ASTM E997-84(1992)e1

(Test Method)Standard Test Method for Structural Performance of Glass in Exterior Windows, Curtain Walls, and Doors Under the Influence of Uniform Static Loads by Destructive Methods

Standard Test Method for Structural Performance of Glass in Exterior Windows, Curtain Walls, and Doors Under the Influence of Uniform Static Loads by Destructive Methods

SCOPE

1.1 This test method is a procedure to determine if the probability of breakage of glass specimens tested is significantly greater than, signficantly less than, or not significantly different than the specified probability of breakage when exposed to a specified 60-s duration equivalent design load. It is not intended to be a design standard for determining the load resistance of glass. Practice E1300 shall be used for this purpose.

1.2 This test method describes apparatus and procedures to select and apply a 60-s duration proof load to glass specimens, to determine the number of glass specimens to be tested, and to evaluate statistically the probability of breakage. This test method may be conducted using the standard test frame specified herein or a test frame of the user's design.

1.3 Proper use of this test method requires a knowledge of the principles of pressure measurement and an understanding of recommended glazing practices.

1.4 The values stated in inch-pound units are to be regarded as standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: E 997 – 84 (Reapproved 1992) An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Structural Performance of Glass in Exterior Windows,

Curtain Walls, and Doors Under the Influence of Uniform

Static Loads by Destructive Methods

This standard is issued under the fixed designation E 997; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Section 15 was added editorially in December 1991.

1. Scope 2.6 positive load—a load that results in the outdoor side of

a glass specimen being the high-pressure side.

1.1 This test method is a procedure to determine if the

2.7 probability of failure—the probability that a glass speci-

probability of failure of glass specimens exposed to a specified

men will fail when tested at a given load. General industry

60-s duration equivalent design load meets specified require-

practice is to express the probability of failure as lights per

ments.

1000 lights.

1.2 This test method describes apparatus and procedures to

2.8 proof load—a magnitude of uniform load at which glass

select and apply a 60-s duration proof load to glass specimens,

specimens shall be tested.

to determine the number of glass specimens to be tested, and to

2.9 proof load factor, a—the constant which, when multi-

evaluate statistically the probability of failure. This test method

plied by the equivalent design load, determines the proof load.

may be conducted using the standard test frame specified

2.10 specifying authority—professional(s) responsible for

herein or a test frame of the user’s design.

determining and furnishing information required to perform the

1.3 Proper use of this test method requires a knowledge of

test.

the principles of pressure measurement and an understanding

of recommended glazing practices.

3. Summary of Test Method

1.4 The values stated in inch-pound units are to be regarded

3.1 This test method consists of individually glazing glass

as standard.

specimens in a test frame that is mounted into or against one

1.5 This standard does not purport to address all of the

face of a test chamber and supplying air to, or exhausting air

safety problems, if any, associated with its use. It is the

from, the test chamber so that each glass specimen is exposed

responsibility of the user of this standard to establish appro-

to a 60-s duration proof load. Load-time records shall be kept

priate safety and health practices and determine the applica-

for each glass specimen. Each glass specimen failure shall be

bility of regulatory limitations prior to use. Specific precau-

recorded.

tionary statements are given in Section 6.

3.2 After testing the required number of glass specimens, it

2. Terminology is determined if the probability of failure is greater than the

specified probability of failure based upon the number of glass

2.1 coeffıcient of variation, v—ratio of the standard devia-

specimen failures.

tion of the failure load to the mean failure load.

2.2 equivalent design load—a magnitude of 60-s duration

4. Significance and Use

uniform load selected by specifying authority to represent

4.1 Glass specimens to be tested shall be mounted in a

design loads.

standard test frame with four sides supported, or in a test frame

2.3 glass specimen—the glass to be tested, for example, a

designed to represent specific glazing conditions.

single pane, an insulating glass unit, laminated glass, etc. (does

4.1.1 A standard test frame shall be used when it is desired

not include test frame).

to evaluate the probability of failure of glass specimens with

2.4 glass specimen failure—the fracture or cracking of any

edge support conditions held constant.

glass component of a glass specimen.

4.1.2 A test frame designed to represent a specific glazing

2.5 negative load—a load that results in the indoor side of a

condition will be used when it is desired to evaluate the

glass specimen being the high-pressure side.

probability of failure of glass specimens in the specified

glazing system.

This test method is under the jurisdiction of ASTM Committee E-6 on

4.2 Loads on glass in windows, curtain walls, and doors

Performance of Buildings and is the direct responsibility of Subcommittee E06.51

may vary greatly in magnitude, direction, and duration. Any

on Component Performance of Windows, Curtain Walls, and Doors.

load (wind, snow, etc.) that can be transformed into a 60-s

Current edition approved Nov. 14, 1984. Published January 1985.

E 997

duration equivalent uniform design load can be considered. glass specimens shall not be tested.

Load transformation techniques are addressed in the litera-ture 7.3 Glass specimens shall be handled carefully at all times

(1, 2, 3). because the strength of glass is influenced by its surface and

4.3 The strength of glass varies with many different factors edge conditions.

including surface condition, load duration, geometry, relative

8. Calibration

humidity, and temperature (4). A thorough understanding of

those strength variations is required to interpret results of this

8.1 Pressure-measuring systems should be routinely

test method.

checked. If calibration is required, the manufacturer’s recom-

mendations or good engineering practices should be followed.

5. Apparatus

5.1 The description of apparatus is general in nature. Any

9. Required Information

equipment capable of performing the test procedure within the

9.1 The specifying authority shall provide the magnitude of

allowable tolerances is permitted.

the equivalent design load (positive or negative), the allowable

5.2 Major Components:

probability of failure for the glass specimens, and the coeffi-

5.2.1 Test Frame, in which glass specimens are mounted for

cient of variation of the failure loads typical of the glass

testing. The test frame shall provide either standardized sup-

specimens tested.

port conditions or specified support conditions. Specifications

9.2 The specifying authority shall state whether the glass

of standardized support conditions are presented in Annex A1.

specimens shall be glazed in a standard test frame (see Annex

5.2.2 Test Chamber, sealed, with an opening in which or

A1) or in a test frame designed to simulate a specific glazing

against which the test frame is installed. At least one static

system. If the test frame is to simulate a specific glazing

pressure tap shall be provided to measure the test chamber

system, complete glazing details and support conditions shall

pressure and shall be so located that the reading is minimally

be provided by the specifying authority.

affected by the velocity of the air supply to or from the test

chamber or any air movement. The air supply opening into the

10. Selection of Proof Load and Sample Size

test chamber shall be arranged so that the air does not impinge

10.1 The glass specimens shall be tested with a proof load

directly on the glass specimen with any significant velocity. A

that is larger than the equivalent design load. The proof load is

means of access into the test chamber may be provided to

found by multiplying the design load by the proof load factor,

facilitate adjustments and observations after the specimen has

a, as follows:

been installed.

q 5 aq (1)

p d

5.2.3 Air System, a controllable blower, compressed air

supply, exhaust system, reversible blower, or other device

where:

designed to apply the proof load to the glass specimen with

q 5 proof load,

p

required control.

a 5 proof load factor, and

5.2.4 Pressure Measuring Apparatus, to record continuous

q 5 equivalent design load.

d

test chamber pressures within an accuracy of 62%.

10.1.1 If the glass specimens are to be tested in a standard

5.2.5 Temperature Measuring Apparatus, to measure the

test frame, the proof load factor, a, is found in Tables 1-4, given

ambient temperature within an accuracy of 61°F (0.6°C).

the equivalent design load probability of failure and the

5.2.6 Relative Humidity Apparatus, to measure the relative

appropriate coefficient of variation, n. The proof load factor, a,

humidity within an accuracy of 62%.

corresponding to the minimum sample size or the maximum

capacity of the loading apparatus, would normally be selected.

6. Safety Precautions

10.1.2 If the glass specimens are to be tested in a test frame

6.1 Proper precautions to protect observers in the event of

that is representative of a specific glazing system, the maxi-

glass failure should be observed. At the pressures used in this

mum allowable proof load that can be resisted by the test frame

test method, considerable energy and hazard are involved. In

shall be determined using engineering principles. The proof

cases of failure, the hazard to personnel is less with an exhaust

load factor, a, is then determined by dividing the maximum

system, as the specimen will tend to blow into rather than out

of the test chamber. No personnel should be permitted in such

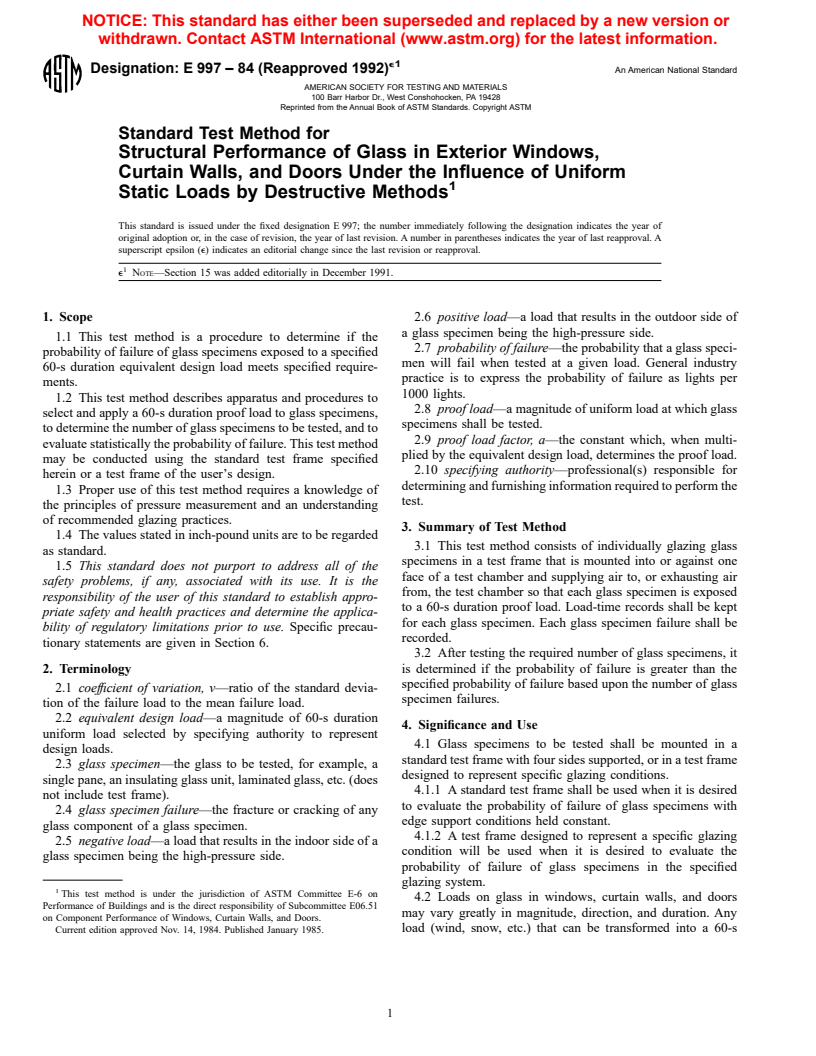

TABLE 1 Required Sample Size (n 5 0.10)

chambers during tests. All reasonable precautions should be

exercised during conduct of the test. Proof Load Factor, a

1.2 1.3

7. Sampling and Glass Specimens

0.010 11

7.1 Surface condition, cutting, fabrication, and packaging of

0.009 12

the glass specimens shall be representative of the glass whose 0.008 12

0.007 13

strength is to be evaluated.

Equivalent Design Load 0.006 15

7.2 All glass specimens shall be visually inspected for edge

Probability of Failure 0.005 17

0.004 19

or surface irregularities prior to testing, and all questionable

0.003 24

0.002 31 10

A

2 0.001 53 15

The boldface numbers in parentheses refer to the references listed at the end of

A

this method. Testing is not recommended because of excess expense.

E 997

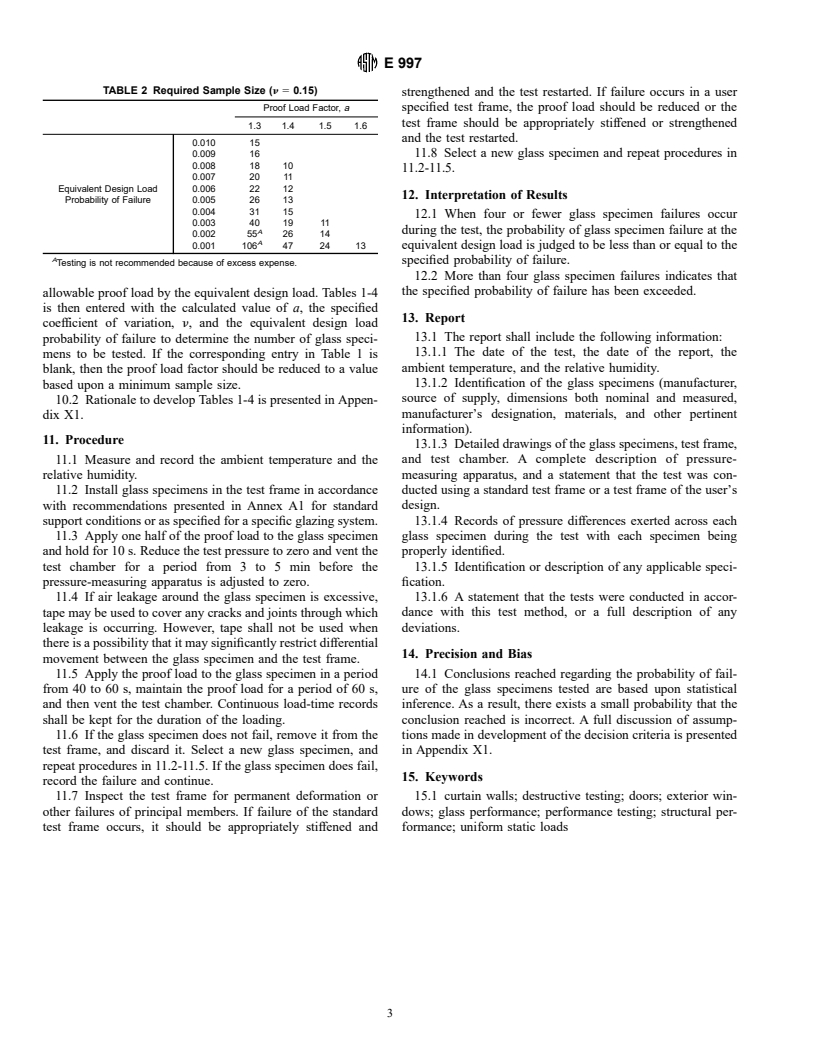

TABLE 2 Required Sample Size (n 5 0.15)

strengthened and the test restarted. If failure occurs in a user

Proof Load Factor, a specified test frame, the proof load should be reduced or the

test frame should be appropriately stiffened or strengthened

1.3 1.4 1.5 1.6

and the test restarted.

0.010 15

11.8 Select a new glass specimen and repeat procedures in

0.009 16

0.008 18 10

11.2-11.5.

0.007 20 11

Equivalent Design Load 0.006 22 12

12. Interpretation of Results

Probability of Failure 0.005 26 13

0.004 31 15

12.1 When four or fewer glass specimen failures occur

0.003 40 19 11

A during the test, the probability of glass specimen failure at the

0.002 55 26 14

A

0.001 106 47 24 13 equivalent design load is judged to be less than or equal to the

A

specified probability of failure.

Testing is not recommended because of excess expense.

12.2 More than four glass specimen failures indicates that

the specified probability of failure has been exceeded.

allowable proof load by the equivalent design load. Tables 1-4

is then entered with the calculated value of a, the specified

13. Report

coefficient of variation, n, and the equivalent design load

13.1 The report shall include the following information:

probability of failure to determine the number of glass speci-

13.1.1 The date of the test, the date of the report, the

mens to be tested. If the corresponding entry in Table 1 is

ambient temperature, and the relative humidity.

blank, then the proof load factor should be reduced to a value

13.1.2 Identification of the glass specimens (manufacturer,

based upon a minimum sample size.

source of supply, dimensions both nominal and measured,

10.2 Rationale to develop Tables 1-4 is presented in Appen-

manufacturer’s designation, materials, and other pertinent

dix X1.

information).

11. Procedure

13.1.3 Detailed drawings of the glass specimens, test frame,

11.1 Measure and record the ambient temperature and the and test chamber. A complete description of pressure-

relative humidity. measuring apparatus, and a statement that the test was con-

11.2 Install glass specimens in the test frame in accordance ducted using a standard test frame or a test frame of the user’s

design.

with recommendations presented in Annex A1 for standard

support conditions or as specified for a specific glazing system. 13.1.4 Records of pressure differences exerted across each

glass specimen during the test with each specimen being

11.3 Apply one half of the proof load to the glass specimen

and hold for 10 s. Reduce the test pressure to zero and vent the properly identified.

13.1.5 Identification or description of any applicable speci-

test chamber for a period from 3 to 5 min before the

pressure-measuring apparatus is adjusted to zero. fication.

13.1.6 A statement that the tests were conducted in accor-

11.4 If air leakage around the glass specimen is excessive,

tape may be used to cover any cracks and joints through which dance with this test method, or a full description of any

leakage is occurring. However, tape shall not be used when deviations.

there is a possibility that it may significantly restrict differential

14. Precision and Bias

movement between the glass specimen and the test frame.

11.5 Apply the proof load to the glass specimen in a period 14.1 Conclusions reached regarding the probability of fail-

from 40 to 60 s, maintain the proof load for a period of 60 s, ure of the glass specimens tested are based upon statistical

and then vent the test chamber. Continuous load-time records inference. As a result, there exists a small probability that the

shall be kept for the duration of the loading. conclusion reached is incorrect. A full discussion of assump-

11.6 If the glass specimen does not fail, remove it from the tions made in development of the decision criteria is presented

test frame, and discard it. Select a new glass specimen, and in Appendix X1.

repeat procedures in 11.2-11.5. If the glass specimen does fail,

15. Keywords

record the failure and continue.

11.7 Inspect the test frame for permanent deformation or 15.1 curtain walls; destructive testing; doors; exterior win-

other failures of principal members. If failure of the standard dows; glass performance; performance testing; structural per-

test frame occurs, it should be appropriately stiffened and formance; uniform static loads

E 997

TABLE 3 Required Sample Size (n 5 0.20)

Proof Load Factor, a

1.5 1.6 1.7 1.8 1.9 2.0 2.1 2.2

0.010 15 10

0.009 16 11

0.008 18 12

Equivalent 0.007 20 13

Design Load 0.006 23 15 10

Probability of 0.005 27 18 12

Failure 0.004 33 21 15 10

0.003 45 29 19 13 10

A

0.002 66 41 27 19 13 10

A A A

0.001 142 88 57 39 27 19 14 11

A

Te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.