ASTM E1131-08(2014)

(Test Method)Standard Test Method for Compositional Analysis by Thermogravimetry

Standard Test Method for Compositional Analysis by Thermogravimetry

SIGNIFICANCE AND USE

5.1 This test method is intended for use in quality control, material screening, and related problem solving where a compositional analysis is desired or a comparison can be made with a known material of the same type.

5.2 The parameters described should be considered as guidelines. They may be altered to suit a particular analysis, provided the changes are noted in the report.

5.3 The proportion of the determined components in a given mixture or blend may indicate specific quality or end use performance characteristics. Particular examples include the following:

5.3.1 Increasing soot (carbon) content of used diesel lubricating oils indicates decreasing effectiveness.

5.3.2 Specific carbon-to-polymer ratio ranges are required in some elastomeric and plastic parts in order to achieve desired mechanical strength and stability.

5.3.3 Some filled elastomeric and plastic products require specific inert content (for example, ash, filler, reinforcing agent, etc.) to meet performance specifications.

5.3.4 The volatile matter, fixed carbon, and ash content of coal and coke are important parameters. The “ranking” of coal increases with increasing carbon content and decreasing volatile and hydrocarbon, (medium volatility) content.

SCOPE

1.1 This test method provides a general technique incorporating thermogravimetry to determine the amount of highly volatile matter, medium volatile matter, combustible material, and ash content of compounds. This test method will be useful in performing a compositional analysis in cases where agreed upon by interested parties.

1.2 This test method is applicable to solids and liquids.

1.3 The temperature range of test is typically room temperature to 1000°C. Composition between 1 and 100 weight % of individual components may be determined.

1.4 This test method utilizes an inert and reactive gas environment.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard is related ISO 11358 but is more detailed and specific.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1131 − 08 (Reapproved 2014)

Standard Test Method for

1

Compositional Analysis by Thermogravimetry

This standard is issued under the fixed designation E1131; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E1582 Practice for Calibration of Temperature Scale for

Thermogravimetry

1.1 This test method provides a general technique incorpo-

E2040 Test Method for Mass Scale Calibration of Thermo-

rating thermogravimetry to determine the amount of highly

gravimetric Analyzers

volatile matter, medium volatile matter, combustible material,

3

2.2 ISO Standards:

and ash content of compounds. This test method will be useful

ISO 11358 Plastics-Thermogravimetry (TG) of Polymers —

in performing a compositional analysis in cases where agreed

General Principles

upon by interested parties.

1.2 This test method is applicable to solids and liquids. 3. Terminology

3.1 Definitions:

1.3 Thetemperaturerangeoftestistypicallyroomtempera-

ture to 1000°C. Composition between 1 and 100 weight % of 3.1.1 Many of the technical terms used in this test method

are defined in Terminologies E473 and E1142.

individual components may be determined.

1.4 This test method utilizes an inert and reactive gas 3.2 Definitions of Terms Specific to This Standard:

3.2.1 highly volatile matter—moisture, plasticizer, residual

environment.

solvent or other low boiling (200°C or less) components.

1.5 The values stated in SI units are to be regarded as

3.2.2 medium volatile matter—medium volatility materials

standard. No other units of measurement are included in this

such as oil and polymer degradation products. In general, these

standard.

materials degrade or volatilize in the temperature range 200 to

1.6 This standard is related ISO 11358 but is more detailed

750°C.

and specific.

3.2.3 combustible material—oxidizablematerialnotvolatile

1.7 This standard does not purport to address all of the

(in the unoxidized form) at 750°C, or some stipulated tempera-

safety concerns, if any, associated with its use. It is the

ture dependent on material. Carbon is an example of such a

responsibility of the user of this standard to establish appro-

material.

priate safety and health practices and determine the applica-

3.2.4 ash—nonvolatile residues in an oxidizing atmosphere

bility of regulatory limitations prior to use.

which may include metal components, filler content or inert

2. Referenced Documents reinforcing materials.

2

3.2.5 mass loss plateau—a region of a thermogravimetric

2.1 ASTM Standards:

curve with a relatively constant mass.

D3172 Practice for Proximate Analysis of Coal and Coke

E473 Terminology Relating to Thermal Analysis and Rhe-

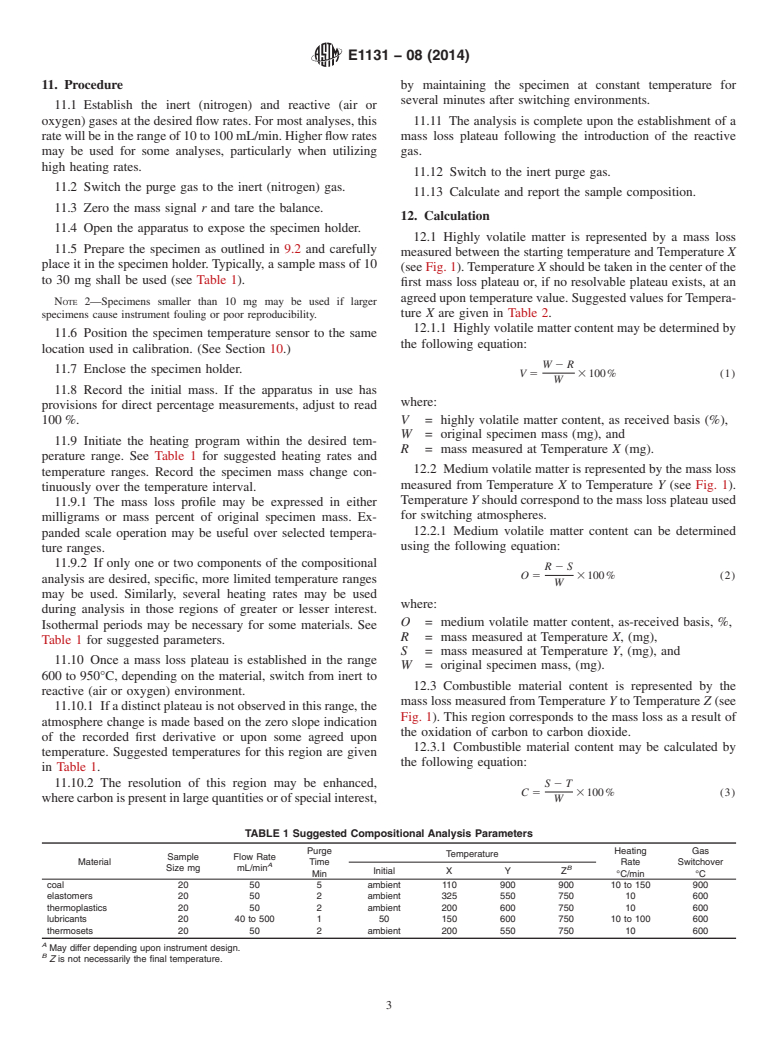

4. Summary of Test Method

ology

4.1 This test method is an empirical technique using ther-

E691 Practice for Conducting an Interlaboratory Study to

mogravimetry in which the mass of a substance, heated at a

Determine the Precision of a Test Method

controlled rate in an appropriate environment, is recorded as a

E1142 Terminology Relating to Thermophysical Properties

function of time or temperature. Mass loss over specific

temperature ranges and in a specific atmosphere provide a

1

ThistestmethodisunderthejurisdictionofASTMCommitteeE37onThermal

compositional analysis of that substance.

Measurements and is the direct responsibility of Subcommittee E37.01 on Calo-

rimetry and Mass Loss.

5. Significance and Use

Current edition approved March 15, 2014. Published April 2014. Originally

5.1 This test method is intended for use in quality control,

approved in 1986. Last previous edition approved in 2008 as E1131 – 08. DOI:

10.1520/E1131-08R14.

material screening, and related problem solving where a

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from International Organization for Standardization (ISO), 1, ch. de

the ASTM website. la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1131 − 08 (2014)

compositional analysis is desired or a comparison can be made temperature range of this test method; (2) a temperature sensor

with a known material of the same type. toprovideanindicationofthespecimen/furnacetemperatureto

61°C; (3) an electrobalance to continuously measure the

5.2 The parameters described should be considered as

specim

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.