ASTM F462-79(1999)

(Specification)Consumer Safety Specification for Slip-Resistant Bathing Facilities

Consumer Safety Specification for Slip-Resistant Bathing Facilities

SCOPE

1.1 This consumer safety specification covers the slip resistance of bathtubs and shower structures or combinations, used for bathing or showering, or both, herein referred to as bathing facilities.

1.2 This specification establishes definitions, methods of testing the slip resistance of bathing facilities, and the in-use performance requirements needed to minimize the accidents caused by slipperiness during any reasonable use.

1.3 This consumer safety specification is intended to describe a means to reduce accidents to persons, especially children and the aged, resulting from the use of bathing facilities.

1.4 The following safety hazards caveat pertains only to the test method portion, Section 8, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 462 – 79 (Reapproved 1999)

Standard Consumer Safety Specification for

Slip-Resistant Bathing Facilities

This standard is issued under the fixed designation F 462; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Thisconsumersafetyspecificationaddressesthebathtubandshoweraccidentsthataredueinwhole

or in part to the slipperiness of the bathing surface.

In response to the accident analysis and assignment of causes developed and identified for the U.S.

Consumer Product Safety Commission by the Abt Associates, Inc., final report, “A Systematic

Program to Reduce the Incidence and Severity of Bathtub and Shower Area Injuries,” June 4, 1975,

this consumer safety specification provides a means to reduce accidents in bath and shower units

caused directly or indirectly by the slipperiness of the bathing surface.

It is not possible to cover, in this consumer safety specification, bath and shower units that are used

in a manner for which they were never intended. Furthermore, children do not always act prudently,

and the motions of the elderly and infirm are not always under complete control. These problems will

be covered in a consumer-education-type publication, designed to describe the hazards of the bathing

area, and suggestions concerning bather’s conduct to reduce these hazards.

This consumer safety specification is written within the current state of the art of bath and shower

technology.

1. Scope of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

1.1 This consumer safety specification covers the slip resis-

tions prior to use.

tance of bathtubs and shower structures or combinations, used

for bathing or showering, or both, herein referred to as bathing

2. Referenced Documents

facilities.

2.1 ASTM Standards:

1.2 This specification establishes definitions, methods of

D 459 Terminology Relating to Soaps and Other Deter-

testing the slip resistance of bathing facilities, and the in-use

gents,

performance requirements needed to minimize the accidents

D 799 Specification for Liquid Toilet Soap

caused by slipperiness during any reasonable use.

2.2 Federal Specification:

1.3 This consumer safety specification is intended to de-

PS-624g Soap, Toilet, Liquid and Paste

scribe a means to reduce accidents to persons, especially

children and the aged, resulting from the use of bathing

3. Terminology

facilities.

3.1 Definitions:

1.4 The following safety hazards caveat pertains only to the

3.1.1 applique—a material affixed to the bathing surface or

test method portion, Section 8, of this specification. This

sump of a bathtub or shower for the purpose of increasing its

standard does not purport to address all of the safety concerns,

slip resistance.

if any, associated with its use. It is the responsibility of the user

3.1.2 bathing—the act of subjecting all, a substantial part,

or a specified part of the body to the action of water in a

This specification is under the jurisdiction of ASTM Committee F15 on

Consumer Products and is the direct responsibility of Subcommittee F15.03 on

Safety Standards for Bathtub and Shower Structures. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 10, 1999. Published May 1979. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Available from the Consumer Product Safety Commission, Washington, DC Standards volume information, refer to the standard’s Document Summary page on

20207. the ASTM website.

3 5

“Performance Characteristics of Sanitary Plumbing Fixtures,” available from AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the Consumer Product Safety Commission, Washington, DC 20207. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 462 – 79 (1999)

bathing facility, with or without soap or bath oil, for purposes 3.1.16 water (pure)— the liquid that consists of an oxide of

of health or cleansing. hydrogen of the ratio one atom of oxygen to two atoms of

hydrogen.

3.1.3 bathing facility—a bathtub, shower structure, or a

combination of a bathtub and shower, designed to restrict or

4. Compliance

contain the flow of water, or both, usually for the bathing use

of one adult or one child at a time.

4.1 No bathing facility shall either by label or other means

3.1.4 bathing surface—the portion of the sump of a bathing

indicate compliance with this specification unless it conforms

facility on which, by either common usage or design, a bather

to all requirements contained herein.

might be expected to step, stand, sit, or come in contact with

4.2 No product intended to be used as a slip-resistant retrofit

while bathing or showering.

item to a bathing facility shall either by label or other means

3.1.5 bath oil—a functional (emollient) or nonfunctional

indicate compliance with this specification unless it conforms

(cosmetic) formulation in the form of a liquid (clear or

to all requirements contained herein.

opaque), oil or nonoil, spray, powder, or encapsulated liquid.

4.3 If a bathing facility is intended to be retrofitted, treated,

3.1.6 coeffıcient of friction—the ratio of the frictional force

etc., to provide slip resistance after installation, there must be

to the force, usually gravitational, acting perpendicular to the

an indication, by label or other means, that the unit will not be

two surfaces in contact. This coefficient is a measure of the

in compliance unless the surface is treated with the approved

relative difficulty with which the surface of one material

material(s) provided, in accordance with manufacturer’s instal-

willslide over a surface adjoining itself, or of another material.

lation instructions.

The static or starting coefficient of friction is related to the

force measured to begin movement of the surfaces relative to

5. Requirements

each other. The kinetic or sliding coefficient of friction is

5.1 The slip-resistant requirements specified herein are de-

related to the force measured in sustaining this movement.

signed to reduce the probability of falls due to slipping.

3.1.7 dam—a horizontal elevated surface that must be

5.2 For any surface that is textured or treated with appli-

traversed to enter a tub or shower structure, or a combination

ques, the pattern shall be such that a 1 ⁄2 by 3-in. (38.1 by

of both. Relative terms are “rim” for tubs and combination

76.2-mm)rectangulartemplateplacedanywhereonthebathing

tub/showers, and “threshold” for shower structures.

surface shall cover some textured or treated area.

3.1.8 friction—the resisting force that arises when a surface

5.3 The slip resistance of the bathing surface shall remain at

of one substance slides, or tends to slide, against a surface

or above the level required by this specification during the life

adjoining itself or another substance. Between surfaces of

of the manufacturer’s guarantee, using cleaning methods rec-

solids in contact there may be two kinds of friction: (1) static

ommended by the manufacturer.

friction—the resistance opposing the force required to start to

move one surface on or over another; and (2) dynamic

NOTE 1—It is emphasized that this specification was written within the

friction—the resistance opposing the force required to move

state of the art existing in early 1976. It is intended that a section dealing

with durability will replace 5.3 at the time of the next revision of this

one surface on or over another at a variable, fixed, or

specification.

predetermined speed.

3.1.9 retrofit—a component used to replace similar worn or

5.4 Any nonintegral slip-resistant material applied to a

expended parts of a manufactured product; a component that is

sump or bathing surface shall be removable without harm to

employed to modify a finished product in order to alter its

the bathing surface.

functional character.

5.5 All slip-resistant surfaces shall withstand, without

3.1.10 soap—the product formed by the saponification or

marked deterioration, the action of normal bathing soaps, bath

neutralization of fats, oils, waxes, rosins, or their acids, with

oils, body oils, and dirt normally encountered in bathing and

organic or inorganic bases.

showering.

3.1.11 slip resistance—thepropertyofabathingsurfacethat

5.6 Characteristics of the Slip-Resistant Surface—Thiscon-

acts in opposition to those forces and movements exerted by a

sumer safety specification provides for nine pairs of measure-

bather under all conditions of bathing or showering that can

ments (see 9.1.1) distributed over that portion of the bathing

result in uncontrolled sliding; it is directly proportional to the

surface upon which measurements can be made as a basis for

coefficient of friction.

determining compliance. These measurements are assumed

3.1.12 slipperiness—the property of a surface that indicates characteristic of the entire bathing surface. In order to make

the degree of which uncontrolled sliding (of portions of the this assumption valid, the entire bathing surface is required to

body) may occur. have the same characteristics as the region chosen for slip-

resistance measurements. Conformance with this requirement

3.1.13 smooth surface—a surface that is not textured.

is determined by visual inspection and consideration of the

3.1.14 sump—the portion of a bathing facility intended for

quality control methods applied to the manufacturing process.

the collection of water, as limited by the height of the dam.

3.1.15 textured surface—a bathing surface that contains

6. Instructions for the Operation of the NIST-

elevationsordepressions,orboth,orthatincorporatesasecond

Brungraber Portable Slip-Resistance Tester

material for the purpose of improving the slip resistance of the

surface. 6.1 Principles of Operation:

F 462 – 79 (1999)

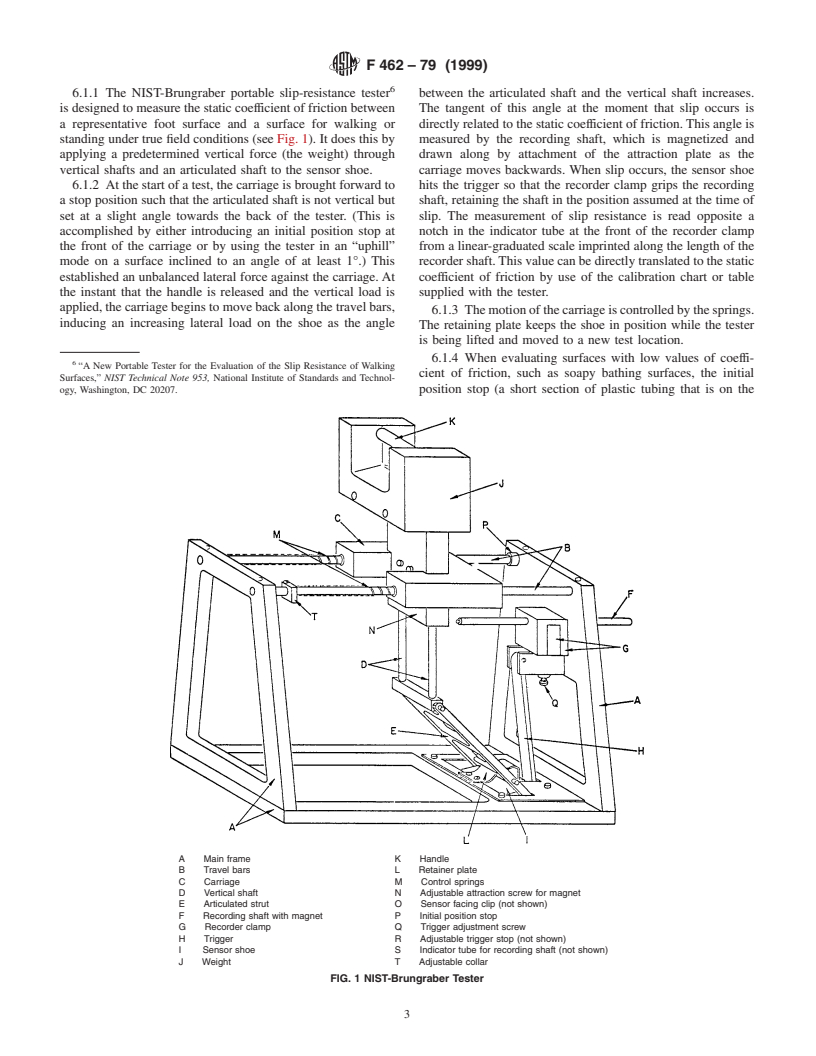

6.1.1 The NIST-Brungraber portable slip-resistance tester between the articulated shaft and the vertical shaft increases.

is designed to measure the static coefficient of friction between The tangent of this angle at the moment that slip occurs is

a representative foot surface and a surface for walking or directly related to the static coefficient of friction. This angle is

standing under true field conditions (see Fig. 1). It does this by measured by the recording shaft, which is magnetized and

applying a predetermined vertical force (the weight) through drawn along by attachment of the attraction plate as the

vertical shafts and an articulated shaft to the sensor shoe. carriage moves backwards. When slip occurs, the sensor shoe

6.1.2 At the start of a test, the carriage is brought forward to hits the trigger so that the recorder clamp grips the recording

a stop position such that the articulated shaft is not vertical but shaft, retaining the shaft in the position assumed at the time of

set at a slight angle towards the back of the tester. (This is slip. The measurement of slip resistance is read opposite a

accomplished by either introducing an initial position stop at notch in the indicator tube at the front of the recorder clamp

the front of the carriage or by using the tester in an “uphill” from a linear-graduated scale imprinted along the length of the

mode on a surface inclined to an angle of at least 1°.) This recorder shaft.This value can be directly translated to the static

established an unbalanced lateral force against the carriage.At coefficient of friction by use of the calibration chart or table

the instant that the handle is released and the vertical load is supplied with the tester.

applied, the carriage begins to move back along the travel bars,

6.1.3 Themotionofthecarriageiscontrolledbythesprings.

inducing an increasing lateral load on the shoe as the angle

The retaining plate keeps the shoe in position while the tester

is being lifted and moved to a new test location.

6.1.4 When evaluating surfaces with low values of coeffi-

“A New Portable Tester for the Evaluation of the Slip Resistance of Walking

cient of friction, such as soapy bathing surfaces, the initial

Surfaces,” NIST Technical Note 953, National Institute of Standards and Technol-

ogy, Washington, DC 20207. position stop (a short section of plastic tubing that is on the

A Main frame K Handle

B Travel bars L Retainer plate

C Carriage M Control springs

D Vertical shaft N Adjustable attraction screw for magnet

E Articulated strut O Sensor facing clip (not shown)

F Recording shaft with magnet P Initial position stop

G Recorder clamp Q Trigger adjustment screw

H Trigger R Adjustable trigger stop (not shown)

I Sensor shoe S Indicator tube for recording shaft (not shown)

J Weight T Adjustable collar

FIG. 1 NIST-Brungraber Tester

F 462 – 79 (1999)

front end of one of the travel rods) should be removed. This direction of test, adjust the collars for the control springs to

permitsthetestertostartinthepositioncorrespondingtoazero prevent excessive speed of travel of the tester carriage. For

value of coefficient of friction and requires that the carriage be surfaces inclined up to as much as 4°, if the tester is adjusted

given a slight initial push immediately after the handle is as described to permit full travel of the carriage without an

released, unless the test is conducted “uphill” on a surface excessive jolt at the end of travel, satisfactory calibrations are

inclined to at least 1°. For best results and to reduce operator obtained.

error as much as possible, tests on bathing surfaces should be

7. Test Specimens

conducted in the “uphill” mode whenever possible, since in

this mode the tester is self-actuating. 7.1 Description—The test specimen shall consist of the

bathing surface.

6.1.5 Tests on soapy surfaces should never be conducted in

the “downhill” position as this will cause a premature forward 7.2 Leveling—Bathing facilities are normally tested in the

installed condition. After leveling, the bathing surfaces will

motion of the shoe and the tester will not function.Also, when

conducting tests on soapy surfaces, the tester should be have the same slopes encountered under normal bathing

conditions and test measurements taken on these slopes are

restrained from slipping by holding firmly with the hand that is

not being used to operate it. more indicative of the slip situation existing during bathing.

6.2 Operation of the Tester—For a detailed step-by-step 7.3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.