ASTM C1697-10

(Specification)Standard Specification for Blended Supplementary Cementitious Materials

Standard Specification for Blended Supplementary Cementitious Materials

SCOPE

1.1 This specification covers blended supplementary cementitious materials that result from the blending or intergrinding of two or three ASTM compliant supplementary cementitious materials, for use in concrete or mortar where hydraulic or pozzolanic action, or both, is desired. The supplementary cementitious materials include slag cement conforming to Specification C989, natural pozzolans and coal fly ash conforming to Specification C618 and silica fume conforming to Specification C1240.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

Note 1—The incorporation of supplementary cementitious materials as separate additions or as a manufactured blend may significantly alter the properties of fresh and hardened concrete. The user should be aware of these changes and is referred to the ACI Manual of Concrete Practice for information and guidelines. Specific reference is made to: ACI 232.1RUse of Natural Pozzolans in Concrete ACI 232.2RUse of Fly Ash in Concrete ACI 233RSlag Cement in Concrete and Mortar ACI 234RGuide for the Use of Silica Fume in Concrete

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1697 −10

StandardSpecification for

Blended Supplementary Cementitious Materials

This standard is issued under the fixed designation C1697; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C150 Specification for Portland Cement

C151 Test Method for Autoclave Expansion of Hydraulic

1.1 This specification covers blended supplementary ce-

Cement

mentitiousmaterialsthatresultfromtheblendingorintergrind-

C183 Practice for Sampling and the Amount of Testing of

ing of two or three ASTM compliant supplementary cementi-

Hydraulic Cement

tious materials, for use in concrete or mortar where hydraulic

C311 Test Methods for Sampling and Testing Fly Ash or

or pozzolanic action, or both, is desired. The supplementary

Natural Pozzolans for Use in Portland-Cement Concrete

cementitious materials include slag cement conforming to

C618 Specification for Coal Fly Ash and Raw or Calcined

Specification C989, natural pozzolans and coal fly ash con-

Natural Pozzolan for Use in Concrete

forming to Specification C618 and silica fume conforming to

C989 Specification for Slag Cement for Use in Concrete and

Specification C1240.

Mortars

1.2 The values stated in SI units are to be regarded as

C1240 Specification for Silica Fume Used in Cementitious

standard. No other units of measurement are included in this

Mixtures

standard.

NOTE 1—The incorporation of supplementary cementitious materials as

3. Terminology

separate additions or as a manufactured blend may significantly alter the

properties of fresh and hardened concrete. The user should be aware of

3.1 Definitions:

these changes and is referred to the ACI Manual of Concrete Practice for

3.1.1 For definitions of other terms used in this

information and guidelines. Specific reference is made to:

specification, refer to Terminology C125.

ACI 232.1R Use of Natural Pozzolans in Concrete

ACI 232.2R Use of Fly Ash in Concrete

3.2 Definitions of Terms Specific to This Standard:

ACI 233R Slag Cement in Concrete and Mortar

3.2.1 slag cement, n—granulated blast furnace slag that is

ACI 234R Guide for the Use of Silica Fume in Concrete

ground to cement fineness with or without additions and meets

1.3 This standard does not purport to address all of the

Specification C989.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.2.2 supplementary cementitious material, n—a slag ce-

priate safety and health practices and determine the applica-

ment or pozzolan that contributes to the properties of concrete

bility of regulatory limitations prior to use.

or mortar through hydraulic or pozzolanic activity, or both.

3.2.3 silica fume, n—as defined in Specification C1240.

2. Referenced Documents

2.1 ASTM Standards:

4. Classification

C114 Test Methods for Chemical Analysis of Hydraulic

4.1 This specification applies to a hydraulic or pozzolanic

Cement

material composed of a blend of multiple supplementary

C125 Terminology Relating to Concrete and Concrete Ag-

cementitious materials as defined in Table 1. The supplemen-

gregates

tary cementitious materials of the blend are identified in

accordance with the Type listed in the first column of Table 1.

This specification is under the jurisdiction of ASTM Committee C09 on For the purpose of conformance to the requirements of this

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

specification, the blend is classified according to the predomi-

C09.24 on Supplementary Cementitious Materials.

nant supplementary cementitious material. For blended supple-

Current edition approved Feb. 1, 2010. Published March 2010. DOI: 10.1520/

mentary cementitious matierals that have no predominant

C1697-10.

Available fromAmerican Concrete Institute (ACI), P.O. Box 9094, Farmington

constituent, the manufacturer selects the blend type.

Hills, MI 48333-9094, http://www.concrete.org.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 4.2 The naming practice for reporting blended supplemen-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tary cementitious materials is as follows:

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. SCMb 2 Axx/Byy/Czz

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1697−10

TABLE 1 Classification of Supplementary Cementitious Materials

applicable analytical methods of Test Methods C311 or Test

Type Name Methods C114.Analyze for major and minor oxides present in

N Class N Pozzolan meeting Specification C618

greatest quantity that together, including loss-on-ignition con-

F Class F fly ash meeting Specification C618

stitutes at least 98 % of the total mass of the material.

C Class C fly ash meeting Specification C618

SF Silica Fume meeting Specification C1240

7.2 There are no chemical requirements for the blended

S Slag cement meeting Specification C989

supplementary cementitious material but the chemical compo-

sition of the constituents and of the blended supplementary

where:

cementitious material are necessary to verify blend propor-

tions.

SCMb = designation of the product as a blended supplemen-

tary cementitious material,

8. Physical and Optional Properties

A = targeted mass % of the predominant supplementary

cementitious material in the blended supplementary

8.1 Blended supplementary cementitious materials shall

cementitious material expressed by mass of the

conform to the physical requirements in Table 3, where the

final blended supplementary cementitious material,

blend type is in accordance with Section 4.

xx = predominant supplementary cementitious

8.2 Blended supplementary cementitious materials shall

material—use Type designation in accordance with

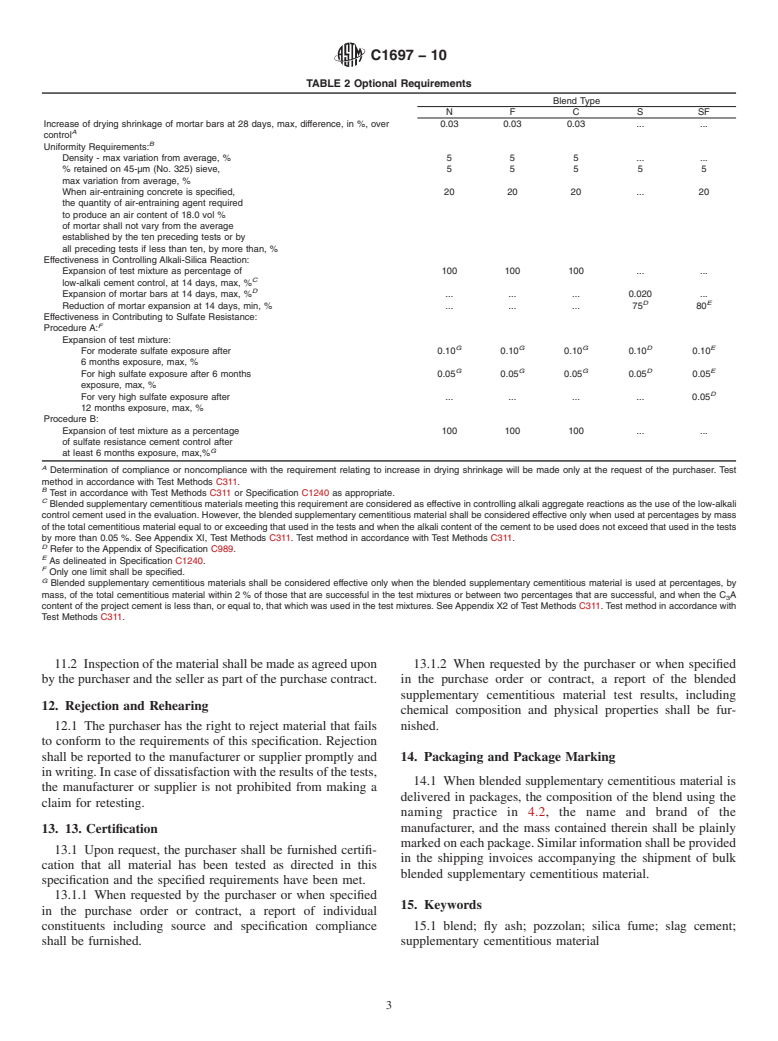

conform to the optional requirements in Table 2, only when

Table 1,

specifically requested by the purchaser. The blend type is in

B = targeted mass % of the secondary supplementary

accordance with Section 4.

cementitious material in the blended supplementary

cementitious material expressed by mass of the

9. Permissible Variations in Blending Accuracy

final blended supplementary cementitious material,

yy = secondary supplementary cementitious material—

9.1 The amount of pozzolan or slag cement in the finished

use Type designation in accordance with Table 1, blended supplementary cementitious material shall not vary

C = targeted mass % of the tertiary supplementary

from the target value by more than 62.5 percentage points for

cementitious material in the blended supplementary

silica fume and not more than 65 percentage points for other

cementitious material expressed by mass of the supplementary cementitious materials, with a 99 % probability

final blended supplementary cementitious material.

of compliance.

NOTE 4—To satisfy the 99 % probability of compliance, the blending

This would be required only for ternary mixtures,

process must be capable of producing a blend containing silica fume such

and

that the standard deviation of the measured mass percentage of silica fume

zz = tertiary supplementary cementitious material—use

in the blend is less than 1 %. For constituents other than silica fume, the

Type designation in accordance with Table 1

standard deviations of their measured mass percentages have to be less

NOTE 2—Examples of the naming practice are as follows:

than 1.9 %.

Abinary mixture of 65 % Class C fly ash and 35 % slag cement would be:

9.2 The chemical composition of the individual constituents

SCMb 2 65C/35S

and of the finished blended supplementary cementitious mate-

A ternary mixture of 60 % Class F fly ash, 35 % slag cement and 5 %

rial shall be determined in accordance with Section 7. The

silica fume would be:

composition of the blend in terms of mass percentage of the

SCMb 2 60F/35S/5SF

constituents shall be calculated.

NOTE 5—Appendix X1 provides an example to illustrate how the

5. Ordering Information

composition of the blend can be calculated from the various measured

5.1 Orders for material under this specification shall include chemical compositions.

the following:

10. Sampling

5.1.1 Specification number,

5.1.2 The composition of the blend using the naming

10.1 The manufacturer shall sample and test the finished

convention in 4.2.

blended supplementary cementitious material in order to verify

5.1.3 Any optional requirements as delineated in Table 2.

compliance with this specification.

NOTE 3—In advance of ordering, it is important to check for market

10.1.1 Uponrequestofthepurchaser,themanufacturershall

availability of blended supplementary cementitious materials.

furnishthesamplingprocedureusedtocertifycompliancewith

this specification.

6. Materials and Manufacture

6.1 All individual constituents used in the manufacture of 10.2 If the purchaser desires to verify product compliance

with this specification, appropriate sampling and testing pro-

the blended supplementary cementitious material shall con-

form to their applicable specification. cedures shall be used. For guidance, refer to standard Practice

C183.

6.2 All blended supplementary cementitious materials shall

consist of a uniform mixture of constituents within the limits

11. Storage and Inspection

specified in Section 9.

11.1 The blended supplementary cementitious materials

7. Chemical Composition

shall be protected from the detrimental effects of exposure to

7.1 The individual constituents and the blended supplemen- the environment and stored in such a manner as to permit easy

tary cementitious material shall be chemically analyzed using access for proper inspection and identification.

C1697−10

TABLE 2 Optional Requirements

Blend Type

NF C S SF

Increase of drying shrinkage of mortar bars at 28 days, max, difference, in %, over 0.03 0.03 0.03 . .

A

control

B

Uniformity Requirements:

Density - max variation from average, % 5 5 5 . .

% retained on 45-µm (No. 325) sieve, 55 5 5 5

max variation from average, %

When air-entraining concrete is specified, 20 20 20 . 20

the quantity of air-entraining agent required

to produ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.