ASTM E2551-13

(Test Method)Standard Test Method for Humidity Calibration (or Conformation) of Humidity Generators for Use with Thermogravimetric Analyzers

Standard Test Method for Humidity Calibration (or Conformation) of Humidity Generators for Use with Thermogravimetric Analyzers

SIGNIFICANCE AND USE

5.1 This test method calibrates or demonstrates conformity of the humidity level in a purge gas generated by a humidity generator at a fixed temperature. Such calibration or demonstration of conformity may be required by quality initiatives.

5.2 Conformance demonstrates that the humidified purge gas is within some established limits.

5.3 Calibration provides an offset and or slope value that may be used for establishing the relative humidity scale of the apparatus.

SCOPE

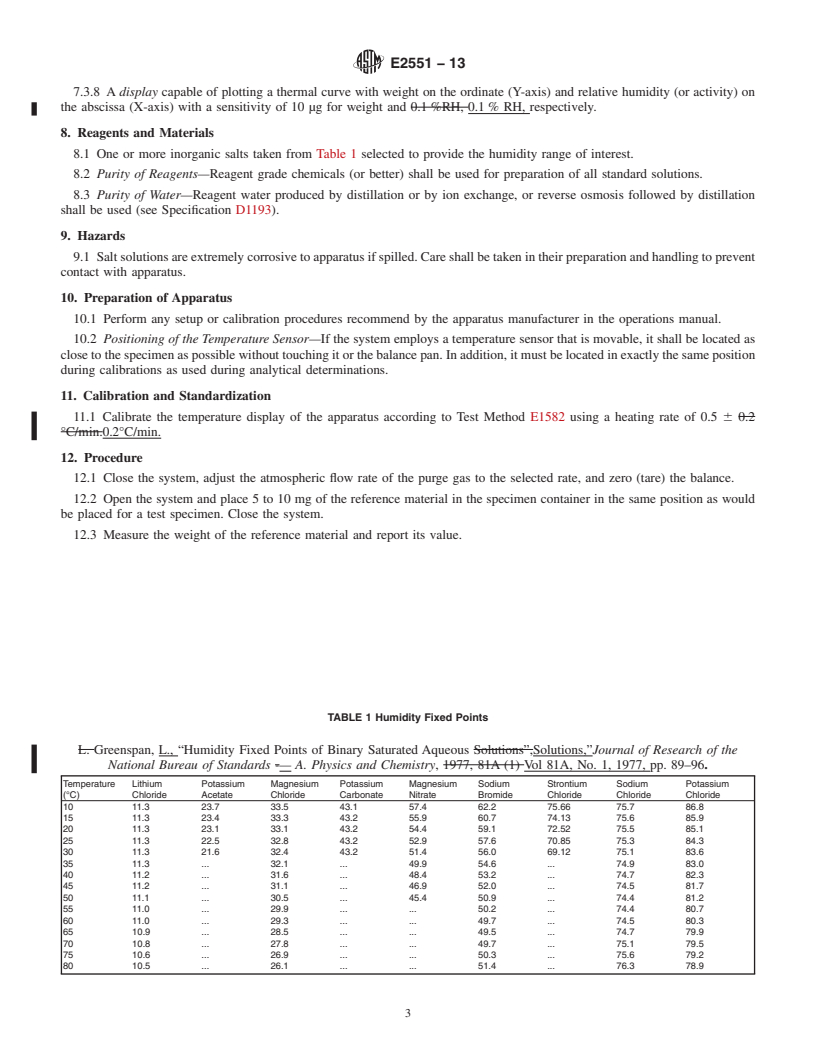

1.1 This test method describes the humidity calibration (or conformance) of humidity generators for use with thermogravimetric analyzers and other thermal analysis apparatus. The humidity range covered is 5 to 95 % relative humidity (% RH) and the temperature range is 0 to 80°C.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 There are no ISO equivalents to this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2551 − 13

Standard Test Method for

Humidity Calibration (or Conformation) of Humidity

1

Generators for Use with Thermogravimetric Analyzers

This standard is issued under the fixed designation E2551; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 relative humidity, n—the ratio of actual partial pres-

1.1 This test method describes the humidity calibration (or

sure of water to the saturated water vapor pressure at the same

conformance) of humidity generators for use with thermogra-

temperature, expressed as a percentage.

vimetric analyzers and other thermal analysis apparatus. The

humidity range covered is 5 to 95 % relative humidity (% RH)

3.2.2 water activity, n—the ratio of actual partial pressure of

and the temperature range is 0 to 80°C.

water to the saturated water vapor pressure at the same

1.2 The values stated in SI units are to be regarded as temperature, expressed as a decimal fraction.

standard. No other units of measurement are included in this

3.2.2.1 Discussion—Water activity is also known as relative

standard.

pressure in some applications areas.

1.3 There are no ISO equivalents to this standard.

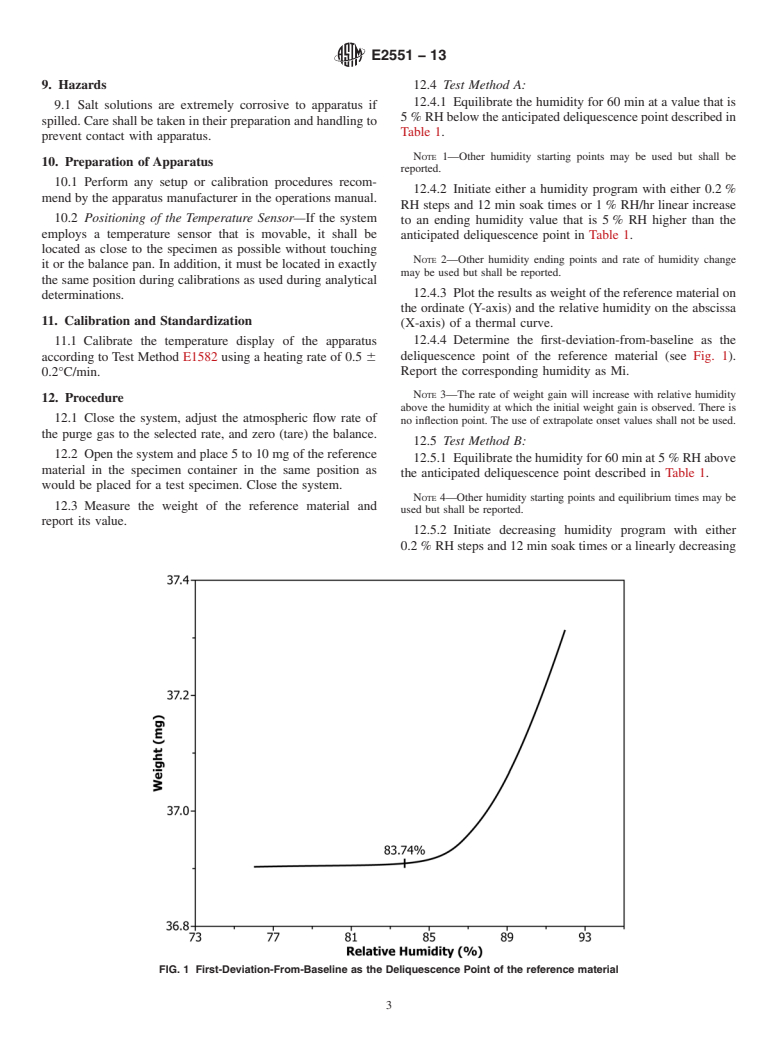

3.2.3 first-deviation-from-baseline, n—the relative humidity

1.4 This standard does not purport to address all of the or water activity at which a deflection from the established

safety concerns, if any, associated with its use. It is the

baseline is first observed.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Summary of Test Method

bility of regulatory limitations prior to use.

4.1 Humidity generators are devices aimed at producing a

2. Referenced Documents

specific level of humidity in the purge gas used by thermogra-

2

vimetric analyzers or other thermal analysis apparatus. The

2.1 ASTM Standards:

requested humidity levels may be held constant (isohum) or

D1193 Specification for Reagent Water

increased or decreased in a continuous or stepped fashion.

E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

4.2 The humidified purge gas is submitted to a thermogra-

E473 Terminology Relating to Thermal Analysis and Rhe-

vimetric analyzer in which the weight of a hygroscopic

ology

material is observed. The relative humidity (or activity) of the

E691 Practice for Conducting an Interlaboratory Study to

moisture in the purge gas is stepped or scanned through a

Determine the Precision of a Test Method

humidity range. At a fixed humidity of the purge gas, the test

E1142 Terminology Relating to Thermophysical Properties

specimen deliquesces and gains weight. In Test MethodA, the

E1582 Practice for Calibration of Temperature Scale for

humidity of the onset of this weight gain is taken as the

Thermogravimetry

humidity calibration point. In Methods B and C, the rate of

weight change is zero at the humidity calibration point.

3. Terminology

3.1 Specifictechnicaltermsusedinthisstandardaredefined

5. Significance and Use

in Terminologies E473 and E1142. These terms include ther-

mal curve and thermogravimetric analysis. 5.1 This test method calibrates or demonstrates conformity

of the humidity level in a purge gas generated by a humidity

1

ThistestmethodisunderthejurisdictionofASTMCommitteeE37onThermal generator at a fixed temperature. Such calibration or demon-

Measurements and is the direct responsibility of Subcommittee E37.10 on

stration of conformity may be required by quality initiatives.

Fundamental, Statistical and Mechanical Properties.

Current edition approved April 1, 2013. Published May 2013. Originally

5.2 Conformance demonstrates that the humidified purge

approved in 2007. Last previous edition approved in 2007 as E2551 – 07. DOI:

gas is within some established limits.

10.1520/E2551-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.3 Calibration provides an offset and or slope value that

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

may be used for establishing the relative humidity scale of the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. apparatus.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2551 − 13

6. Interferences 7.3 Thermogravimetric Analyzer (TGA)—The essential in-

strumentation required to provide the minimum thermogravi-

6.1 Temperature regulation of any solution-head space e

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2551 − 07 E2551 − 13

Standard Test Method for

Humidity Calibration (or Conformation) of Humidity

1

Generators for Use with Thermogravimetric Analyzers

This standard is issued under the fixed designation E2551; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method describes the humidity calibration (or conformance) of humidity generators for use with thermogravimetric

analyzers and other thermal analysis apparatus. The humidity range covered is 5 to 95 % relative humidity (%RH) (% RH) and

the temperature range is 0 to 80 °C.80°C.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 There are no ISO equivalents to this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E473 Terminology Relating to Thermal Analysis and Rheology

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E1142 Terminology Relating to Thermophysical Properties

E1582 Practice for Calibration of Temperature Scale for Thermogravimetry

3. Terminology

3.1 Specific technical terms used in this standard are defined in Terminologies E473 and E1142. These terms include thermal

curve and thermogravimetric analysis.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 relative humidity, n—the ratio of actual partial pressure of water to the saturated water vapor pressure at the same

temperature, expressed as a percentage.

3.2.2 water activity, n—the ratio of actual partial pressure of water to the saturated water vapor pressure at the same temperature,

expressed as a decimal fraction.

1

This test method is under the jurisdiction of ASTM Committee E37 on Thermal Measurements and is the direct responsibility of Subcommittee E37.10 on Fundamental,

Statistical and Mechanical Properties.

Current edition approved March 1, 2007April 1, 2013. Published May 2007 May 2013. Originally approved in 2007. Last previous edition approved in 2007 as E2551

– 07. DOI: 10.1520/E2551-07.10.1520/E2551-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.2.2.1 Discussion—

Water activity is also known as relative pressure in some applications areas.

3.2.3 first-deviation-from-baseline, n—the relative humidity or water activity at which a deflection from the established baseline

is first observed.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2551 − 13

4. Summary of Test Method

4.1 Humidity generators are devices aimed at producing a specific level of humidity in the purge gas used by thermogravimetric

analyzers or other thermal analysis apparatus. The requested humidity levels may be held constant (isohum) or increased or

decreased in a continuous or stepped fashion.

4.2 The humidified purge gas is submitted to a thermogravimetric analyzer in which the weight of a hygroscopic material is

observed. The relative humidity (or activity) of the moisture in the purge gas is stepped or scanned through a humidity range. At

a fixed humidity of the purge gas, the test specimen deliquesces and gains weight. In Test Method A, the humidity of the onset

of this weight gain is taken as the humidity calibration point. In Methods B and C, the rate of weight change is zero at the humidity

calibration point.

5. Significance and Use

5.1 This test method calibrates or demonstrates conformity of the humidity level in a purge gas generated by a humidity

generator at a fixed temperature. Such calibration or demonstration of conformity may be required by quality initiatives.

5.2 Conformance demonstrates that the humidified purge gas is within

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.