ASTM C610-05

(Specification)Standard Specification for Molded Expanded Perlite Block and Pipe Thermal Insulation

Standard Specification for Molded Expanded Perlite Block and Pipe Thermal Insulation

SCOPE

1.1 This specification covers molded expanded perlite block, fittings, and pipe thermal insulation intended for use on surfaces with temperatures between 80 to 1200°F (27 to 649°C).

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

When the installation or use of thermal insulation materials, accessories, and systems may pose safety or health problems, the manufacturer shall provide the user appropriate current information regarding any known problems associated with the recommended use of the company's products and shall also recommend protective measures to be employed in their safe utilization. The following safety caveat applies only to the test methods portion of this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 610 – 05

Standard Specification for

Molded Expanded Perlite Block and Pipe Thermal

1

Insulation

This standard is issued under the fixed designation C 610; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope C 203 Test Methods for Breaking Load and Flexural Prop-

erties of Block-Type Thermal Insulation

1.1 This specification covers molded expanded perlite

C 302 Test Method for Density of Preformed Pipe-

block, fittings, and pipe thermal insulation intended for use on

Covering-Type Thermal Insulation

surfaces with temperatures between 80 to 1200°F (27 to

C 303 Test Method for Density of Preformed Block-Type

649°C).

Thermal Insulation

1.2 The values stated in inch-pound units are to be regarded

C 335 Test Method for Steady-State Heat Transfer Proper-

as the standard. The values given in parentheses are for

ties of Horizontal Pipe Insulations

information only.

C 356 Test Method for Linear Shrinkage of Preformed

1.3 When the installation or use of thermal insulation

High-Temperature Thermal Insulation Subjected to Soak-

materials, accessories, and systems may pose safety or health

ing Heat

problems, the manufacturer shall provide the user appropriate

C 390 Practice for Sampling and Acceptance of Thermal

current information regarding any known problems associated

Insulation Lots

withtherecommendeduseofthecompany’sproductsandshall

C411 Test Method for Hot-Surface Performance of High-

also recommend protective measures to be employed in their

Temperature Thermal Insulation

safe utilization. The following safety caveat applies only to the

C 421 Test Method for Tumbling Friability of Preformed

test methods portion of this specification: This standard does

Block-Type Thermal Insulation

not purport to address all of the safety concerns, if any,

C 446 Test Method for Breaking Load and Calculated

associated with its use. It is the responsibility of the user of this

Modulus of Rupture of Preformed Insulation for Pipes

standard to establish appropriate safety and health practices

C 450 Practice for Prefabrication and Field Fabrication of

and determine the applicability of regulatory limitations prior

Thermal Insulating Fitting Covers for NPS Piping, Vessel

to use.

Lagging, and Dished Head Segments

2. Referenced Documents C 518 Test Method for Steady-State Heat Flux Measure-

2

ments and Thermal Transmission Properties by Means of

2.1 ASTM Standards:

the Heat Flow Meter Apparatus

C 165 Test Method for Measuring Compressive Properties

C 585 Practice for Inner and Outer Diameters of Rigid

of Thermal Insulations

Thermal Insulation for Nominal Sizes of Pipe and Tubing

C 168 Terminology Relating to Thermal Insulating Materi-

(NPS System)

als

C 692 Test Method for Evaluating the Influence of Thermal

C 177 Test Method for Steady-State Heat Flux Measure-

Insulations on the External Stress Corrosion Cracking

ments and Thermal Transmission Properties by Means of

Tendency of Austenitic Steel

the Guarded Hot Plate Apparatus

C 795 Specification for Thermal Insulation for Use in Con-

tact with Austenitic Stainless Steel

1

This specification is under the jurisdiction of ASTM Committee C16 on

C 1045 PracticeforCalculatingThermalTransmissionfrom

Thermal Insulation and is the direct responsibility of Subcommittee C16.20 on

Steady-State Heat Flux Measurements

Homogeneous Inorganic Thermal Insulations.

C 1058 Practice for Selecting Temperatures for Evaluating

Current edition approved April 1, 2005. Published April 2005. Originally

and Reporting Thermal Properties of Thermal Insulation

approved in 1967. Last previous edition approved in 1999 as C 610 – 99.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

E84 Test Method for Surface Burning Characteristics of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Building Materials

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

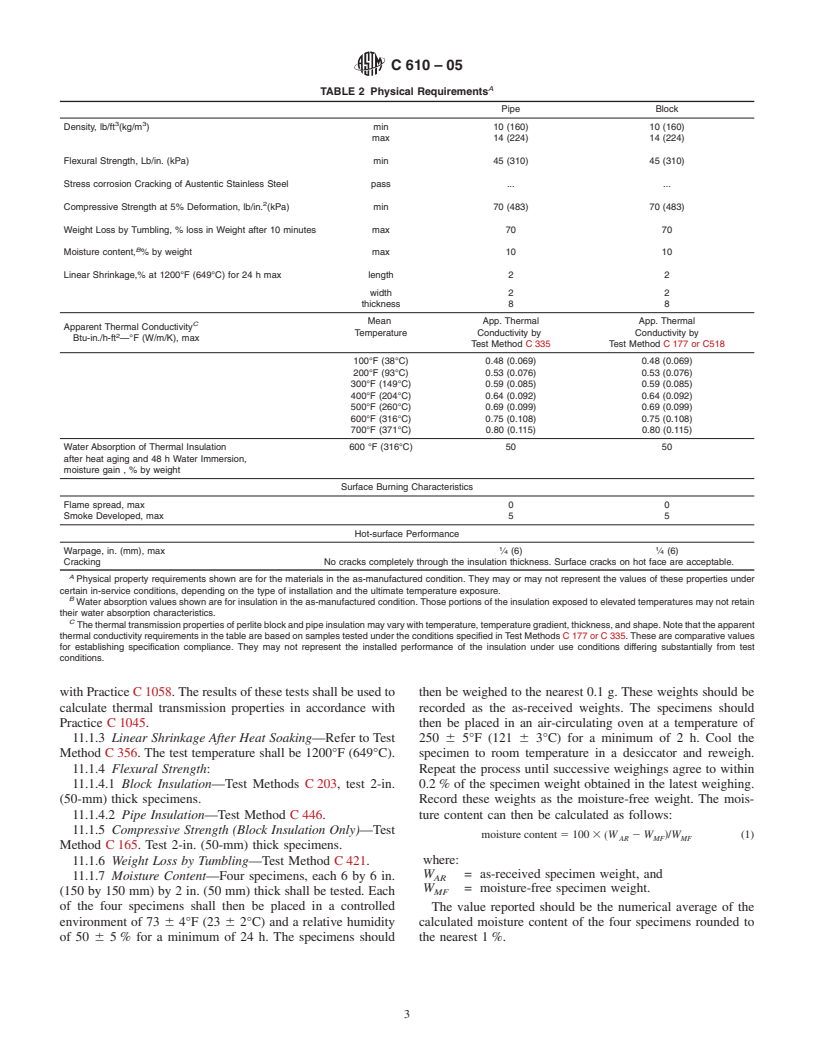

C610–05

3. Terminology 5.2.3 Half-Section Balance—The plane formed by the split

between half sections shall include the cylindrical axis. Devia-

3.1 General—Terminology C 168 shall be considered as

tion of the split plane from the cylinder axis over the 36 or

applying to the terms used in this specification.

1

39.37-in. (914 or 1000-mm) length shall not exceed ⁄8 in. (3.2

3.2 Definitions of Terms Specific t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.