ASTM A418/A418M-07

(Test Method)Standard Practice for Ultrasonic Examination of Turbine and Generator Steel Rotor Forgings

Standard Practice for Ultrasonic Examination of Turbine and Generator Steel Rotor Forgings

SIGNIFICANCE AND USE

This practice shall be used when ultrasonic inspection is required by the order or specification for inspection purposes where the acceptance of the forging is based on limitations of the number, amplitude, or location of discontinuities, or a combination thereof, which give rise to ultrasonic indications.

The acceptance criteria shall be clearly stated as order requirements.

SCOPE

1.1 This practice for ultrasonic examination covers turbine and generator steel rotor forgings covered by Specifications A 293, A 469/A 469M, and A 470/A 470M. This standard shall be used for contact testing only.

1.2 This practice describes a basic procedure of ultrasonically inspecting turbine and generator rotor forgings. It shall in no way restrict the use of other ultrasonic methods such as reference block calibrations when required by the applicable procurement documents nor is it intended to restrict the use of new and improved ultrasonic test equipment and methods as they are developed. The procedure utilizes different calibration techniques than had been used in previous issues. The frequency or amplitudes of recordable indications should not be interpreted necessarily as a change in quality of the product being examined.

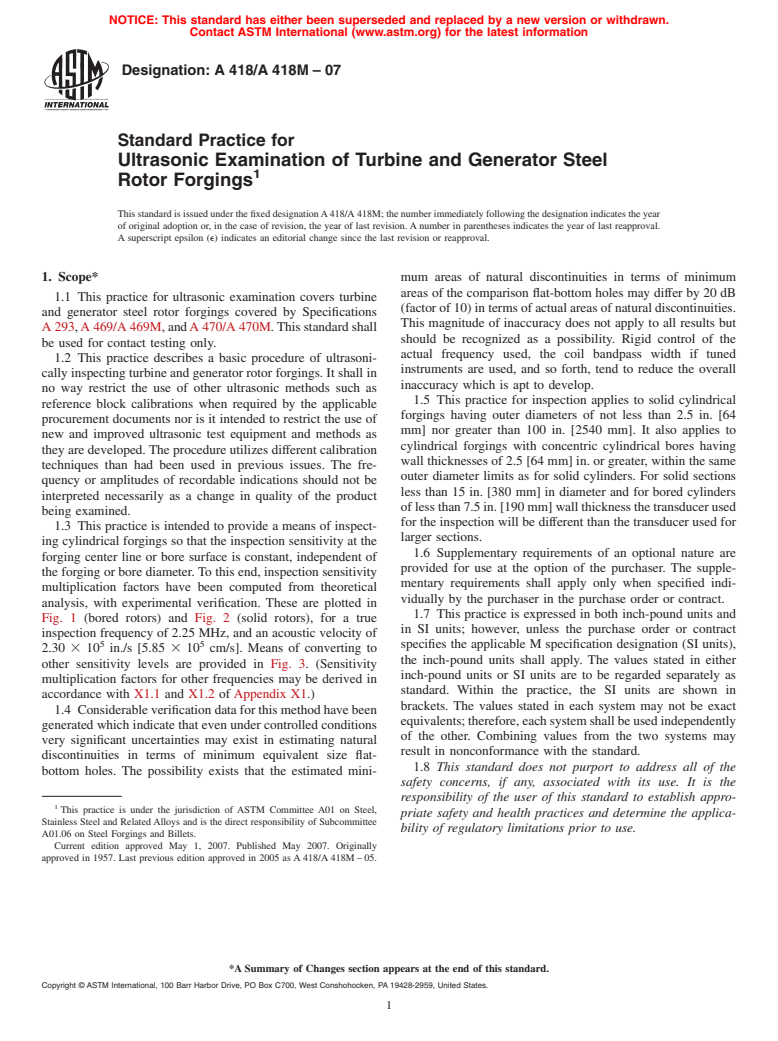

1.3 This practice is intended to provide a means of inspecting cylindrical forgings so that the inspection sensitivity at the forging center line or bore surface is constant, independent of the forging or bore diameter. To this end, inspection sensitivity multiplication factors have been computed from theoretical analysis, with experimental verification. These are plotted in Fig 1 (bored rotors) and Fig 2. (solid rotors), for a true inspection frequency of 2.25 MHz, and an acoustic velocity of 2.30 105 in./s [5.85 105 cm/s]. Means of converting to other sensitivity levels are provided in Fig. 3. (Sensitivity multiplication factors for other frequencies may be derived in accordance with X1.1 and X1.2 of Appendix X1.)

1.4 Considerable verification data for this method have been generated which indicate that even under controlled conditions very significant uncertainties may exist in estimating natural discontinuities in terms of minimum equivalent size flat-bottom holes. The possibility exists that the estimated minimum areas of natural discontinuities in terms of minimum areas of the comparison flat-bottom holes may differ by 20 dB (factor of 10) in terms of actual areas of natural discontinuities. This magnitude of inaccuracy does not apply to all results but should be recognized as a possibility. Rigid control of the actual frequency used, the coil bandpass width if tuned instruments are used, and so forth, tend to reduce the overall inaccuracy which is apt to develop.

1.5 This practice for inspection applies to solid cylindrical forgings having outer diameters of not less than 2.5 in. [64 mm] nor greater than 100 in. [2540 mm]. It also applies to cylindrical forgings with concentric cylindrical bores having wall thicknesses of 2.5 [64 mm] in. or greater, within the same outer diameter limits as for solid cylinders. For solid sections less than 15 in. [380 mm] in diameter and for bored cylinders of less than 7.5 in. [190 mm] wall thickness the transducer used for the inspection will be different than the transducer used for larger sections.

1.6 Supplementary requirements of an optional nature are provided for use at the option of the purchaser. The supplementary requirements shall apply only when specified individually by the purchaser in the purchase order or contract.

1.7 This practice is expressed in both inch-pound units and in SI units; however, unless the purchase order or contract specifies the applicable M specification designation (SI units), the inch-pound units shall apply. The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the practice, the SI units are shown in brackets. The values stated in each system ma...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 418/A 418M – 07

Standard Practice for

Ultrasonic Examination of Turbine and Generator Steel

1

Rotor Forgings

ThisstandardisissuedunderthefixeddesignationA418/A418M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* mum areas of natural discontinuities in terms of minimum

areas of the comparison flat-bottom holes may differ by 20 dB

1.1 This practice for ultrasonic examination covers turbine

(factorof10)intermsofactualareasofnaturaldiscontinuities.

and generator steel rotor forgings covered by Specifications

This magnitude of inaccuracy does not apply to all results but

A293,A469/A469M,andA470/A470M.Thisstandardshall

should be recognized as a possibility. Rigid control of the

be used for contact testing only.

actual frequency used, the coil bandpass width if tuned

1.2 This practice describes a basic procedure of ultrasoni-

instruments are used, and so forth, tend to reduce the overall

callyinspectingturbineandgeneratorrotorforgings.Itshallin

inaccuracy which is apt to develop.

no way restrict the use of other ultrasonic methods such as

1.5 This practice for inspection applies to solid cylindrical

reference block calibrations when required by the applicable

forgings having outer diameters of not less than 2.5 in. [64

procurement documents nor is it intended to restrict the use of

mm] nor greater than 100 in. [2540 mm]. It also applies to

new and improved ultrasonic test equipment and methods as

cylindrical forgings with concentric cylindrical bores having

they are developed.The procedure utilizes different calibration

wall thicknesses of 2.5 [64 mm] in. or greater, within the same

techniques than had been used in previous issues. The fre-

outer diameter limits as for solid cylinders. For solid sections

quency or amplitudes of recordable indications should not be

less than 15 in. [380 mm] in diameter and for bored cylinders

interpreted necessarily as a change in quality of the product

oflessthan7.5in.[190mm]wallthicknessthetransducerused

being examined.

for the inspection will be different than the transducer used for

1.3 This practice is intended to provide a means of inspect-

larger sections.

ing cylindrical forgings so that the inspection sensitivity at the

1.6 Supplementary requirements of an optional nature are

forging center line or bore surface is constant, independent of

provided for use at the option of the purchaser. The supple-

the forging or bore diameter.To this end, inspection sensitivity

mentary requirements shall apply only when specified indi-

multiplication factors have been computed from theoretical

vidually by the purchaser in the purchase order or contract.

analysis, with experimental verification. These are plotted in

1.7 This practice is expressed in both inch-pound units and

Fig. 1 (bored rotors) and Fig. 2 (solid rotors), for a true

in SI units; however, unless the purchase order or contract

inspection frequency of 2.25 MHz, and an acoustic velocity of

5 5

specifies the applicable M specification designation (SI units),

2.30 3 10 in./s [5.85 3 10 cm/s]. Means of converting to

the inch-pound units shall apply. The values stated in either

other sensitivity levels are provided in Fig. 3. (Sensitivity

inch-pound units or SI units are to be regarded separately as

multiplication factors for other frequencies may be derived in

standard. Within the practice, the SI units are shown in

accordance with X1.1 and X1.2 of Appendix X1.)

brackets. The values stated in each system may not be exact

1.4 Considerableverificationdataforthismethodhavebeen

equivalents;therefore,eachsystemshallbeusedindependently

generated which indicate that even under controlled conditions

of the other. Combining values from the two systems may

very significant uncertainties may exist in estimating natural

result in nonconformance with the standard.

discontinuities in terms of minimum equivalent size flat-

1.8 This standard does not purport to address all of the

bottom holes. The possibility exists that the estimated mini-

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

1

This practice is under the jurisdiction of ASTM Committee A01 on Steel,

priate safety and health practices and determine the applica-

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

bility of regulatory limitations prior to use.

A01.06 on Steel Forgings and Billets.

Current edition approved May 1, 2007. Published May 2007. Originally

approved in 1957. Last previous edition approved in 2005 as A418/A418M–05.

*A Summary of Changes sectio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.