ASTM D1570-95(2003)

(Test Method)Standard Test Methods for Sampling and Chemical Analysis of Fatty Alkyl Sulfates

Standard Test Methods for Sampling and Chemical Analysis of Fatty Alkyl Sulfates

ABSTRACT

These test methods cover the sampling and chemical analysis of paste, powder, or liquid detergent fatty alkyl sulfates. The different procedure for sampling and chemical analysis of past, powder, or liquid detergent are presented and discussed in details. Distillation test, titration test, and gravimetric test shall be performed to meet the requirements prescribed. The calculations methods for chlorides as sodium chloride are presented in details.

SCOPE

1.1 These test methods cover the sampling and chemical analysis of paste, powder, or liquid detergent fatty alkyl sulfates.

1.2 The procedures for sampling and analysis appear in the following order:SectionsSampling:Powders and Flakes Packed in Cans or Cartons4Powders and Flakes in Bulk5Liquids6Pastes7Preparation of Sample8Moisture by the Distillation Test Method11-14pH15Alkalinity16-19Alcohol-Soluble Matter20-22Alcohol-Insoluble Matter23 and 24Unsulfated Material25-28Combined Alcohols29-32Ester SO3:Method A. Titration Test Method36 and 37Method B. Gravimetric Test Method38 and 39Sodium Sulfate40-43Chlorides Calculated as Sodium Chloride (NaCl)44-47

1.3 The values stated in either inch-pound or SI units are to be regarded separately as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Material Safety Data Sheets are available for reagents and materials. Review them for hazards prior to usage.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D1570–95(Reapproved 2003)

Standard Test Methods for

Sampling and Chemical Analysis of Fatty Alkyl Sulfates

This standard is issued under the fixed designation D1570; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

Sections

Ester SO :

1.1 These test methods cover the sampling and chemical

Method B. Gravimetric Test Method 38 and

analysis of paste, powder, or liquid detergent fatty alkyl

Sodium Sulfate 40-43

sulfates.

Chlorides Calculated as Sodium Chloride (NaCl) 44-47

1.2 The procedures for sampling and analysis appear in the

1.3 The values stated in either inch-pound or SI units are to

following order:

be regarded separately as the standard. The values given in

Sections

Sampling:

parentheses are for information only.

Powders and Flakes Packed in Cans or Cartons 4

1.4 This standard does not purport to address all of the

Powders and Flakes in Bulk 5

safety concerns, if any, associated with its use. It is the

Liquids 6

Pastes 7

responsibility of the user of this standard to establish appro-

Preparation of Sample 8

priate safety and health practices and determine the applica-

Moisture by the Distillation Test Method 11-14

bility of regulatory limitations prior to use. Material Safety

pH 15

Alkalinity 16-19

Data Sheets are available for reagents and materials. Review

Alcohol-Soluble Matter 20-22

them for hazards prior to usage.

Alcohol-Insoluble Matter 23 and

2. Referenced Documents

Unsulfated Material 25-28

Combined Alcohols 29-32

2.1 ASTM Standards:

Ester SO :

2 3

D216 Method for Distillation of Natural Gasoline

Method A. Titration Test Method 36 and

D1172 Guide for pH of Aqueous Solutions of Soaps and

Detergents

D1193 Specification for Reagent Water

These test methods are under the jurisdiction of ASTM Committee D12 on

Soaps and Other Detergents, and are the direct responsibility of Subcommittee

D12.12 on Analysis of Soaps and Synthetic Detergents.

Current edition approved April 15, 1995. Published June 1995. Originally Discontinued 1988, see 1987 Annual Book of ASTM Standards, Vol 05.01.

published as D1570 – 58 T. Last previous edition D1570 – 89. DOI: 10.1520/ Annual Book of ASTM Standards, Vol 15.04.

D1570-95R03. Annual Book of ASTM Standards, Vol 11.01.

SAMPLING

3. General Requirement thereof. The gross sample shall in all cases consist of not less

than three cans or cartons taken at random from separate

3.1 The seller shall have the option of being represented at

containers. In the case of very large lots where the sample

the time of sampling and when he so requests, shall be

drawnasabovewillamounttomorethan20lb(9.1kg),reduce

furnished with a duplicate sample.

the percentage of packages sampled so that the amount drawn

4. Powders and Flakes Packed in Cans or Cartons

will not exceed 20 lb (9.1 kg).Tightly wrap the individual cans

or cartons at once in paraffined paper and seal by rubbing the

4.1 Take one can or carton at random from not less than 1%

edges with a heated iron. The inspector shall accurately weigh

of the seller’s shipping containers, provided each package

each wrapped can or carton and record its weight and the date

contains not less than 50 lb (22.7 kg). In the case of smaller

of weighing on the wrapper. Place the wrapped cans or cartons

containers, take a can or carton at random from each lot of

in an airtight container, which should be nearly filled, and

containers totaling not more than 5000 lb (2268 kg) or fraction

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1570–95 (2003)

which shall then be sealed, marked, and sent to the laboratory than three cans or cartons taken at random from separate

for test. Samples shall be kept cool until tested. containers. In the case of very large lots where the sample

drawnasabovewillamounttomorethan20lb(9.1kg),reduce

5. Powders and Flakes in Bulk

the percentage of packages sampled so that the amount drawn

5.1 Take a grab sample of not less than 0.5 lb (227 g) at shall not exceed 20 lb (9.1 kg). The samples shall be wrapped,

random from not less than 1 % of the seller’s shipping

sealed, marked, and sent to the laboratory for test.

containers,providedeachpackagecontainsnotlessthan100lb 7.2 Pastes Packed in Bulk—Take a “trier” sample (Note 1)

(45.4 kg). In the case of smaller containers, take a grab sample

of not less than 0.5 lb (227 g) at random from not less than 1 %

of not less than 0.5 lb (227 g) at random from each lot of of the seller’s shipping containers, provided each package

containers totaling not more than 10 000 lb (4536 kg) or

contains not less than 50 lb (22.7 kg). In the case of smaller

fraction thereof. The gross sample shall in all cases consist of containers, take a “trier” sample of not less than 0.5 lb (227 g)

not less than three grab samples of 0.5 lb (227 g) each taken at

at random from each lot of containers totaling not more than

random from separate containers. In the case of very large lots 5000 lb (2268 kg) or fraction thereof.The gross sample shall in

where the sample drawn as above will amount to more than 20

all cases consist of not less than three 0.5-lb (227-g) samples,

lb (9.1 kg), reduce the percentage of packages sampled so that

each taken at random from separate containers.With very large

the amount drawn shall not exceed 20 lb (9.1 kg). The lotswherethesampledrawnasabovewillamounttomorethan

inspector shall rapidly mix the gross sample and place it in an

10 lb (4.5 kg), reduce the percentage of packages sampled so

airtight container, which shall be filled, sealed, marked, accu- that the amount drawn shall not exceed 10 lb (4.5 kg). The

rately weighed, with its weight and the date of weighing

inspector shall promptly place the gross sample in a clean, dry,

recorded on the package, and be sent to the laboratory for test. airtight and watertight container, which shall be filled, sealed,

Samples shall be kept cool until tested.

marked, and sent to the laboratory for test.

NOTE 1—A trier sample is obtained by inserting a “trier” into the

6. Liquids

1 3

material.Atrier is a half-round steel cylinder ⁄2 to ⁄4 in. (12.7 to 19 mm)

6.1 Take a sample of not less than 0.5 pt (236.6 mL) at

in diameter, 6 to 36 in. (152 to 914 mm) in length, pointed on one end and

random from not less than 1 % of the seller’s shipping

having a grip handle on the other end. After insertion, the trier is turned

containers, provided each package contains not less than 10 gal two or three times, and upon removal a core of the material being sampled

is obtained.

(37.9 L). In the case of smaller containers, take a sample of not

less than 0.5 pt (236.6 mL) at random from each lot of

8. Preparation of Sample

containers totaling not more than 1000 gal (3785.4 L) or

8.1 Powders and Flakes—Minimizing exposure to air, rap-

fraction thereof. The gross sample shall in all cases consist of

idly disintegrate and mix the sample of powdered, flake, or

not less than three samples of 0.5 pt (236.6 mL) each taken at

chip product. If desired, quarter down to about 1 lb (453.6 g).

random from separate containers. Before drawing the sample

Weigh at once all portions for analysis, preserving the remain-

from the container selected, thoroughly agitate the contents of

der in an airtight container in a cool place.

the container. The inspector shall thoroughly mix the gross

8.2 Liquids—No preparation of the sample of liquid, other

sample, place it in clean, dry cans or bottles, which shall be

than a thorough mixing, is necessary unless it is received

completely filled and securely stoppered with clean corks or

during very cold weather, when it should be allowed to stand

caps, then sealed, marked, and sent to the laboratory for test.

at least 1 h after it has warmed to room temperature (20 to

7. Pastes

30°C) before it is tested, particularly for its lathering qualities

7.1 Pastes Packed in Cans or Cartons of 5 lb (2.27 kg) or (Note 2).

8.3 Pastes—Store preferably in glass. If crystals separate,

Less—Takeonecanorcartonatrandomfromnotlessthan1 %

of the seller’s shipping containers, provided each package melt on water bath.

contains not less than 50 lb (22.7 kg). In the case of smaller

NOTE 2—If pastes or liquids are known to be acidic, and decomposition

containers, take a can or carton at random from each lot of

of sample can result from heating, the samples shall be adequately labeled

containers totaling not more than 5000 lb (2268 kg) or fraction

for precautionary treatment and warmed to room temperature or other

thereof. The gross sample shall in all cases consist of not less maximum temperature as agreed upon for mixing and sampling.

D1570–95 (2003)

TEST METHODS OF CHEMICALANALYSIS

9. Purity of Reagents 11.1.1 Flask—A 1000-mL flask of either the short-neck,

round-bottom type or the Erlenmeyer type.

9.1 Reagent grade chemicals shall be used in all tests.

11.1.2 Heat Source, either an oil bath (stearic acid, paraffin

Unless otherwise indicated, it is intended that all reagents shall

wax, etc.), or an electric heater provided with a sliding rheostat

conform to the specifications of the Committee on Analytical

or other means of heat control.

Reagents of the American Chemical Society, where such

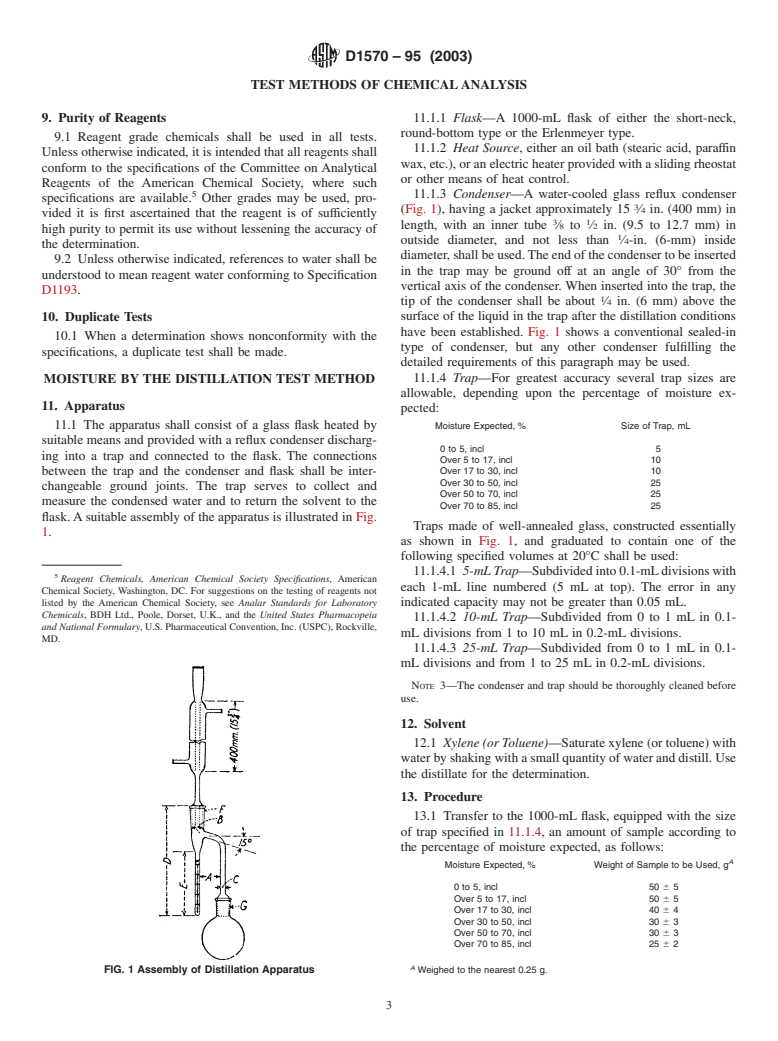

5 11.1.3 Condenser—A water-cooled glass reflux condenser

specifications are available. Other grades may be used, pro-

(Fig. 1), having a jacket approximately 15 ⁄4 in. (400 mm) in

vided it is first ascertained that the reagent is of sufficiently

3 1

length, with an inner tube ⁄8 to ⁄2 in. (9.5 to 12.7 mm) in

high purity to permit its use without lessening the accuracy of

outside diameter, and not less than ⁄4-in. (6-mm) inside

the determination.

diameter, shall be used.The end of the condenser to be inserted

9.2 Unless otherwise indicated, references to water shall be

in the trap may be ground off at an angle of 30° from the

understood to mean reagent water conforming to Specification

vertical axis of the condenser. When inserted into the trap, the

D1193.

tip of the condenser shall be about ⁄4 in. (6 mm) above the

surface of the liquid in the trap after the distillation conditions

10. Duplicate Tests

have been established. Fig. 1 shows a conventional sealed-in

10.1 When a determination shows nonconformity with the

type of condenser, but any other condenser fulfilling the

specifications, a duplicate test shall be made.

detailed requirements of this paragraph may be used.

11.1.4 Trap—For greatest accuracy several trap sizes are

MOISTURE BYTHE DISTILLATION TEST METHOD

allowable, depending upon the percentage of moisture ex-

11. Apparatus

pected:

11.1 The apparatus shall consist of a glass flask heated by Moisture Expected, % Size of Trap, mL

suitable means and provided with a reflux condenser discharg-

0to5,incl 5

ing into a trap and connected to the flask. The connections

Over 5 to 17, incl 10

between the trap and the condenser and flask shall be inter- Over 17 to 30, incl 10

Over 30 to 50, incl 25

changeable ground joints. The trap serves to collect and

Over 50 to 70, incl 25

measure the condensed water and to return the solvent to the

Over 70 to 85, incl 25

flask.Asuitable assembly of the apparatus is illustrated in Fig.

Traps made of well-annealed glass, constructed essentially

1.

as shown in Fig. 1, and graduated to contain one of the

following specified volumes at 20°C shall be used:

11.1.4.1 5-mLTrap—Subdividedinto0.1-mLdivisionswith

Reagent Chemicals, American Chemical Society Specifications, American

each 1-mL line numbered (5 mL at top). The error in any

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory indicated capacity may not be greater than 0.05 mL.

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

11.1.4.2 10-mL Trap—Subdivided from 0 to 1 mL in 0.1-

and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

mL divisions from 1 to 10 mL in 0.2-mL divisions.

MD.

11.1.4.3 25-mL Trap—Subdivided from 0 to 1 mL in 0.1-

mL divisions and from 1 to 25 mL in 0.2-mL divisions.

NOTE 3—The condenser and trap should be thoroughly cleaned before

use.

12. Solvent

12.1 Xylene (or Toluene)—Saturate xylene (or toluene) with

water by shaking with a small quantity of water and distill. Use

the distillate for the determination.

13. Procedure

13.1 Transfer to the 1000-mL flask, equipped with the size

of trap specified in 11.1.4, an amount of sample according to

the percentage of moisture expected, as follows:

A

Moisture Expected, % Weight of Sample to be Used, g

0 to 5, incl 50 6 5

Over 5 to 17, incl 50 6 5

Over 17 to 30, incl 40 6 4

Over 30 to 50, incl 30 6 3

Over 50 to 70, incl 30 6 3

Over 70 to 85, incl 25 6 2

A

FIG. 1 Assembly of Distillation Apparatus Weighed to the nearest 0.25 g.

D1570–95 (2003)

Add immediately about 100 mL of xylene or toluene. Place 17.3 Sodium Hydroxide, Standard Solution 1.0 N—Prepare

a small, thin sheet of long-fiber, chemical-resistant glass 328 and standardize a 1.0 N NaOH solution.A0.5 N NaOH solution

on the surface of the toluene. The glass wool should be

may be used with proper corrections in calculation.

thoroughly dried in the oven and held in the desiccator before

use.

18. Procedure

13.2 Connect the flask and receiver to the condenser and

18.1 Weigh 5 6 0.001 g of the sample into a 400-mL

pour sufficient xylene or toluene down the condenser tube to

beaker. Dissolve in 100 to 150 mL of warm water (about

cause a slight overflow through the side tube. Wrap the flask

35°C). Add 2 drops of methyl orange indicator and 2 drops of

and tube leading to the receiver with asbestos cloth, so that

phenolphthalein indicator and titrate in accordance with 18.2,

refluxing will be under better control.

18.3,or 18.4.

13.3 Heat the oil bath with a gas burner or other source of

18.2 If the sample solution is acid to methyl orange, titrate

heat, or apply heat directly to the flask with an electric heater

with 1 N NaOH solution to the methyl orange end point.

and distill slowly. The rate at the start should be approximately

100 drops/min. When the greater part of the water has distilled 18.3 If the sample solution is alkaline to methyl orange and

over, increase the distillation rate to 200 drops/min until no

acid to phenolphthalein, titrate with 1 N acid to the methyl

more water is collected. Purge the reflux condenser during the

orange end point.

dist

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.