be used for establishing the relative humidity scale of the apparatus.

SCOPE

1.1 This test method describes the humidity calibration (or conformance) of humidity generators for use with thermogravimetric analyzers and other thermal analysis apparatus. The humidity range covered is 5 to 95 % relative humidity (%RH) and the temperature range is 0 to 80 °C.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 There are no ISO equivalents to this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2551 − 07

StandardTest Method for

Humidity Calibration (or Conformation) of Humidity

Generators for Use with Thermogravimetric Analyzers

This standard is issued under the fixed designation E2551; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.2 water activity, n—the ratio of actual partial pressure of

water to the saturated water vapor pressure at the same

1.1 This test method describes the humidity calibration (or

temperature, expressed as a decimal fraction.

conformance) of humidity generators for use with thermogra-

3.2.2.1 Discussion—Water activity is also known as relative

vimetric analyzers and other thermal analysis apparatus. The

pressure in some applications areas.

humidity range covered is 5 to 95 % relative humidity (%RH)

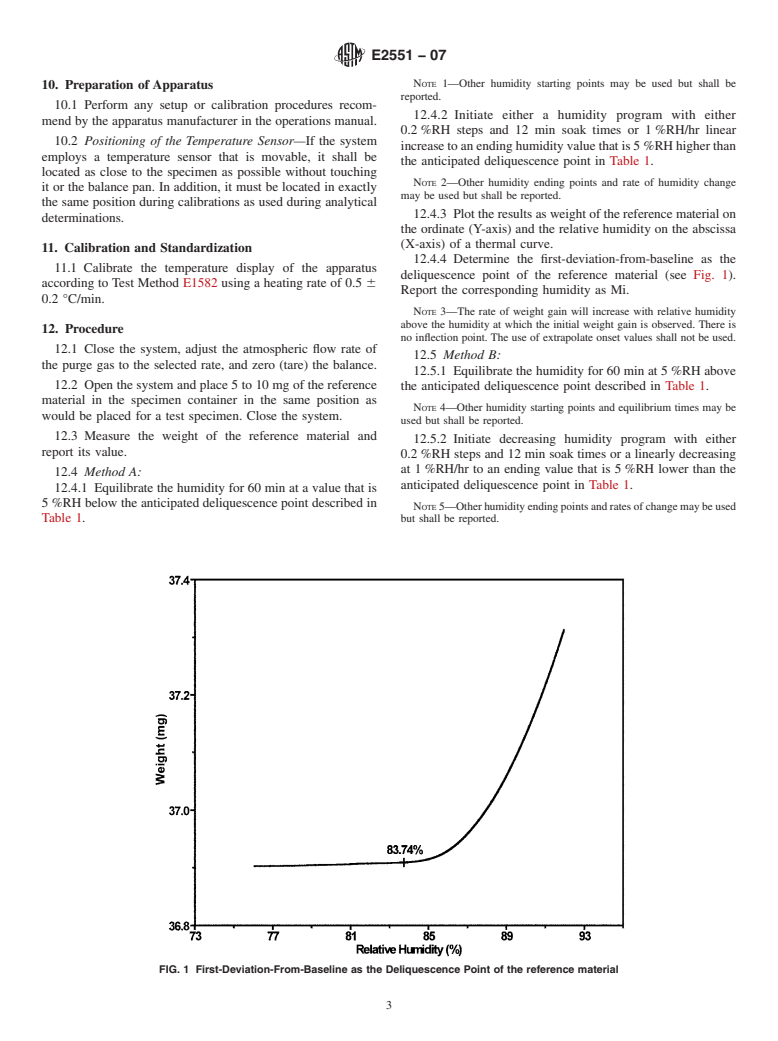

3.2.3 first-deviation-from-baseline, n—the relative humidity

and the temperature range is 0 to 80 °C.

or water activity at which a deflection from the established

1.2 The values stated in SI units are to be regarded as

baseline is first observed.

standard. No other units of measurement are included in this

standard.

4. Summary of Test Method

1.3 There are no ISO equivalents to this standard.

4.1 Humidity generators are devices aimed at producing a

1.4 This standard does not purport to address all of the

specific level of humidity in the purge gas used by thermogra-

safety concerns, if any, associated with its use. It is the

vimetric analyzers or other thermal analysis apparatus. The

responsibility of the user of this standard to establish appro-

requested humidity levels may be held constant (isohum) or

priate safety and health practices and determine the applica-

increased or decreased in a continuous or stepped fashion.

bility of regulatory limitations prior to use.

4.2 The humidified purge gas is submitted to a thermogra-

vimetric analyzer in which the weight of a hygroscopic

2. Referenced Documents

material is observed. The relative humidity (or activity) of the

2.1 ASTM Standards:

moisture in the purge gas is stepped or scanned through a

D1193 Specification for Reagent Water

humidity range. At a fixed humidity of the purge gas, the test

E473 Terminology Relating to Thermal Analysis and Rhe-

specimen deliquesces and gains weight. In Method A, the

ology

humidity of the onset of this weight gain is taken as the

E1142 Terminology Relating to Thermophysical Properties

humidity calibration point. In Methods B and C, the rate of

E1582 Practice for Calibration of Temperature Scale for

weight change is zero at the humidity calibration point.

Thermogravimetry

5. Significance and Use

3. Terminology

5.1 This test method calibrates or demonstrates conformity

3.1 Specifictechnicaltermsusedinthisstandardaredefined

of the humidity level in a purge gas generated by a humidity

in Terminologies E473 and E1142. These terms include ther-

generator at a fixed temperature. Such calibration or demon-

mal curve and thermogravimetric analysis.

stration of conformity may be required by quality initiatives.

3.2 Definitions of Terms Specific to This Standard:

5.2 Conformance demonstrates that the humidified purge

3.2.1 relative humidity, n—the ratio of actual partial pres-

gas is within some established limits.

sure of water to the saturated water vapor pressure at the same

temperature, expressed as a percentage.

5.3 Calibration provides an offset and or slope value that

may be used for establishing the relative humidity scale of the

ThistestmethodisunderthejurisdictionofASTMCommitteeE37onThermal

apparatus.

Measurements and is the direct responsibility of Subcommittee E37.10 on

Fundamental, Statistical and Mechanical Properties.

6. Interferences

Current edition approved March 1, 2007. Published May 2007. DOI: 10.1520/

E2551-07.

6.1 Temperature regulation of any solution-head space en-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

vironment to within 6 0.1 °C is essential for realizing

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

generated relative humidity values stable to within 6 1 %RH

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. (expected).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2551 − 07

7. Apparatus 7.3.2 A temperature sensor to provide an indication of the

specimen or furnace temperature to within 6 0.1 °C.

7.1 The humidity generator that is the focus of this standard

7.3.3 A continuously recording balance to measure the

may be an accessory providing a humidified purge gas to some

specimen weight with a minimum capacity of 100 mg and

otherthermalanalysisapparatus(typicallyathermogravimetric

sensitivity of 6 10 µg.

analyzer) or it may be part of a self-contained instrument that

7.3.4 Ameans of maintaining the specimen/container under

includes both the humidity generator and the thermal analysis

apparatus. In the former case, some of the components de- atmospheric control at a purge rate of 10 to 200 mL/min 6 10

mL/min or 1 %, whichever is greater.

scribed below may be redundant.

7.3.5 A temperature controller capable of executing a spe-

7.2 Humidity Generator—The essential instrumentation re-

cific temperature program by operating the furnace between

quired to provide the minimum humidity generator capability

selected temperature limits at a rate of temperature change of

for this method includes:

0.5 °C/min constant to within 6 0.1 °C/min or to an isothermal

7.2.1 Temperature Sensor—to provide an indication of the

temperature that is maintained constant to within 6 0.1 °C for

purge gas temperature readable to within 6 0.1 °C.

a minimum of 100 h.

7.2.2 Temperature Controller—capable of executing a spe-

7.3.6 Containers (pans, crucibles, etc.) that are inert to the

cific temperature program by operating heaters or coolers

between selected temperature limits at a rate of temperature specimen and that will remain gravimetrically stable within the

temperature limits of this method.

change of 0.5 °C/min constant to 6 0.1 °C/min or at an

isothermal temperature constant to within 6 0.1 °C.

7.3.7 Data storage capable of storage of the weight and

7.2.3 Humidity Sensor—capable of indicating the humidity

relative humidity signals.

of the purge gas over the range of 5 to 95 % relative humidity

7.3.8 A display capable of plotting a thermal curve with

(%RH) readable to within 6 0.1 %RH.

weight on the ordinate (Y-axis) and relative humidity (or

7.2.4 Humidity Controller—capable of executing a specific

activity) on the abscissa (X-axis) with a sensitivity of 10 µg for

humidity program by operating purge gas humidifiers between

weight and 0.1 %RH, respectively.

selected humidity limits at a rate of humidity change of

0.5 %RH/min constant to within 6 0.1 %RH or at an isohum

8. Reagents and Materials

relative humidity to within 6 0.1 %RH.

8.1 One or more inorganic salts taken from Table 1 selected

7.2.5 Purge Gas Flow Sensor—capable of measuring purge

to provide the humidity range of interest.

gas flow readable to within 6 0.1 mL/min.

7.2.6 Purge Gas Flow Controller—capable of controlling

8.2 Purity of Reagents—Reagentgradechemicals(orbetter)

purge gas flow readable to within 6 0.1 mL/min.

shall be used for preparation of all standard solutions.

7.2.7 Humdifier element—capableofgeneratingpurgegases

8.3 Purity of Water—Reagent water produced by distillation

with relative humidity continuously over the range of 5 to

or by ion exchange, or reverse osmosis followed by distillation

95 %RH.

shall be used (see Specification D1193).

7.3 Thermogravimetric Analyzer (TGA)—The essential in-

strumentation required to provide the minimum thermogravi-

9. Hazards

metric analytical capability for this method includes:

7.3.1 A furnace to provide uniform controlled heating or 9.1 Salt solutions are extremely corrosive to apparatus if

coolingofaspecimentoaconstanttemperatureorataconstant spilled. Care shall be taken in their preparation and handling to

rate within the applicable temperature range of this method. prevent contact with appara

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.