ASTM A850-85

(Specification)Specification for Steel Bars, Carbon Manganese Merchang Quality with 50 KSI (345 MPA) Yield Point (Withdrawn 1990)

Specification for Steel Bars, Carbon Manganese Merchang Quality with 50 KSI (345 MPA) Yield Point (Withdrawn 1990)

General Information

Standards Content (Sample)

~~l~ Designation: A 850 - 85

Standard Specification for

Steel Bars, Carbon-Manganese, Merchant Quality with 50 ksi

1

(345 MPa) Yield Point

This standard is issued under the fixed designation A 850; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (~) indicates an editorial change since the last revision or reapproval.

practice and grain size are at the manufacturers option.

I. Scope

3.3 Unless otherwise specified, the bars shall be furnished

1.1 This specification covers hot-wrought merchant

as rolled and not pickled, blast cleaned, or oiled.

quality carbon-manganese steel bars and bar size shapes

produced to mechanical property requirements and intended

4. Ordering Information

for noncritical constructional applications (see 3.2).

4.1 Orders under this specification shall include the fol-

1.2 Merchant quality hot-wrought steel bar is available in.

lowing requirements:

the following ranges of size and sedion:

4.1.l Quantity (weight or number of pieces),

1.2. l Rounds, squares, and hexagons with diameters or

4.1.2 Dimensions (cross-sectional shape, size, and length),

distance across flats under 3 in. (76.2 mm).

4.1.3 Name of material (merchant quality carbon steel

1.2.2 Bar size shapes with maximum dimensions under 3

bars),

in.

4.1.4 ASTM specification designation and year of issue,

1.2.3 Other bar sections with weight per foot under 40.84

4. I. 5 Class,

lb/ft (60.78 kg/m).

4.1.6 Heat analysis or test report (request, if required),

1.2.4 Flats 6 in. (152 mm) or under in width, over 0.203

4.1. 7 Application and processing, and

in. (5.15 mm) in thickness, and under 40.84 lb/ft (60.78

2 2

4.1.8 Supplem.entary requirements (if required)

kg/m) or 12 in. (77.4 cm ) in cross-sectional area.

1.2.5 Flats over 6 in. to 8 in. (203 mm), inclusive in width,

5. Materials and Manufacture

0.230 in. (5.84 mm) and over in thickness and under 40.84

2

5.1 The steel shall be made by the open-hearth, basic

lb/ft (60.78 kg/m) or 12 in.2 (774 cm ) in cross-sectional

oxygen, or electric furnace process.

area.

1.2.6 Hot-wrought merchant quality steel bars, subject to

6. Chemical Composition

mechanical property requirements, are furnished in straight

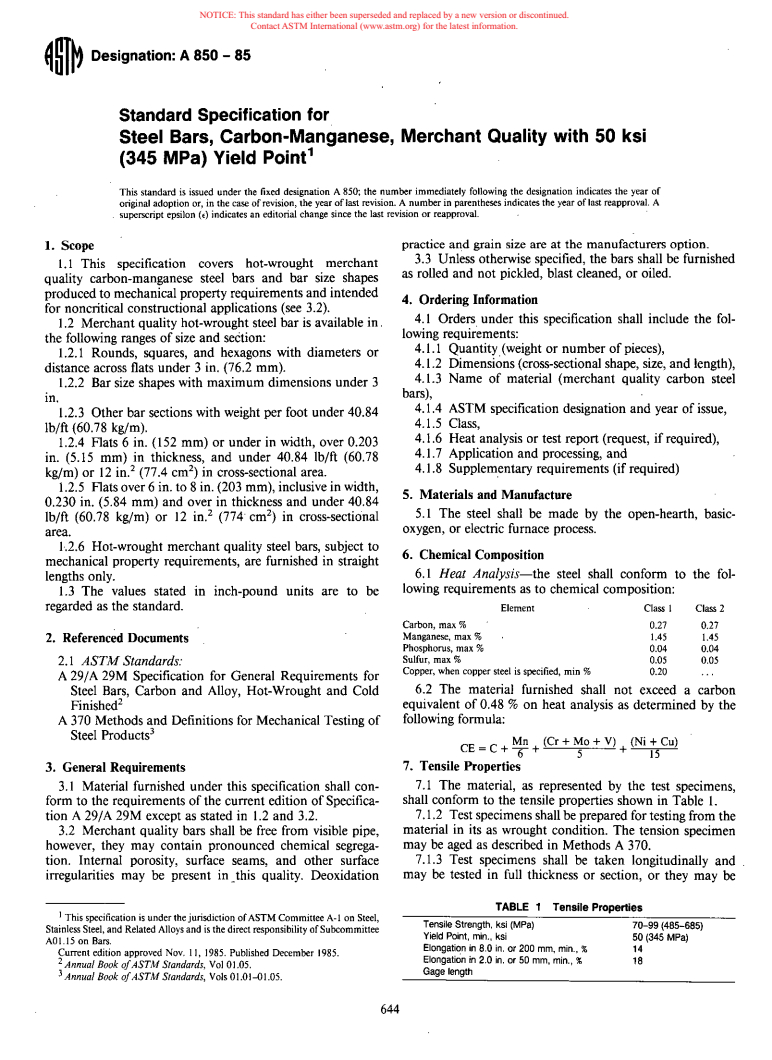

6.1 Heat Analysis-the steel shall conform to the fol

lengths only.

lowing requirements as to chemical composition:

1.3 The values stated in inch-pound units are to be

regarded as the standard. Element Class I

Class 2

Carbon, max %

0.27 0.27

Manganese, max %

1.45 1.45

2. Referenced Documents

Phosphorus, max %

0.04 0.04

Sulfur, max% 0.05 0.05

2.1 ASTM Standards:

Copper, when copper steel is specified, min %

0.20

A 29/ A 29M Specification for General Requirements for

6.2 The material furnished shall not exceed a carbon

Steel Bars, Carbon and Alloy, Hot-Wrought and Cold

equivalent of 0.48 % on heat analysis as determined by the

Finished'

following formula:

A 370 Methods and Definitions for Mechanical Testing of

3

Steel Products

CE C Mn (Cr + Mo + V) (Ni + Cu)

~ +6+ 5 + 15

7. Tensile Properties

3. General Requirements

7. l The material, as represented by the test specimens,

3.1 Material furnished under this specification shall con

form to the requirements of the current edition of Specifica shall conform to the tensile properties shown in Table l.

1.2 and 3.2. 7 .1.2 Test specimens shall be prepared for testing from the

tion A 29/A 29M except as stated in

material in its as wrought condition. The tension specimen

3.2 Merchant quality bars shall be free from visible pipe,

may be aged as described in Methods A 370.

however, they may contain pronounced chemical segrega

tion. Internal porosity, surface seams, and other surface 7. l.3 Test specimens shall be taken longitudinally and

irregularities may be present in_ this quality. Deoxidation may be tested in full thickness or section, or they may be

TABLE 1 Tensile Properties

1

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

Tensile Strength, ksi (MPa)

70-99 (485-685)

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

Yield Point, min., ksi

50 (345 MPa)

AOl.15 on Bars.

Elongation in 8.0 in. or 200 mm, min., %

14

Current edition approved Nov. 11, 1985. Published December 1985.

2 ElongatiOn in 2.0 in. or 50 mm, min.,%

18

Annual Book of ASTM Standards, Vol 01.05.

Gage length

3

Annual Book of ASTM Standards, Vols 01.01-01.05.

644

---------------------- Page: 1 ----------------------

~~ A 850

machined to the dimensions shown in Figs. 4 or 5 of in. or 50 mm specified in Table I of 1.00 % shall be made for

Methods A 370. If test specimens are selected conforming to each 1 in. (25 mm) of specified thickness or diameter or

the dimensions of Fig. 5, they shall be machined from a

fraction thereof over 2 in.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.