ASTM D5656-10(2017)

(Test Method)Standard Test Method for Thick-Adherend Metal Lap-Shear Joints for Determination of the Stress-Strain Behavior of Adhesives in Shear by Tension Loading

Standard Test Method for Thick-Adherend Metal Lap-Shear Joints for Determination of the Stress-Strain Behavior of Adhesives in Shear by Tension Loading

SIGNIFICANCE AND USE

5.1 This test method can be used to determine the stress-strain properties of an adhesive in shear and to establish the proportional-limit of the stress-stain relationship. This data may be useful for the design and analysis of adhesively bonded joints.

5.2 This test method is not intended to determine adhesion characteristics of an adhesive to a particular substrate; rather this test method is intended to characterize the adhesive shear stress-strain properties that may be relevant for design considerations.

5.3 This test method has been developed and applied using bonded aluminum adherends. At this time no assumptions regarding the validity of this test method with non-aluminum adherends can be made.

SCOPE

1.1 This test method covers the preparation and testing of thick-adherend lap-shear samples for the determination of the stress-strain behavior of adhesives.

1.2 This test method covers data reduction and analysis of stress-strain curves obtained using thick-adherend lap-shear samples.

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound units in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 7.3.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5656 − 10 (Reapproved 2017)

Standard Test Method for

Thick-Adherend Metal Lap-Shear Joints for Determination of

the Stress-Strain Behavior of Adhesives in Shear by

1

Tension Loading

This standard is issued under the fixed designation D5656; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E4 Practices for Force Verification of Testing Machines

1.1 This test method covers the preparation and testing of

3. Terminology

thick-adherend lap-shear samples for the determination of the

3.1 Definitions:

stress-strain behavior of adhesives.

3.1.1 Many terms in this test method are defined in Termi-

1.2 This test method covers data reduction and analysis of

nology D907.

stress-strain curves obtained using thick-adherend lap-shear

3.2 Definitions of Terms Specific to This Standard:

samples.

3.2.1 knee, n—inflection point on a load-deflection curve;

1.3 The values stated in SI units are to be regarded as the

the point at which plastic yielding of the adhesive begins to

standard. The inch-pound units in parentheses are for informa-

dominate the deformation response of the load-deflection

tion only.

curve.

1.4 This standard does not purport to address all of the

3.2.2 panel, n—two plates of a rigid material having the

safety concerns, if any, associated with its use. It is the

same dimensions that are adhesively bonded together on one

responsibility of the user of this standard to establish appro-

face such that the thickness of the panel is approximately twice

priate safety, health, and environmental practices and deter-

the thickness of each individual plate.

mine the applicability of regulatory limitations prior to use.

Specific precautionary statements are given in 7.3. 4. Summary of Test Method

1.5 This international standard was developed in accor-

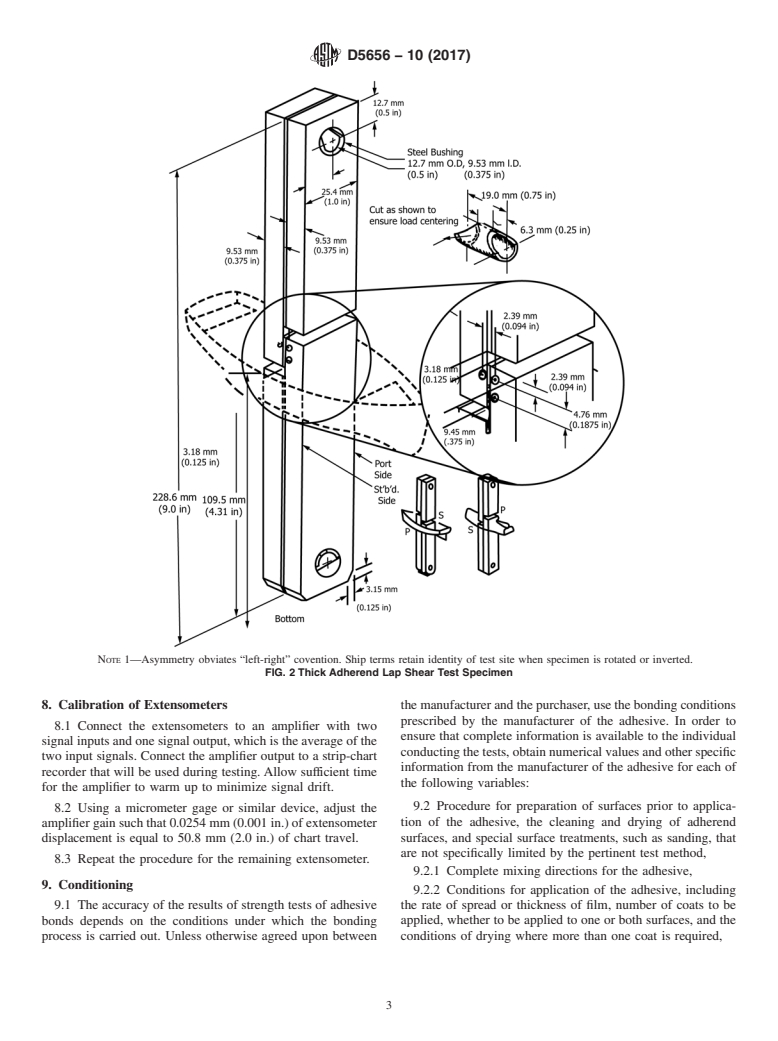

4.1 This test method consists of testing thick-adherend

dance with internationally recognized principles on standard-

lap-shear samples whereby a tensile load is applied to the

ization established in the Decision on Principles for the

sample but the adhesive is placed in shear. Unlike Guide

Development of International Standards, Guides and Recom-

D4896, the adherends used in this standard test method are

mendations issued by the World Trade Organization Technical

thick and rigid, peel forces are minimized and the shear

Barriers to Trade (TBT) Committee.

stress-strain properties of the adhesive are obtained. Refer-

enced data presents a finite element analysis of the thick-

2. Referenced Documents

adherent metal lap shear specimen and calculates the effect of

2

3

2.1 ASTM Standards:

varying the adherent and adhesive stiffness. User of this

D907 Terminology of Adhesives

standard is cautioned that since the stress is not totally uniform

D2651 GuideforPreparationofMetalSurfacesforAdhesive

across the over-lap of the specimen, factors such as adhesive

Bonding

stiffness, adherent stiffness and location of shear strain mea-

D4896 Guide for Use ofAdhesive-Bonded Single Lap-Joint

surement along the length of the bond can affect the experi-

3,4

Specimen Test Results

mentally obtained load-displacement curve.

NOTE 1—The peel forces generated during testing are a function of the

bending deformation in the adherends. Greater adherend stiffness results

1

This test method is under the jurisdiction of ASTM Committee D14 on

in less bending and smaller peel forces.

Adhesives and is the direct responsibility of Subcommittee D14.80 on Metal

Bonding Adhesives.

Current edition approved Nov. 15, 2017. Published November 2017. Originally

3

approved in 1995. Last previous edition approved in 2010 as D5656 – 10. DOI: Kassapoglou, C. and Adelmann, John C., “KGR-1 Thick Adherend Specimen

rd

10.1520/D5656-10R17. Evaluation for the Determination of Adhesive Mechanical Properties,” 23 Inter-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or national SAMPE Conference, Oct. 21–24, 1991.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Krieger, R. B., Jr., “Stiffness Characteristics of StructuralAdhesives for Stress

Standards volume information, refer to the standard’s Document Summary page on Analysis in Hostile Environment,” American Cyanamid Co., Havre de Grace, MD,

the ASTM website. 1975.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5656 − 10 (201

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.