ASTM A831/A831M-95(2000)

(Specification)Standard Specification for Austenitic and Martensitic Stainless Steel Bars, Billets, and Forgings for Liquid Metal Cooled Reactor Core Components (Withdrawn 2005)

Standard Specification for Austenitic and Martensitic Stainless Steel Bars, Billets, and Forgings for Liquid Metal Cooled Reactor Core Components (Withdrawn 2005)

SCOPE

1.1 This specification covers hot- and cold-finished austenitic and martensitic stainless steel bars, billets, and forgings intended for use in manufacturing core components used at high temperatures in liquid metal cooled nuclear reactors.

1.2 The bars, billets, and forgings are intended for machining, welding, hot- and cold-forming operations.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.4 This specification and the applicable material specifications are expressed in both inch-pound and SI units. However, unless the order specifies the applicable "M" specification designation (SI units), the material shall be furnished in inch-pound units.

WITHDRAWN RATIONALE

This specification covers hot- and cold-finished austenitic and martensitic stainless steel bars, billets, and forgings intended for use in manufacturing core components used at high temperatures in liquid metal cooled nuclear reactors.

Formerly under the jurisdiction of A01 on Steel, Stainless Steel and Related Alloys, this specification was withdrawn in March 2005. This specification is being withdrawn without replacement due to its limited use in the industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 831/A831M – 95 (Reapproved 2000)

Standard Specification for

Austenitic and Martensitic Stainless Steel Bars, Billets, and

Forgings for Liquid Metal Cooled Reactor Core

Components

This standard is issued under the fixed designationA831/A831M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 112 Test Methods for Determining Average Grain Size

E 407 Test Methods for Microetching Metals and Alloys

1.1 This specification covers hot- and cold-finished austen-

2.2 ANSI Standard:

itic and martensitic stainless steel bars, billets, and forgings

B 46.1 Surface Texture

intended for use in manufacturing core components used at

2.3 ASNDT Standard:

high temperatures in liquid metal cooled nuclear reactors.

SNT-TC-1A Recommended Practice for Nondestructive

1.2 The bars, billets, and forgings are intended for machin-

Testing Personnel Qualifications and Certification

ing, welding, hot- and cold-forming operations.

2.4 ASME Standard:

1.3 The values stated in either inch-pound units or SI units

NQA-1 Quality Assurance Program Requirements for

are to be regarded separately as standard. Within the text, the

Nuclear Facilities

SI units are shown in brackets. The values stated in each

system are not exact equivalents; therefore, each system shall

3. Ordering Information

be used independently of the other. Combining values from the

3.1 It is the responsibility of the purchaser to specify all

two systems may result in nonconformance with the specifi-

requirements that are necessary for material ordered under this

cation.

specification. Such requirements may include but are not

1.4 This specification and the applicable material specifica-

limited to the following:

tions are expressed in both inch-pound and SI units. However,

3.1.1 Quantity (weight or number of pieces).

unless the order specifies the applicable “M” specification

3.1.2 Condition (cold-worked, annealed, or tempered).

designation (SI units), the material shall be furnished in

3.1.3 Finish.

inch-pound units.

3.1.4 Applicable dimensions, including size, thickness,

2. Referenced Documents width, and length (if forgings, include prints or sketches).

3.1.5 Form (bars, billets, etc.).

2.1 ASTM Standards:

3.1.6 Grade designation.

A 370 Test Methods and Definitions for MechanicalTesting

2 3.1.7 ASTM designation and year of issue.

of Steel Products

3.1.8 Marking requirements.

A 388/A388M Practice for Ultrasonic Examination of

3 3.1.9 Other applicable documents (2.4).

Heavy Steel Forgings

3.1.10 Melting process (4.1).

A 484/A484M Specification for General Requirements for

3 3.1.11 Approval of procedures for conversion of ingots

Stainless Steel Bars, Billets, and Forgings

(4.2).

A 751 Test Methods, Practices, and Terminology for

2 3.1.12 Cold working requirements for austenitic grades

Chemical Analysis of Steel Products

(4.4.3).

E 3 Methods of Preparation of Metallographic Specimens

3.1.13 Identification requirements (4.6).

E 45 Practice for Determining the Inclusion Content of

3.1.14 Chemistry requirements (5.1).

Steel

3.1.15 Product analysis tolerances (5.3).

3.1.16 Grain size limits for bar, billets, and forgings requir-

ing rework (6.1).

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

A01.17 on Flat Stainless Steel Products. Available from American National Standards Institute, 11 W. 42nd St., 13th

Current edition approved Jan. 15, 1995. Published March 1995. Originally Floor, New York, NY 10036.

published as A 831 – 84. Last previous edition A 831 – 94. Available from American Society for Nondestructive Testing, P.O. Box 5642,

Annual Book of ASTM Standards, Vol 01.03. 3200 Riverside Dr., Columbus, OH 43228.

3 7

Annual Book of ASTM Standards, Vol 01.05. Available from American Society of Mechanical Engineers, 345 E. 47th St.,

Annual Book of ASTM Standards, Vol 03.01. New York, NY 10017.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 831/A831M – 95 (2000)

3.1.17 Alternate inclusion limits (6.2). 4.4.2.2 S42100—1365°F [740°C] minimum, 1470°F

3.1.18 Surface roughness limits (4.3.2). [799°C] maximum.

3.1.19 Surface marring limits (4.3.3). 4.4.3 Cold-Worked Austenitic Grades—If required by the

3.1.20 Ultrasonic test requirements (8.1). purchaser, austenitic grades shall be furnished in the cold-

3.1.21 Sampling levels (10.1). worked condition. Prior to any final cold working operations,

3.1.22 Packaging requirements (12.1). solutionannealingshallbeperformedinaccordancewith4.4.1.

Percentage of cold work shall be based upon reduction in area.

NOTE 1—A typical ordering description is as follows: 5000-lb [2000-

4.4.4 Cleanliness During Manufacture—All lubricants shall

kg] stainless steel, annealed and centerless ground, round bar 1 ⁄2 in. [38

be removed prior to any heat treatment.

mm] in diameter, 10 to 12 ft. [3 to 4 m] Type 316, ASTM Specification

A 831 – xx. 4.5 Lotting—Items of the same nominal dimension shall be

lotted on the basis of material having the same metallurgical

4. Manufacture

history, produced from the same melt heat, processed in one

4.1 Melting—Unless an alternative melting process has final tooling setup, annealed in the same annealing charge (or

been specified in Section 9, the process for austenitic grades

processed in one continuous run if annealed in a continuous

shall consist of a vacuum induction melt followed by a

furnace) and given the same cold work.

consumable electrode vacuum-arc remelt. Additions of rare 4.6 Identification—Material shall be identified and pro-

earths during melting are prohibited unless approved by the

cessed in a manner that will ensure traceability as specified in

purchaser. The melting process for other grades shall be the order.

specified in the order.

4.7 Handling—Special handling procedures shall be em-

4.2 Ingot Processing—Aprocedure for conversion of ingots ployed to maintain the identity of material from the final

shall be approved by the purchaser prior to use if specified in

working operation through packaging for shipment. The han-

the order. The parameters for the conversion of austenitic dling procedure shall be submitted to the purchaser for review

grades shall be selected to minimize the formation of complex

and approval prior to use.

carbides and carbonitrides.

4.3 Surface Requirements:

5. Chemical Requirements

4.3.1 Surface Condition—The finished bar shall be free of

5.1 The material shall conform to the applicable chemistry

all scale, splits, laps, cracks, seams, and visible oxide.

requirements specified in Table 2 unless otherwise specified in

4.3.2 Surface Roughness—The surface finish of finished bar

the order.

shall meet the minimum requirements listed in Table 1. The

5.2 An analysis of each heat of steel shall be made by the

surface finish of bar that will be machined subsequently shall

steel manufacturer in accordance withTest Methods, Practices,

be as specified in the order and shall be compatible with

and Terminology A 751 to determine the percentages of the

nondestructive examination requirements.

elements specified. If secondary melting processes are em-

4.3.3 Surface Marring—The finished bar shall be free of

ployed, the heat analysis shall be obtained from one remelted

scratches, dents, or mars as specified in the order.

ingot or the product of one remelted ingot of each primary

4.4 Heat Treatment:

melt. The chemical composition thus determined shall be

4.4.1 Austenitic Grades—Except for material ordered in the

reported to the purchaser or his representative and shall

cold-worked condition, all austenitic grade material shall be

conform to the requirements specified in 5.1.

furnished in the solution-annealed condition. Solution anneal-

ing shall consist of heating the material to a temperature of

1900°F [1038°C] minimum, for a time appropriate to ensure

TABLE 2 Chemical Requirements

full carbide solution, followed by rapid cooling in air or water

to prevent carbide precipitation at the grain boundaries.

Grade (UNS Designation)

4.4.2 Martensitic Grades—Unless otherwise specified by

316 (S31600) . . . S 38660 . . . S 42100 T91 (. . .)

the purchaser, martensitic grade materials shall be supplied in

Carbon 0.040 to 0.060 0.030 to 0.050 0.17 to 0.23 0.08 to 0.12

the normalized and tempered condition. Tempered material

Manganese 1.00 to 2.00 1.65 to 2.35 0.40 to 0.70 0.30 to 0.60

Phosphorus, max 0.040 0.040 0.040 0.020

shall be normalized at 1900°F [1038°C] minimum as a final

Sulfur, max 0.010 0.010 0.010 0.010

heat treatment. Tempered martensitic materials shall be held at

Silicon 0.50 to 0.75 0.50 to 1.00 0.20 to 0.30 0.20 to 0.50

tempering temperature for at least 1 h/1in. [25 mm] of cross

Nickel 13.0 to 14.0 14.5 to 16.5 0.30 to 0.80 0.40 max

Chromium 17.0 to 18.0 12.5 to 14.5 11.0 to 12.5 8.0 to 9.5

section as follows:

Molybdenum 2.00 to 3.00 1.50 to 2.50 0.80 to 1.20 0.85 to 1.05

4.4.2.1 Grade T91—1350°F [732°C] minimum, 1485°F

A

Titanium . . . 0.10 to 0.40 . .

[807°C] maximum. Columbium 0.050 max 0.050 max 0.050 max 0.06 to 0.10

Tantalum, max 0.020 0.020 . . . . . .

Tungsten . . . . . . 0.40 to 0.60 . . .

Nitrogen 0.010 max 0.005 max . . . 0.03 to 0.07

TABLE 1 Austenitic Stainless Steel Bar—Surface Finishes

Aluminum, max 0.050 0.050 0.050 0.04

Arsenic, max 0.030 0.030 . . . . . .

Bar Diameter, in. (mm) Surface Designation (ANSI B 46.1) Boron, max 0.0020 0.0020 . . . . . .

Cobalt, max 0.050 0.050 . . . . . .

1 1

⁄8 to ⁄4 [3.2 to 6.4] incl 32 µin. [0.8 µm] or finer

Copper, max 0.04 0.04 . . . . . .

over ⁄4to 2 [6.4 to 50.8] incl 63 µin. [1.6 µm] or finer

Vanadium 0.05 max 0.05 max 0.25 to 0.35 0.18 to 0.25

over 2 to 10 [50.8 to 254.0] incl 125 µin. [3.2 µm] or finer

A

Aim for 0.25.

A 831/A831M – 95 (2000)

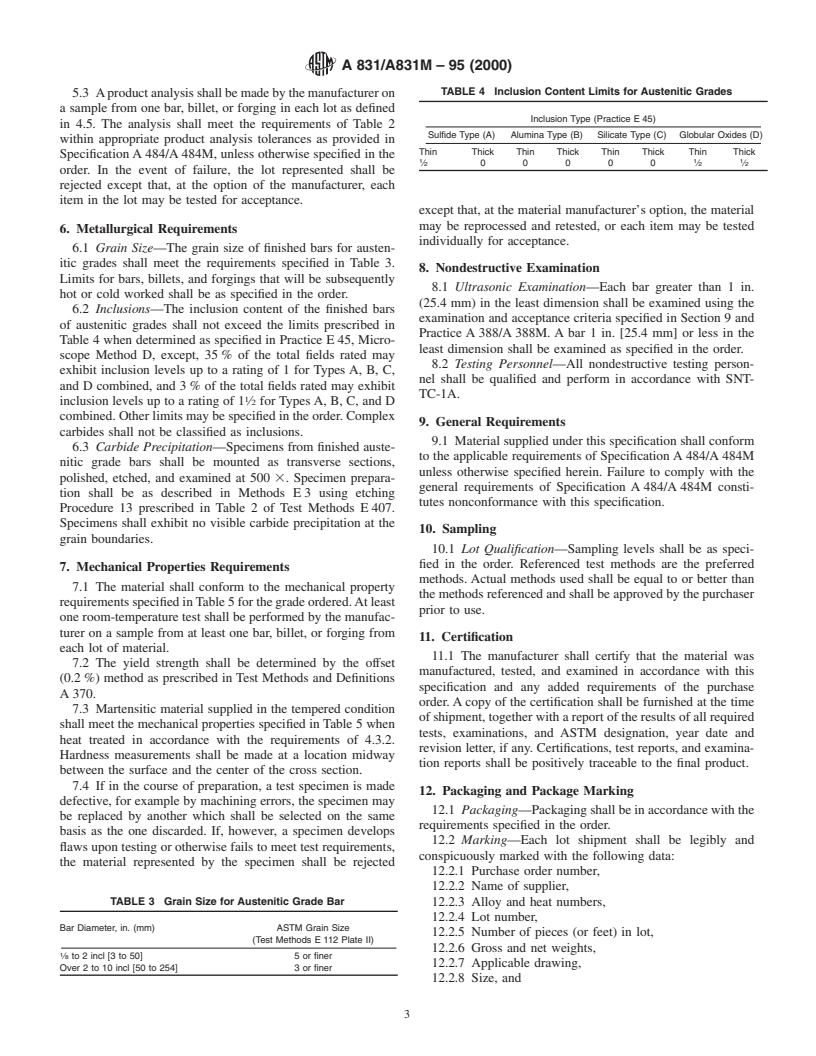

TABLE 4 Inclusion Content Limits for Austenitic Grades

5.3 Aproductanalysisshallbemadebythemanufactureron

a sample from one bar, billet, or forging in each lot as defined

Inclusion Type (Practice E 45)

in 4.5. The analysis shall meet the requirements of Table 2

Sulfide Type (A) Alumina Type (B) Silicate Type (C) Globular Oxides (D)

within appropriate product analysis tolerances as provided in

Thin Thick Thin Thick Thin Thick Thin Thick

Specification A 484/A 484M, unless otherwise specified in the

1 1 1

⁄2 0 0 0 0 0 ⁄2 ⁄2

order. In the event of failure, the lot represented shall be

rejected except that, at the option of the manufacturer, each

item in the lot may be tested for acceptance.

except that, at the material manufacturer’s option, the material

may be reprocessed and retested, or each item may be tested

6. Me

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.