ASTM C1581-04

(Test Method)Standard Test Method for Determining Age at Cracking and Induced Tensile Stress Characteristics of Mortar and Concrete under Restrained Shrinkage

Standard Test Method for Determining Age at Cracking and Induced Tensile Stress Characteristics of Mortar and Concrete under Restrained Shrinkage

SIGNIFICANCE AND USE

This test method is for relative comparison of materials and is not intended to determine the age at cracking of mortar or concrete in any specific type of structure, configuration, or exposure.

This test method is applicable to mixtures with aggregates of 0.5-in. (13-mm) maximum nominal size or less.

This test method is useful for determining the relative likelihood of early-age cracking of different cementitious mixtures and for aiding in the selection of cement-based materials that are less likely to crack under retrained shrinkage. Actual cracking tendency in service depends on many variables including type of structure, degree of restraint, rate of property development, construction and curing methods, and environmental conditions.

This test method can be used to determine the relative effects of material variations on induced tensile stresses and cracking potential. These variations can include, but are not limited to, aggregate source, aggregate gradation, cement type, cement content, water content, supplementary cementing materials, or chemical admixtures.

For materials that have not cracked during the test, the rate of tensile stress development at the time the test is terminated provides a basis for comparison of the materials.

SCOPE

1.1 This test method covers the laboratory determination of the age at cracking and induced tensile stress characteristics of mortar or concrete specimens under restrained shrinkage. The procedure can be used to determine the effects of variations in the proportions and material properties of mortar or concrete on cracking due to both drying shrinkage and deformations caused by autogenous shrinkage and heat of hydration.

1.2 This test method is not intended for expansive materials.

1.3 The values stated in inch-pound units are to be regarded as standard. The values shown in parenthesis are in SI units and are given for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use. (Warning-Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure.)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1581 – 04

Standard Test Method for

Determining Age at Cracking and Induced Tensile Stress

Characteristics of Mortar and Concrete under Restrained

Shrinkage

This standard is issued under the fixed designation C 1581; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Test Specimens in the Laboratory

C 387 SpecificationforPackagedDry,CombinedMaterials

1.1 This test method covers the laboratory determination of

for Mortar and Concrete

the age at cracking and induced tensile stress characteristics of

C 595 Specification for Blended Hydraulic Cements

mortar or concrete specimens under restrained shrinkage. The

C 1157 Performance Specification for Hydraulic Cement

procedure can be used to determine the effects of variations in

C 1437 Test Method for Flow of Hydraulic Cement Mortar

the proportions and material properties of mortar or concrete

F 441 Specification for Chlorinated Poly (Vinyl Chloride)

on cracking due to both drying shrinkage and deformations

(CPVC) Plastic Pipe, Schedules 40 and 80

caused by autogenous shrinkage and heat of hydration.

2.2 ASME Standards:

1.2 Thistestmethodisnotintendedforexpansivematerials.

B 46.1 Surface Texture (Surface Roughness, Waviness and

1.3 The values stated in inch-pound units are to be regarded

Lay)

asstandard.ThevaluesshowninparenthesisareinSIunitsand

are given for information only.

3. Summary of Test Method

1.4 This standard does not purport to address all of the

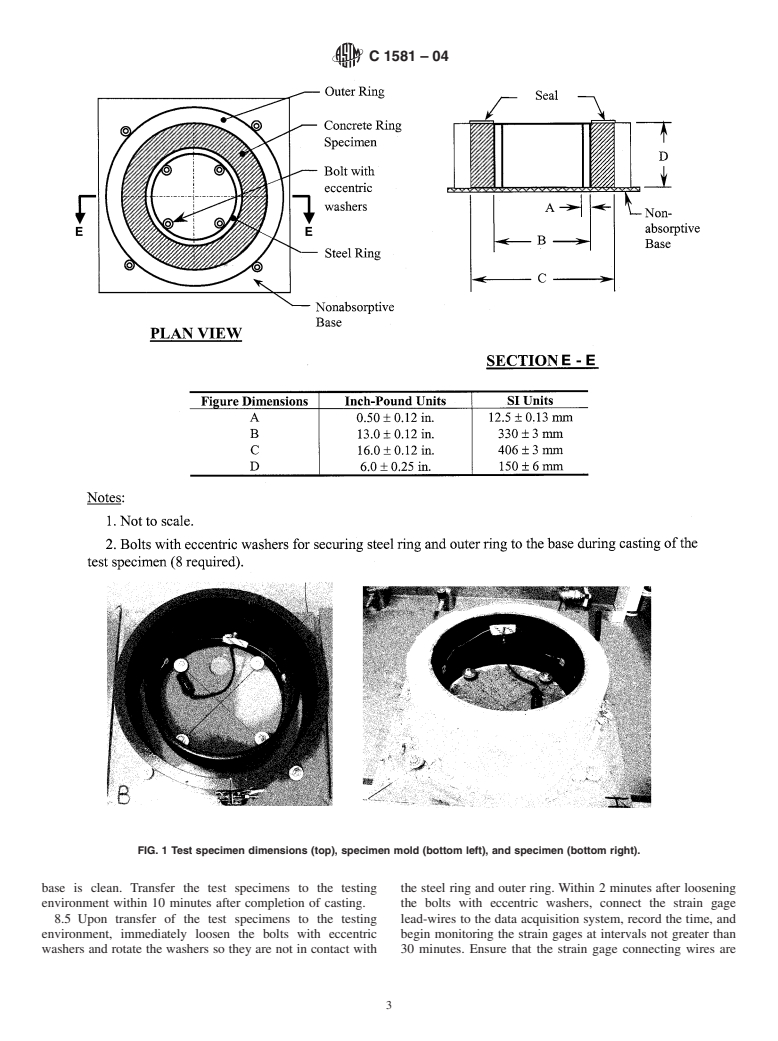

3.1 A sample of freshly mixed mortar or concrete is com-

safety concerns, if any, associated with its use. It is the

pacted in a circular mold around an instrumented steel ring.

responsibility of the user of this standard to establish appro-

The compressive strain developed in the steel ring caused by

priate safety and health practices and to determine the

the restrained shrinkage of the mortar or concrete specimen is

applicability of regulatory limitations prior to use.

measured from the time of casting (1-6) . Cracking of the test

(Warning—Fresh hydraulic cementitious mixtures are caustic

specimen is indicated by a sudden decrease in the steel ring

and may cause chemical burns to skin and tissue upon

strain. The age at cracking and the rate of tensile stress

prolonged exposure.)

development in the test specimen are indicators of the materi-

2. Referenced Documents al’s resistance to cracking under restrained shrinkage.

2.1 ASTM Standards:

4. Significance and Use

C 33 Specification for Concrete Aggregates

4.1 This test method is for relative comparison of materials

C 138/C 138 M Test Method for Density (Unit Weight),

and is not intended to determine the age at cracking of mortar

Yield and Air Content (Gravimetric) of Concrete

or concrete in any specific type of structure, configuration, or

C 143/C 143 M Test Method for Slump of Hydraulic-

exposure.

Cement Mortar

4.2 This test method is applicable to mixtures with aggre-

C 150 Specification for Portland Cement

gates of 0.5-in. (13-mm) maximum nominal size or less.

C 171 SpecificationforSheetMaterialsforCuringConcrete

4.3 This test method is useful for determining the relative

C 192/C 192 M Practice for Making and Curing Concrete

likelihood of early-age cracking of different cementitious

mixtures and for aiding in the selection of cement-based

materialsthatarelesslikelytocrackunderretrainedshrinkage.

This test method is under the jurisdiction of ASTM Committee C09 on

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

Actualcrackingtendencyinservicedependsonmanyvariables

C09.68 on Volume Change.

Current edition approved July 1, 2004. Published August 2004.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Society of Mechanical Engineers, 22 Law Drive,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Fairfield, NJ 07007-2900.

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parenthesis refer to the list of references at the end of

the ASTM website. this test method

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1581–04

including type of structure, degree of restraint, rate of property 6.1.2 Aggregates—Aggregates shall conform to Specifica-

development, construction and curing methods, and environ- tion C 33. The maximum nominal size of the coarse aggregate

mental conditions. shall be 0.5-in. (13-mm) or less.

4.4 This test method can be used to determine the relative 6.2 Mixing:

effects of material variations on induced tensile stresses and

6.2.1 Concrete mixtures—Machine mix the concrete as

cracking potential. These variations can include, but are not prescribed in Practice C 192/C 192M.

limited to, aggregate source, aggregate gradation, cement type,

6.2.2 Mortar mixtures—Mix the mortar as prescribed in

cement content, water content, supplementary cementing ma-

Specification C 387.

terials, or chemical admixtures.

4.5 For materials that have not cracked during the test, the

7. Properties of Fresh Mixtures

rate of tensile stress development at the time the test is

7.1 Concrete mixtures—Samples of freshly mixed concrete

terminated provides a basis for comparison of the materials.

shall be tested in accordance with the following methods:

7.1.1 Density (unit weight) and air content—Test Method

5. Apparatus

C 138/C 138M.

5.1 Steel ring—Structuralsteelpipewithawallthicknessof

7.1.2 Slump—Test Method C 143/C 143M.

0.50 6 0.05 in. (13 6 0.12 mm), an outside diameter of 13.0

7.2 Mortar mixtures—Samples of freshly mixed mortar

6 0.12 in. (330 6 3.3 mm) and a height of 6.0 6 0.25 in. (152

shall be tested in accordance with the following methods:

6 6 mm) (see Fig. 1). Machine the inner and outer faces to

7.2.1 Density—Specification C 387.

produce smooth surfaces with a texture of 63 microinches (1.6

7.2.2 Flow—Test Method C 1437.

micrometres) or finer, as defined in ASME B 46.1.

5.2 Strain gages—As a minimum, use two electrical resis-

8. Specimen Fabrication and Test Setup

tancestraingagestomonitorthestraindevelopmentinthesteel

ring. Each strain gage shall be wired in a quarter-bridge

8.1 Bond two strain gages at midheight locations on the

configuration (that is, one leg of a fullWheatstone bridge). See

interiorsurfaceofthesteelringalongadiameter;thatis,mount

Note 1 for additional information.

the second gage diametrically opposite the first gage. Orient

5.3 Data acquisition system—The data acquisition system

the gages to measure strain in the circumferential direction.

shall be compatible with the strain instrumentation and auto-

Follow the manufacturer’s procedures for mounting and wa-

maticallyrecordeachstraingageindependently.Theresolution

terproofing the gages on the steel ring and connecting lead-

of the system shall be 60.0000005 in./in. (m/m). The system

wires to the strain gage tabs.

shall be capable of recording strain data at intervals not to

8.2 Test specimen mold—The test specimen mold consists

exceed 30 minutes.

of a base, an inner steel ring and an outer ring.

8.2.1 Fabricate a base for each test specimen as described in

NOTE 1—Use of a precision resistor, to balance the leg of the bridge, a

Section 5.4. The top surface of each base shall minimize

strain conditioner input module, to complete the other half of the bridge,

anda16-channelinterfaceboardhasbeenfoundtoadequatelyprovidethe frictional restraint of the specimen.

required resolution of the system.

NOTE 2—Use of an epoxy coating or a Mylar sheet covering has been

5.4 Base—Epoxy-coated plywood or other non-absorptive

found to provide a suitable surface between the test specimen and the

and non-reactive surface.

base.

5.5 Outer ring—Use one of the following alternative mate-

8.2.2 Secure the steel ring to the base before casting using

rials as the outer ring.

bolts with eccentric washers (see Fig. 1).

5.5.1 PVC pipe—Schedule 80-18 PVC pipe, in accordance

8.2.2.1 Coat the outer surface of the steel ring with a release

withSpecificationF441,witha16.0 60.12-in.(406 63-mm)

agent.

inside diameter and 6.0 6 0.25-in. (152 6 6-mm) height (see

8.2.3 Coat the inner surface of the outer ring with a release

Fig. 1).

agent.

5.5.2 Steel outer ring—0.125-in. (3-mm) thick steel sheet-

8.2.4 Secure the outer ring to the base to complete the test

ing formed to obtain a 16.0 6 0.12-in. (406 6 3-mm) inside

specimen mold using bolts with eccentric washers. Maintain a

diameter and 6.0 6 0.25-in. (152 6 6-mm) height.

1.50 6 0.12-in. (38 6 3-mm) space between the inner steel

5.5.3 Other materials—Other suitable non-absorptive and

ring and the outer ring (see Fig. 1).

non-reactive materials formed to obtain a 16.0 6 0.12-in. (406

8.3 Make and cure at least three test specimens for each

6 3-mm) inside diameter and 6.0 6 0.25-in. (152 6 6-mm)

material and test condition following the applicable require-

height.

mentsofPracticeC 192/C 192M.Inmakingaspecimen,place

5.6 Testing environment—Store the specimens in an envi-

thetestspecimenmoldonavibratingtable,fillthemoldintwo

ronmentally controlled room with constant air temperature of

approximately equal layers, rod each layer 75 times using a

73.5 6 3.5 °F (23.0 6 2.0 °C) and relative humidity of 50 6

⁄8-in. (10-mm) diameter rod, and vibrate each layer to consoli-

4%.

date the mixture.

6. Materials and Mixing

8.4 Strike-off the test specimen surface after consolidation.

6.1 Materials: Finish with the minimum manipulation necessary to achieve a

6.1.1 Cement—Cement shall conform to Specifications flat surface. Remove any fresh concrete or mortar that has

C 150, C 595, or C 1157. spilled inside the steel ring or outside the outer ring so that the

C1581–04

FIG. 1 Test specimen dimensions (top), specimen mold (bottom left), and specimen (bottom right).

base is clean. Transfer the test specimens to the testing the steel ring and outer ring. Within 2 minutes after loosening

environment within 10 minutes after completion of casting. the bolts with eccentric washers, connect the strain gage

8.5 Upon transfer of the test specimens to the testing lead-wires to the data acquisition system, record the time, and

environment, immediately loosen the bolts with eccentric begin monitoring the strain gages at intervals not greater than

washers and rotate the washers so they are not in contact with 30 minutes. Ensure that the strain gage connecting wires are

C1581–04

clean of loose material before making the connections. The 8.7.4 For the calculations outlined subsequently, the age

time of the first strain measurement is taken as zero age of the when drying is initiated is the time when the first strain reading

specimen. is made after the test specimens have been sealed.

NOTE 3—Monitoring the strain gages soon after casting provides

9. Measurement Procedure

information on the internal deformations caused by autogenous shrinkage

9.1 Recordthetimeatthestartofstrainmonitoringasstated

and heat of hydration (4).

in Section 8.5.

8.6 Curing—Unless otherwise specified, test specimens

9.2 Record ambient temperature and relative humidity of

shall be moist cured in the molds for 24 h at 73.5 6 3.5 °F

the testing environment every day.

(23.0 6 2.0 °C) using wet burlap covered with polyethylene

9.3 Monitor the strains in the steel rings at intervals not to

film meeting the requirements of Specification C 171. Begin

exceed 30 minutes, recording the output of each strain gage

the curing process within 5 minutes after the first strain

separately with the data acquisition system. Record both the

reading. If the curing period is longer than 24 h, remove the

time and the strain at each measurement.Asudden decrease in

outer ring at 24 h and continue the curing process.

compressive strain in one or both strain gages indicates

8.7 At the end of curing and between strain measurements,

cracking (see Note 6) (1-5). Review the strain measurements

prepare the test specimens for drying as follows. Complete the

and visually inspect the specimens for cracking at time

test specimen preparation within 15 minutes.

intervals not greater than 3 days.

8.7.1 Remove the outer ring, if it is still in place, and/or

NOTE 6—The sudden decrease in compressive strain at cracking is

remove the polyethylene film and burlap.

usually greater than 30 microstrains (see Fig. 2).

8.7.2 Gently remove loose material, if present, from the top

surface of the test specimen.

9.4 Monitor and record the strain in the steel rings for at

8.7.3 Seal the top surface of the test specimen using one of

least 28 days after initiation of drying, unless cracking occurs

the following alternative procedures.

prior to 28 days.

9.5 Plot the steel ring strain for each strain gage against

NOTE 4—With the top surface sealed, and the specimen resting on its

specimen age (see Fig. 2).

base, the test specimen dries from the outer circumferential surface only.

8.7.3.1 Paraffın wax—Coat the top surface of the test

10. Calculation

specimen with molten paraffin wax.Take precautions to ensure

10.1 Age at cracking—Determine the age at cracking as the

that the outer circumference of the test specimen is not coated

age of each test specimen (measured from the time of casting)

with the paraffin wax.

when a sudden decrease in strain occurs. Report the age at

NOTE 5—Use of a 1.5-in. (38-mm) wide brush has been found to be an cracking to the nearest 0.25 day. If a test specimen does not

appropriate means of applying the paraffin wax to the top surface of the

crack within the duration of the test, report the result as “no

test specimens.

cracking” and record the age when the test was terminated.

8.7.3.2 Adhesive aluminum-foil tape—Seal the top surface 10.1.1 Average age at cracking—Calculate the average age

of the test specimen with adhesive aluminum-foil tape. at cracking for the test specimens to the nearest day.

FIG. 2 Steel ring strain versus specimen age.

C1581–04

10.2 Initial strain—Fromthetime-straindataforeachstrain

where:

gage, record the initial strain as the strain corresponding to the

q = stress rate in each test specimen, psi/day (MPa/

age when drying was initiated (see Fig. 2).

day),

10.2.1 Average initial strain—Calculate the average initial G = 10.47 3 10 psi (72.2 GPa),

strain for the test specimens. |a | = absolute value of the average strain rate factor for

avg

1/2 1/2

each test specimen, (in./in.)/day ((m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.