ASTM F1181-19

(Test Method)Standard Test Method for Measuring Binocular Disparity in Transparent Parts

Standard Test Method for Measuring Binocular Disparity in Transparent Parts

SIGNIFICANCE AND USE

5.1 Diplopia or doubling of vision occurs when there is sufficient binocular disparity present so that the bounds of Panum's area (the area of single vision) is exceeded. This condition arises whenever one object is significantly closer (or farther) than another so that looking at one will cause the image of the other to appear double. This can be easily demonstrated: Close one eye and look at a clock (or other object) on a distant wall. Now place your thumb to one side of the image of the clock. Now open both eyes. If you look at the clock, you should see two thumbs. If you look at your thumb, you should see two clocks.

5.2 Complaints from pilots flying aircraft equipped with wide field of view head up displays (HUDs), such as the LANTIRN HUD, indicated that they were experiencing discomfort (eye fatigue, headaches, and so forth) or seeing either two targets or two pippers (aiming symbols on the HUD) when using the HUD. Subsequent investigations revealed that the problem arose from the fact that the aircraft transparency and the HUD significantly changed the optical distances of the target and the HUD imagery so that binocular disparity, which exceeded Panum's area was induced. Use of this test method provides a procedure by which the amount of binocular disparity being experienced by a human operator due to the presence of a transparent part in their field of view may be easily and precisely measured.

SCOPE

1.1 This test method covers the amount of binocular disparity that is induced by transparent parts such as aircraft windscreens, canopies, HUD combining glasses, visors, or goggles. This test method may be applied to parts of any size, shape, or thickness, individually or in combination, so as to determine the contribution of each transparent part to the overall binocular disparity present in the total “viewing system” being used by a human operator.

1.2 This test method represents one of several techniques that are available for measuring binocular disparity, but is the only technique that yields a quantitative figure of merit that can be related to operator visual performance.

1.3 This test method employs apparatus currently being used in the measurement of optical angular deviation under Test Method F801.

1.4 The values stated in inches (Imperial units) are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1181 − 19

Standard Test Method for

1

Measuring Binocular Disparity in Transparent Parts

This standard is issued under the fixed designation F1181; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method covers the amount of binocular dispar-

F801 Test Method for Measuring OpticalAngular Deviation

ity that is induced by transparent parts such as aircraft

of Transparent Parts

windscreens, canopies, HUD combining glasses, visors, or

goggles. This test method may be applied to parts of any size,

3. Terminology

shape, or thickness, individually or in combination, so as to

determine the contribution of each transparent part to the 3.1 Definitions:

overall binocular disparity present in the total “viewing sys- 3.1.1 angular deviation, n—the angular displacement of a

light ray as it passes through a transparent part, expressed as an

tem” being used by a human operator.

angular measurement, for example, degree, minutes of arc,

1.2 This test method represents one of several techniques

milliradians.

that are available for measuring binocular disparity, but is the

3.1.1.1 Discussion—Since it is an angular measurement, the

only technique that yields a quantitative figure of merit that can

amount of linear displacement increases with distance.

be related to operator visual performance.

3.1.2 binoculardisparity,n—the difference between the two

1.3 This test method employs apparatus currently being

images on the retina resulting from the lateral separation

used in the measurement of optical angular deviation under

between the two eyes when viewing an object at a fixation

Test Method F801.

point or due to the fact that an object is either nearer or farther

than the fixation point.

1.4 The values stated in inches (Imperial units) are to be

regarded as standard. The values given in parentheses are

3.1.2.1 Discussion—Acertain amount of disparity is benefi-

mathematical conversions to SI units that are provided for

cial and natural, leading to the perception of depth. However,

information only and are not considered standard.

when the disparity exceeds the limits for binocular fusion,

doubling of vision, eye fatigue, and headaches occur as the

1.5 This standard does not purport to address all of the

eyes strain to merge the disparate images.

safety concerns, if any, associated with its use. It is the

3.1.3 diplopia, n—the doubling of images of an object due

responsibility of the user of this standard to establish appro-

to the fact that the object is either nearer or farther than the

priate safety, health, and environmental practices and deter-

point of fixation or due to the fact that the lines of regard of the

mine the applicability of regulatory limitations prior to use.

eyes do not intersect at the point of fixation.

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard- 3.1.4 Panum’s area, n—the area on the retina in which the

eyes are able to fuse disparate images so that single vision

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- occurs.

mendations issued by the World Trade Organization Technical

4. Summary of Test Method

Barriers to Trade (TBT) Committee.

4.1 Using an optoelectronic system (consisting of a trans-

mitter and a receiver, described in Test Method F801) and with

1

This test method is under the jurisdiction of ASTM Committee F07 on

Aerospace and Aircraft and is the direct responsibility of Subcommittee F07.08 on

2

Transparent Enclosures and Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2019. Published November 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1988. Last previous edition approved in 2014 as F1181 – 09(2014). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/F1181-19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1181 − 19

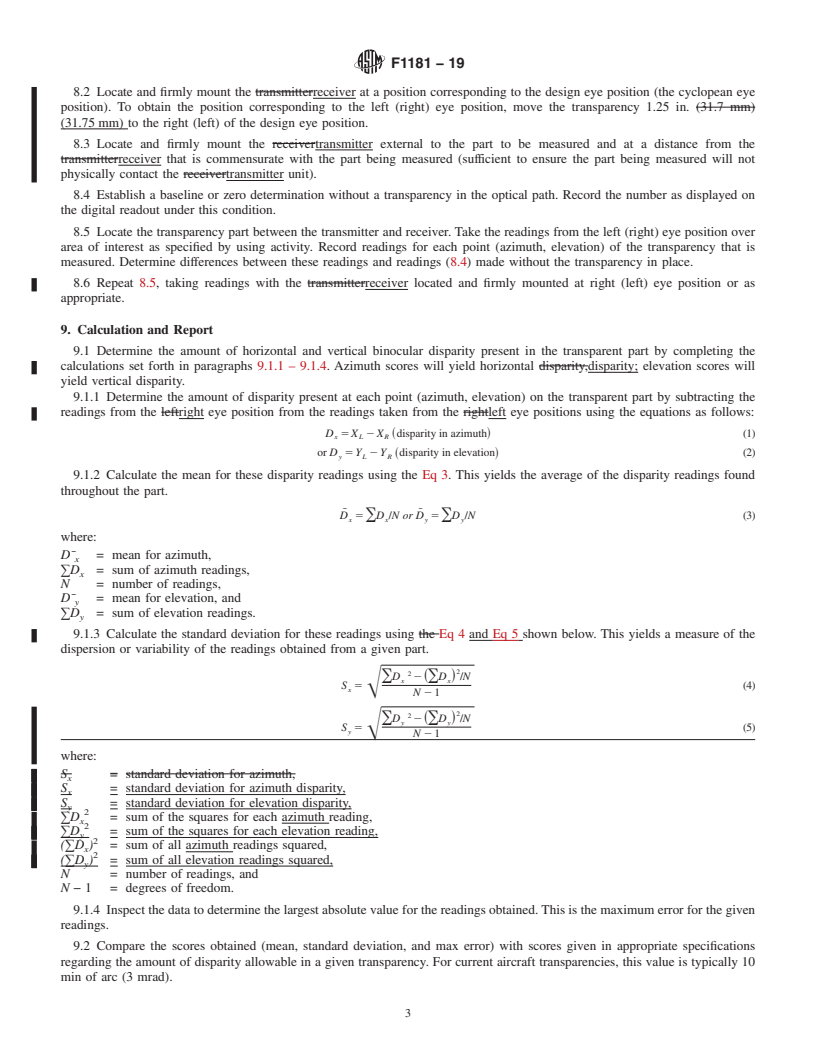

the part held in its installed angle, two sets of angular deviation (0.0254 mm). Using this element spacing and the 10 in.

measurements are made at several intervals (for example, 2°) (254 mm) lens,

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1181 − 09 (Reapproved 2014) F1181 − 19

Standard Test Method for

1

Measuring Binocular Disparity in Transparent Parts

This standard is issued under the fixed designation F1181; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the amount of binocular disparity that is induced by transparent parts such as aircraft windscreens,

canopies, HUD combining glasses, visors, or goggles. This test method may be applied to parts of any size, shape, or thickness,

individually or in combination, so as to determine the contribution of each transparent part to the overall binocular disparity present

in the total “viewing system” being used by a human operator.

1.2 This test method represents one of several techniques that are available for measuring binocular disparity, but is the only

technique that yields a quantitative figure of merit that can be related to operator visual performance.

1.3 This test method employs apparatus currently being used in the measurement of optical angular deviation under Test Method

F801.

1.4 The values stated in inch-pound units inches (Imperial units) are to be regarded as standard. The values given in parentheses

are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

F801 Test Method for Measuring Optical Angular Deviation of Transparent Parts

3. Terminology

3.1 Definitions:

3.1.1 angular deviation—deviation, n—the angular displacement of a light ray as it passes through a transparent part, expressed

as an angular measurement, for example, degree, minutes of arc, milliradians. Since it is an angular measurement, the amount of

linear displacement increases with distance.

3.1.1.1 Discussion—

Since it is an angular measurement, the amount of linear displacement increases with distance.

3.1.2 binocular disparity—disparity, n—the difference between the two images on the retina resulting from the lateral separation

between the two eyes when viewing an object at a fixation point or due to the fact that an object is either nearer or farther than

the fixation point. A certain amount of disparity is beneficial and natural, leading to the perception of depth. However, when the

disparity exceeds the limits for binocular fusion, doubling of vision, eye fatigue, and headaches occur as the eyes strain to merge

the disparate images.

1

This test method is under the jurisdiction of ASTM Committee F07 on Aerospace and Aircraft and is the direct responsibility of Subcommittee F07.08 on Transparent

Enclosures and Materials.

Current edition approved Dec. 1, 2014Nov. 1, 2019. Published December 2014November 2019. Originally approved in 1988. Last previous edition approved in 20092014

as F1181 – 09.F1181 – 09(2014). DOI: 10.1520/F1181-09R14.10.1520/F1181-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1181 − 19

3.1.2.1 Discussion—

A certain amount of disparity is beneficial and natural, leading to the perception of depth. However, when the disparity exceeds

the limits for binocular fusion, doubling of vision, eye fatigue, and headaches occur as the eyes strain to merge the disparate

images.

3.1.3 diplopia—diplopia, n—the doubling of images of an object due to the fact that the object is eit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.