ASTM D6241-04(2009)e1

(Test Method)Standard Test Method for the Static Puncture Strength of Geotextiles and Geotextile-Related Products Using a 50-mm Probe

Standard Test Method for the Static Puncture Strength of Geotextiles and Geotextile-Related Products Using a 50-mm Probe

SIGNIFICANCE AND USE

5.1 This test method for determining the puncture strength of geotextiles is to be used by the industry as an index of puncture strength. The use of this test method is to establish an index value by providing standard criteria and a basis for uniform reporting.

5.2 This test method is considered satisfactory for acceptance testing of commercial shipments of geotextiles.

5.3 In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens that are as homogeneous as possible and that are from a lot of the type in question. The test specimens then should be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using Student's t-test for unpaired data and an acceptable probability level chosen by the two parties before the testing is begun. If a bias is found, either its cause must be found and corrected, or the purchaser and the supplier must agree to interpret future test results in the light of the known bias.

5.4 This test method is not applicable to materials that are manufactured in sizes that are too small to be placed into the test apparatus in accordance with the procedures in this test method. Furthermore, it is not appropriate to separate plies of a geosynthetic or geocomposite for use in this test method.

SCOPE

1.1 This test method is an index test used to measure the force required to puncture a geotextile and geotextile-related products. The relatively large size of the plunger provides a multidirectional force on the geotextile.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D6241 − 04(Reapproved 2009)

Standard Test Method for the

Static Puncture Strength of Geotextiles and Geotextile-

Related Products Using a 50-mm Probe

This standard is issued under the fixed designation D6241; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Title was added to Table 1 and editorial changes were made throughout in February 2014.

1. Scope 3. Terminology

3.1 Definitions—For definitions of other textile terms used

1.1 This test method is an index test used to measure the

in this test method, refer to Terminology D123. For definitions

force required to puncture a geotextile and geotextile-related

of other terms relating to geosynthetics used in this test

products. The relatively large size of the plunger provides a

method, refer to Terminology D4439.

multidirectional force on the geotextile.

3.2 Definitions of Terms Specific to This Standard:

1.2 The values stated in SI units are to be regarded as the

3.2.1 atmoshere for testing geotextiles, n—air maintained at

standard. The values given in parentheses are for information

a relative humidity of 50 to 70 % and a temperature of 21 6

only.

2°C (70 6 4°F).

1.3 This standard does not purport to address all of the

3.2.2 geotextile, n—a permeable geosynthetic composed

safety concerns, if any, associated with its use. It is the

solely of textiles.

responsibility of the user of this standard to establish appro-

3.2.3 puncture resistance, n—the inherent resisting mecha-

priate safety and health practices and determine the applica-

nism of the test specimen to the failure by a penetrating or

bility of regulatory limitations prior to use.

puncturing object.

2. Referenced Documents

4. Summary of Test Method

2.1 ASTM Standards:

4.1 A test specimen is clamped without tension between

D76 Specification for Tensile Testing Machines for Textiles

circular plates and secured in a tensile or compression testing

D123 Terminology Relating to Textiles

machine, or both. A force is exerted against the center of the

D1776 Practice for Conditioning and Testing Textiles

unsupported portion of the test specimen by a steel plunger

D1883 Test Method for CBR (California Bearing Ratio) of

attached to the load indicator until rupture occurs. The maxi-

Laboratory-Compacted Soils mum force is the value of puncture strength.

D4354 Practice for Sampling of Geosynthetics and Rolled

5. Significance and Use

Erosion Control Products(RECPs) for Testing

D4439 Terminology for Geosynthetics

5.1 This test method for determining the puncture strength

E691 Practice for Conducting an Interlaboratory Study to

of geotextiles is to be used by the industry as an index of

Determine the Precision of a Test Method

puncture strength. The use of this test method is to establish an

index value by providing standard criteria and a basis for

NOTE 1—Test Method D1883 describes a mold (CBR mold) that can be

uniform reporting.

used for this test method.

5.2 This test method is considered satisfactory for accep-

tance testing of commercial shipments of geotextiles.

This test method is under the jurisdiction of ASTM Committee D35 on

5.3 In case of a dispute arising from differences in reported

Geosynthetics is the direct responsibility of Subcommittee D35.01 on Mechanical

test results when using this test method for acceptance testing

Properties

of commercial shipments, the purchaser and the supplier

CurrenteditionapprovedJune1,2009.PublishedJuly2009.Originallyapproved

should conduct comparative tests to determine if there is a

in 1998. Last previous edition approved in 2004 as D6241 – 04. DOI: 10.1520/

D6241-04R09E01.

statistical bias between their laboratories. Competent statistical

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

assistance is recommended for the investigation of bias. As a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

minimum, the two parties should take a group of test speci-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. mens that are as homogeneous as possible and that are from a

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6241 − 04 (2009)

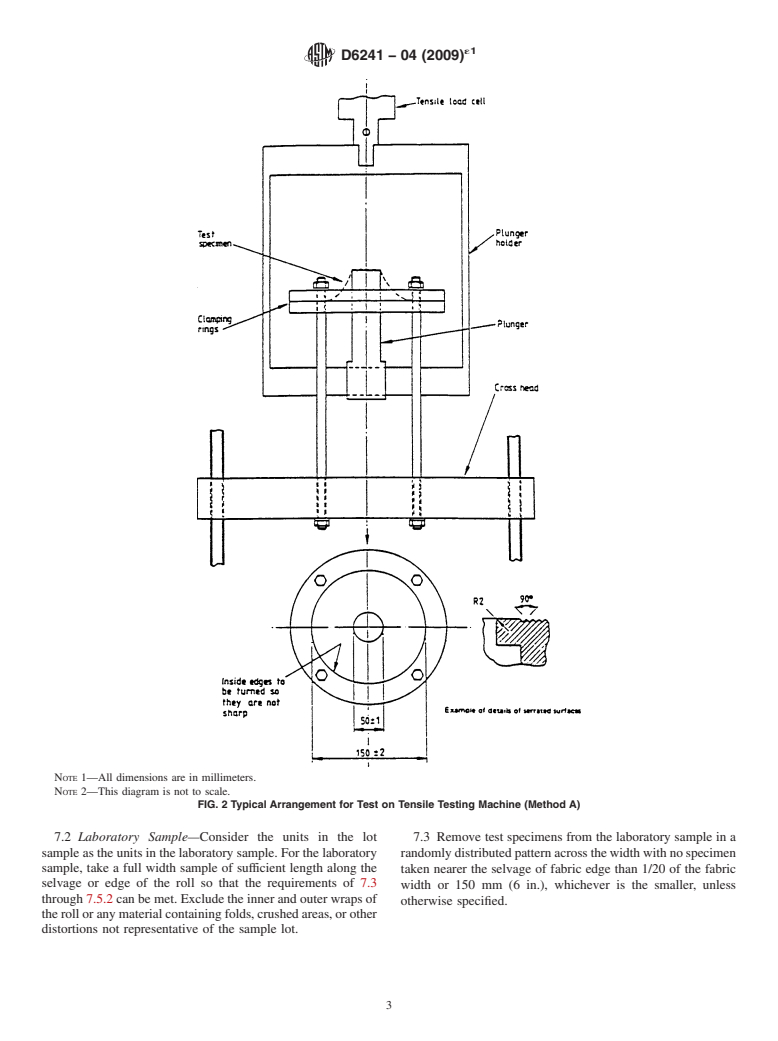

lot of the type in question. The test specimens then should be 6.3 Clamping Apparatus, consisting of concentric plates

randomly assigned in equal numbers to each laboratory for with an internal diameter of 150 mm (5.9 in.), capable of

testing.Theaverageresultsfromthetwolaboratoriesshouldbe

clamping the test specimen without slippage (limit slippage of

compared using Student’s t-test for unpaired data and an

test specimen to 5 mm). The external diameter is suggested to

acceptable probability level chosen by the two parties before

be 250 mm (9.8 in.). The diameter of the holes used for

the testing is begun. If a bias is found, either its cause must be

securing the ring clamp assemblage is suggested to be 11 mm

found and corrected, or the purchaser and the supplier must

(7/16 in.) and equally spaced at a diameter of 220 mm (8.7 in.).

agree to interpret future test results in the light of the known

The surfaces of these plates can consist of grooves with rubber

bias.

O-rings or coarse sandpaper bonded onto opposing surfaces. It

5.4 This test method is not applicable to materials that are

is suggested that 9.5-mm (3/8-in.) bolts be welded to the

manufactured in sizes that are too small to be placed into the

bottom plate so that the top plate can be placed over the bolts

test apparatus in accordance with the procedures in this test

and nuts easily tightened. A guide block may be used to help

method. Furthermore, it is not appropriate to separate plies of

seat the material being clamped. Other clamps that eliminate

a geosynthetic or geocomposite for use in this test method.

slippage are acceptable. See Fig. 2 and Fig. 3.

6. Apparatus NOTE 2—Plans for a hydraulic clamping apparatus are on file atASTM.

6.1 Testing Machine, must be constant-rate-of extension

7. Sampling

(CRE) type, with autographic recorder conforming to the

requirement of Specification D76.

7.1 Lot Sample—In the absence of other guidelines, divide

the product into lots and take lot samples as specified in

6.2 Plunger, with a flat diameter of 50 6 1 mm with a radial

edge of 2.5 6 0.5 mm. See Fig. 1. Practice D4354.

NOTE 1—All dimensions are in millimeters.

NOTE 2—This diagram is not to scale.

FIG. 1 Plunger

´1

D6241 − 04 (2009)

NOTE 1—All dimensions are in millimeters.

NOTE 2—This diagram is not to scale.

FIG. 2 Typical Arrangement for Test on Tensile Testing Machine (Method A)

7.2 Laboratory Sample—Consider the units in the lot 7.3 Remove test specimens from the laboratory sample in a

sample as the units in the laboratory sample. For the laboratory randomlydistributedpatternacrossthewidthwithnospecimen

sample, take a full width sample of sufficient length along the

taken nearer the selvage of fabric edge than 1/20 of the fabric

selvage or edge of the roll so that the requirements of 7.3

width or 150 mm (6 in.), whichever is the smaller, unless

through 7.5.2 can be met. Exclude the inner and outer wraps of

otherwise specified.

therolloranymaterialcontainingfolds,crushedareas,orother

distort

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.