ASTM F2989-12

(Specification)Standard Specification for Metal Injection Molded Unalloyed Titanium Components for Surgical Implant Applications

Standard Specification for Metal Injection Molded Unalloyed Titanium Components for Surgical Implant Applications

SCOPE

1.1 This specification covers the chemical, mechanical, and metallurgical requirements for three grades of metal injection molded (MIM) unalloyed titanium components in two types to be used in the manufacture of surgical implants.

1.2 The Type 1 MIM components covered by this specification may have been densified beyond their as-sintered density by post-sinter processing.

1.3 Values in either inch-pound or SI are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore each system shall be used independent of the other. Combining values from the two systems may result in non-conformance with the specification.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2989 −12

StandardSpecification for

Metal Injection Molded Unalloyed Titanium Components for

Surgical Implant Applications

This standard is issued under the fixed designation F2989; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E407Practice for Microetching Metals and Alloys

E539TestMethodforAnalysisofTitaniumAlloysbyX-Ray

1.1 This specification covers the chemical, mechanical, and

Fluorescence Spectrometry

metallurgical requirements for three grades of metal injection

E1409TestMethodforDeterminationofOxygenandNitro-

molded (MIM) unalloyed titanium components in two types to

gen in Titanium and Titanium Alloys by the Inert Gas

be used in the manufacture of surgical implants.

Fusion Technique

1.2 The Type 1 MIM components covered by this specifi-

E1447Test Method for Determination of Hydrogen in Tita-

cation may have been densified beyond their as-sintered

nium and Titanium Alloys by Inert Gas Fusion Thermal

density by post-sinter processing.

Conductivity/Infrared Detection Method

E1941Test Method for Determination of Carbon in Refrac-

1.3 Values in either inch-pound or SI are to be regarded

separately as standard. The values stated in each system may toryandReactiveMetalsandTheirAlloysbyCombustion

Analysis

not be exact equivalents; therefore each system shall be used

independent of the other. Combining values from the two E2371Test Method for Analysis of Titanium and Titanium

Alloys by Atomic Emission Plasma Spectrometry

systems may result in non-conformance with the specification.

E2626Guide for Spectrometric Analysis of Reactive and

1.4 This standard does not purport to address all of the

Refractory Metals

safety concerns, if any, associated with its use. It is the

F67Specification for Unalloyed Titanium, for Surgical Im-

responsibility of the user of this standard to establish appro-

plant Applications (UNS R50250, UNS R50400, UNS

priate safety and health practices and determine the applica-

R50550, UNS R50700)

bility of regulatory limitations prior to use.

F601Practice for Fluorescent Penetrant Inspection of Me-

2. Referenced Documents tallic Surgical Implants

2 F629Practice for Radiography of Cast Metallic Surgical

2.1 ASTM Standards:

Implants

B243Terminology of Powder Metallurgy

SI 10American National Standard for Use of the Interna-

B311Test Method for Density of Powder Metallurgy (PM)

tional System of Units (SI): The Modern Metric System

Materials Containing Less Than Two Percent Porosity

2.2 ISO Standards:

B923Test Method for Metal Powder Skeletal Density by

ISO5832-3ImplantsforSurgery—MetallicMaterials—Part

Helium or Nitrogen Pycnometry

3: Wrought Titanium 6-Aluminum 4-Vanadium Alloy

E3Guide for Preparation of Metallographic Specimens

ISO 6892Metallic Materials—Tensile Testing at Ambient

E8/E8MTest Methods for Tension Testing of Metallic Ma-

Temperature

terials

ISO 9001Quality Management Systems—Requirements

E29Practice for Using Significant Digits in Test Data to

2.3 Aerospace Material Specifications:

Determine Conformance with Specifications

AMS 2249Chemical Check Analysis Limits, Titanium and

E165Practice for Liquid Penetrant Examination for General

Titanium Alloys

Industry

2.4 MPIF Standards:

Standard 10Determination of the Tensile Properties of

This specification is under the jurisdiction of ASTM Committee F04 on

Powder Metallurgy Materials

Medical and Surgical Materials and Devices and is the direct responsibility of

Subcommittee F04.12 on Metallurgical Materials.

Current edition approved Dec. 1, 2012. Published January 2013. DOI: 10.1520/ Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

F2989-12. 4th Floor, New York, NY 10036, http://www.ansi.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or AvailablefromSAEInternational(SAE),400CommonwealthDr.,Warrendale,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM PA 15096-0001, http://aerospace.sae.org.

Standards volume information, refer to the standard’s Document Summary page on Available from Metal Powder Industries Federation (MPIF), 105 College Rd.

the ASTM website. East, Princeton, NJ 08540, http://www.mpif.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2989−12

Standard 42Determination of Density of Compacted or 3.3.10 relative density, n—the density ratio, often expressed

Sintered Powder Metallurgy Product as a percentage, of the density of a porous material to the

absolute density of the same material, completely free of

Standard 50 Preparing and Evaluating Metal Injection

Molded Sintered/Heat Treated Tension Specimens porosity.

Standard 63Density Determinations of MIM Components

3.3.11 sintering, v—themetallurgicalbondingofparticlesin

(Gas Pycnometry)

a MIM component resulting from a thermal treatment at a

Standard 64Terms Used in Metal Injection Molding

temperature below the melting point of the main constituent.

3.3.12 Type 1, n—a MIM component that may have been

3. Terminology

desified beyond its as-sintered density by post-sinter process-

ing.

3.1 DefinitionsofpowdermetallurgyandMIMtermscanbe

foundinTerminologyB243andMPIFStandard64.Additional

3.3.13 Type 2, n—a MIM component that shows the as-

descriptive information is available in the Related Material

sintered density and was not densified after sintering.

Section of Vol. 02.05 of the Annual Book of ASTM Standards.

4. Ordering Information

3.2 The materials produced by means of the metal injection

4.1 Include with inquiries and orders for material under this

moldingprocessaredesignatedbytheprefix,“MIM”,followed

specification the following information:

by the appropriate designation for the alloy grade. The MIM

4.1.1 Quantity,

designates that it was made by metal injection molding.

4.1.2 ASTM specification and date of issue,

3.3 Definitions of Terms Specific to This Standard:

4.1.3 Grade (MIM 1, MIM 2 or MIM 3),

3.3.1 absolute density, n—the value of density used to 4.1.4 Type (1 or 2),

characterize a powder material with a particular chemical 4.1.5 Units to be certified—SI or Inch-Pounds,

composition as if it were a fully dense material, completely 4.1.6 Component configuration (engineering drawing or 3D

free of porosity. solid model, or both) and dimensional requirements,

4.1.7 Condition (5.2),

3.3.1.1 Discussion—For the purposes of this specification,

4.1.8 Mechanical properties (if applicable),

the skeletal density (also referred to as pycnometer density)

4.1.9 Finish (5.2),

measured on the raw material powders using the pycnometry

4.1.10 Special tests (9, 10 and 11), if any, and

method of Test Method B923 shall be used to represent the

4.1.11 Other requirements.

absolute density of the particular chemical composition.

3.3.2 debinding, v—a step between molding and sintering

5. Materials and Manufacture

where the majority of the binder used in molding is extracted

5.1 Components conforming to this specification shall be

by heat, solvent, a catalyst, or other techniques.

produced by the metal injection molding process using unal-

loyed metal powders with major elemental composition meet-

3.3.3 feedstock, n—in metal injection molding, a moldable

mixture of metal powder and binder. ing the chemical requirements of Table 1.

5.2 Post-sintering operations may be employed to achieve

3.3.4 feedstock batch, n—a specified quantity of feedstock

the desired density, shape, size, surface finish, or other com-

made up of the same lot of metallic powders and the same lot

ponent properties. The post-sintering operations shall be

of binder materials mixed under the same conditions at

agreed upon between the supplier and purchaser.

essentially the same time.

5.3 The condition and finish of the components shall be

3.3.5 lot, n—a specified quantity of components made up of

agreed upon between the supplier and purchaser.

the same batch of feedstock, debound, sintered, and post-

processed under the same conditions at essentially the same

6. Chemical Requirements

time.

6.1 The components supplied under this specification shall

3.3.6 metal injection molded component, n—product fabri-

conform to the chemical requirements in Table 1.The supplier

cated by a metal injection molding process consisting of

shall not ship components with chemistry outside the require-

mixing metal powders with binders to make a feedstock,

ments specified in Table 1.

introducing this feedstock into a mold by injection or other

means, debinding to remove the binders, and sintering.

TABLE 1 Chemical Composition

3.3.7 near net component, n—a component that meets

Composition for both Type 1 and Type 2

dimensional tolerance as built with little post processing.

Composition, % (mass/mass)

3.3.8 net component, n—a component that meets dimen- Element Grade MIM 1 Grade MIM 2 Grade MIM 3

sional tolerance as built with no post processing. Nitrogen, max 0.03 0.03 0.05

Carbon, max 0.08 0.08 0.08

3.3.9 pre-alloyed powder, n—powder composed of two or

Hydrogen, max 0.015 0.015 0.015

Iron, max 0.020 0.030 0.030

more elements that are alloyed in the powder manufacturing

Oxygen, max 0.18 0.25 0.30

process in which the particles are of the same nominal

Titanium Balance Balance Balance

composition throughout.

F2989−12

6.2 Chemical analysis of the finished component or a 7.1.1 The components supplied under this specification

representative sample shall be used for reporting all chemical shallconformtothemechanicalpropertyrequirementsinTable

requirements. Any representative sample shall be produced 3.

from the same feedstock batch, debound, sintered, and post

7.1.2 TestspecimensshallbetakenfromaMIMcomponent

processed concurrently with the finished components that it

if possible, or from a representative sample or molded tensile

represents.

specimen.Arepresentative sample or molded tensile specimen

6.2.1 Requirements for the major and minor elemental

may only be used only if the component configuration is such

constituents are listed in Table 1. Also listed are important

that a tensile specimen cannot be obtained from the compo-

residualelements.Thepercentageoftitaniumisdeterminedby

nent.

difference and need not be determined or certified.

7.1.3 The number of tensile tests should be agreed upon

6.2.2 Intentional elemental additions other than those speci-

between the supplier and the purchaser.

fied in Table 1 are not permitted.

7.2 Representative samples or molded tensile specimens

6.2.3 Analysis for elements not listed in Table 1 is not

shall be produced from the same feedstock batch, debound,

required to verify compliance with this specification.

sintered and post processed concurrently with the finished

6.3 Product Analysis:

components that they represent.

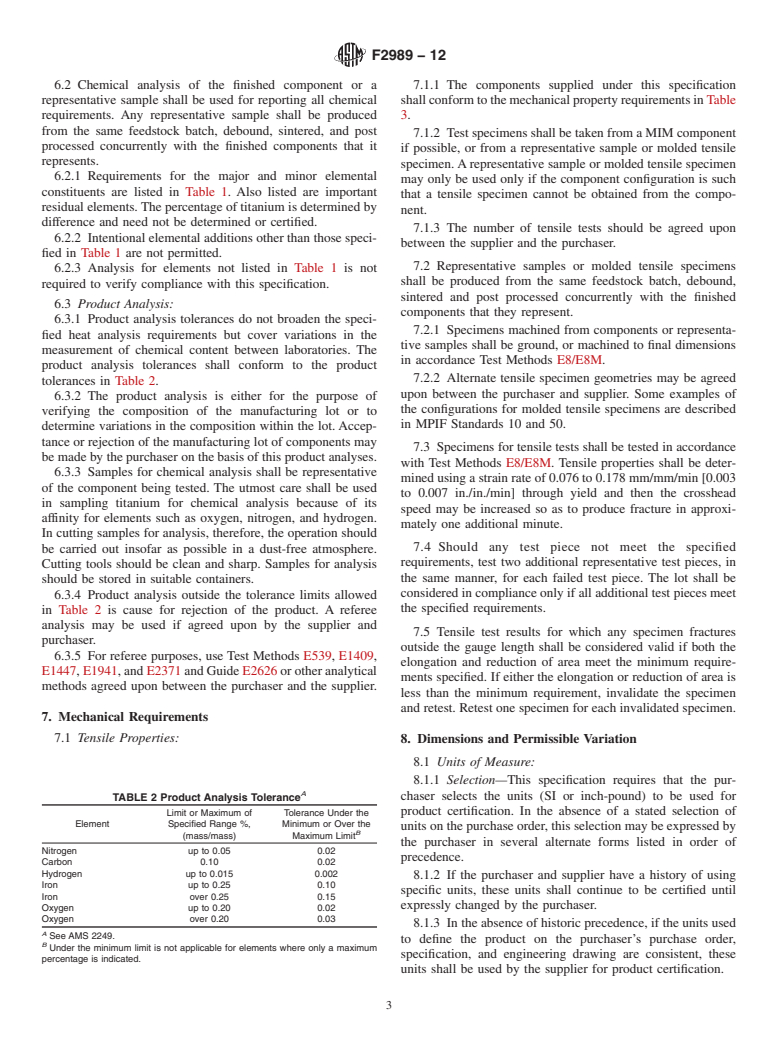

6.3.1 Product analysis tolerances do not broaden the speci-

7.2.1 Specimens machined from components or representa-

fied heat analysis requirements but cover variations in the

tive samples shall be ground, or machined to final dimensions

measurement of chemical content between laboratories. The

in accordance Test Methods E8/E8M.

product analysis tolerances shall conform to the product

7.2.2 Alternate tensile specimen geometries may be agreed

tolerances in Table 2.

upon between the purchaser and supplier. Some examples of

6.3.2 The product analysis is either for the purpose of

the configurations for molded tensile specimens are described

verifying the composition of the manufacturing lot or to

in MPIF Standards 10 and 50.

determine variations in the composition within the lot.Accep-

tance or rejection of the manufacturing lot of components may

7.3 Specimens for tensile tests shall be tested in accordance

bemadebythepurchaseronthebasisofthisproductanalyses.

with Test Methods E8/E8M. Tensile properties shall be deter-

6.3.3 Samples for chemical analysis shall be representative

minedusingastrainrateof0.076to0.178mm/mm/min[0.003

of the component being tested. The utmost care shall be used

to 0.007 in./in./min] through yield and then the crosshead

in sampling titanium for chemical analysis because of its

speed may be increased so as to produce fracture in approxi-

affinity for elements such as oxygen, nitrogen, and hydrogen.

mately one additional minute.

In cutting samples for analysis, therefore, the operation should

7.4 Should any test piece not meet the specified

be carried out insofar as possible in a dust-free atmosphere.

requirements, test two additional representative test pieces, in

Cutting tools should be clean and sharp. Samples for analysis

the same manner, for each failed test piece. The lot shall be

should be stored in suitable containers.

consideredincomplianceonlyifalladditionaltestpiecesmeet

6.3.4 Product analysis outside the tolerance limits allowed

the specified requirements.

in Table 2 is cause for rejection of the product. A referee

analysis may be used if agreed upon by the supplier and

7.5 Tensile test results for which any specimen fractures

purchaser.

outside the gauge length shall be considered valid if both the

6.3.5 For referee purposes, use Test Methods E539, E1409,

elongation and reduction of area meet the minimum require-

E1447,E1941,andE2371andGuideE2626orotheranalytical

ments specified. If either the elongation or reduction of area is

methods agreed upon between the purchaser and the supplier.

less than the minimum requirement, invalidate the specimen

and retest. Retest one specimen for each invalidated specimen.

7. Mechanical Requirements

7.1 Tensile Properties:

8. Dimensions and Permissible Variation

8.1 Units of Measure:

8.1.1 Selection—This specification requires that the pur-

A

chaser selects the units (SI or inch-pound) to be used for

TABLE 2 Product Analysis Tolerance

product certification. In the absence of a stated selection of

Limit or Maximum of Tolerance Under the

Element Specified Range %, Minimum or Over the

unitsonthepurchaseorder,thisselectionmaybeexpressedby

B

(mass/mass) Maximum Limit

the purchaser in several alternate forms listed in order of

Nitrogen up to 0.05 0.02

precedence.

Carbon 0.10 0.02

Hydrogen up to 0.015 0.002

8.1.2 If the purchaser and supplier have a history of using

Iron up to 0.25 0.10

specific units, these units shall continue to be certified until

Iron over 0.25 0.15

expressly changed by the purchaser.

Oxygen up to 0.20 0.02

Oxygen over 0.20 0.03

8.1.3 Intheabsenceofhistoricprecedence,iftheunitsused

A

See AMS 2249.

to define the product on the purchaser’s purchase order,

B

Under the minimum limit is not applicable for elements where only a maximum

specification, and engineer

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.