ASTM D6071-06

(Test Method)Standard Test Method for Low Level Sodium in High Purity Water by Graphite Furnace Atomic Absorption Spectroscopy

Standard Test Method for Low Level Sodium in High Purity Water by Graphite Furnace Atomic Absorption Spectroscopy

SIGNIFICANCE AND USE

Small quantities of sodium, 1 to 10 μg/L, can be significant in high pressure boiler systems and in nuclear power systems. Steam condensate from such systems must have less than 10 μg/L. In addition, condensate polishing system effluents should have less than 1 μg/L. Graphite furnace atomic absorption spectroscopy (GFAAS) represents technique for determining low concentrations of sodium.

SCOPE

1.1 This test method covers the determination of trace sodium in high purity water. The method range of concentration is 1 to 40 g/L sodium. The analyst may extend the range once its applicability has been ascertained. Note 1It is necessary to perform replicate analysis and take an average to accurately determine values at the lower end of the stated range.

1.2 This test method is a graphite furnace atomic absorption spectrophotometric method for the determination of trace sodium impurities in ultra high purity water.

1.3 This test method has been used successfully with a high purity water matrix. It is the responsibility of the analyst to determine the suitability of the test method for other matrices.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6071 − 06

StandardTest Method for

Low Level Sodium in High Purity Water by Graphite Furnace

1

Atomic Absorption Spectroscopy

This standard is issued under the fixed designation D6071; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Graphite Furnace Atomic Absorption Spectrophotometry

D4453 Practice for Handling of High Purity Water Samples

1.1 This test method covers the determination of trace

D5810 Guide for Spiking into Aqueous Samples

sodium in high purity water. The method range of concentra-

D5847 Practice for Writing Quality Control Specifications

tion is 1 to 40 µg/L sodium. The analyst may extend the range

for Standard Test Methods for Water Analysis

once its applicability has been ascertained.

NOTE 1—It is necessary to perform replicate analysis and take an

3. Terminology

average to accurately determine values at the lower end of the stated

range. 3.1 Definitions:

3.1.1 For definitions of terms used in this test method, refer

1.2 This test method is a graphite furnace atomic absorption

to Terminology D1129.

spectrophotometric method for the determination of trace

sodium impurities in ultra high purity water.

4. Summary of Test Method

1.3 This test method has been used successfully with a high

2

4.1 Sodium is determined by atomic absorption utilizing a

purity water matrix. It is the responsibility of the analyst to

graphite furnace for sample atomization.

determine the suitability of the test method for other matrices.

4.2 Asamplevolumeofseveralmicrolitres,dependingupon

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the theconcentrationoftheanalyte,isdepositedona graphitetube

housed within an electrical furnace, and the system is heated in

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- an inert gas environment.The sample is evaporated to dryness,

ashed (charred or pyrolyzed), and atomized.

bility of regulatory limitations prior to use.

4.3 Ground-stateatomsareproducedduringtheatomization

2. Referenced Documents

stage of the temperature program. The ground-state atoms

2.1 ASTM Standards:

absorb the energy at a specific wavelength produced from a

D1066 Practice for Sampling Steam

source as they are bombarded by the energy. The amount of

D1129 Terminology Relating to Water

energy absorbed is proportional to the concentration of the

D1192 Guide for Equipment for Sampling Water and Steam

analyte in the sample.

3

in Closed Conduits (Withdrawn 2003)

4.4 The absorption signal produced during atomization is

D1193 Specification for Reagent Water

recorded on a chart recorder or stored in microprocessor

D2777 Practice for Determination of Precision and Bias of

memory and compared to those standards taken through the

Applicable Test Methods of Committee D19 on Water

same process by means of an analytical curve.

D3370 Practices for Sampling Water from Closed Conduits

D3919 Practice for Measuring Trace Elements in Water by 4.5 A general guide for graphite furnace applications is

given in Practice D3919.

1

This test method is under the jurisdiction of ASTM Committee D19 on Water

5. Significance and Use

and is the direct responsibility of Subcommittee D19.03 on Sampling Water and

Water-Formed Deposits, Analysis of Water for Power Generation and Process Use,

5.1 Small quantities of sodium, 1 to 10 µg/L, can be

On-Line Water Analysis, and Surveillance of Water.

significantinhighpressureboilersystemsandinnuclearpower

Current edition approved July 1, 2006. Published July 2006. Originally approved

systems. Steam condensate from such systems must have less

in 1996. Last previous edition approved in 2000 as D6071 – 96 (2000). DOI:

10.1520/D6071-06.

than 10 µg/L. In addition, condensate polishing system efflu-

2

RP2712 Sub Program—Grab Sample Method Validation Report Results,

ents should have less than 1 µg/L. Graphite furnace atomic

Electric Power Research Institute, Palo Alto, CA 1987.

3

absorption spectroscopy (GFAAS) represents technique for

The last approved version of this historical standard is referenced on

www.astm.org. determining low concentrations of sodium.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

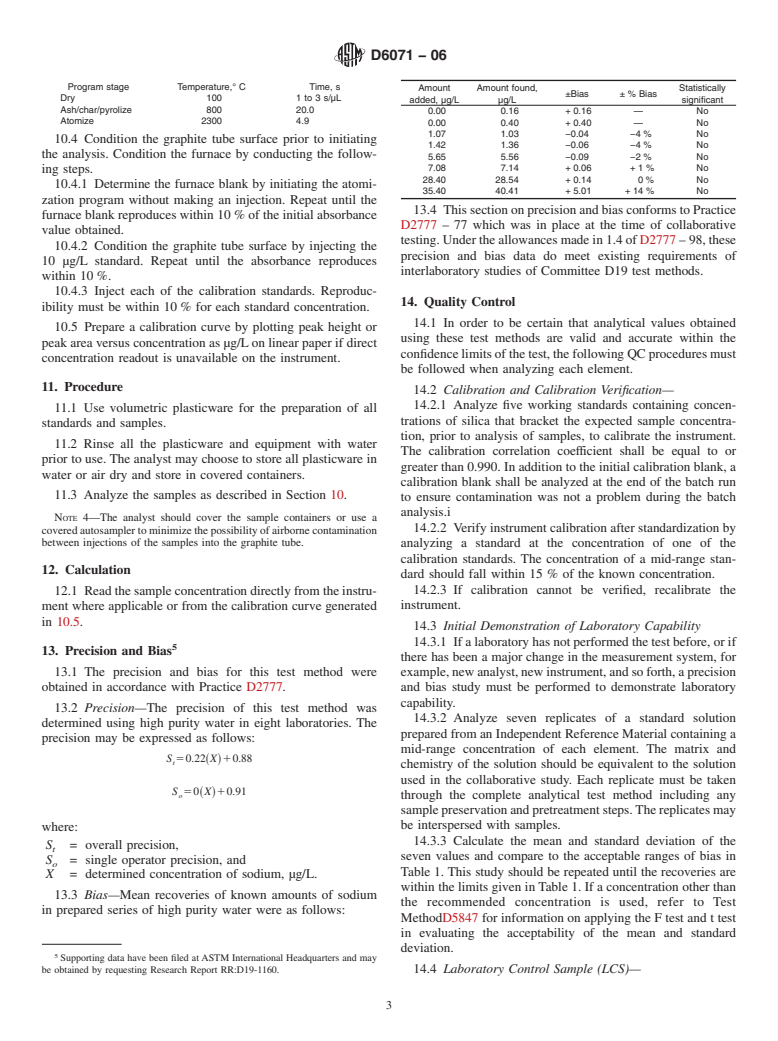

---------------------- Page: 1 ----------------------

D6071 − 06

4

6. Interferences tee onAnalytical Reagents of theAmerican Chemical Society.

Other grades may be used, provided it is first ascertained that

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.