ASTM B762-90(1999)

(Test Method)Standard Test Method of Variables Sampling of Metallic and Inorganic Coatings

Standard Test Method of Variables Sampling of Metallic and Inorganic Coatings

SCOPE

1.1 This method provides sampling plans that are intended for use in the inspection of metallic and inorganic coatings on products for the purpose of deciding whether submitted lots of coated products comply with the specifications applicable to the coating.

1.2 The sampling plans are variables plans. In plans of this type, several articles of product are drawn from a production lot. A characteristic of the coating on the drawn articles is measured. The values obtained are used to estimate the number of articles in the lot that do not conform to a numerical limit, for example a minimum thickness. The number is compared to a maximum allowable.

1.3 Variables plans can only be used when the characteristic of interest is measurable, the test method gives a numerical measure of the characteristic, and the specification places a numerical limit on the measured value. It is also necessary that the variation of the characteristic from article to article in a production lot be normally distributed (see Appendix X2). Each article must be tested in the same way (for example, coating thickness must be measured at the same location, see X2.7) so that the values from article to article are comparable. If one or more of these conditions are not met, a variables plan cannot be used. Instead, an attributes plan must be used. These are given in Method B 602 and Guidelines B 697.

1.4 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B762–90(Reapproved 1999)

Standard Test Method of

Variables Sampling of Metallic and Inorganic Coatings

This standard is issued under the fixed designation B 762; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope MIL-STD-105 Sampling Procedures and Tables for Inspec-

tion by Attributes

1.1 This test method provides sampling plans that are

MIL-STD-414 Sampling Procedures and Tables for Inspec-

intended for use in the inspection of metallic and inorganic

tion by Variables for Percent Defective

coatings on products for the purpose of deciding whether

2.3 Other:

submitted lots of coated products comply with the specifica-

ANSI/ASQC Z1.9-1979 Sampling Procedures and Tables

tions applicable to the coating.

for Inspection by Variables for Percent Non-

1.2 The sampling plans are variables plans. In plans of this

Conformance

type, several articles of product are drawn from a production

ANSI/ASQC Z1.4-1981 Sampling Procedures and Tables

lot. A characteristic of the coating on the drawn articles is

for Inspection by Attributes

measured.Thevaluesobtainedareusedtoestimatethenumber

of articles in the lot that do not conform to a numerical limit,

3. Terminology Definitions

for example a minimum thickness. The number is compared to

3.1 destructive test—a test that destroys the tested article or

a maximum allowable.

makes it nonconforming to a requirement.

1.3 Variables plans can only be used when the characteristic

3.2 nondestructive test—a test that neither destroys the

of interest is measurable, the test method gives a numerical

tested article nor makes it nonconforming to a requirement.

measure of the characteristic, and the specification places a

3.3 inspection lot—a collection of articles of the same kind

numerical limit on the measured value. It is also necessary that

that is submitted to inspection for acceptance or rejection as a

the variation of the characteristic from article to article in a

group.

production lot be normally distributed (see Appendix X2).

3.4 sample—articles randomly selected from an inspection

Each article must be tested in the same way (for example,

lot whose quality is used to decide whether or not the

coating thickness must be measured at the same location, see

inspection lot is of acceptable quality.

X2.7) so that the values from article to article are comparable.

3.5 standard deviation—a measure of dispersion equal to

If one or more of these conditions are not met, a variables plan

the square root of the mean of the squares of the deviations

cannot be used. Instead, an attributes plan must be used. These

from the arithmetic mean of the distribution (see 9.2.6).

are given in Test Method B 602 and Guide B 697.

1.4 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

4.1 The plans in this test method provide the same protec-

responsibility of the user of this standard to establish appro-

tion as the attributes plans in Table 1, Table 2, and Table 3 of

priate safety and health practices and determine the applica-

Test Method B 602 and are interchangeable with them when

bility of regulatory limitations prior to use.

the conditions necessary for variables sampling exist. This

2. Referenced Documents method has no plan comparable to Table 4 of Test Method

B 602, because variables plans are subject to an excessive

2.1 ASTM Standards:

probability of error when the number of nonconforming

B 602 Test Method for Attribute Sampling of Metallic and

2 articles in a lot is expected to be approximately 1% or less as

Inorganic Coatings

it is for the Table 4 plan. Also for this reason, comparable

B 697 Guide for Selection of Sampling Plans for Inspection

2 variables plans are not given for the smallest lot sizes of Table

of Electrodeposited Metallic and Inorganic Coatings

1 and Table 2 of Test Method B 602. The plans of Table 4,

2.2 Military Standards:

Table 1, and Table 2 in Test Method B 602 are described as

This method is under the jurisdiction ofASTM Committee B-8 on Metallic and

Inorganic Coatingsand is the direct responsibility of Subcommittee B08.10on

General Test Methods. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Current edition approved Oct. 15, 1990. Published November 1990. Originally Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

published as B 762 – 86. Last previous edition B 762 – 86. Available from theAmerican National Standards Institute, 11W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 02.05. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B762

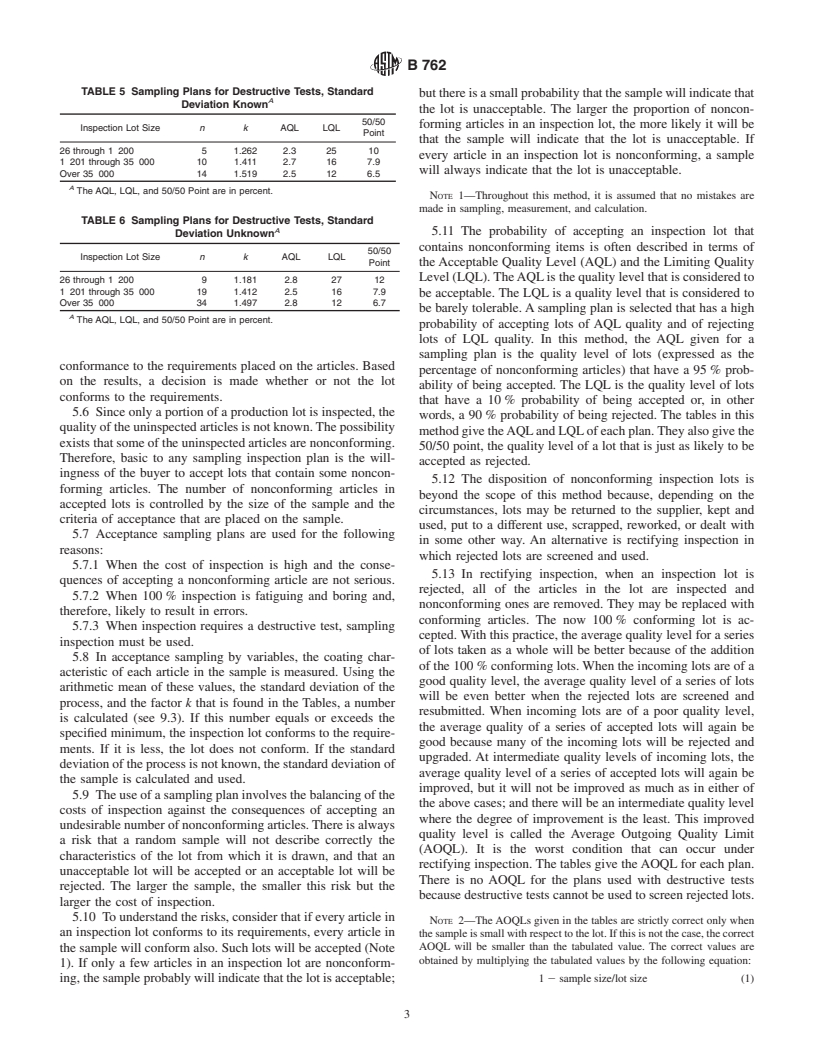

TABLE 2 Level II—Sampling Plans for Nondestructive Tests,

Level I, Level II, and Level III respectively. For consistency,

A

Standard Deviation Unknown

Table 1 and Table 2 of this method are described as Level II

Inspection 50/50

since they are comparable to Table 1 of Test Method B 602,

nk AQL LQL AOQL

Lot Size Point

and Table 3 and Table 4 are described as Level III.

91 through 16 1.663 1.0 12 4.8 2.4

4.2 The main advantage of a variables sampling plan over

an attributes plan is that fewer articles need to be inspected to

281 through 29 1.649 1.7 10 5.0 2.6

obtain the same protection. For example, a sample of 12 using

501 through 40 1.713 1.7 8.2 4.3 2.2

variables can give the same protection as a sample of 50 using

1 200

attributes.Ontheotherhand,moreexpensivetestmethodsmay

1 201 through 61 1.704 2.1 7.4 4.4 2.5

3 200

be required to yield the measurements required by variables

3 201 through 92 1.778 2.0 5.9 3.8 2.2

sampling.

10 000

4.3 Generally, thickness is the only characteristic of a

10 001 through 137 1.825 2.0 4.9 3.4 2.0

35 000

coating that meets the conditions of a variables plan given in

Over 35 000 223 1.893 1.9 4.0 3.0 1.9

1.3. For that reason, the plans in this method are designed to be

A

The AQL, LQL, 50/50 Point, and AOQL are in percent.

used when the specification for the characteristic in question is

aminimumvalue,whichistheusualcaseforcoatingthickness.

TABLE 3 Level III—Sampling Plans for Nondestructive Tests,

Variables plans can be used when the limit is a maximum and

A

Standard Deviation Known

when there are both a minimum and a maximum. Plans for

Inspection 50/50

these cases are given in the references.

nk AQL LQL AOQL

Lot Size Point

4.4 The sampling plans in Table 1 and Table 2 of this

51 through 6 1.432 1.8 18 7.6 3.8

methodareconsideredtobestandardfornondestructivetesting

and will be used unless the buyer specifies otherwise. Table 5

151 through 10 1.411 2.7 16 7.9 4.1

andTable 6 will be used for destructive testing; these plans use

281 through 14 1.470 2.8 13 7.1 3.5

smaller samples to reduce the cost of inspection with a

resultant reduction of the ability to distinguish between con- 501 through 23 1.492 3.3 11 6.8 3.8

1 200

forming and nonconforming lots.

1 201 through 30 1.551 3.2 9.4 6.0 3.5

4.5 Additional variables plans are given in Appendix X3.

3 200

Alsofoundthereareinstructionsforthecalculationofplansfor 3 201 through 44 1.618 3.1 7.7 5.3 3.2

16 000

needs that are not covered.

16 001 through 66 1.680 3.0 6.4 4.6 3.0

35 000

5. Significance and Use Over 35 000 103 1.719 3.0 5.6 4.4 2.9

A

The AQL, LQL, 50/50 Point, and AOQL are in percent.

5.1 Sampling inspection permits the estimation of the over-

all quality of a group of product articles through the inspection

TABLE 4 Level III—Sampling Plans for Nondestructive Tests,

of a relatively small number of product articles drawn from the

A

Standard Deviation Unknown

group.

Inspection 50/50

5.2 The specification of a sampling plan provides purchas-

nk AQL LQL AOQL

Lot Size Point

ers and sellers a means of identifying the minimum quality

51 through 12 1.433 1.7 19 7.6 3.8

level that is considered to be satisfactory.

5.3 Because sampling plans yield estimates of the quality of

151 through 19 1.410 2.6 16 7.9 3.7

a product, the results of the inspection are subject to error. 280

281 through 29 1.470 2.8 13 7.1 3.8

Through the selection of a sampling plan, the potential error is

known and controlled.

501 through 48 1.494 3.3 11 6.7 3.8

1 200

1 201 through 66 1.551 3.2 9.4 6.0 3.5

3 200

TABLE 1 Level II—Sampling Plans for Nondestructive Tests,

3 201 through 102 1.618 3.1 7.7 5.3 3.2

A

Standard Deviation Known

16 000

16 001 through 159 1.680 3.0 6.4 4.6 3.0

Inspection 50/50

nk AQL LQL AOQL

35 000

Lot Size Point

Over 35 000 248 1.717 3.0 5.6 4.3 2.9

91 through 7 1.664 1.1 12 4.8 2.4

A

The AQL, LQL, 50/50 Point, and AOQL are in percent.

281 through 12 1.649 1.7 10 5.0 2.6

501 through 16 1.712 1.7 8.2 4.4 2.3

5.4 Sampling inspection is used when a decision must be

1 200

madeaboutwhattodowithaquantityofarticles.Thisquantity

1 201 through 25 1.704 2.1 7.4 4.4 2.5

may be a shipment from a supplier, articles that are ready for

3 200

3 201 through 36 1.778 2.0 5.9 3.8 2.2

a subsequent manufacturing operation, or articles ready for

10 000

shipment to a customer.

10 001 through 52 1.829 2.0 4.9 3.4 2.1

5.5 In sampling inspection, a relatively small number of

35 000

Over 35 000 82 1.893 1.9 4.0 2.9 1.9

articles(thesample)isselectedrandomlyfromalargernumber

A

The AQL, LQL, 50/50 Point, and AOQL are in percent. of articles (the inspection lot); the sample is inspected for

B762

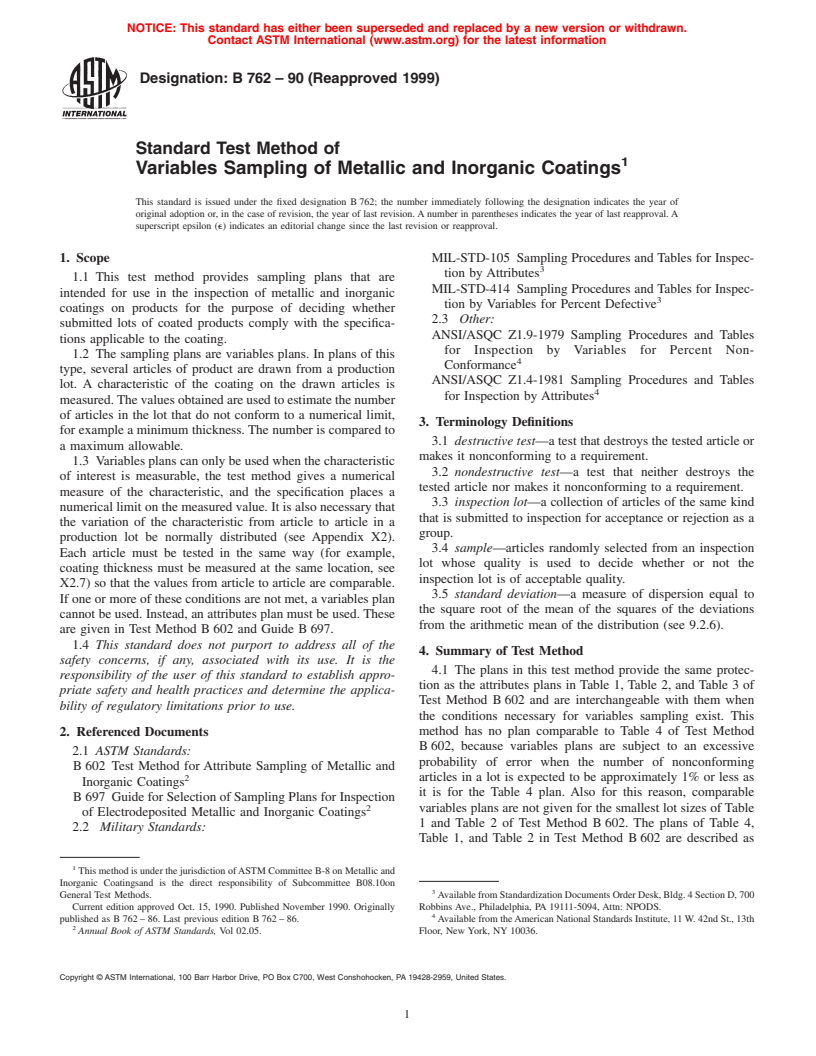

TABLE 5 Sampling Plans for Destructive Tests, Standard

butthereisasmallprobabilitythatthesamplewillindicatethat

A

Deviation Known

the lot is unacceptable. The larger the proportion of noncon-

50/50

forming articles in an inspection lot, the more likely it will be

Inspection Lot Size nk AQL LQL

Point

that the sample will indicate that the lot is unacceptable. If

26 through 1 200 5 1.262 2.3 25 10

every article in an inspection lot is nonconforming, a sample

1 201 through 35 000 10 1.411 2.7 16 7.9

will always indicate that the lot is unacceptable.

Over 35 000 14 1.519 2.5 12 6.5

A

The AQL, LQL, and 50/50 Point are in percent.

NOTE 1—Throughout this method, it is assumed that no mistakes are

made in sampling, measurement, and calculation.

TABLE 6 Sampling Plans for Destructive Tests, Standard

A

5.11 The probability of accepting an inspection lot that

Deviation Unknown

contains nonconforming items is often described in terms of

50/50

Inspection Lot Size nk AQL LQL

Point the Acceptable Quality Level (AQL) and the Limiting Quality

Level (LQL).TheAQLis the quality level that is considered to

26 through 1 200 9 1.181 2.8 27 12

1 201 through 35 000 19 1.412 2.5 16 7.9

be acceptable. The LQL is a quality level that is considered to

Over 35 000 34 1.497 2.8 12 6.7

be barely tolerable.Asampling plan is selected that has a high

A

The AQL, LQL, and 50/50 Point are in percent.

probability of accepting lots of AQL quality and of rejecting

lots of LQL quality. In this method, the AQL given for a

sampling plan is the quality level of lots (expressed as the

conformance to the requirements placed on the articles. Based

percentage of nonconforming articles) that have a 95 % prob-

on the results, a decision is made whether or not the lot

ability of being accepted. The LQL is the quality level of lots

conforms to the requirements.

that have a 10 % probability of being accepted or, in other

5.6 Since only a portion of a production lot is inspected, the

words, a 90 % probability of being rejected. The tables in this

qualityoftheuninspectedarticlesisnotknown.Thepossibility

methodgivetheAQLandLQLofeachplan.Theyalsogivethe

exists that some of the uninspected articles are nonconforming.

50/50 point, the quality level of a lot that is just as likely to be

Therefore, basic to any sampling inspection plan is the will-

accepted as rejected.

ingness of the buyer to accept lots that contain some noncon-

5.12 The disposition of nonconforming inspection lots is

forming articles. The number of nonconforming articles in

beyond the scope of this method because, depending on the

accepted lots is controlled by the size of the sample and the

circumstances, lots may be returned to the supplier, kept and

criteria of acceptance that are placed on the sample.

used, put to a different use, scrapped, reworked, or dealt with

5.7 Acceptance sampling plans are used for the following

in some other way. An alternative is rectifying inspection in

reasons:

which rejected lots are screened and used.

5.7.1 When the cost of inspection is high and the conse-

5.13 In rectifying inspection, when an inspection lot is

quences of accepting a nonconforming article are not serious.

rejected, all of the articles in the lot are inspected and

5.7.2 When 100 % inspection is fatiguing and boring and,

nonconforming ones are removed. They may be replaced with

therefore, likely to result in errors.

conforming articles. The now 100 % conforming lot is ac-

5.7.3 When inspection requires a destructive test, sampling

cepted. With this practice, the average quality level for a series

inspection must be used.

of lots taken as a whole will be better because of the addition

5.8 In acceptance sampling by variables, the coating char-

of the 100 % conforming lots. When the incoming lots are of a

acteristic of each article in the sample is measured. Using the

good quality level, the average quality level of a series of lots

arithmetic mean of these values, the standard deviation of the

will be even better when the rejected lots are screened and

process, and the factor k that is found in the Tables, a number

resubmitted. When incoming lots are of a poor quality level,

is calculated (see 9.3). If this number equals or exceeds the

the average quality of a series of accepted lots will again be

specified minimum, the inspection lot conforms to the require-

good because many of the incoming lots will be rejected and

ments. If it is less, the lot does not conform. If the standard

upgraded. At intermediate quality levels of incoming lots, the

deviationoftheprocessisnotknown,thestandarddeviationof

average quality level of a series of accepted lots will again be

the sample is calculated and used.

improved, but it will not be improved as much as in either of

5.9 Theuseofasamplingplaninvolvesthebalancingofthe

the above cases; and there will be an intermediate quality level

costs of inspection against the consequences of accepting an

where the degree of improvement is the least. This improved

undesirablenumberofnonconformingarticles.Thereisalways

quality level is called the Average Outgoing Quality Limit

a risk that

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.