ASTM D6772/D6772M-22

(Test Method)Standard Test Method for Dimensional Stability of Sandwich Core Materials

Standard Test Method for Dimensional Stability of Sandwich Core Materials

SIGNIFICANCE AND USE

5.1 Sandwich panel cores may change planar dimensions when heated. This phenomenon can be associated with the effects of heating upon the core material itself, as well as changes in core moisture content resulting from the heating cycle. It is prudent to know if this may be problematic with regard to the intended final part dimensions.

5.2 This test method provides a standard method of characterizing the dimensional stability of sandwich core materials for design properties, material specifications, research and development applications, and quality assurance.

5.3 Factors that influence dimensional stability of sandwich core materials and shall therefore be reported include the following: core material, methods of material fabrication, core geometry, core thickness, core thickness uniformity, cell wall thickness, specimen geometry, specimen preparation, heating and cooling environments (including temperatures and humidity levels), and specimen conditioning (both prior to and after heating).

SCOPE

1.1 This test method covers the determination of the sandwich core dimensional stability in the two plan dimensions.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.2.1 Within the text, the inch-pound units are shown in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6772/D6772M − 22

Standard Test Method for

1

Dimensional Stability of Sandwich Core Materials

This standard is issued under the fixed designation D6772/D6772M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Specified Precision, the Average for a Characteristic of a

Lot or Process

1.1 This test method covers the determination of the sand-

E177 Practice for Use of the Terms Precision and Bias in

wich core dimensional stability in the two plan dimensions.

ASTM Test Methods

1.2 Units—The values stated in either SI units or inch-

E456 Terminology Relating to Quality and Statistics

pound units are to be regarded separately as standard. The

values stated in each system are not necessarily exact equiva-

3. Terminology

lents; therefore, to ensure conformance with the standard, each

3.1 Definitions—Terminology D3878 defines terms relating

system shall be used independently of the other, and values

to high-modulus fibers and their composites, as well as terms

from the two systems shall not be combined.

relating to sandwich constructions. Terminology D883 defines

1.2.1 Within the text, the inch-pound units are shown in

terms relating to plastics.Terminology E456 and Practice E177

brackets.

define terms relating to statistics. In the event of a conflict

1.3 This standard does not purport to address all of the

between terms, Terminology D3878 shall have precedence

safety concerns, if any, associated with its use. It is the

over the other terminologies.

responsibility of the user of this standard to establish appro-

3.2 Symbols:

priate safety, health, and environmental practices and deter-

3.2.1 CV—coefficient of variation statistic of a sample

mine the applicability of regulatory limitations prior to use.

population for a given property (in percent)

1.4 This international standard was developed in accor-

3.2.2 L — initial (pre-test) measured dimension

dance with internationally recognized principles on standard-

i

ization established in the Decision on Principles for the

3.2.3 L —post-heating measured dimension

f

Development of International Standards, Guides and Recom-

3.2.4 S —standard deviation statistic of a sample popula-

n-1

mendations issued by the World Trade Organization Technical

tion for a given property

Barriers to Trade (TBT) Committee.

3.2.5 x —test result for an individual specimen from the

I

sample population for a given property

2. Referenced Documents

2 3.2.6 x¯—mean or average (estimate of mean) of a sample

2.1 ASTM Standards:

population for a given property

C271/C271M Test Method for Density of Sandwich Core

Materials

4. Summary of Test Method

D883 Terminology Relating to Plastics

4.1 This test method consists of placing a small piece of

D3878 Terminology for Composite Materials

sandwichcorematerialinanelevatedtemperatureenvironment

D5229/D5229M Test Method for MoistureAbsorption Prop-

for a specified period of time. After cooling, the dimensional

erties and Equilibrium Conditioning of Polymer Matrix

changes in the planar dimensions are measured and compared

Composite Materials

to the initial measurements taken prior to thermal exposure,

E122 Practice for Calculating Sample Size to Estimate,With

both immediately after heating and after re-conditioning. A

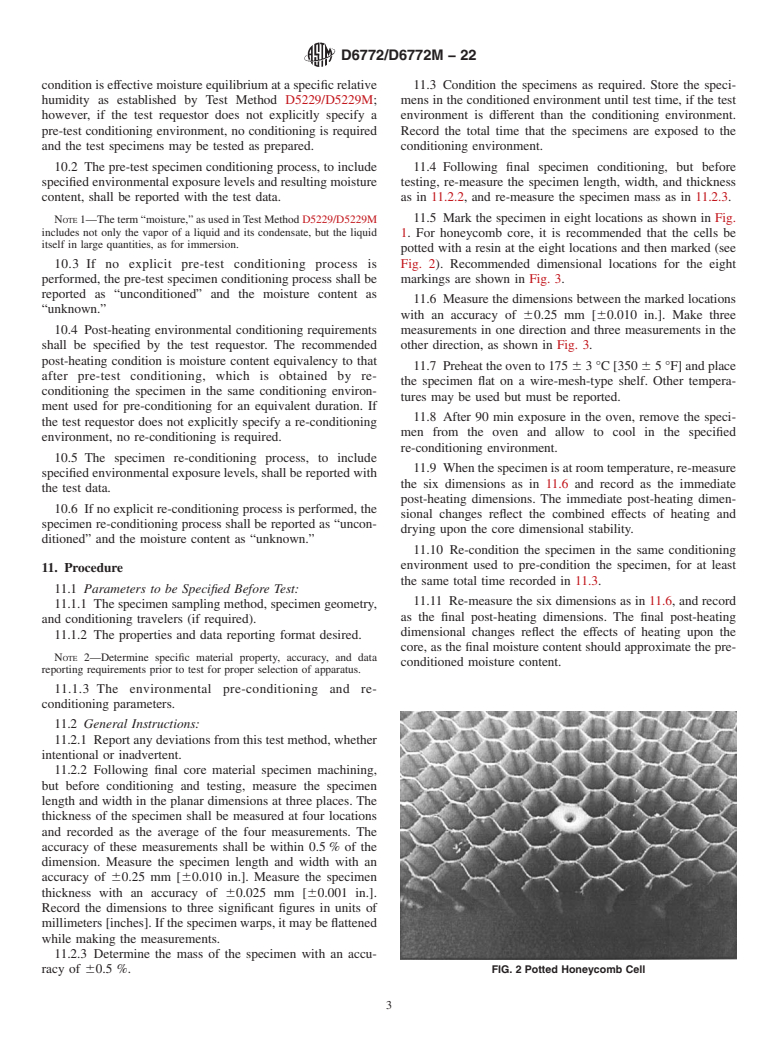

typical honeycomb core specimen is shown in Fig. 1.

1

This test method is under the jurisdiction of ASTM Committee D30 on

5. Significance and Use

Composite Materials and is the direct responsibility of Subcommittee D30.09 on

Sandwich Construction.

5.1 Sandwich panel cores may change planar dimensions

Current edition approved May 1, 2022. Published May 2022. Originally

when heated. This phenomenon can be associated with the

approved in 2002. Last previous edition approved in 2016 as D6772/D6772M – 16.

DOI: 10.1520/D6772_D6772M-22.

effects of heating upon the core material itself, as well as

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

changes in core moisture content resulting from the heating

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

cycle. It is prudent to know if this may be problematic with

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. regard to the intended final part dimensions.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6772/D6

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6772/D6772M − 16 D6772/D6772M − 22

Standard Test Method for

1

Dimensional Stability of Sandwich Core Materials

This standard is issued under the fixed designation D6772/D6772M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the sandwich core dimensional stability in the two plan dimensions.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in

each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used

independently of the other, and values from the two systems shall not be combined.

1.2.1 Within the text, the inch-pound units are shown in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C271/C271M Test Method for Density of Sandwich Core Materials

D883 Terminology Relating to Plastics

D3878 Terminology for Composite Materials

D5229/D5229M Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite

Materials

E122 Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or

Process

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E456 Terminology Relating to Quality and Statistics

3. Terminology

3.1 Definitions—Terminology D3878 defines terms relating to high-modulus fibers and their composites, as well as terms relating

1

This test method is under the jurisdiction of ASTM Committee D30 on Composite Materials and is the direct responsibility of Subcommittee D30.09 on Sandwich

Construction.

Current edition approved April 1, 2016May 1, 2022. Published April 2016May 2022. Originally approved in 2002. Last previous edition approved in 20152016 as

D6772 – 15.D6772/D6772M – 16. DOI: 10.1520/D6772_D6772M-16.10.1520/D6772_D6772M-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6772/D6772M − 22

to sandwich constructions. Terminology D883 defines terms relating to plastics. Terminology E456 and Practice E177 define terms

relating to statistics. In the event of a conflict between terms, Terminology D3878 shall have precedence over the other

terminologies.

3.2 Symbols:

3.2.1 CV—coefficient of variation statistic of a sample population for a given property (in percent)

3.2.2 L — initial (pre-test) measured dimension

i

3.2.3 L —post-heating measured dimension

f

3.2.4 S —standard deviation statistic of a sample population for a given property

n-1

3.2.5 x —test result for an individual specimen from the sample population for a given property

I

3.2.6 x¯—mean or average (estimate of mean) of a sample population for a given property

4. Summary of Test Method

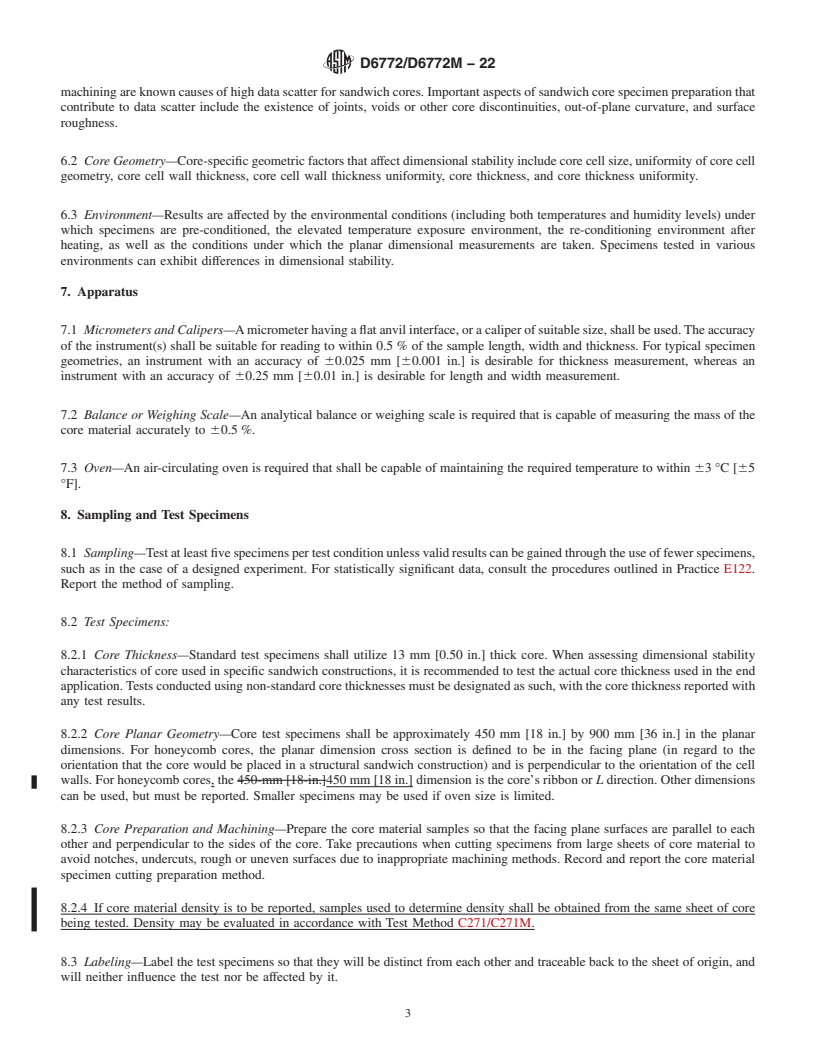

4.1 This test method consists of placing a small piece of sandwich core material in an elevated temperature environment for a

specified period of time. After cooling, the dimensional changes in the planar dimensions are measured and compared to the initial

measurements taken prior to thermal exposure, both immediately after heating and after re-conditioning. A typical honeycomb core

specimen is shown in Fig. 1.

FIG. 1 Dimensional Stability Specimen

5. Significance and Use

5.1 Sandwich panel cores may change planar dimensions when heated. This phenomenon

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.