ASTM D7811-13(2022)

(Test Method)Standard Test Method for Bow and Skew Using a Measuring Tool

Standard Test Method for Bow and Skew Using a Measuring Tool

SIGNIFICANCE AND USE

5.1 This test method provides a standard procedure for obtaining data for research and development, quality control, acceptance and rejection under specifications, and for special purposes.

5.2 The data obtained by this test method is applicable to the material under the conditions of this particular test and is not necessarily the same as obtained under other environments in use.

5.3 This test method is considered satisfactory for acceptance testing of commercial shipments.

5.4 If there are differences of practical significance between reported test results for two laboratories (or more), comparative tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, the test samples to be used are as homogeneous as possible, are drawn from the material from which the disparate test results were obtained, and are randomly assigned in equal numbers to each laboratory for testing. Other fabrics with established test values may be used for this purpose. The test results from the two laboratories should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If a bias is found, either its cause must be found and corrected, or future test results must be adjusted in consideration of the known bias.

5.5 Bow or skew can be induced during fabric manufacturing, dyeing, tentering, finishing, or other operations where a potential exists for uneven distribution of tensions across the fabric width. Bow and skew are more visually displeasing in colored, patterned fabrics such as plaids and horizontal stripes rather than in solid colors because the contrast makes the distortion more prominent. These defects may cause sewing problems in such fabrics and draping problems in finished products. Wavy or sharp breaks in the bow line are more detrimental to the appearance of small specimens of a sewn assembly.

SCOPE

1.1 This test method is used to determine the bow and skew of woven and knitted fabrics over a fixed distance, using a measuring tool.

1.2 This test method is useful when a small specimen or cut parts need to be evaluated for bow and skew, provided a warp or fill, or both, reference line is available, to aid in aligning the tool.

1.3 Test Method D3882 may be used when measuring bow and skew in fabric in rolls. However, results obtained with D3882 may not be comparable with results obtained by this test method.

1.4 There is no known ISO equivalent standard.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7811 − 13 (Reapproved 2022)

Standard Test Method for

Bow and Skew Using a Measuring Tool

This standard is issued under the fixed designation D7811; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3882 Test Method for Bow and Skew in Woven and

Knitted Fabrics

1.1 This test method is used to determine the bow and skew

D3990 Terminology Relating to Fabric Defects

of woven and knitted fabrics over a fixed distance, using a

E177 Practice for Use of the Terms Precision and Bias in

measuring tool.

ASTM Test Methods

1.2 This test method is useful when a small specimen or cut

E691 Practice for Conducting an Interlaboratory Study to

parts need to be evaluated for bow and skew, provided a warp

Determine the Precision of a Test Method

or fill, or both, reference line is available, to aid in aligning the

tool.

3. Terminology

1.3 Test Method D3882 may be used when measuring bow

3.1 For all terminology related to fabric defect terms, refer

and skew in fabric in rolls. However, results obtained with

to Terminology D3990.

D3882maynotbecomparablewithresultsobtainedbythistest

3.1.1 Thefollowingtermsarerelevanttothisstandard:bow,

method.

double bow, double hooked bow, double reverse bow, hooked

bow, knitted fabric, skew, standard atmosphere for testing

1.4 There is no known ISO equivalent standard.

textiles.

1.5 The values stated in SI units are to be regarded as

3.2 For all other terminology related to textiles, refer to

standard. No other units of measurement are included in this

Terminology D123.

standard.

1.6 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

4.1 A straightedge is placed across the fabric between two

responsibility of the user of this standard to establish appro-

priate safety, health and environmental practices and deter- points at which a marked filling yarn, knitted course, desig-

mine the applicability of regulatory limitations prior to use. nated printed line, or designated design meets the two selvages

1.7 This international standard was developed in accor- or edges. The greatest distance between the straightedge and

dance with internationally recognized principles on standard- the marked filling line, knitted course, designated printed line,

ization established in the Decision on Principles for the or designated design is measured parallel to the selvage.

Development of International Standards, Guides and Recom-

5. Significance and Use

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

5.1 This test method provides a standard procedure for

obtaining data for research and development, quality control,

2. Referenced Documents

acceptance and rejection under specifications, and for special

2.1 ASTM Standards: purposes.

D123 Terminology Relating to Textiles

5.2 Thedataobtainedbythistestmethodisapplicabletothe

D1776 Practice for Conditioning and Testing Textiles

material under the conditions of this particular test and is not

necessarily the same as obtained under other environments in

use.

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

5.3 This test method is considered satisfactory for accep-

and is the direct responsibility of Subcommittee D13.60 on Fabric Physical Test

Methods B.

tance testing of commercial shipments.

CurrenteditionapprovedJune1,2022.PublishedJuly2022.Originallyapproved

5.4 If there are differences of practical significance between

in 2013. Last previous edition approved in 2017 as D7811-13(2017). DOI:

10.1520/D7811-13R22.

reported test results for two laboratories (or more), compara-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

tive tests should be performed to determine if there is a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

statistical bias between them, using competent statistical assis-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. tance. As a minimum, the test samples to be used are as

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7811 − 13 (2022)

homogeneous as possible, are drawn from the material from 6.4 Flat Surface, of sufficient area to lay the test specimen.

which the disparate test results were obtained, and are ran-

6.5 Fabric Inspection Table (Optional) with suffıcient

domlyassignedinequalnumberstoeachlaboratoryfortesting.

lighting, for fabric on rolls or bolts.

Other fabrics with established test values may be used for this

purpose. The test results from the two laboratories should be

7. Interferences

compared using a statistical test for unpaired data, at a

7.1 None identified.

probability level chosen prior to the testing series. If a bias is

found, either its cause must be found and corrected, or future

8. Sampling

test results must be adjusted in consideration of the known

8.1 When testing fabric in rolls, consider rolls to be the

bias.

primarysamplingunitsandselectatleastthreeareasfromeach

5.5 Bow or skew can be induced during fabric

roll for testing, excluding the first and last fifth of the roll.

manufacturing, dyeing, tentering, finishing, or other operations

Select areas for testing at random, and no closer to one another

where a potential exists for uneven distribution of tensions

than one fifth of the length of the roll.

across the fabric width. Bow and skew are more visually

8.2 Forcutpartsofsufficientsizefortesting(i.e.atleast400

displeasing in colored, patterned fabrics such as plaids and

mm in length), consider each part a test specimen, and test at

horizontal stripes rather than in solid colors because the

least three randomly chosen specimens.

contrast makes the distortion more prominent. These defects

may cause sewing problems in such fabrics and draping

9. Calibration and Standardization

problemsinfinishedproducts.Wavyorsharpbreaksinthebow

9.1 Bow and Skew Measurement Tool Calibration:

line are more detrimental to the appearance of small specimens

of a sewn assembly.

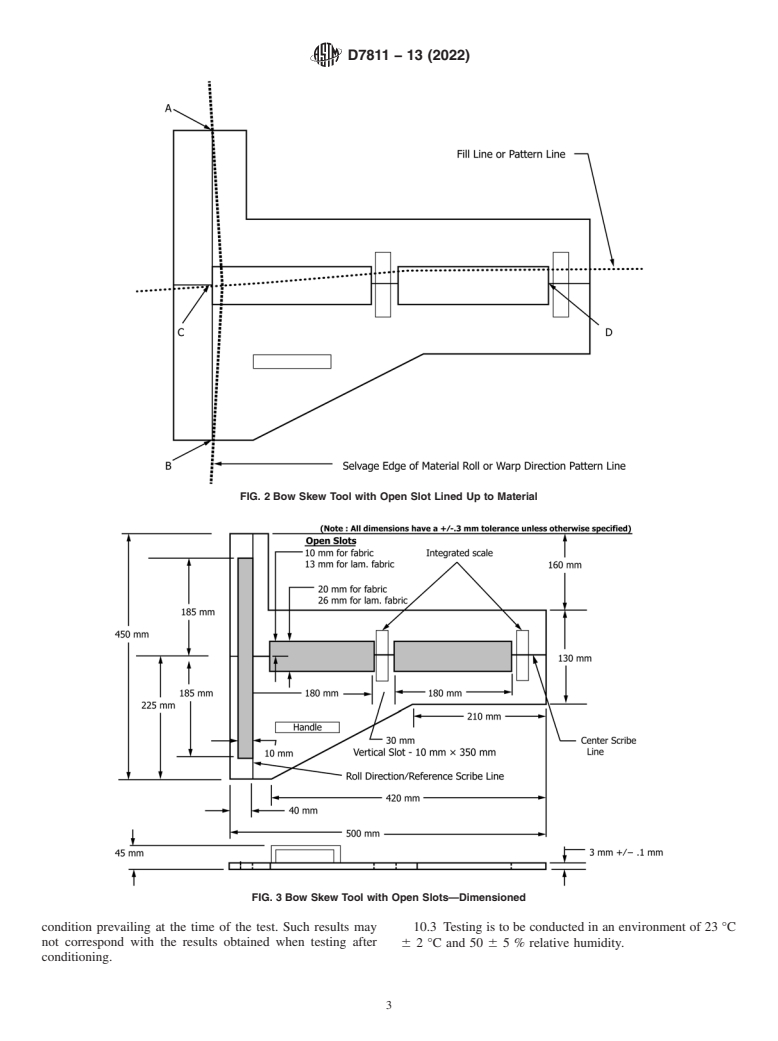

9.2 Bow Skew Measurement Tool is to be verified to Fig. 3

dimensions by using scale or rule traceable to NIST or

6. Apparatus

equivalent national standard.

6.1 Millimeter Rule, graduated in 1 mm ( ⁄16-in.) divisions.

10. Conditioning

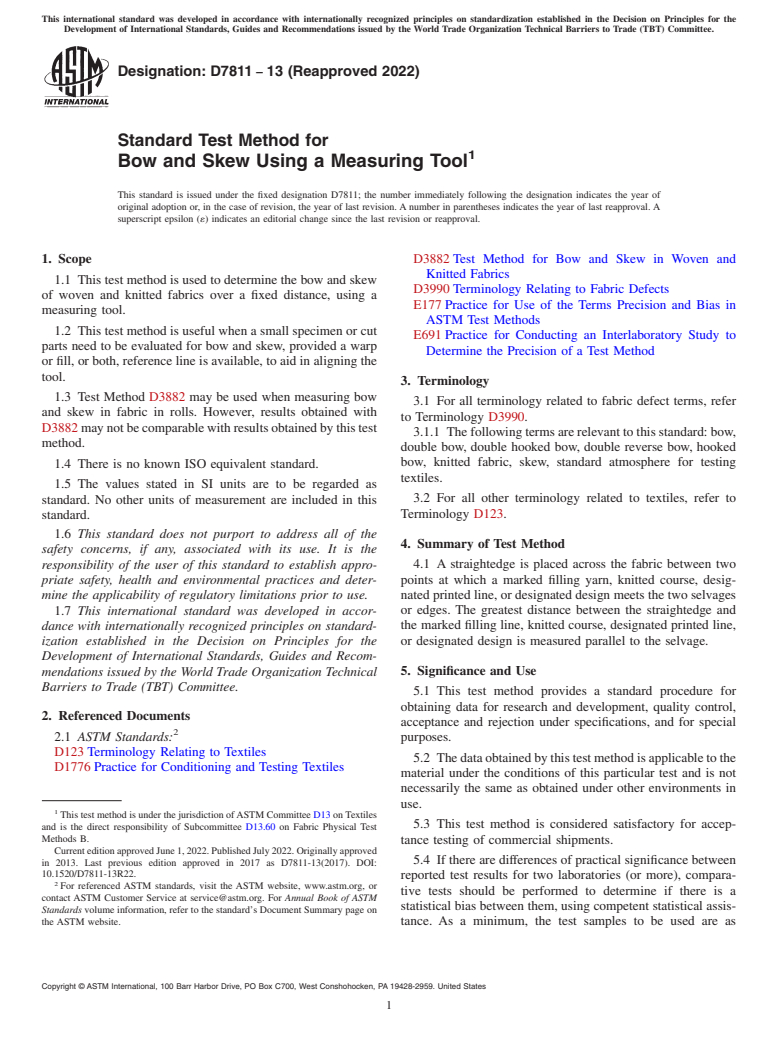

6.2 Test Fixture—See Fig. 1 and Fig. 3. This tool, hereafter

referred to as “bow and skew measurement tool” is to be used 10.1 Condition the test specimens to moisture equilibrium

for each measurement. for testing in the standard atmosphere for testing textiles in

6.2.1 Fig. 3 is a dimensioned drawing of bow and skew accordance with Practice D1776 or, if applicable, in the

measurement tool. specified atmosphere in which the testing is to be performed.

6.3 Bow Skew Measurement Tool Construction: 10.2 When full rolls or bolts of fabric cannot be properly

6.3.1 Transparent material such as polycarbonate. conditioned in a reasonable time with available facilities,

perform the test without conditioning and report the actual

6.3.2 Thickness 3 mm to 5 mm.

FIG. 1 Bow Skew Tool with Open Slot

D7811 − 13 (2022)

FIG. 2 Bow Skew Tool with Open Slot Lined Up to Material

FIG. 3 Bow Skew Tool with Open Slots—Dimensioned

condition prevailing at the time of the test. Such results may 10.3 Testing is to be conducted in an environment of 23 °C

not correspond with the results obtained when testing after 6 2 °C and 50 6 5 % relative humidity.

conditioning.

D7811 − 13 (2022)

FIG. 4 Photograph of Test Tool (Typical)

10.4 Condition test specimens for 24 h in an environment of 11.7 Record the measurement. The scale on the Bow and

23 °C 6 2 °C and 50 6 5 % relative humidity. Skew Measurement Tool has 1 mm increments grouped in

sections of 5 mm each totaling 620 mm from Line CD.

10.5 If test specimens are conditioned for less than 24 h, or

11.8 Move the Bow and Skew Measurement Tool to the

under different conditions, note and report the alternative

times/conditions used. right so that point C is now located where point D was

previously(LineCDis400mmwhichisthedimensionthatthe

10.6 If the test specimen is tested in an environment other

Bow or Skew is to be measured over).

than the environment outlined in 10.3, note actual environmen-

11.9 Line up point C on the same fill line or pattern that was

tal conditions at the time of testing.

chosen in step 11.3.

11. Procedure A—Using the Tool on Rolled Goods

11.10 PositiontheBowandSkewMeasurementToolsothat

11.1 Start by positioning the Bow and Skew Measurement

Line AB is now located over a warp line or pattern instead of

Tool (reference Fig. 1 and Fig. 2) to the far left side of the

selvage edge (use method in step 11.2) if warp line or pattern

unrolled material.

is not straight.

11.2 Line up line AB on the Bow and Skew Measurement

11.11 Recheck that Line CD is on the correct fill line or

Tool to the selvage edge of the material (selvage may curve

pattern and recheck that Line AB is still on a warp line or

away from LineAB – match pointsA& B to edge as shown in

pattern – repeat 11.9 and 11.10 as

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.