ASTM D1795-13

(Test Method)Standard Test Method for Intrinsic Viscosity of Cellulose

Standard Test Method for Intrinsic Viscosity of Cellulose

SIGNIFICANCE AND USE

4.1 This test is a sensitive measure of the degradation of cellulose resulting from the action of heat, light, acids, alkalies, oxidizing and reducing agents, and the like, used in its processing or purification. The intrinsic viscosity value may be converted to degree of polymerization (DP) or to intrinsic fluidity, if desired.

4.2 Solutions of cellulose are not Newtonian liquids; that is, their viscosity depends upon the rate-of-shear or velocity gradient during measurement. This effect is smaller for samples of low molecular mass (DP) and at low concentrations than for high-DP samples and at high concentrations. For the celluloses and concentrations included within the limits set forth in this test method, the effect of rate-of-shear is assumed to be negligible for referee purposes. For other conditions and for research purposes this assumption may be invalid, but to discuss ways of accounting for this effect is beyond the scope of the present test method.

SCOPE

1.1 This test method covers the determination of the intrinsic viscosity of purified celluloses such as bleached wood pulps, cotton linters, and regenerated cellulose. It is applicable to all cellulose samples with an intrinsic viscosity of 15 dl/g or less. Most native (unpurified) celluloses have intrinsic viscosity values too high for measurement by this test method. Note 1—The use of cuprammonium hydroxide solution for regular viscosity determination is described in Method T 206 m-55 of the Technical Association of Pulp and Paper Industry on “Cuprammonium Disperse Viscosity of Pulp,” and Joint Army-Navy Specifications JAN-C-206.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

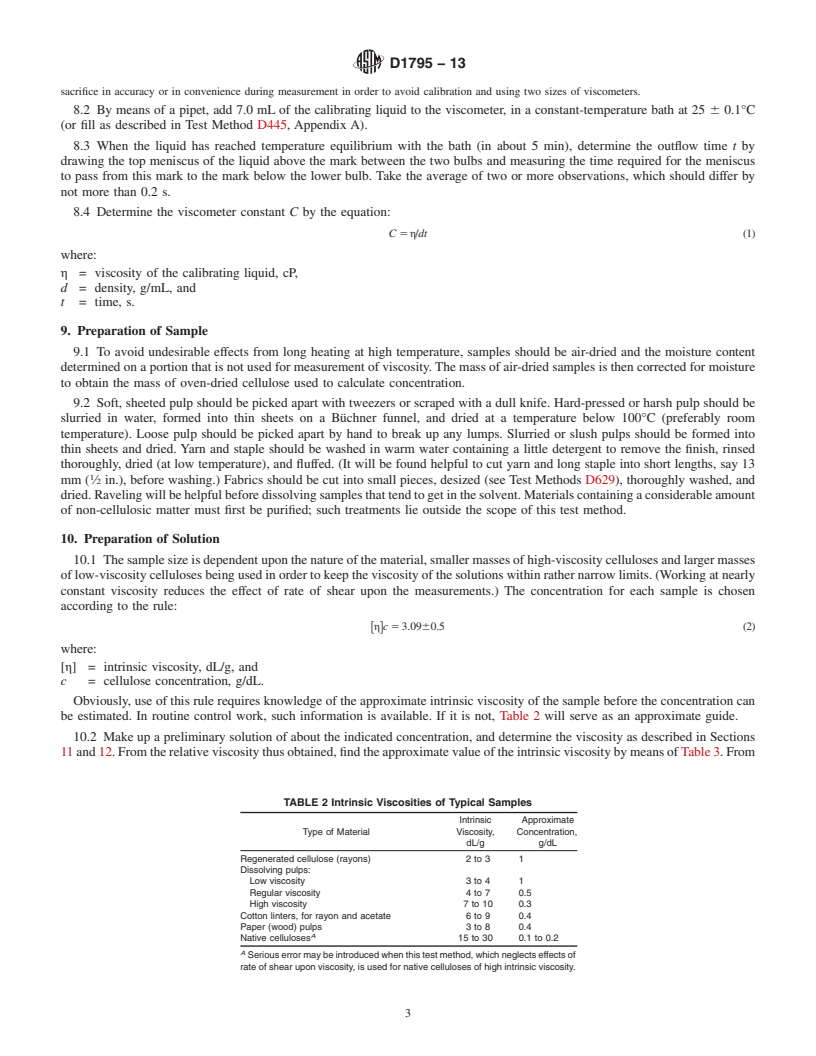

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1795 − 13

Standard Test Method for

1

Intrinsic Viscosity of Cellulose

This standard is issued under the fixed designation D1795; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope solution, and also that of the solvent, is determined at 25°C by

means of a calibrated glass capillary-type viscometer. The

1.1 This test method covers the determination of the intrin-

relative viscosity is calculated and the corresponding intrinsic

sic viscosity of purified celluloses such as bleached wood

viscosity is read from a table.

pulps, cotton linters, and regenerated cellulose. It is applicable

to all cellulose samples with an intrinsic viscosity of 15 dl/g or

4. Significance and Use

less. Most native (unpurified) celluloses have intrinsic viscos-

4.1 This test is a sensitive measure of the degradation of

ity values too high for measurement by this test method.

celluloseresultingfromtheactionofheat,light,acids,alkalies,

NOTE 1—The use of cuprammonium hydroxide solution for regular

oxidizing and reducing agents, and the like, used in its

viscosity determination is described in Method T206 m-55 of the

processingorpurification.Theintrinsicviscosityvaluemaybe

Technical Association of Pulp and Paper Industry on “Cuprammonium

converted to degree of polymerization (DP) or to intrinsic

Disperse Viscosity of Pulp,” and Joint Army-Navy Specifications JAN-

C-206.

fluidity, if desired.

1.2 The values stated in SI units are to be regarded as

4.2 SolutionsofcellulosearenotNewtonianliquids;thatis,

standard. No other units of measurement are included in this

their viscosity depends upon the rate-of-shear or velocity

standard.

gradientduringmeasurement.Thiseffectissmallerforsamples

oflowmolecularmass(DP)andatlowconcentrationsthanfor

1.3 This standard does not purport to address all of the

high-DPsamplesandathighconcentrations.Forthecelluloses

safety concerns, if any, associated with its use. It is the

and concentrations included within the limits set forth in this

responsibility of the user of this standard to establish appro-

test method, the effect of rate-of-shear is assumed to be

priate safety and health practices and determine the applica-

negligible for referee purposes. For other conditions and for

bility of regulatory limitations prior to use.

research purposes this assumption may be invalid, but to

2. Referenced Documents

discuss ways of accounting for this effect is beyond the scope

2

of the present test method.

2.1 ASTM Standards:

D445Test Method for Kinematic Viscosity of Transparent

5. Apparatus

and Opaque Liquids (and Calculation of DynamicViscos-

5.1 Viscometer, Glass, Capillary Type—The Cannon-

ity)

D629Test Methods for Quantitative Analysis of Textiles Fenske, Ubbelohde, or similar capillary type instrument as

described in Test Method D445 is recommended. In order to

E1Specification for ASTM Liquid-in-Glass Thermometers

E2251Specification for Liquid-in-Glass ASTM Thermom- avoidcorrectionforthekineticenergyeffect,chooseaviscom-

eterwithasmallenoughcapillarytogiveanoutflowtimeof80

eters with Low-Hazard Precision Liquids

s or more for the Cannon-Fenske type. (Asize 100 viscometer

3. Summary of Test Method

is normally used for the sample solution and a size 50 for the

solvent.)

3.1 Aweighedsampleofthematerialisdissolvedina0.5M

cupriethylenediamine hydroxide solution.The viscosity of this

5.2 Thermometer—ASTM Kinematic Viscosity Thermom-

eter for use at 25°C, having a range from 19 to 27°C and

conforming to the requirement for Thermometer 17C as

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

prescribed in Specification E1. Thermometric devices such as

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.36 on Cellulose and Cellulose Derivatives.

RTDs, thermistors and liquid-in-glass thermometers (as speci-

CurrenteditionapprovedJune1,2013.PublishedJuly2013.Originallyapproved

fied in Specification E2251) of equal or better accuracy in the

ε1

in 1960. Last previous edition approved in 2007 as D1795–96(2007) . DOI:

specified temperature range, may be used.

10.1520/D1795-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.3 Bath—Aconstant-temperature bath at 25°C suitable for

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

immersion of the viscometer so that the reservoir or the top of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. the capillary, whichever is uppermost, is immersed at least 50

Copyright © ASTM International, 100 Barr Har

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D1795 − 96 (Reapproved 2007) D1795 − 13

Standard Test Method for

1

Intrinsic Viscosity of Cellulose

This standard is issued under the fixed designation D1795; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Specification E 1 was replaced with Specification E 2251 in Section 2 and 5.2 in June 2007.

1. Scope

1.1 This test method covers the determination of the intrinsic viscosity of purified celluloses such as bleached wood pulps,

cotton linters, and regenerated cellulose. It is applicable to all cellulose samples with an intrinsic viscosity of 15 dl/g or less. Most

native (unpurified) celluloses have intrinsic viscosity values too high for measurement by this test method.

NOTE 1—The use of cuprammonium hydroxide solution for regular viscosity determination is described in Method T 206 m-55 of the Technical

Association of Pulp and Paper Industry on “Cuprammonium Disperse Viscosity of Pulp,” and Joint Army-Navy Specifications JAN-C-206.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information

only.standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity)

D629 Test Methods for Quantitative Analysis of Textiles

E1 Specification for ASTM Liquid-in-Glass Thermometers

E2251 Specification for Liquid-in-Glass ASTM Thermometers with Low-Hazard Precision Liquids

3. Summary of Test Method

3.1 A weighed sample of the material is dissolved in a 0.5 M cupriethylenediamine hydroxide solution. The viscosity of this

solution, and also that of the solvent, is determined at 25°C by means of a calibrated glass capillary-type viscometer. The relative

viscosity is calculated and the corresponding intrinsic viscosity is read from a table.

4. Significance and Use

4.1 This test is a sensitive measure of the degradation of cellulose resulting from the action of heat, light, acids, alkalies,

oxidizing and reducing agents, and the like, used in its processing or purification. The intrinsic viscosity value may be converted

to degree of polymerization (DP) or to intrinsic fluidity, if desired.

4.2 Solutions of cellulose are not Newtonian liquids; that is, their viscosity depends upon the rate-of-shear or velocity gradient

during measurement. This effect is smaller for samples of low molecular mass (DP) and at low concentrations than for high-DP

samples and at high concentrations. For the celluloses and concentrations included within the limits set forth in this test method,

the effect of rate-of-shear is assumed to be negligible for referee purposes. For other conditions and for research purposes this

assumption may be invalid, but to discuss ways of accounting for this effect is beyond the scope of the present test method.

5. Apparatus

5.1 Viscometer, Glass, Capillary Type—The Cannon-Fenske, Ubbelohde, or similar capillary type instrument as described in

Test Method D445 is recommended. In order to avoid correction for the kinetic energy effect, choose a viscometer with a small

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.36 on Cellulose and Cellulose Derivatives.

Current edition approved June 1, 2007June 1, 2013. Published July 2007July 2013. Originally approved in 1960. Last previous edition approved in 20012007 as

ε1

D1795 – 96 (2001)(2007) . DOI: 10.1520/D1795-96R07E01.10.1520/D1795-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 --------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.