ASTM E1834-96

(Test Method)Standard Test Method for Determination of Lead in Nickel Alloys by Electrothermal Atomic Absorption Spectrometric Method

Standard Test Method for Determination of Lead in Nickel Alloys by Electrothermal Atomic Absorption Spectrometric Method

SCOPE

1.1 This test method covers the determination of lead in nickel and nickel alloys in the concentration range of 0.00005 % to 0.001 % by electrothermal atomic absorption spectrometry.

Note 1—If this test method is used to test materials having contents less than 0.0001 % lead, users in different laboratories will experience more than the usual 5 % risk that their results will differ by more than 50 % relative error.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazards associated with the use of this practice see Practices E 50.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1834 – 96

Standard Test Method for

Determination of Lead in Nickel Alloys by Electrothermal

Atomic Absorption Spectrometric Method

This standard is issued under the fixed designation E 1834; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Test Method

1.1 This test method covers the determination of lead in 3.1 The sample is dissolved in a mixture of nitric acid,

nickel and nickel alloys in the concentration range of hydrofluoric acid, and water. The sample and a nickel-

0.00005 % to 0.001 % by electrothermal atomic absorption ammonium phosphate matrix modifier are injected into the

spectrometry. electrothermal atomizer of an atomic absorption spectrometer,

which is provided with a background corrector. Measurement

NOTE 1—If this test method is used to test materials having contents

of the absorbance is made at a wavelength of 283.3 nm. The

less than 0.0001 % lead, users in different laboratories will experience

lead concentration is determined from a calibration curve

more than the usual 5 % risk that their results will differ by more than

50 % relative error. established with nickel solutions containing a known amount

of lead.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

4.1 This test method is intended to be used for the determi-

priate safety and health practices and determine the applica-

nation of trace levels of lead in nickel and nickel alloys. It is

bility of regulatory limitations prior to use. For specific hazards

assumed that the procedure will be performed by trained

associated with the use of this practice see Practices E 50.

analysts capable of performing common laboratory practices

skillfully and safely. It is expected that the work will be

2. Referenced Documents

performed in a properly equipped laboratory and proper waste

2.1 ASTM Standards:

disposal procedures will be followed.

E 50 Practices for Apparatus, Reagents, and Safety Precau-

tions for Chemical Analysis of Metals

5. Apparatus

E 1184 Practice for Electrothermal (Graphite Furnace)

5.1 Atomic Absorption Spectrometer, with electrothermal

Atomic Absorption Analysis

atomizer, equipped with an appropriate background corrector, a

E 1452 Practice for Preparation of Calibration Solutions for

signal output device, such as a video display screen, a digital

Spectrophotometric and Spectroscopic Atomic Analysis

computer, a printer or strip chart recorder, and an autosampler.

E 1601 Practice for Conducting an Interlaboratory Study to

5.2 Pyrolytically Coated Graphite Tubes, grooved, con-

Evaluate the Performance of an Analytical Method

forming to the instrument manufacturer’s specifications.

E 1770 Practice for Optimization of Electrothermal Atomic

5.3 Pyrolytic Graphite Platforms, L’vov design, fitted to the

Absorption Spectrometric Equipment

tubes specified in 5.2.

2.2 ISO Standards:

5.4 Radiation Source, lead hollow cathode lamp, or elec-

ISO Standard 11437–Nickel Alloys–Determination of

trodeless discharge lamp with an appropriate power supply.

Trace-Element Content–Electrothermal Atomic Absorp-

tion Spectrometric Method–Part 2: Determination of Lead

6. Instrument Parameters and Criteria

Content

6.1 The atomic absorption spectrometer and electrothermal

ISO Guide 5725–Accuracy, Trueness, and Precision of

atomizer are satisfactory if after adjustment of the instruments

Measurements, Methods and Results

and optimization of the furnace heating program as described

in Practice E 1770, they meet the criteria given in 6.4-6.7.

1 6.2 Calibration solutions S through S prepared in accor-

0 3

This test method is under the jurisdiction of ASTM Committee E-1 on

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct dance with 7.9 and summarized in Table 1 shall be used for

responsibility of Subcommittee E01.08 on Ni and Co and High Temperature Alloys.

testing criteria.

Current edition approved Oct. 10, 1996. Published December 1996.

6.3 The parameters for the determination of lead and the

Annual Book of ASTM Standards, Vol 03.05.

establishing of the instrument criteria are as follows:

Annual Book of ASTM Standards, Vol 03.06.

Available from American National Standards Institute, 11 W. 42nd St., 13th

6.3.1 The injection volume is 20 μL.

Floor, New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 1834

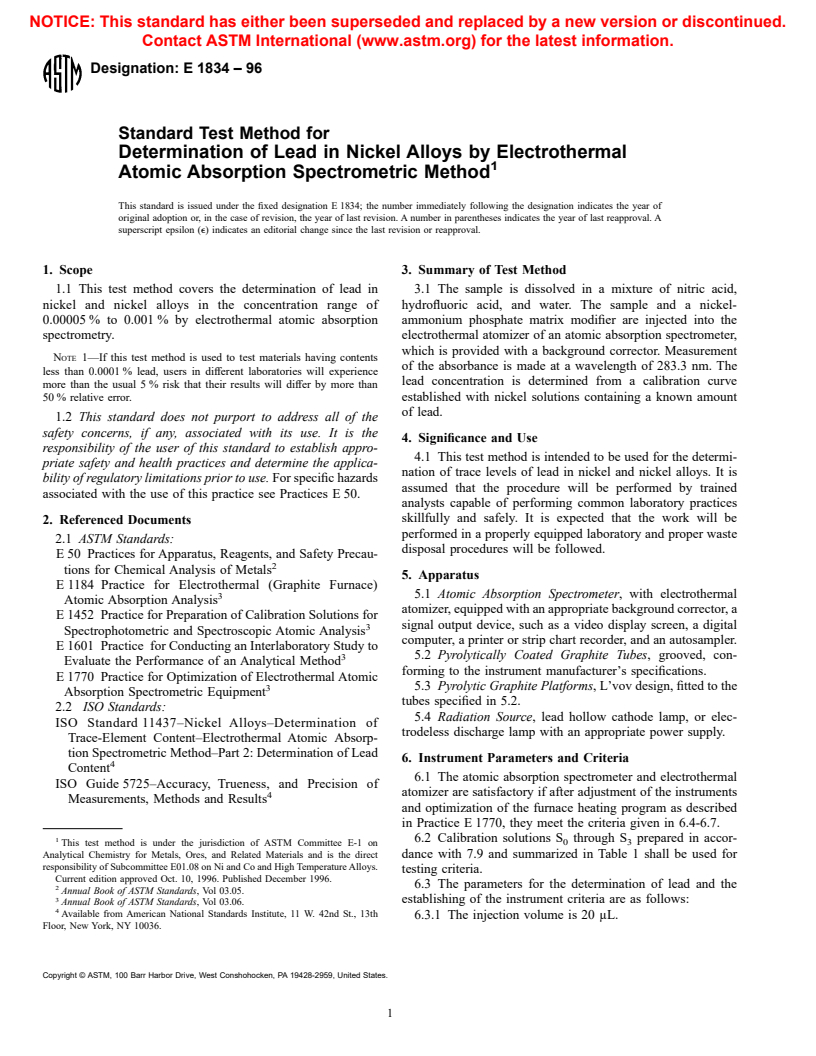

TABLE 1 Lead Concentration of Calibration Solutions

acid (1:1) in a 250-mL beaker. Heat to assist dissolution. Cool

Pb Concentration in and transfer to 1-L volumetric flask, dilute to mark with water

Calibration Solution

and mix. Store in polypropylene or high density polyethylene

Concentration of Pb in Calibration

Corresponds to

Calibration

Solution

bottle.

Concentration of Pb in

Solution

A

Sample 7.8 Lead Standard Solution (1.0 mg/L)—Pipette 10.0 mL of

the lead reference solution (7.7) into a 1-L volumetric flask.

μg/L ng/mL ppm (g/metric ton)

Add 20 mL nitric acid and dilute to volume with water and

S 00 0

S 10 10 2 mix. This solution shall be freshly prepared.

S 20 20 4

7.9 Calibration Solutions—Transfer 10.0 mL nickel solu-

S 30 30 6

tion (50 g/L) to each of six 100 mL volumetric flasks. Add

S 40 40 8

S 60 60 12 respectively 0, 1.0, 2.0, 3.0, 4.0, and 6.0 mL of lead standard

A

solution (7.8). Dilute with water and mix. These calibration

Based 0.500 g sample/100 mL sample solution (9.1).

solutions contain 0, 10.0, 20.0, 30.0, 40.0 and 60.0 μg Pb/L.

These calibration solutions shall be identified as calibration

6.3.2 The peak area absorbance integration measurements

solutions S through S , respectively (see Table 1).

0 5

shall be at a wavelength of 283.3 nm.

6.4 Characteristic Mass—The characteristic mass deter- 8. Sampling and Sample Preparation

mined in accordance with Practice E 1770 shall be within 20 %

8.1 Sampling and sample preparation are to be performed

of that given in the manufacturer’s literature.

by procedures agreed upon between buyer and seller.

6.5 Precision—The variability obtained from calibration

8.2 The sampling procedure shall not involve any steps or

solution S shall not exceed 10 % of the mean absorbance of

procedures that can result in the loss or pick up of lead in the

the same solution, and the variability of calibration solution S

sample.

shall not exceed 4 % of the mean absorbance of solution S

NOTE 3—Sometimes a heterogeneous scrap composite is homogenized

when determined in accordance with Practice E 1770.

by melting, then milling a laboratory sample from the solid. Arc melting

6.6 Limit of Detection—The limit of detection of lead as

of the sample or induction melting of the sample under vacuum can result

described in Practice E 1770 shall be less than 20 pg (equiva-

in significant loss of several elements, including lead, that have a low

lent to 1.0 μg/L in the test solution or 0.2 ppm in the original

vapor pressure. Arc melting of the sample should be avoided and

sample). induction melting should be performed only with at least a partial inert

atmosphere.

6.7 Linearity—The linearity of the calibration as deter-

mined in Practice E 1770 shall not be less than 0.7.

8.3 In most cases the laboratory sample is in the form of

homogeneous turnings, millings or drillings and no further

7. Reagents

mechanical preparation of the sample is necessary.

7.1 Purity and Concentration of Reagents—The purity and

8.4 The laboratory sample shall be cleaned by first washing

concentration of common chemical reagents shall conform to

in pure acetone and drying in air.

Practices E 50. The reagents should be free of or contain

8.5 If brazed alloy tools are used in the preparation of the

minimal amounts (<0.01 μg/g) of lead.

sample, the sample shall be further cleaned by pickling in

7.2 Dissolution Acid Mixture—To 150 mL water carefully

dilute nitric acid for a few minutes. The sample shall then be

add 150 mL nitric acid and 150 mL hydrofluoric acid. Mix and

washed several times with water followed by several washes

store in plastic bottle.

with acetone and air dried.

7.3 Pure Nickel Metal—99.9 % minimum purity nickel, and

9. Procedure

shall contain less than 0.1 ppm lead.

9.1 Preparation of Test Solution—Transfer 0.50 g sample,

7.4 Nickel, Stock Solution (50 g/L)—Dissolve 25 6 0.1gof

weighed to the nearest mg, to a 100 mL PTFE beaker. Add 20

the pure nickel in 200 mL of nitric acid (1:1) in a 600 mL

mL of the dissolu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.