ASTM C1482-00

(Specification)Standard Specification for Polyimide Flexible Cellular Thermal and Sound Absorbing Insulation

Standard Specification for Polyimide Flexible Cellular Thermal and Sound Absorbing Insulation

SCOPE

1.1 This specification covers the composition and physical properties of lightweight, flexible open-cell polyimide foam insulation intended for use as thermal and sound-absorbing insulation for temperatures from -328 up to +572o F (-200 and +300o C) in commercial and industrial environments.

1.1.1 Annex A1 includes faced polyimide foam as specified by the U.S. Navy for marine applications.

1.1.2 This standard is designed as a material specification and not a design document. Physical property requirements vary by application and temperature. No single test is adequate for estimating either the minimum or maximum use temperature of polyimide foam under all possible conditions. Consult the manufacturer for specific recommendations and physical properties for specific applications.

1.1.3 The use of an appropriate vapor retarder is required in all applications where condensation could occur and cause a decrease in thermal performance or affect other system properties.

1.2 The values stated in inch-pound units are to be regarded as the standard. The System International equivalents of the inch-pound units are given in parentheses for information only and may be approximate.

1.3 This standard does not purport to address all of the safety concerns associated with its use. It is the responsibility of the user to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

Note 1—The subject matter of this material specification is not covered by any other ASTM specification. There is no known ISO standard covering the subject of this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1482 – 00

Standard Specification for

Polyimide Flexible Cellular Thermal and Sound Absorbing

Insulation

This standard is issued under the fixed designation C 1482; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope C 177 Test Method for Steady-State Heat-Flux Measure-

ments and Thermal Transmission Properties by Means of

1.1 This specification covers the composition and physical

the Guarded-Hot-Plate Apparatus

properties of lightweight, flexible open-cell polyimide foam

C 302 Test Method for Density and Dimensions of Pre-

insulation intended for use as thermal and sound-absorbing

formed Pipe-Covering-Type Thermal Insulation

insulation for temperatures from -328 up to +572° F (-200 and

C 335 Test Method for Steady-State Heat Transfer Proper-

+300° C) in commercial and industrial environments.

ties of Horizontal Pipe Insulation

1.1.1 Annex A1 includes faced polyimide foam as specified

C 390 Criteria for Sampling and Acceptance of Preformed

by the U.S. Navy for marine applications.

Thermal Insulation Lots

1.1.2 This standard is designed as a material specification

C 411 Test Method for Hot-Surface Performance of High-

and not a design document. Physical property requirements

Temperature Thermal Insulation

vary by application and temperature. No single test is adequate

C 423 Test Method for Sound Absorption and Sound Ab-

for estimating either the minimum or maximum use tempera-

sorption Coefficients by the Reverberation Room Method

ture of polyimide foam under all possible conditions. Consult

C 447 Practice for Estimating the Maximum Use Tempera-

the manufacturer for specific recommendations and physical

ture of Thermal Insulations

properties for specific applications.

C 518 Test Method for Steady-State Heat Flux Measure-

1.1.3 The use of an appropriate vapor retarder is required in

ments and Thermal Transmission Properties by Means of

all applications where condensation could occur and cause a

the Heat Flow Meter Apparatus

decrease in thermal performance or affect other system prop-

C 634 Terminology Relating to Environmental Acoustics

erties.

C 665 Specification for Mineral-Fiber Blanket Insulation

1.2 The values stated in inch-pound units are to be regarded

for Light Frame Construction and Manufactured Housing

as the standard. The System International equivalents of the

C 1045 Practice for Calculating Thermal Transmission

inch-pound units are given in parentheses for information only

Properties From Steady-State Heat Flux Measurements

and may be approximate.

C 1058 Practice for Selecting Temperatures for Evaluating

1.3 This standard does not purport to address all of the

and Reporting Thermal Properties of Thermal Insulation

safety concerns associated with its use. It is the responsibility

C 1114 Test Method for Steady-State Thermal Transmission

of the user to establish appropriate safety and health practices

Properties by Means of the Thin-Heater Apparatus

and determine the applicability of regulatory requirements

D 395 Test Method for Rubber Property - Compression Set

prior to use.

D 543 Test Method for Resistance of Plastics to Chemical

NOTE 1—The subject matter of this material specification is not covered 4

Reagents

by any other ASTM specification. There is no known ISO standard

D 638 Test Method for Tensile Properties of Plastics

covering the subject of this standard.

D 2126 Test Method for Response of Rigid Cellular Plastics

to Thermal and Humid Aging

2. Referenced Documents

D 2863 Test Method for Measuring the Minimum Oxygen

2.1 ASTM Standards:

Concentration to Support Candle-like Combustion of Plas-

C 165 Test Method for Measuring Compressive Properties

2 tics (Oxygen Index)

of Thermal insulations

D 3574 Test Methods for Flexible Cellular Materials - Slab,

C 168 Terminology Relating to Thermal Insulating Materi-

2 Bonded, and Molded Urethane Foams

als

D 3675 Test Method for Surface Flammability of Flexible

Cellular Materials Using A Radiant Heat Energy Source

This specification is under the jurisdiction of ASTM Committee C16 on

Thermal Insulation and is the direct responsibility of Subcommittee C16.22 on Annual Book of ASTM Standards, Vol 09.01.

Organic and Non-homogenous Inorganic Thermal Insulations. Annual Book of ASTM Standards, Vol 08.01.

Current edition approved October 10, 2000. Published January 2001. Annual Book of ASTM Standards, Vol 08.02.

2 6

Annual Book of ASTM Standards, Vol 04.06. Annual Book of ASTM Standards, Vol 09.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

C 1482

E 84 Test Method for Surface Burning Characteristics of 3.2.2 slab—a rectangular section, piece, or sheet of foam

Building Materials that is cut from a bun, or block of foam.

E 96 Test Method for Water Vapor Transmission of Mate- 3.2.3 polyimide foam—a flexible cellular product in which

rials the bonds formed between monomers during polymerization

E 176 Terminology of Fire Standards are imide or amide bonds. The theoretical mole fraction of

E 662 Test Method for Specific Optical Density of Smoke imide bonds must be greater than the theoretical mole fraction

Generated by Solid Materials of amide bonds.

E 795 Practices for Mounting Test Specimens During

4. Classification

Sound Absorption Tests

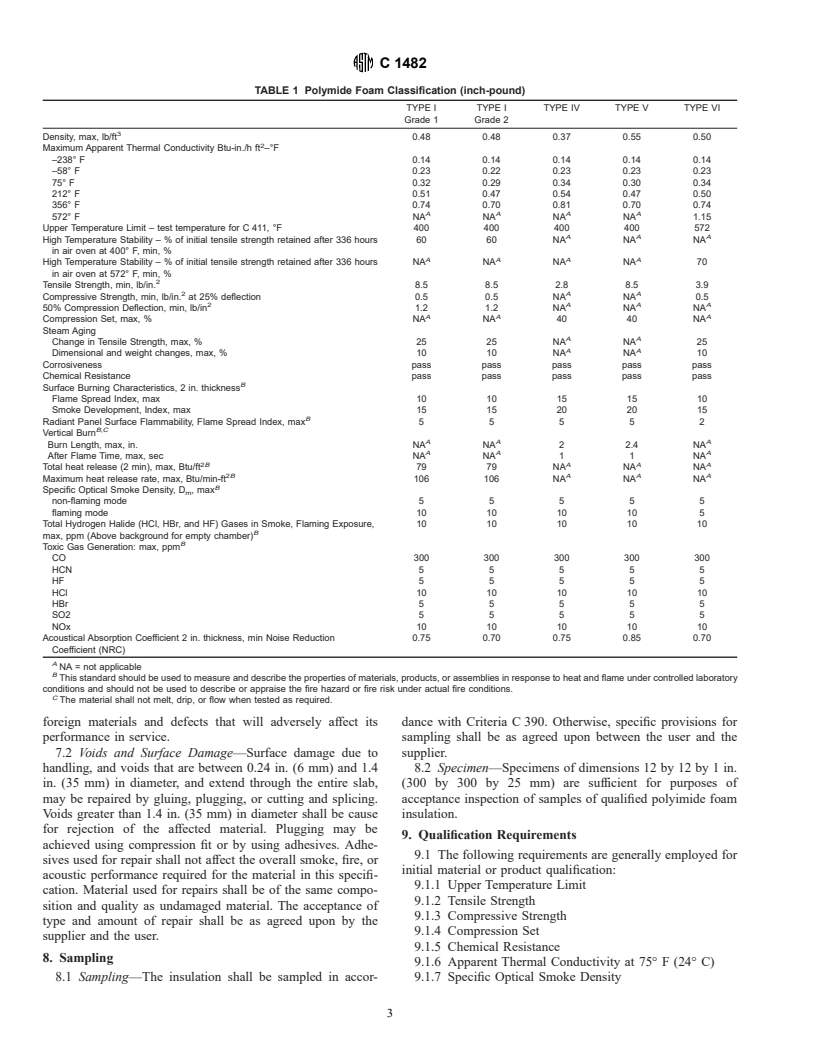

4.1 The flexible polyimide cellular insulations of this speci-

E 800 Guide for Measurement of Gases Present or Gener-

7 fication are classified into Types I through VI as listed in Tables

ated During Fires

1 and 2(Note 2). Type I is further subdivided into two Grades

E 1354 Test Method for Heat and Visible Smoke Release

based on maximum allowable thermal conductivity at 75° F

Rates for Materials and Products Using an Oxygen Con-

7 (24° C). . The Types II and III are subdivided into Classes

sumption Calorimeter

(Note 3).

2.2 U.S. Federal Standards:

FAR 25.853(a), Appendix F, Part 1, (a) (1) (i) Test Criteria

NOTE 2—Although all types find application in a wide variety of

and Procedures for Showing Compliance with Sec. markets, the current primary market for each type is as follows:

Type I—marine and industrial applications.

25.853, or 25.855

Type II—Type II is Type I foam faced and used in specific marine

MIL-C-20079 Cloth, Glass; Tape, Textile Glass; and

applications, as specified for the U.S. Navy in Annex A1.

Thread, Glass

Type III—Type III is Type I foam pipe shaped and used in specific

MIL-A-3316 Adhesive, Fire-Resistant, Thermal Insulation

marine applications, as specified for the U.S. Navy in Annex A1.

MIL-PRF-24688A Performance Specification Insulation,

Types IV and V—aerospace applications depending on density.

Thermal and Acoustic Absorptive

Type VI—applications requiring improved high temperature and fire

performance.

DOD-E-24607 Enamel, Interior, Nonflaming (Dry), Chlori-

NOTE 3—The Type II and Type III designations as well as the

nated Alkyd Resin, Semigloss (Metric)

subdivision of Types into Classes is to maintain uniformity with existing

2.3 Private Sector Standards:

U.S. Navy nomenclature (Annex A1).

Boeing BSS 7239 Test Method for Toxic Gas Generation by

Materials on Combustion

5. Materials and Manufacture

TAPPI T 803 Puncture and Stiffness Test of Container

5.1 Polyimide foam shall be manufactured from the appro-

Board

priate monomers, and necessary compounding ingredients to

TM-232 Vertical Pipe-Chase Test to Determine Flame-

conform to 3.2.3. This is not intended to imply that foam

Propagation Characteristics of Pipe Covering

products made using different materials are equivalent with

respect to all physical properties.

3. Terminology

6. Physical Properties

3.1 Definitions—Terms used in this specification are defined

6.1 The insulation shall conform to the requirements in

in Terminology C 168, Terminology C 634, and Terminology

Tables 1 and 2 for each type, unless specifically stated

E 176. In the case of a conflict, Terminology C 168 shall be the

otherwise by agreement between the supplier and the pur-

dominant authority.

chaser. Tests shall be made in accordance with the methods

3.2 Definitions of Terms Specific to This Standard:

specified in 11.1-11.20.

3.2.1 flexible cellular product—a cellular organic polymeric

6.1.1 Upper Temperature Limit—Upper temperature limit

material that will not rupture when a specimen 8 by 1 by 1 in.

shall be determined according to 11.4 at the application’s

(200 by 25 by 25 mm) is bent around a 1 in. (25 mm) diameter

intended maximum use temperature or at a temperature deter-

mandrel at a uniform rate of one lap in 5 sec. at a temperature

mined by agreement between the purchaser and manufacturer.

between 64 and 85°F (18 and 29°C), in accordance with the

6.1.2 Burning Characteristics—The uncoated and unfaced

description of a flexible cellular product (currently Subsection

foam shall conform to the requirements in Tables 1 and 2 for

3.1.3) in Test Methods D 3574.

each type, when tested in accordance with 11.12-11.19, without

the use of flame/smoke or heat suppressant barriers or coatings.

6.1.3 Sound Absorbing Performance—Unless specifically

Annual Book of ASTM Standards, Vol 04.07.

Federal Aviation Regulations Part 25 (Airworthiness Standards, Transport otherwise agreed to between the supplier and the purchaser, all

Category Aircraft, and Section 25.853. Procedure in appendix F, Part I, (a) (1) (i)

tests shall be made in accordance with the methods specified in

and (ii). Available from Superintendent of Documents, U.S. Government Printing

11.20.

Office P.O. Box 371954, Pittsburgh, PA 15250-7954.

6.2 The values stated in Tables 1 and 2 should not be used

Available from the Standardization Document Order Desk, 700 Robbins

Avenue, Building 4D, Philadelphia, PA 19111-5094. as design values. It is the buyer’s responsibility to specify

Available from Boeing Commercial Airplane Group, Material Division, P.O.

design requirements and obtain supporting documentation

Box 3707, Seattle, WA 98124-2207.

from the material supplier.

Available from the Technical Association of the Pulp and Paper Industry, P.O.

Box 105113, Atlanta GA 30348.

7. Workmanship and Appearance

Available from Armstrong World Industries, Inc., Research and Development,

P.O. Box 3511, Lancaster, PA 17604. 7.1 The slab offered as saleable material shall be free of

C 1482

TABLE 1 Polymide Foam Classification (inch-pound)

TYPE I TYPE I TYPE IV TYPE V TYPE VI

Grade 1 Grade 2

Density, max, lb/ft 0.48 0.48 0.37 0.55 0.50

Maximum Apparent Thermal Conductivity Btu-in./h ft –°F

–238° F 0.14 0.14 0.14 0.14 0.14

–58° F 0.23 0.22 0.23 0.23 0.23

75° F 0.32 0.29 0.34 0.30 0.34

212° F 0.51 0.47 0.54 0.47 0.50

356° F 0.74 0.70 0.81 0.70 0.74

A A A A

572° F NA NA NA NA 1.15

Upper Temperature Limit – test temperature for C 411, °F 400 400 400 400 572

A A A

High Temperature Stability–%of initial tensile strength retained after 336 hours 60 60 NA NA NA

in air oven at 400° F, min, %

A A A A

High Temperature Stability–%of initial tensile strength retained after 336 hours NA NA NA NA 70

in air oven at 572° F, min, %

Tensile Strength, min, lb/in. 8.5 8.5 2.8 8.5 3.9

2 A A

Compressive Strength, min, lb/in. at 25% deflection 0.5 0.5 NA NA 0.5

2 A A A

50% Compression Deflection, min, lb/in 1.2 1.2 NA NA NA

A A A

Compression Set, max, % NA NA 40 40 NA

Steam Aging

A A

Change in Tensile Strength, max, % 25 25 NA NA 25

A A

Dimensional and weight changes, max, % 10 10 NA NA 10

Corrosiveness pass pass pass pass pass

Chemical Resistance pass pass pass pass pass

B

Surface Burning Characteristics, 2 in. thickness

Flame Spread Index, max 10 10 15 15 10

Smoke Development, Index, max 15 15 20 20 15

B

Radiant Panel Surface Flammability, Flame Spread Index, max 55552

B,C

Vertical Burn

A A A

Burn Length, max, in. NA NA 2 2.4 NA

A A A

After Flame Time, max, sec NA NA 11 NA

2B A A A

Total heat release (2 min), max, Btu/ft 79 79 NA NA NA

2B A A A

Maximum heat release rate, max, Btu/min-ft 106 106 NA NA NA

B

Specific Optical Smoke Density, D , max

m

non-flaming mode 5 5 5 5 5

flaming mode 10 10 10 10 5

Total Hydrogen Halide (HCl, HBr, and HF) Gases in Smoke, Flaming Exposure, 10 10 10 10 10

B

max, ppm (Above background for empty chamber)

B

Toxic Gas Generation: max, ppm

CO 300 300 300 300 300

HCN 55555

HF 55555

HCl 10 10 10 10 10

HBr 55555

SO2 55555

NOx 10 10 10 10 10

Acoustical Absorption Coefficient 2 in. thickness, min Noise Reduction 0.75 0.70 0.75 0.85 0.70

Coefficient (NRC)

A

NA = not applicable

B

This standard should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory

conditions and should not be used to describe or appraise the fire hazard or fire risk under actual fire conditions.

C

The material shall not melt, drip, or flow when tested as required.

foreign materials and defects that will adversely affect its dance with Criteria C 390. Otherwise, specific provisions for

performance in service. sampling shall be as agreed upon between the user and the

7.2 Voids and Surface Damage—Surface damage due to supplier.

handling, and voids that are between 0.24 in. (6 mm) and 1.4 8.2 Specimen—Specimens of dimensions 12 by 12 by 1 in.

in. (35 mm) in diameter, and extend through the entire slab, (300 by 300 by 25 mm) are sufficient for purposes of

may be repaired by gluing, plugging, or cutting and splicing. acceptance inspection of samples of qualified polyimide foam

Voids greater than 1.4 in. (35 mm) in diameter shall be cause insulation.

for rejection of the affected material. Plugging may be

9. Qualification Requirements

achieved using compression fit or by using adhesives. Adhe-

9.1 The following requirements are generally employed for

sives used for repair shall not affect the overall smoke, fire, or

initial material or product qualification:

acoustic performance required for the material in this specifi-

9.1.1 Upper Temperature Limit

cation. Material used for repairs shall be of the same compo-

9.1.2 Tensile Strength

sition and quality as undamaged material. The acceptance of

9.1.3 Compressive Strength

type and amount of repair shall be as agreed upon by the

9.1.4 Compression Set

supplier and the user.

9.1.5 Chemical Resistance

8. Sampling

9.1.6 Apparent Thermal Conductivity at 75° F (24° C)

8.1 Sampling—The insulation shall be sampled in accor- 9.1.7 Specific Optical Smoke Density

C 1482

TABLE 2 Polymide Foam Classification (SI units)

TYPE I TYPE I TYPE IV TYPE V TYPE VI

Grade 1 Grade

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.