ASTM D3165-00

(Test Method)Standard Test Method for Strength Properties of Adhesives in Shear by Tension Loading of Single-Lap-Joint Laminated Assemblies

Standard Test Method for Strength Properties of Adhesives in Shear by Tension Loading of Single-Lap-Joint Laminated Assemblies

SCOPE

1.1 This test method (Note 1) is intended for determining the comparative shear strengths of adhesives in large area joints when tested on a standard single-lap-joint specimen and under specified conditions of preparation and testing. Adhesives respond differently in small versus large area joints (Note 2). Note 1-While this test method is intended for use in metal-to-metal applications, it may be used for measuring the shear properties of adhesives using plastic adherends, provided consideration is given to the thickness and rigidity of the plastic adherends. Doublers may be required for plastic adherends to prevent bearing failure in the adherends. Note 2-This variation can be influenced by adhesive density, flow characteristics, cure rate, gel time, carrier composition, entrapped volatiles, volatiles released during cure, etc. and also by cure cycle variables including: temperature, time, pressure, rise rate to temperature, cool-down rate, etc.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3165–00

Standard Test Method for

Strength Properties of Adhesives in Shear by Tension

Loading of Single-Lap-Joint Laminated Assemblies

This standard is issued under the fixed designation D 3165; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope B 209 Specification for Aluminum and Aluminum-Alloy

Sheet and Plate

1.1 This test method (Note 1) is intended for determining

B 265 Specification for Titanium and Titanium Alloy Strip,

the comparative shear strengths of adhesives in large area

Sheet, and Plate

joints when tested on a standard single-lap-joint specimen and

D 907 Terminology of Adhesives

under specified conditions of preparation and testing. Adhe-

D 2093 PracticeforPreparationofSurfacesofPlasticsPrior

sives respond differently in small versus large area joints (Note

to Adhesive Bonding

2).

D 2651 Guide for Preparation of Metal Surfaces for Adhe-

NOTE 1—While this test method is intended for use in metal-to-metal 6

sive Bonding

applications, it may be used for measuring the shear properties of

D 3933 Guide for Preparation of Aluminum Surfaces for

adhesives using plastic adherends, provided consideration is given to the

Structural Adhesives Bonding (Phosphoric Acid Anodiz-

thickness and rigidity of the plastic adherends. Doublers may be required

ing)

for plastic adherends to prevent bearing failure in the adherends.

NOTE 2—This variation can be influenced by adhesive density, flow D 4896 Guide for Use of Adhesive-Bonded Single-Lap-

characteristics, cure rate, gel time, carrier composition, entrapped vola-

Joint Specimen Test Results

tiles, volatiles released during cure, etc. and also by cure cycle variables

E 4 Practices for Force Verification of Testing Machines

including: temperature, time, pressure, rise rate to temperature, cool-down

rate, etc.

3. Terminology

1.2 The values stated in SI units are to be regarded as the

3.1 Definitions—Many terms in this test method are defined

standard. The values given in parentheses are provided for

in Terminology D 907.

infomation purposes only.

4. Significance and Use

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4.1 This test method is useful in that the joint configuration

responsibility of the user of this standard to establish appro-

closelysimulatestheactualjointconfigurationofmanybonded

priate safety and health practices and determine the applica-

assemblies and can be used to develop design parameters for

bility of regulatory limitations prior to use.

such assemblies.

4.2 This test method is also useful as an in-process quality

2. Referenced Documents

control test for laminated assemblies. In practice the laminated

2.1 ASTM Standards:

assembly is either made over size and test specimens removed

A 167 Specification for Stainless and Heat-Resisting

from it or a percentage of the assemblies are destructively

Chromium-Nickel Steel Plate, Sheet, and Strip

tested.

A 366/A366M Specification for Steel, Sheet, Carbon, Cold-

4.3 The misuse of strength values obtained from this test

Rolled, Commercial Quality

method as design allowable stress values for structural joints

B 36 Specification for Brass Plate, Sheet, Strip, and Rolled

could lead to product failure, property damage, and human

Bar

injury. The apparent shear strength of an adhesive obtained

B 152 Specification for Copper Sheet, Strip, Plate, and

from a given small single-lap specimen may differ from that

Rolled Bar

obtained from a joint made with different adherends or by a

different bonding process.The normal variation of temperature

and moisture in the service environment causes the adherends

This test method is under the jurisdiction of ASTM Committee D-14 on

Adhesives and is the direct responsibility of Subcommittee D14.80 on Metal

Bonding Adhesives.

Current edition approved May 10, 2000. Published August 2000. Originally Annual Book of ASTM Standards, Vol 02.02.

published as D 3165 – 73. Last previous edition D 3165 – 95. Annual Book of ASTM Standards, Vol 02.04.

2 6

Annual Book of ASTM Standards, Vol 01.03. Annual Book of ASTM Standards, Vol 15.06.

3 7

Annual Book of ASTM Standards, Vol 02.01. Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3165

and the adhesive to swell and shrink. The adherends and grips shall engage the outer 25.4 mm (1 in.) of each end of the

adhesive are likely to have different thermal and moisture test specimen firmly (Note 3). The grips and attachments shall

coefficients of expansion. be so constructed that they will move into alignment with the

4.3.1 Even in small specimens, short-term environmental test specimen as soon as the load is applied, so that the long

changes can induce internal stresses or chemical changes in the axis of the test specimen will coincide with the direction of the

adhesive that permanently affect the apparent strength and applied pull through the center of the grip assembly.

other mechanical properties of the adhesive. The problem of

NOTE 3—The length of overlap in the specimen may be varied where

predicting joint behavior in a changing environment is even

necessary.Thelengthofthespecimenbetweenthejaws,andtheendofthe

more difficult if a different type of adherend is used in a larger

lap however, must not be varied. The distance from the end of the lap to

structural joint than was used in the small specimen. the end of the jaws should be 50.8 to 63.5 mm (2.0 to 2.5 in.) in all tests.

4.4 The apparent shear strength measured with a single-lap

6. Test Specimens

specimen is not suitable for determining design allowable

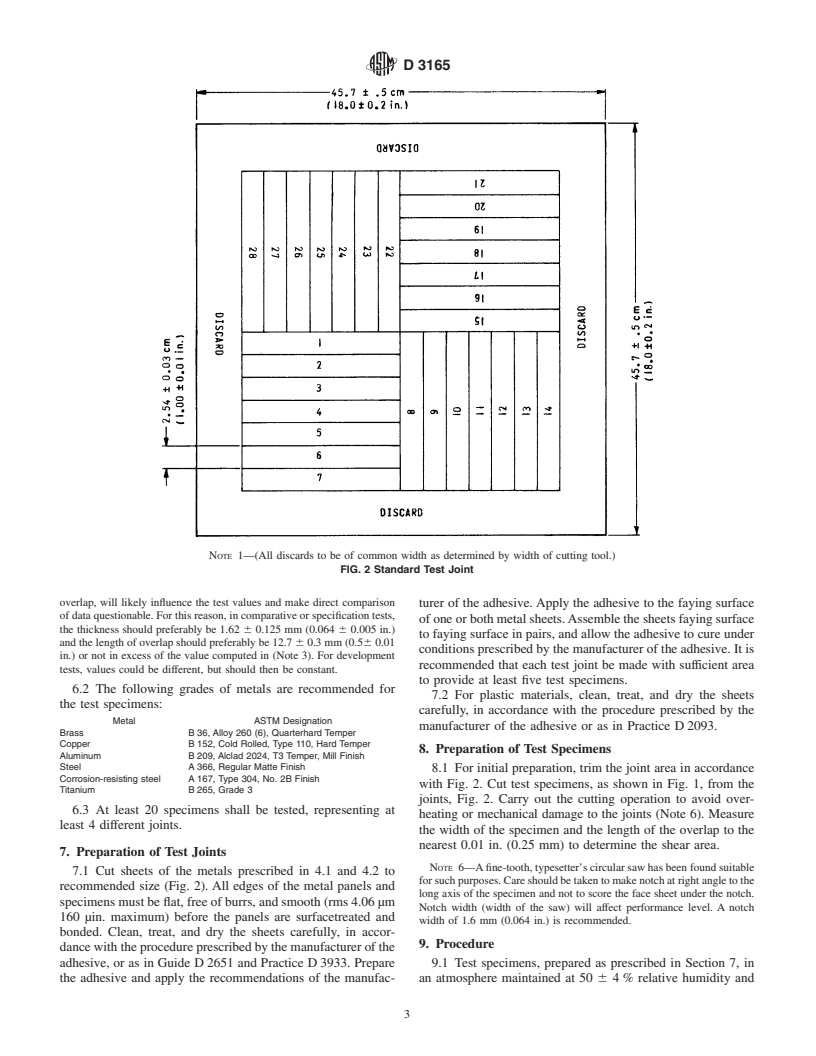

stresses for designing structural joints that differ in any manner 6.1 Test specimens shall conform to the form and dimen-

sions shown in Fig. 1. These shall be cut from test joints Fig.

from the joints tested without thorough analysis and under-

standing of the joint and adhesive behaviors. 2, prepared as prescribed in Section 5. The recommended

4.5 Single-lap tests may be used for comparing and select- thickness of most metal sheets is 1.62 6 0.125 mm (0.064 6

ing adhesives or bonding processes for susceptibility to fatigue 0.005 in.) (Note 4). The recommended length of overlap for

and environmental changes, but such comparisons must be mostmetalsof1.62mm(0.064in.)thicknessis12.7 60.3mm

made with great caution since different adhesives may respond (0.50 6 0.01 in.) (Note 5).

differently in different joints. Review Guide D 4896 for further

NOTE 4—Since it is undesirable to exceed the yield point of the metal

discussion of concepts for interpretation of adhesive-bonded

in tension during test, the permissible length of overlap in the specimen

single-lap joint data.

will vary with the thickness and type of metal, and on the general level of

strength of the adhesive being investigated. The maximum permissible

5. Apparatus

length may be computed from the following relationship:

5.1 Testing Machine, conforming to the requirements of

L 5 Fty T/t (1)

Practice E 4. The testing machine shall be so selected that the

where:

breaking load of the specimens falls between 15 and 85 % of

L = length of overlap, in.,

the full-scale capacity. The machine shall be capable of

T = thickness of metal, in.

maintaining a rate of loading of 8.3 to 9.7 MPa/min (1200 to

Fty = yield point of metal (or the stress at proportional

1400 psi/min), or, if the rate is dependent on crosshead motion,

limit), psi, and

the machine should be set

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.