ASTM F1507-99(2006)

(Specification)Standard Specification for Surge Suppressors for Shipboard Use

Standard Specification for Surge Suppressors for Shipboard Use

ABSTRACT

This specification establishes the performance requirements for surge suppressors used on shipboard ac power circuits that may consist of a single circuit element or may be a hybrid device using several suppression devices. The surge suppressor shall be a protective device for limiting voltage transients on equipment by discharging, dissipating internally, bypassing surge current, or a combination thereof, and which prevents continued flow of follow current to ground and is capable of repeating these functions. Surge suppressors shall be classified into the following classes and types: Class A—surge suppressor associated with long circuit branch; Class B—surge suppressor for short branch circuit; and Type I—permanent connected type; Type II—plug-in type; Type III—cord-connected type; and Type IV—power director (power center) type. The surge suppressors shall conform to specified performance, operating, grounding, and supplementary protection requirements. They shall also undergo designated design, and conformance production tests such as insulation withstand test, power frequency withstand test, impulse voltage-time tests (including fast-front impulse suppression tests and slow-front impulse suppression tests), voltage protection level tests, duty cycle tests, life cycle tests (including voltage and current impulses), load current and voltage drop tests (including rated current and voltage drop and inrush current), and ground continuity test.

SCOPE

1.1 This standard establishes performance requirements of surge suppressors for use on shipboard ac power circuits.

1.2 Surge suppressor shall be a protective device for limiting voltage transients on equipment by discharging, dissipating internally, bypassing surge current, or a combination thereof; and which prevents continued flow of follow current to ground and is capable of repeating these functions.

1.3 Surge suppressors covered by this specification may consist of a single circuit element, or may be a hybrid device employing several suppression devices.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F1507 – 99 (Reapproved 2006)

Standard Specification for

Surge Suppressors for Shipboard Use

This standard is issued under the fixed designation F1507; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This specification establishes performance requirements 3.1 Definitions:

of surge suppressors for use on shipboard ac power circuits.

NOTE 1—These definitions other than specific to the standard are taken

1.2 Surge suppressor shall be a protective device for limit-

from UL 1449, ANSI/IEEE C62.41, and MIL-STD 1399 to provide for

ing voltage transients on equipment by discharging, dissipating

harmonization of terms.

internally, bypassing surge current, or a combination thereof

3.2 power interface—The electrical points where the surge

and which prevents continued flow of follow current to ground

suppression device is electrically connected to the ac power

and is capable of repeating these functions.

system.

1.3 Surge suppressors covered by this specification may

3.3 combination wave—Asurge delivered by an instrument

consist of a single circuit element or may be a hybrid device

that has the inherent capability of applying a 1.2/50-µs voltage

using several suppression devices.

wave across an open circuit and delivering an 8/20-µs current

wave into a short circuit. The exact wave that is delivered is

2. Referenced Documents

determined by the instantaneous impedance to which the

2.1 The following documents of the issue in effect on the

combination wave is applied. (Also called combination

dateofmaterialpurchaseformapartofthisspecificationtothe

voltage/current surge or combination V/I surge.)

extent referenced herein:

3.4 crest (peak) value (of a wave, surge or impulse)—The

2.2 American National Standards:

maximum value that a wave, surge, or impulse attains.

ANSI/IEEE Std 4 IEEE Standard Techniques for High

3.5 electric power source—The electric power that is sup-

Voltage Testing

plied for testing.

ANSI/IEEE C62.41 Recommended Practice on Surge Volt-

3.6 electric power system ground—Ground is a plane or

age in Low-Voltage AC Power Circuits

surface used by the electric power system as a common

ANSI/IEEE C62.45 Guide on Surge Testing for Equipment

reference to establish zero potential. Usually, this surface is the

Connected to Low-Voltage AC Power Circuits

metallic hull of the ship. On a nonmetallic hull ship, a special

ANSI/IEEE C84.1 Electrical Power Systems and

ground system is installed for this purpose.

Equipment—Voltage Ratings

3.7 follow(power)current—Thecurrentfromtheconnected

2.3 Military Standard:

power source that flows through a surge protective device

MIL-STD-1399 Section 300; Military Standard Interface

following the passage of discharge current.

Standard for Shipboard Systems, Section 300, Electric

3.8 frequency tolerance—Frequency tolerance is the maxi-

Power, Alternating Current

mum permitted departure from nominal frequency during

2.4 Underwriters Laboratories Standard:

normal operation, excluding transient and cyclic frequency

UL 1449 Transient Voltage Surge Suppressors, 2nd Edition

variations. This includes variations such as those caused by

load changes, switchboard frequency meter error, and drift.

This specification is under the jurisdiction of ASTM Committee F25 on Ships Unless specified otherwise, frequency tolerance shall be con-

and Marine Technology and is the direct responsibility of Subcommittee F25.10 on

sidered to be 610 % of nominal frequency.

Electrical.

3.9 inrush current—The inrush current is a sudden change

Current edition approved Feb. 1, 2006. Published February 2006. Originally

in line current that occurs during startup or as a result of a

approved in 1994. Last previous edition approved in 1999 as F1507 – 99. DOI:

10.1520/F1507-99R06.

change to the operating mode. Inrush current is dependent on

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the type of load connected to the surge suppressor, and

4th Floor, New York, NY 10036.

3 typically will rise to a maximum value in a few milliseconds

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

and decay to rated value in several milliseconds to several

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Available from Underwriters Laboratories (UL), Corporate Progress, 333

seconds.

Pfingsten Rd., Northbrook, IL 60062.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1507 – 99 (2006)

3.10 leakage current—Line current drawn, either line-to- 3.23 transient voltage surge suppressor (TVSS)—A surge

line or line-to-ground, by the suppressor when operated at the protective device intended for connection electrically on the

maximum continuous operating voltage. load side of the main overcurrent protection in circuits not

exceeding 600V. (Location CategoriesAand B as described in

3.11 maximum continuous operating voltage—Maximum

ANSI/IEEE C62.41.)

sinusoidal rms voltage which may be continuously applied

3.24 two-port transient voltage surge suppressor—ATVSS

without degradation or deleterious effects.

having one set of electrical connections (terminals, leads and

3.12 measured limiting voltage—The crest (peak) value of

the like) intended for connection to the ac power circuit and

the voltage measured at the leads, terminals, receptacle con-

one or more separate sets of electrical connections (terminals,

tacts and the like, intended for connection to the load(s) to be

leads, outlet receptacles, and so forth) intended for connecting

protected, and resulting from application of a specified surge.

theload(s)tobeprotected.Thisdeviceisseries-connectedsuch

3.13 nominal frequency—the nominal frequency is the des-

that load current will flow through the transient voltage surge

ignated frequency in Hz.

suppressor.

3.14 nominal system voltage—A nominal value assigned to

3.25 voltage drop—Voltage differential measured from in-

designate a system of a given voltage class in accordance with

put terminals to output terminals under conditions of rated load

ANSI/IEEE C84.1. For the purpose of this standard, nominal

current for two-port surge suppressors.

system voltages are 120, 208, 240, and 480 vac.All voltages in

3.26 voltage protection level—A suppression rating (or

this standard are root-mean-square (rms) unless stated other-

ratings) in volts or kilovolts, selected by the manufacturer that

wise. All tolerances are expressed in percent of the nominal

is based on the measured limiting voltage determined during

system voltage.

surgetesting.Alsoreferredtoasthesuppressionvoltagerating.

3.15 one-port transient voltage surge suppressor—ATVSS

3.27 voltage spike—A voltage spike is a voltage change of

having one set of electrical connections (terminals, leads and

veryshortduration(100µsto ⁄2cycle).Thestandard1.2/50-µs

the like) intended only for shunt-connection to the ac power

lightning impulse, as defined by ANSI/IEEE Std 4,isthe

circuit, such that load current in the ac power circuit bypasses

characteristic voltage spike used for test purposes.

the TVSS.

3.28 voltage tolerance—Voltage tolerance is the maximum

3.16 peak overshoot voltage—Maximum voltage above the

permitted departure from nominal system voltage during nor-

voltage protection level (peak voltage minus suppression

mal operation, excluding transient voltage variations. Voltage

voltage rating) across the suppressor output terminals during

tolerance includes variations such as those caused by load

initial response to a voltage spike.

changes, switchboard meter error, and drift. Unless otherwise

3.17 rated rms voltage (varistor)—Maximum continuous

specified, voltage tolerance shall be considered to be 610 % of

sinusoidal rms voltage which may be applied to a varistor.

nominal system voltage.

3.18 response time (varistor)—The time between the point

at which the wave exceeds the voltage protection level (sup- 4. Classification

pression voltage rating) and the peak of the voltage overshoot.

4.1 Surge suppressors covered in this specification shall be

For the purpose of this definition, voltage protection level is

classified by class and type.

defined with an 8/20-µs current waveform of the peak current

4.2 The two classes of surge suppressors covered in this

amplitude as the waveform used for this response time.

specification are based on and reflect ANSI/IEEE C62.41

3.19 secondary surge arrestor—A surge protector device

locations.

acceptable ahead of the service entrance equipment on circuits

4.2.1 Class A—Surge suppressor associated with long cir-

not exceeding 1000-Vrms (location category C as described in

cuitbranchthatbeinggreaterthan30-ftcabledistancefromthe

ANSI/IEEE C62.41).

distribution panel and usually installed as a series-connected

3.20 surge—Atransientovervoltagesuperimposedontheac

TVSS at the distribution system receptacle (wall outlet).

power circuit. A voltage surge is generally one in which the

4.2.2 Class B—Surge suppressor for short branch circuit,

superpositionofthesurgeandnormalpowerfrequencyvoltage

either installed at loads within 30-ft cable distance from the

involves peak voltage levels of twice or more the normal

circuit breaker distribution panel or within the distribution

voltage of the ac power system and generally lasting not more

panel.

than one-half period of the nominal system voltage waveform.

4.3 Type designations for surge suppressors covered in this

3.21 surge protective device (SPD)—A protective device specification are as follows:

composed of any combination of linear or non-linear circuit

4.3.1 Type I; Permanent Connected Type—A suppressor

elements and intended for limiting surge voltages on equip-

designedforhard-wiredorpanel-mountapplications.Thistype

ment by diverting or limiting surge current; it prevents contin-

surge suppressor is the only one-port-type TVSS.

ued flow of follow (power) current and is capable of repeating

4.3.2 Type II; Plug-In Type—A suppressor provided with

these functions as specified.

blades for direct connection at a receptacle and with integral

3.22 temporary overvoltage (TOV)—Avoltage swell from a output receptacle(s). By nature of its design, a plug-in suppres-

sor is inserted into the circuit as a series connection.

sudden change in voltage which goes outside the voltage

tolerance limits but does not exceed 120 % of nominal system 4.3.3 Type III; Cord-Connected Type—A suppressor that is

voltage and returns to and remains within these limits within 2 connected to a receptacle through a flexible cord that is

s after the initiation of the disturbance. permanently attached to the suppressor device. The cord shall

F1507 – 99 (2006)

be in accordance with requirements of UL 1449. Cord-

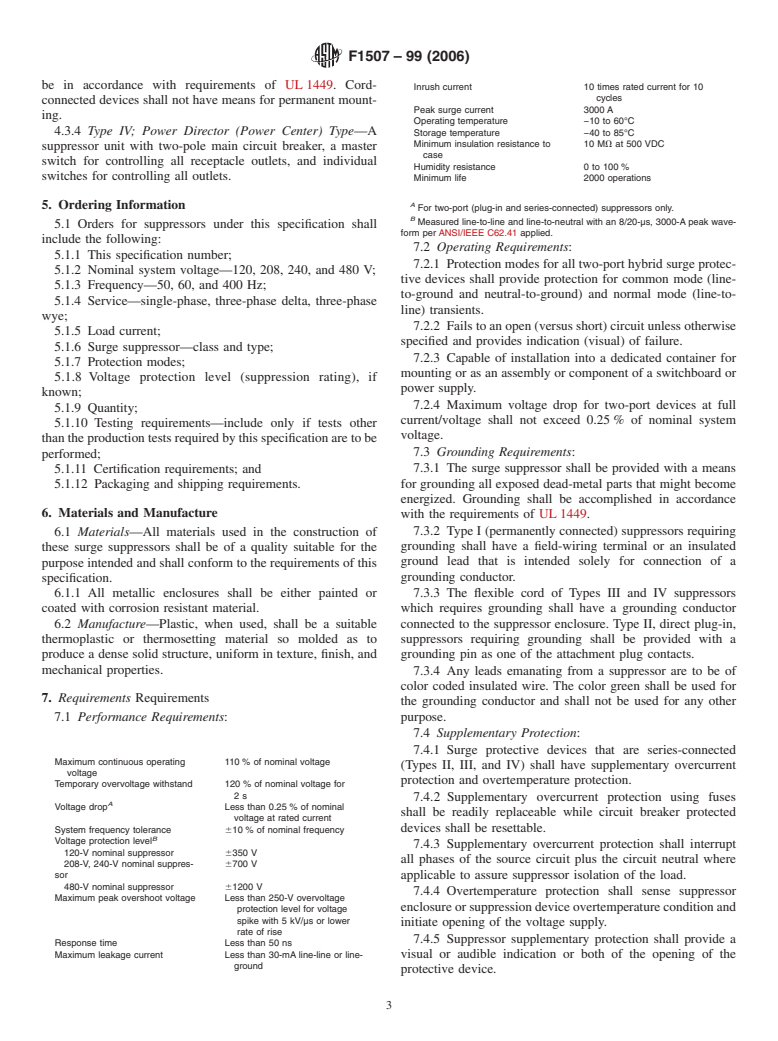

Inrush current 10 times rated current for 10

cycles

connected devices shall not have means for permanent mount-

Peak surge current 3000 A

ing.

Operating temperature −10 to 60°C

4.3.4 Type IV; Power Director (Power Center) Type—A Storage temperature −40 to 85°C

Minimum insulation resistance to 10 MV at 500 VDC

suppressor unit with two-pole main circuit breaker, a master

case

switch for controlling all receptacle outlets, and individual

Humidity resistance 0 to 100 %

switches for controlling all outlets.

Minimum life 2000 operations

A

5. Ordering Information

For two-port (plug-in and series-connected) suppressors only.

B

Measured line-to-line and line-to-neutral with an 8/20-µs, 3000-A peak wave-

5.1 Orders for suppressors under this specification shall

form per ANSI/IEEE C62.41 applied.

include the following:

7.2 Operating Requirements:

5.1.1 This specification number;

7.2.1 Protection modes for all two-port hybrid surge protec-

5.1.2 Nominal system voltage—120, 208, 240, and 480 V;

tive devices shall provide protection for common mode (line-

5.1.3 Frequency—50, 60, and 400 Hz;

to-ground and neutral-to-ground) and normal mode (line-to-

5.1.4 Service—single-phase, three-phase delta, three-phase

line) transients.

wye;

7.2.2 Fails to an open (versus short) circuit unless otherwise

5.1.5 Load current;

specified and provides indication (visual) of failure.

5.1.6 Surge suppressor—class and type;

7.2.3 Capable of installation into a dedicated container for

5.1.7 Protection modes;

mounting or as an assembly or component of a switchboard or

5.1.8 Voltage protection level (suppression rating), if

power supply.

known;

7.2.4 Maximum voltage drop for two-port devices at full

5.1.9 Quantity;

current/voltage shall not exceed 0.25 % of nominal system

5.1.10 Testing requirements—include only if tests other

voltage.

thantheproductiontestsrequiredbythisspecificationaretobe

7.3 Grounding Requirements:

performed;

7.3.1 The surge suppressor shall be provided with a means

5.1.11 Certification requirements; and

5.1.12 Packaging and shipping requirements. for grounding all exposed dead-metal parts that might become

energized. Grounding shall be accomplished in accordance

6. Materials and Manufacture

with the requirements of UL 1449.

7.3.2 Type I (permanently connected) suppressors requiring

6.1 Materials—All materials used in the construction of

these surge suppressors shall be of a quality suitable for the grounding shall have a field-wiring terminal or an insulated

ground lead that is intended solely for connection of a

purpose intended and shall conform to the requirements of this

grounding conductor.

specification.

6.1.1 All metallic enclosures shall be either painted or 7.3.3 The flexible cord of Types III and IV suppressors

coated with corrosion resistant material. which requires grounding shall have a grounding conductor

6.2 Manufacture—Plastic, when used, shall be a suitable connected to the suppressor enclosure. Type II, direct plug-in,

thermoplastic or thermosetting material so molded as to suppressors requiring grounding shall be provided with a

produce a dense solid structure, uniform in texture, finish, and grounding pin as one of the attachment plug contacts.

mechanical properties.

7.3.4 Any leads emanating from a suppressor are to be of

color coded insulated wire. The color green shall be used for

7. Requirements Requirements

the grounding conductor and shall not be used for any other

7.1 Performance Requirements: purpose.

7.4 Supplementary Protection:

7.4.1 Surge protective devices that are series-connected

Maximum continuous operating 110 % of nominal voltage

(Types II, III, and IV) shall have supplementary overcurrent

voltage

protection and overtemperature protection.

Temporary overvol

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.