ASTM D3548-04

(Specification)Standard Specification for Ethyl Acrylate

Standard Specification for Ethyl Acrylate

ABSTRACT

This specification establishes the properties and requirements for ethyl acrylate for use in paint, varnish, lacquer, and related products. Specimens shall be sampled, undergo chemical tests, and conform accordingly to purity, water content, color, acidity, and methyl ether of hydroquinone content requirements.

SCOPE

1.1 This specification covers ethyl acrylate (99 % grade) for use in paint, varnish, lacquer, and related products.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following applies to all specified limits in this standard; for purposes of determining conformance with this standard, an observed value or a calculated value shall be rounded off "to the nearest unit" in the last right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E 29.

1.4 For specification hazard information and guidance, see the Supplier's Material Safety Data Sheet for materials listed in this specification.

1.5 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in 4.1.

General Information

Relations

Standards Content (Sample)

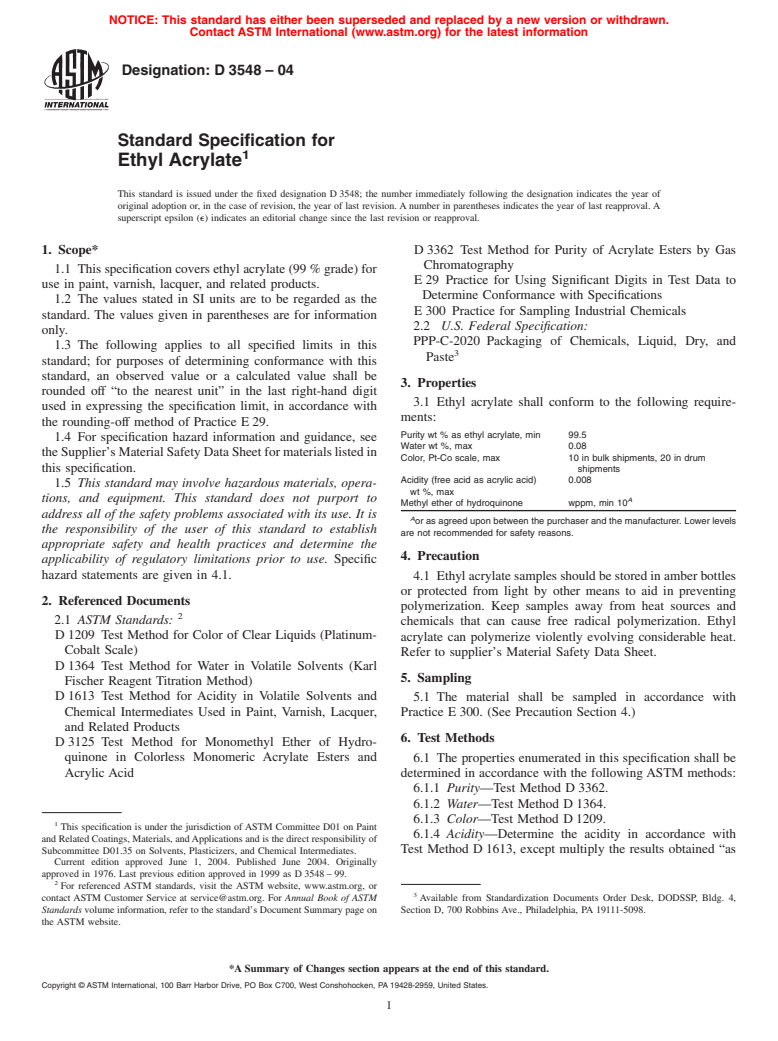

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3548 – 04

Standard Specification for

1

Ethyl Acrylate

This standard is issued under the fixed designation D 3548; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* D 3362 Test Method for Purity of Acrylate Esters by Gas

Chromatography

1.1 This specification covers ethyl acrylate (99 % grade) for

E 29 Practice for Using Significant Digits in Test Data to

use in paint, varnish, lacquer, and related products.

Determine Conformance with Specifications

1.2 The values stated in SI units are to be regarded as the

E 300 Practice for Sampling Industrial Chemicals

standard. The values given in parentheses are for information

2.2 U.S. Federal Specification:

only.

PPP-C-2020 Packaging of Chemicals, Liquid, Dry, and

1.3 The following applies to all specified limits in this

3

Paste

standard; for purposes of determining conformance with this

standard, an observed value or a calculated value shall be

3. Properties

rounded off “to the nearest unit” in the last right-hand digit

3.1 Ethyl acrylate shall conform to the following require-

used in expressing the specification limit, in accordance with

ments:

the rounding-off method of Practice E 29.

Purity wt % as ethyl acrylate, min 99.5

1.4 For specification hazard information and guidance, see

Water wt %, max 0.08

theSupplier’sMaterialSafetyDataSheetformaterialslistedin

Color, Pt-Co scale, max 10 in bulk shipments, 20 in drum

this specification. shipments

Acidity (free acid as acrylic acid) 0.008

1.5 This standard may involve hazardous materials, opera-

wt %, max

tions, and equipment. This standard does not purport to A

Methyl ether of hydroquinone wppm, min 10

address all of the safety problems associated with its use. It is

A

or as agreed upon between the purchaser and the manufacturer. Lower levels

the responsibility of the user of this standard to establish

are not recommended for safety reasons.

appropriate safety and health practices and determine the

4. Precaution

applicability of regulatory limitations prior to use. Specific

hazard statements are given in 4.1.

4.1 Ethyl acrylate samples should be stored in amber bottles

or protected from light by other means to aid in preventing

2. Referenced Documents

polymerization. Keep samples away from heat sources and

2

2.1 ASTM Standards:

chemicals that can cause free radical polymerization. Ethyl

D 1209 Test Method for Color of Clear Liquids (Platinum-

acrylate can polymerize violently evolving considerable heat.

Cobalt Scale)

Refer to supplier’s Material Safety Data Sheet.

D 1364 Test Method for Water in Volatile Solvents (Karl

5. Sampling

Fischer Reagent Titration Method)

D 1613 Test Method for Acidity in Volatile Solvents and

5.1 The material shall be sampled in accordance with

Chemical Intermediates Used in Paint, Varnish, Lacquer, Practice E 300. (See Precaution Section 4.)

and Related Products

6. Test Methods

D 3125 Test Method for Monomethyl Ether of Hydro-

quinone in Colorless Monomeric Acrylate Esters and 6.1 The properties enumerated in this specification shall be

Acrylic Acid determined in accordance with the following

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.