ASTM D2711-22

(Test Method)Standard Test Method for Demulsibility Characteristics of Lubricating Oils

Standard Test Method for Demulsibility Characteristics of Lubricating Oils

SIGNIFICANCE AND USE

5.1 This test provides a guide for determining the demulsibility characteristic of lubricating oils that are prone to water contamination and may encounter the turbulence of pumping and circulation capable of producing water-in-oil emulsions.

SCOPE

1.1 This test method covers the measurement of the ability of oil and water to separate from each other. It is intended for use in testing medium and high-viscosity lubricating oils.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2711 − 22

Standard Test Method for

1

Demulsibility Characteristics of Lubricating Oils

This standard is issued under the fixed designation D2711; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* separate into its components after the mixture has been

vigorously agitated. D4175

1.1 This test method covers the measurement of the ability

of oil and water to separate from each other. It is intended for

4. Summary of Test Method

use in testing medium and high-viscosity lubricating oils.

4.1 For Oils That Do Not Contain Extreme Pressure (EP)

1.2 The values stated in SI units are to be regarded as

Additives—A 405 mL sample of the oil and 45 mL of distilled

standard. No other units of measurement are included in this

water are stirred together for 5 min at 82 °C in a special

standard.

graduated separatory funnel.After a 5 h settling period follow-

1.3 This standard does not purport to address all of the

ing the stirring, a percentage of the water in the oil and the

safety concerns, if any, associated with its use. It is the

volumes of water and emulsion separating from the oil are

responsibility of the user of this standard to establish appro-

measured and recorded.

priate safety, health, and environmental practices and deter-

4.2 For Oils That Contain Extreme Pressure (EP)

mine the applicability of regulatory limitations prior to use.

Additives—A 360 mL sample of the oil and 90 mL of distilled

1.4 This international standard was developed in accor-

water are stirred together for 5 min at 82 °C in a special

dance with internationally recognized principles on standard-

graduated separatory funnel.After a 5 h settling period follow-

ization established in the Decision on Principles for the

ing the stirring, percentage of water in the oil and the volumes

Development of International Standards, Guides and Recom-

ofwaterandemulsionseparatingfromtheoilaremeasuredand

mendations issued by the World Trade Organization Technical

recorded.

Barriers to Trade (TBT) Committee.

5. Significance and Use

2. Referenced Documents

5.1 This test provides a guide for determining the demulsi-

2

2.1 ASTM Standards:

bility characteristic of lubricating oils that are prone to water

D1193 Specification for Reagent Water

contamination and may encounter the turbulence of pumping

D1796 Test Method for Water and Sediment in Fuel Oils by

and circulation capable of producing water-in-oil emulsions.

the Centrifuge Method (Laboratory Procedure)

D4175 Terminology Relating to Petroleum Products, Liquid

6. Apparatus

Fuels, and Lubricants

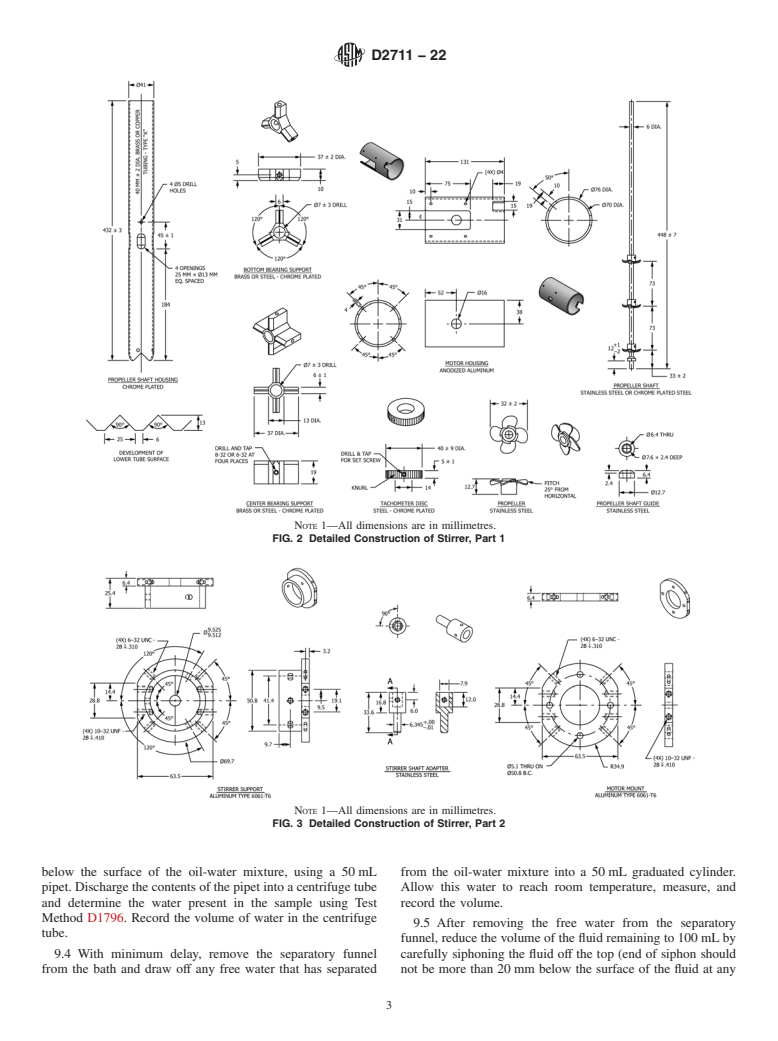

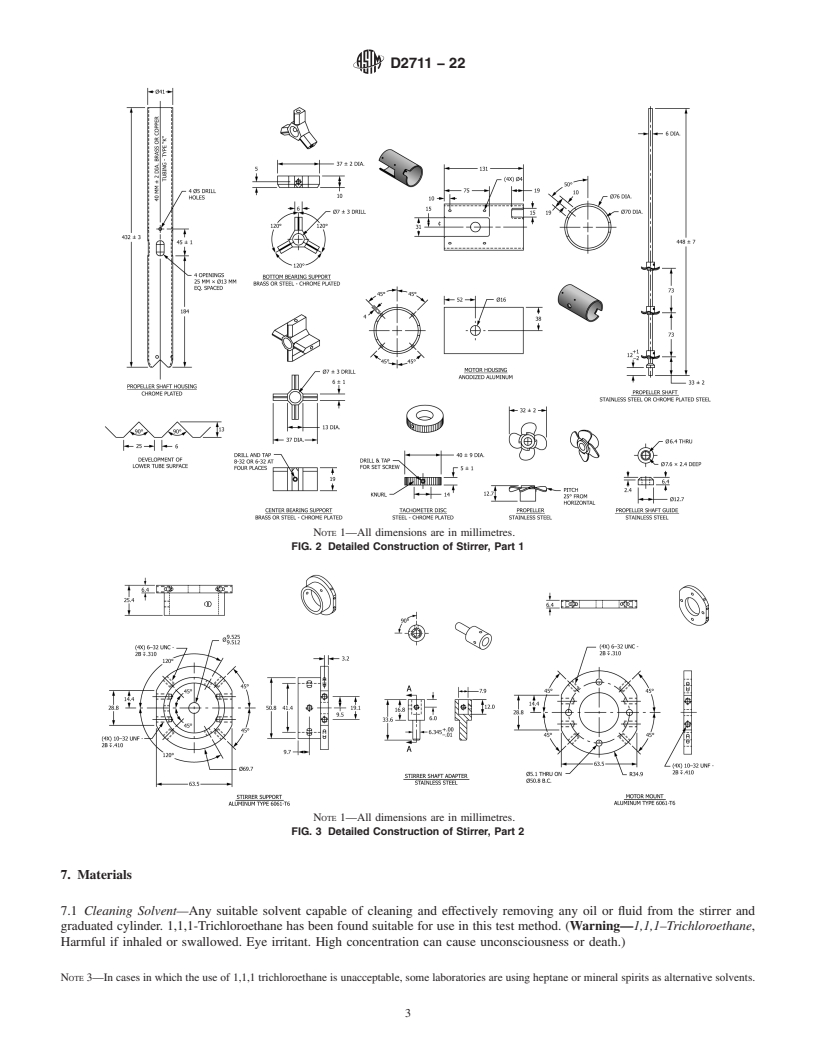

6.1 Stirrer, constructed from parts shown in Figs. 1-3.

3. Terminology

NOTE 1—An air pressure driven motor is suggested to avoid any

potential electrical sparking hazard.

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, refer 6.2 Special Graduated Separatory Funnel, as shown in Fig.

to Terminology D4175.

4.

3.1.2 demulsibility, n—in petroleum products, the ability of

6.3 Heating Bath, sufficiently large and deep to permit the

a mixture of liquids (usually hydrocarbons and water) to

immersion of at least two test separatory funnels in the bath

liquid up to their 500 mL graduation mark. The bath shall be

capable of maintaining a temperature of 82 °C 6 1 °C and

1

This test method is under the jurisdiction of ASTM Committee D02 on

shall be so equipped to hold the separatory funnels securely in

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.L0.01 on Metal Removal Fluids and Lubricants. a position so that the vertical axis of the stirrer corresponds to

Current edition approved Nov. 1, 2022. Published November 2022. Originally

thecenterlineoftheseparatoryfunnelduringthemixingofthe

approved in 1968. Last previous edition approved in 2017 as D2711 – 17. DOI:

oil and water.

10.1520/D2711-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

NOTE 2—The use of silicone oil as a bath medium is discouraged, since

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

any contamination into the oil/water mixture may cause erroneous results.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 6.4 Centrifuge, as described in Test Method D1796.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohoc

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2711 − 17 D2711 − 22

Standard Test Method for

1

Demulsibility Characteristics of Lubricating Oils

This standard is issued under the fixed designation D2711; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the measurement of the ability of oil and water to separate from each other. It is intended for use in

testing medium and high-viscosity lubricating oils.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D1796 Test Method for Water and Sediment in Fuel Oils by the Centrifuge Method (Laboratory Procedure)

D4175 Terminology Relating to Petroleum Products, Liquid Fuels, and Lubricants

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, refer to Terminology D4175.

3.1.2 demulsibility, n—in petroleum products, the ability of a mixture of liquids (usually hydrocarbons and water) to separate into

its components after the mixture has been vigorously agitated. D4175

4. Summary of Test Method

4.1 For Oils That Do Not Contain Extreme Pressure (EP) Additives—A 405 mL sample of the oil and 45 mL of distilled water

are stirred together for 5 min at 82 °C in a special graduated separatory funnel. After a 5 h settling period following the stirring,

a percentage of the water in the oil and the volumes of water and emulsion separating from the oil are measured and recorded.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.L0.01 on Metal Removal Fluids and Lubricants.

Current edition approved June 1, 2017Nov. 1, 2022. Published June 2017November 2022. Originally approved in 1968. Last previous edition approved in 20112017 as

D2711 – 11.D2711 – 17. DOI: 10.1520/D2711-17.10.1520/D2711-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2711 − 22

FIG. 1 Stirrer

4.2 For Oils That Contain Extreme Pressure (EP) Additives—A 360 mL sample of the oil and 90 mL of distilled water are stirred

together for 5 min at 82 °C in a special graduated separatory funnel. After a 5 h settling period following the stirring, percentage

of water in the oil and the volumes of water and emulsion separating from the oil are measured and recorded.

5. Significance and Use

5.1 This test provides a guide for determining the demulsibility characteristic of lubricating oils that are prone to water

contamination and may encounter the turbulence of pumping and circulation capable of producing water-in-oil emulsions.

6. Apparatus

6.1 Stirrer, constructed from parts shown in Figs. 1-3.

NOTE 1—An air pressure driven motor is suggested to avoid any potential electrical sparking hazard.

6.2 Special Graduated Separatory Funnel, as shown in Fig. 4.

6.3 Heating Bath, sufficiently large and deep to permit the immersion of at least two test separatory funnels in the bath liquid up

to their 500 mL graduation mark. The bath shall be capable of maintaining a temperature of 82 °C 6 1 °C and shall be so equipped

to hold the separatory funnels securely in a position so tha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.