ASTM F955-96

(Test Method)Standard Test Method for Evaluating Heat Transfer through Materials for Protective Clothing Upon Contact with Molten Substances

Standard Test Method for Evaluating Heat Transfer through Materials for Protective Clothing Upon Contact with Molten Substances

SCOPE

1.1 This test method covers the evaluation of materials' thermal resistance to molten substance pour by describing means of measuring heat transfer.

Note 1-As used in this test method, the term "molten substance" refers to the three compositions (aluminum, brass, and iron) for which the procedure was validated. The test design may be adapted for use with other substances not validated as part of the test method.

1.2 This test method is applicable to materials from which finished protective apparel articles are made.

1.3 This test method does not measure the flammability of materials, nor is it intended for use in evaluating materials exposed to any other thermal exposure exclusive of the molten substance itself (see Note 1).

1.4 This test method should be used to measure and describe the properties of materials, products, or assemblies in response to molten substance pour under controlled laboratory conditions and should not be used to describe or appraise the thermal hazard or fire risk of materials, products, or assemblies under actual conditions. However, results of this test may be used as elements of a thermal risk assessment which takes into account all the factors that are pertinent to an assessment of the thermal hazard of a particular end use.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 955 – 96

Standard Test Method for

Evaluating Heat Transfer through Materials for Protective

Clothing Upon Contact with Molten Substances

This standard is issued under the fixed designation F 955; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 break-open—in testing thermal protective material, a

response evidenced by the formation of a hole in the material

1.1 This test method covers the evaluation of materials’

which allows the molten substance to pass through the mate-

thermal resistance to molten substance pour by describing

rial.

means of measuring heat transfer.

3.1.2 charring—the formation of carbonaceous residue as

NOTE 1—As used in this test method, the term molten substance refers

the result of pyrolysis or incomplete combustion.

to the three compositions (aluminum, brass, and iron) for which the

3.1.3 dripping—in testing thermal protective material, a

procedure was validated. The test design may be adapted for use with

response evidenced by flowing of the fiber polymer.

other substances not validated as part of the test method.

3.1.4 embrittlement—the formation of a brittle residue as

1.2 This test method is applicable to materials from which

the result of pyrolysis or incomplete combustion.

finished protective apparel articles are made.

3.1.5 heat flux—the thermal intensity indicated by the

1.3 This test method does not measure the flammability of

amount of energy transmitted per unit area and per unit time

materials, nor is it intended for use in evaluating materials

(cal/cm s) (watts/cm ).

exposed to any other thermal exposure exclusive of the molten

3.1.6 human tissue burn tolerance—in the testing of ther-

substance itself (see Note 1).

mal protective materials, the amount of thermal energy pre-

1.4 This test method should be used to measure and describe

dicted to cause a second-degree burn in human tissue.

the properties of materials, products, or assemblies in response

3.1.7 ignition—the initiation of combustion.

to molten substance pour under controlled laboratory condi-

3.1.8 melting—in testing thermal protective material, a

tions and should not be used to describe or appraise the thermal

response evidenced by softening of the material, resulting in a

hazard or fire risk of materials, products, or assemblies under

nonreversible change.

actual conditions. However, results of this test may be used as

3.1.9 response to molten substance pour—in testing thermal

elements of a thermal risk assessment which takes into account

protective material, the observed effect of molten substance

all the factors that are pertinent to an assessment of the thermal

contact on textile properties or deterioration of the material.

hazard of a particular end use.

3.1.10 shrinkage—a decrease in one or more dimensions of

1.5 This standard does not purport to address all of the

an object or material.

safety concerns, if any, associated with its use. It is the

3.1.11 thermal end point—in testing of thermal protective

responsibility of the user of this standard to establish appro-

materials, the point of where the sensor response on the

priate safety and health practices and determine the applica-

recorder chart intersects the human tissue burn tolerance

bility of regulatory limitations prior to use. Specific hazard

criteria overlay.

statements are given in Section 8.

3.2 For definitions of other textile terms used in this test

method, refer to Terminology D 123.

2. Referenced Documents

2.1 ASTM Standards:

4. Summary of Test Method

D 123 Terminology Relating to Textiles

4.1 The test exposes a material used in the fabrication of

protective apparel to a molten substance under standardized

3. Terminology

conditions and measures with a copper calorimeter the amount

3.1 Definitions of Terms Specific to This Standard:

of heat transmitted through the test specimen.

4.2 Comparison of data from this test method with related

information on the tolerance of human skin to heat absorption

This test method is under the jurisdiction of ASTM Committee F-23 on

permits estimation of the protective capacity of the material

Protective Clothing and is the direct responsibility of Subcommittee F23.80 on

Molten Substances. tested.

Current edition approved May 10, 1996. Published July 1996. Originally

4.3 The effect of the molten substance contact with the

e1

published as F 955 – 85. Last previous edition F 955 – 85 (1989) .

specimen is observed and recorded.

Annual Book of ASTM Standards, Vol 07.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 955

5. Significance and Use

5.1 Workers may be exposed to contact with molten sub-

stances. The clothing used should provide some protection.

Whether personal injury results from such contact depends on

the resistance of the material from which the clothing is made

to molten substance contact and the amount of heat transferred

through the material to the wearer.

5.2 This test method rates materials, that are intended for

protective clothing against potential molten substance contact,

for their thermal insulating properties and their reaction to the

test exposure.

5.3 The protective performance, as determined by this test

method, will relate to the actual end-use performance only to

the degree that the end-use exposure is identical to the

exposure used in the test method.

5.4 Visual inspection of the specimen subjectively notes the

material’s resistance to molten substance contact.

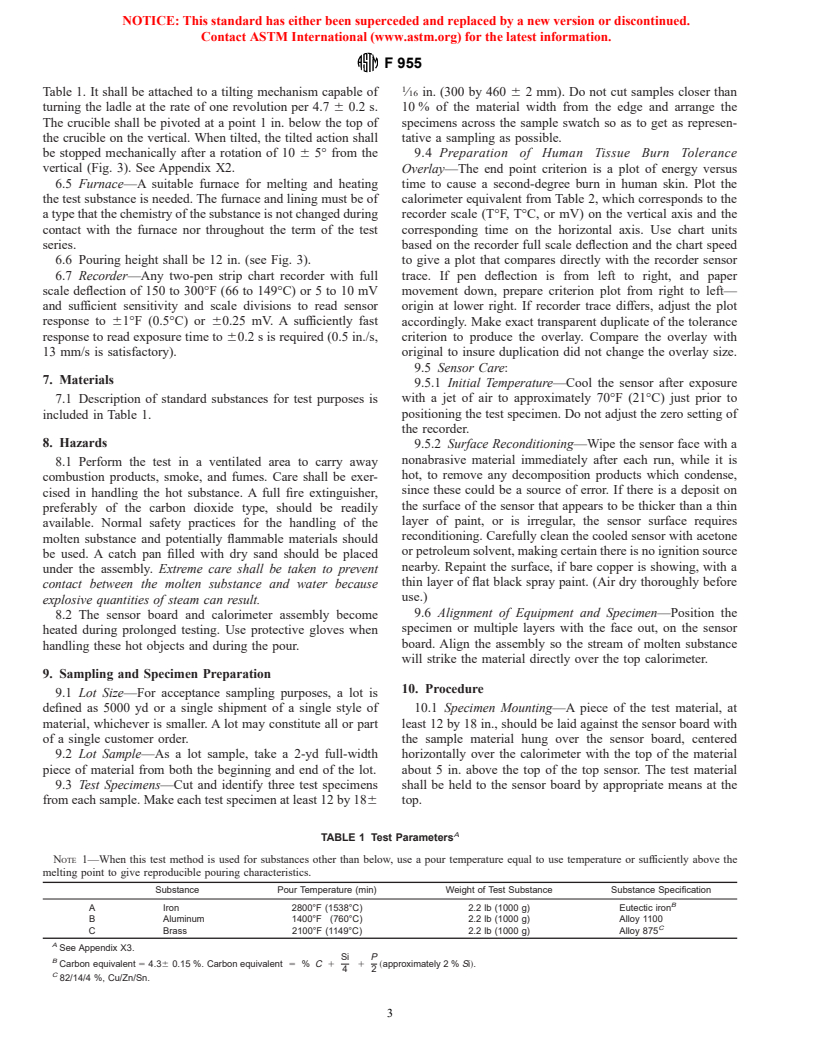

FIG. 2 Assembly

FIG. 1 Sensor Construction

6. Apparatus

6.1 The test apparatus consists of four major components as

follows:

6.1.1 A sensor board with two calorimeters and support

stand,

FIG. 3 Schematic of Test Apparatus

6.1.2 A pouring crucible and pouring mechanism,

6.1.3 A furnace for melting the test metal, and

rimeters is critical. Means should be provided for attaching the

6.1.4 Instruments for measuring test conditions and test

test materials to the top of the sensor board in a manner such

results.

that the test specimen will cover both sensors and extend at

6.2 Sensor—Copper calorimeter mounted in an insulating

least 1 in. beyond all edges. During tests, the sensor board shall

block and constructed as described in Figs. 1 and 2.

be at an angle of 70° from the horizontal. Details of mounting

6.3 Sensor Board—Fabricated of flame and heat resistant

thermocouple leads in the copper calorimeters are illustrated in

material with two copper calorimeters mounted as shown in

Fig. 1 and of the mounting of the calorimeter in the sensor

Fig. 3. The sensor board should be nominally 16 by 10 in. The

board in Fig. 2.

relationship between the pouring ladle position and the calo-

6.4 Pouring Crucible—The pouring crucible shall be suit-

able for the substance being poured and for handling tempera-

tures up to at least 100°F above the pouring temperature.

Marinite which is available from Manville Corp., P.O. Box 5108, Denver, CO

80217 has been found satisfactory. Crucible sizes appropriate for specific substances are shown in

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 955

Table 1. It shall be attached to a tilting mechanism capable of ⁄16 in. (300 by 460 6 2 mm). Do not cut samples closer than

turning the ladle at the rate of one revolution per 4.7 6 0.2 s. 10 % of the material width from the edge and arrange the

The crucible shall be pivoted at a point 1 in. below the top of specimens across the sample swatch so as to get as represen-

the crucible on the vertical. When tilted, the tilted action shall tative a sampling as possible.

be stopped mechanically after a rotation of 10 6 5° from the 9.4 Preparation of Human Tissue Burn Tolerance

vertical (Fig. 3). See Appendix X2. Overlay—The end point criterion is a plot of energy versus

6.5 Furnace—A suitable furnace for melting and heating time to cause a second-degree burn in human skin. Plot the

the test substance is needed. The furnace and lining must be of calorimeter equivalent from Table 2, which corresponds to the

a type that the chemistry of the substance is not changed during recorder scale (T°F, T°C, or mV) on the vertical axis and the

contact with the furnace nor throughout the term of the test corresponding time on the horizontal axis. Use chart units

series. based on the recorder full scale deflection and the chart speed

6.6 Pouring height shall be 12 in. (see Fig. 3). to give a plot that compares directly with the recorder sensor

6.7 Recorder—Any two-pen strip chart recorder with full trace. If pen deflection is from left to right, and paper

scale deflection of 150 to 300°F (66 to 149°C) or 5 to 10 mV movement down, prepare criterion plot from right to left—

and sufficient sensitivity and scale divisions to read sensor origin at lower right. If recorder trace differs, adjust the plot

response to 61°F (0.5°C) or 60.25 mV. A sufficiently fast accordingly. Make exact transparent duplicate of the tolerance

response to read exposure time to 60.2 s is required (0.5 in./s, criterion to produce the overlay. Compare the overlay with

13 mm/s is satisfactory). original to insure duplication did not change the overlay size.

9.5 Sensor Care:

7. Materials

9.5.1 Initial Temperature—Cool the sensor after exposure

with a jet of air to approximately 70°F (21°C) just prior to

7.1 Description of standard substances for test purposes is

positioning the test specimen. Do not adjust the zero setting of

included in Table 1.

the recorder.

8. Hazards

9.5.2 Surface Reconditioning—Wipe the sensor face with a

nonabrasive material immediately after each run, while it is

8.1 Perform the test in a ventilated area to carry away

hot, to remove any decomposition products which condense,

combustion products, smoke, and fumes. Care shall be exer-

since these could be a source of error. If there is a deposit on

cised in handling the hot substance. A full fire

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.