ASTM D3122-95

(Specification)Standard Specification for Solvent Cements for Styrene-Rubber (SR) Plastic Pipe and Fittings

Standard Specification for Solvent Cements for Styrene-Rubber (SR) Plastic Pipe and Fittings

SCOPE

1.1 This specification provides general requirements for styrene-rubber solvent cements to be used in joining styrene-rubber (SR) plastic pipe and fittings.

1.2 A recommended procedure for joining styrene-rubber pipe and fittings is given in the appendix.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 6, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 3122 – 95

Standard Specification for

Solvent Cements for Styrene-Rubber (SR) Plastic Pipe and

Fittings

This standard is issued under the fixed designation D 3122; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope nology F 412, and abbreviations are in accordance with Ter-

minology D 1600, unless otherwise specified.

1.1 This specification provides general requirements for

styrene-rubber solvent cements to be used in joining styrene-

4. General Requirements

rubber (SR) plastic pipe and fittings.

4.1 The solvent cement shall be a solution of styrene-rubber

1.2 A recommended procedure for joining styrene-rubber

(SR) plastic compound or resin meeting the following require-

pipe and fittings is given in the appendix.

ments.

1.3 The values stated in SI units are to be regarded as the

4.1.1 The SR plastic compounds or resin shall contain at

standard. The values given in parentheses are for information

least 50 % styrene plastics, combined with rubbers to a

only.

minimum rubber content of 5 %, and compounding materials

1.4 The following safety hazards caveat pertains only to the

such as antioxidants and lubricants, and may contain up to

test methods portion, Section 6, of this specification: This

15 % acrylonitrile combined in the styrene plastics or rubbers,

standard does not purport to address all of the safety concerns,

or both. The rubbers shall be of the polybutadiene or butadiene-

if any, associated with its use. It is the responsibility of the user

styrene type, or both, with a maximum styrene content of 25 %

of this standard to establish appropriate safety and health

or nitrile type or both. The combined styrene plastics and

practices and determine the applicability of regulatory limita-

rubber content shall be not less than 90 %. No filler may be

tions prior to use.

used. (See Specification D 2852.)

2. Referenced Documents 4.2 Either virgin or clean rework material may be used

provided that the rework material is generated from the solvent

2.1 ASTM Standards:

cement manufacturer’s own production, is compatible with

D 618 Practice for Conditioning Plastics and Electrical

virgin material, and will produce a cement that meets the

Insulating Materials for Testing

requirements of this specification.

D 1084 Test Methods for Viscosity of Adhesives

4.3 The cement shall be free-flowing and shall not contain

D 1600 Terminology for the Abbreviated Terms Relating to

2 4

lumps, macroscopic undissolved particles, or any foreign

Plastics ,

matter that will adversely affect the ultimate joint strength or

D 2852 Specification for Styrene-Rubber (SR) Plastic Drain

chemical resistance of the cement.

Pipe and Fittings

4.4 The cement shall show no gelatin. It shall show no

F 402 Practice for Safe Handling of Solvent Cements,

stratification or separation that cannot be removed by stirring.

Primers, and Cleaners Used for Joining Thermoplastic Pipe

4 4.5 The cement shall be a solution of styrene-rubber (SR)

and Fittings

plastic compound or resin meeting the requirements of 4.1.1

F 412 Terminology Relating to Plastic Piping Systems

dissolved in one of the following solvents:

F 493 Specification for Solvent Cements for Chlorinated

4.5.1 Methyl ethyl ketone.

Poly (Vinyl Chloride) (CPVC) Plastic Pipe and Fittings

4.5.2 Toluene.

3. Terminolgy

NOTE 1—It is recommended that solvent cements made to this speci-

3.1 Definitions—Definitions are in accordance with Termi-

fication not be orange since that color is being recommended for use with

CPVC solvent cement under Specification F 493.

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic

5. Detail Requirements

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining.

5.1 Resin Content—The SR resin compound shall be 20 %

Current edition approved Sept. 10, 1995. Published November 1995. Originally

published as D 3122 – 72. Last previous edition D 3122 – 93.

minimum by mass with methyl ethyl ketone as the solvent or

Annual Book of ASTM Standards, Vol 08.01.

shall be 15 % minimum by mass with toluene as the solvent,

Annual Book of ASTM Standards, Vol 15.06.

4 when tested in accordance with 6.3.

Annual Book of ASTM Standards, Vol 08.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 3122

5.2 Dissolution—The cement shall be capable of dissolving mable solvents and should be maintained at 15 mm Hg

an additional 10 % by mass of styrene-rubber (SR) resin or maximum. Remove the tin from the oven and cap immediately.

compound meeting the requirements of 4.1.1 at 23 6 2°C (73.4 Place in a desiccator until cooled to room temperature. Weigh

6 3.6°F) without evidence of gelation. the tin and dried sample to the nearest 1 mg.

5.3 Viscosity—The minimum viscosity at 23 6 2°C (73.4 6

NOTE 4—This material is usually nonhomogeneous and shall be thor-

3.6°F) shall be 90 mPa·s (90 cP) when tested in accordance

oughly stirred before weighing. The weighing shall also be accomplished

with 6.2.

quickly to avoid loss of solvent by volatilization.

NOTE 5—The use of a vacuum oven is mandatory for drying the

NOTE 2—Cements approaching the minimum viscosity of this specifi-

specimen because this oven has no exposed heating surface nor an open

cation generally are not recommended for noninterference-type fit (where

flame, thus avoiding the danger of flashing. The oven also provides an

gap exists between the pipe and fitting socket).

open vacuum to exhaust solvent fumes.

5.4 Lap Shear Strength:

NOTE 6—The specimen shall be left in the oven for 45 min and no

longer. Specimens left in for1hor more show a definite increase in

5.4.1 The minimum lap shear strength of a cement made

weight.

with methyl ethyl ketone as the solvent when tested in

accordance with 6.4 shall be 3.5 MPa (500 psi) after a 16-h 6.3.3 Calculation—Calculate the percentage total solids,

curing time and 6.0 MPa (900 psi) after a 48-h curing time.

TS, as follows:

5.4.2 The minimum lap shear strength of a cement made

TS,% 5 ~~B 2 A!/~C 2 A!!3 100

with toluene as the solvent when tested in accordance with 6.4

shall be 1.6 MPa (230 psi) after a 16-h curing time and 2.4 MPa where:

A = weight of ointment tin,

(350 psi) after a 48-h curing time.

B = weight of tin and specimen after drying, and

NOTE 3—These values should not be used for designing pipe joints.

C = weight of tin and specimen before drying.

6.3.4 Precision—Duplicate samples shall be tested for best

6. Test Methods

results. Duplicate results obtained by the same analyst, on the

6.1 The properties enumerated in this specification shall be

same material, on the same day, in the same laboratory are

determined in accordance with the following methods:

suspect if they differ by more than 0.52 % absolute. This

6.1.1 Conditioning—Condition the test specimens at 23 6

procedure has a standard deviation of 0.13.

2°C (73.4 6 3.6°F) for not less than 40 h prior to test in

6.4 Lap Shear Strength:

accordance with Procedure A of Practice D 618, for those tests

6.4.1 Number of Specimens—A minimum of five specimens

where conditioning is required.

shall be tested for the requirement specified in 5.4.

6.1.2 Test Conditions—Conduct tests at 23 6 2°C (73.4 6

6.4.2 Cut 25 by 25-mm (1 by 1-in.) and 25 by 50-mm (1 by

3.6°F), unless otherwise specified in the test methods or in this

2-in.) sections from a 6-mm ( ⁄4-in.) thick rigid styrene-rubber

specification.

plastic (SR) sheet. One section of each size is required for each

6.2 Viscosity:

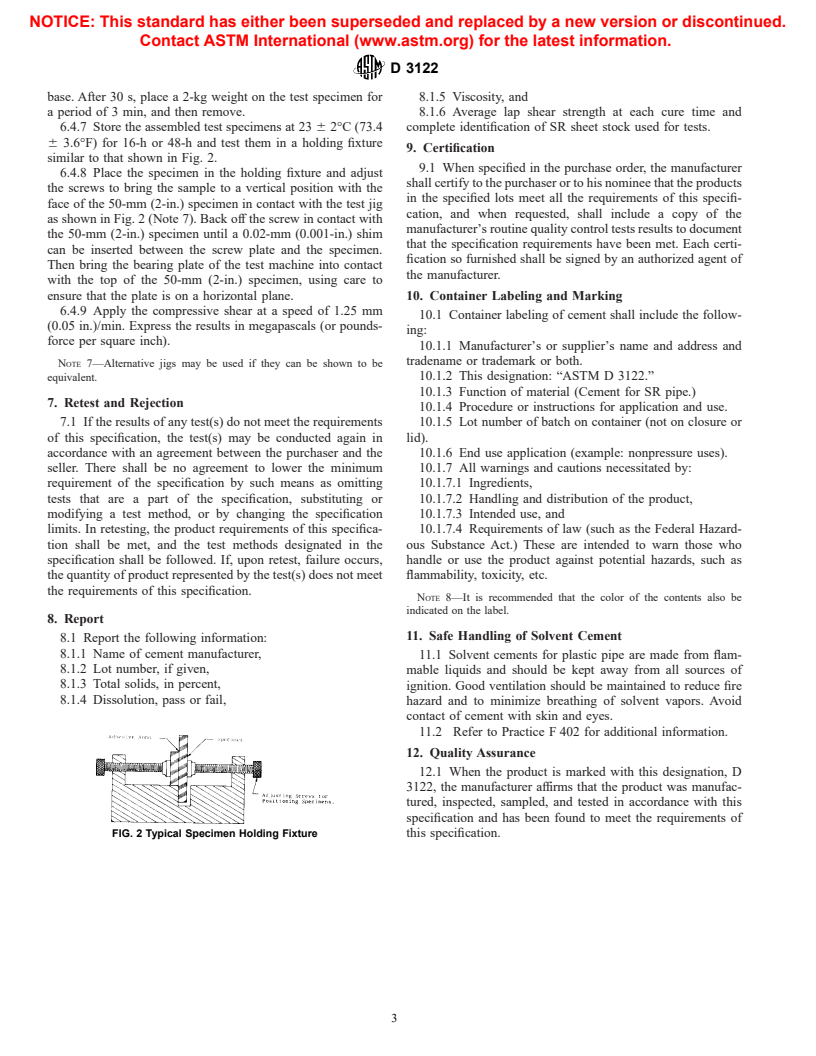

test specimen (Fig. 1).

6.2.1 The samples for test shall be representative of the

6.4.3 Clean the surfaces to be adhered with a cloth damp-

material under consideration. One sample for every batch shall

ened with the solvent (see 4.5) used to make the solvent

be tested in accordance with 6.2.2 unless otherwise agreed

cement.

upon by the supplier and the purchaser.

6.4.4 Using a 25-mm (1-in.) natural bristle brush, apply two

6.2.2 Measure the viscosity in accordance with Method B of

layers of cement in immediate succession to the complete

Test Methods D 1084, except that conditioning to temperature

surface of a 25 by 25-mm (1 by 1-in.) sheet section and to the

equilibrium only is required. Use a Model RVF viscometer, a

center of a 25 by 50-mm (1 by 2-in.) sheet section.

speed of 10 r/min, and the spindle that, by trial, gives the

6.4.5 Assemble these sections immediately and rotate the 25

closest reading to center range of scale for the cement being

by 25-mm (1 by 1-in.) section 180° on the 25 by 50-mm (1 by

tested.

2-in.) section within 5 s using light hand pressure (approxi-

6.3 Total Solids

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.