ASTM C749-15(2020)

(Test Method)Standard Test Method for Tensile Stress-Strain of Carbon and Graphite

Standard Test Method for Tensile Stress-Strain of Carbon and Graphite

SIGNIFICANCE AND USE

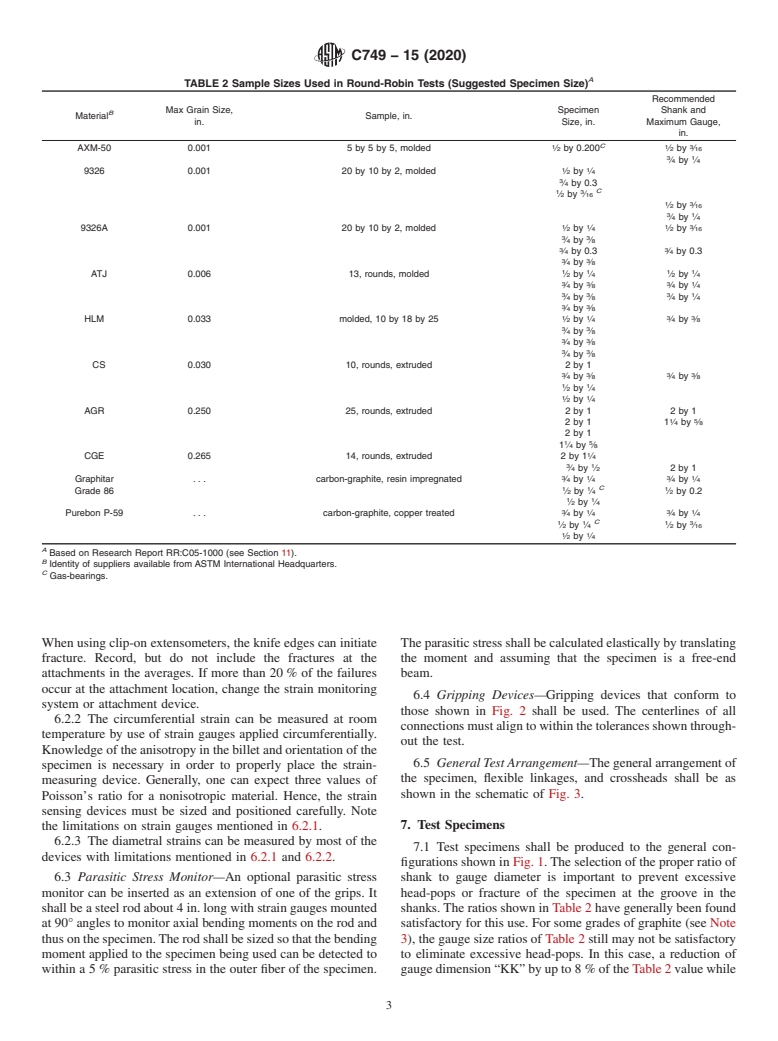

5.1 The round robin testing on which the precision and bias for this test method have been determined employed a range of graphites (see Table 2) whose grain sizes were of the order of 1 mil to 1/4 in. (0.0254 mm to 6.4 mm) and larger. This wide range of carbons and graphites can be tested with uniform gauge diameters with minimum parasitic stresses to provide quality data for use in engineering applications rather than simply for quality control. This test method can be easily adapted to elevated temperature testing of carbons and graphites without changing the specimen size or configuration by simply utilizing elevated temperature materials for the load train. This test method has been utilized for temperatures as high as 4352 °F (2400 °C). The design of the fixtures (Figs. 2-9 and Table 1) and description of the procedures are intended to bring about, on the average, parasitic stresses of less than 5 %. The specimens for the different graphites have been designed to ensure fracture within the gauge section commensurate with experienced variability in machining and testing care at different facilities. The constant gauge diameter permits rigorous analytical treatment.

Note 1: Refer to Fig. 2, Items 101 and 115.

Note 1: Refer to Fig. 2, Items 103 and 117. (A) Screw size.

Note 1: Refer to Fig. 2, Items 107, 109, 111, 113, 121, 123, and 129.

Note 1: Refer to Fig. 2, Items 105, 109, 113, 119, 123, 125, and 129.

Note 1: Refer to Fig. 2, Items 108, 112, 122, and 128.

FIG. 9 Attachment for Strain Flags or Extensometers to Provide Minimum Damage to Surface of Specimen

Note 1: Jig align to ensure precision gauge length; mount post or groove to match type of extensometer.

5.2 Carbon and graphite materials exhibit significant physical property differences within parent materials. Exact sampling patterns and grain orientations must be specified in order to make meaningful tensile strength comparisons. See also Test Methods C565.

SCOPE

1.1 This test method covers the testing of carbon and graphite in tension to obtain the tensile stress-strain behavior, to failure, from which the ultimate strength, the strain to failure, and the elastic moduli may be calculated as may be required for engineering applications. Table 2 lists suggested sizes of specimens that can be used in the tests.

Note 1: The results of about 400 tests, on file at ASTM as a research report, show the ranges of materials that have been tested, the ranges of specimen configurations, and the agreement between the testers. See Section 11.

Note 2: For safety considerations, it is recommended that the chains be surrounded by suitable members so that at failure all parts of the load train behave predictably and do not constitute a hazard for the operator.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. Conversions are not provided in the tables and figures.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C749 − 15 (Reapproved 2020)

Standard Test Method for

Tensile Stress-Strain of Carbon and Graphite

This standard is issued under the fixed designation C749; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Graphite Mechanical Materials

E4 Practices for Force Verification of Testing Machines

1.1 This test method covers the testing of carbon and

E6 Terminology Relating to Methods of Mechanical Testing

graphite in tension to obtain the tensile stress-strain behavior,

E177 Practice for Use of the Terms Precision and Bias in

to failure, from which the ultimate strength, the strain to

ASTM Test Methods

failure, and the elastic moduli may be calculated as may be

E691 Practice for Conducting an Interlaboratory Study to

required for engineering applications. Table 2 lists suggested

Determine the Precision of a Test Method

sizes of specimens that can be used in the tests.

NOTE 1—The results of about 400 tests, on file at ASTM as a research

3. Terminology

report, show the ranges of materials that have been tested, the ranges of

3.1 Definitions:

specimen configurations, and the agreement between the testers. See

Section 11. 3.1.1 The terms as related to tension testing as given in

NOTE 2—For safety considerations, it is recommended that the chains

Terminology E6 shall be considered as applying to the terms

be surrounded by suitable members so that at failure all parts of the load

used in this test method.

train behave predictably and do not constitute a hazard for the operator.

3.1.2 modulus of elasticity, n—the ratio of a force applied to

1.2 The values stated in inch-pound units are to be regarded

a material to the increment of dimensional change along the

as standard. The values given in parentheses are mathematical

force axis, commonly defined as the ratio of tensile stress to

conversions to SI units that are provided for information only

tensile strain.

and are not considered standard. Conversions are not provided

3.1.3 tensile strength, n—property of solid material that

in the tables and figures.

indicates its ability to withstand a uniaxial tensile load,

1.3 This standard does not purport to address all of the

converted to unit stress based on the original cross-section area

safety concerns, if any, associated with its use. It is the

of the tensile test specimen.

responsibility of the user of this standard to establish appro-

3.1.4 ultimate tensile strength, n—the maximum tensile

priate safety, health, and environmental practices and deter-

stress applied in stretching a specimen to rupture.

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

4. Summary of Test Method

dance with internationally recognized principles on standard-

4.1 Atensile specimen (Fig. 1) is placed within a load train

ization established in the Decision on Principles for the

assembly made up of precision chains and other machined

Development of International Standards, Guides and Recom-

parts (Fig. 2).Aload is applied to the specimen provided with

mendations issued by the World Trade Organization Technical

means of measuring strain until it is caused to fracture. This

Barriers to Trade (TBT) Committee.

test yields the tensile strength, elastic constants, and strain to

failure of carbons and graphites.

2. Referenced Documents

2.1 ASTM Standards:

5. Significance and Use

C565 Test Methods for Tension Testing of Carbon and

5.1 The round robin testing on which the precision and bias

for this test method have been determined employed a range of

This test method is under the jurisdiction of ASTM Committee D02 on

graphites (see Table 2) whose grain sizes were of the order of

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

1 mil to ⁄4 in. (0.0254 mm to 6.4 mm) and larger. This wide

Subcommittee D02.F0 on Manufactured Carbon and Graphite Products.

range of carbons and graphites can be tested with uniform

Current edition approved May 1, 2020. Published June 2020. Originally

gauge diameters with minimum parasitic stresses to provide

approved in 1973. Last previous edition approved in 2015 as C749 – 15. DOI:

10.1520/C0749-15R20.

quality data for use in engineering applications rather than

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

simply for quality control. This test method can be easily

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

adapted to elevated temperature testing of carbons and graphi-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. tes without changing the specimen size or configuration by

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C749 − 15 (2020)

TABLE 1 List of Materials Shown in Fig. 2

Assembly Item Quantity Name, Description, Material

1A 101 2 Crosshead attachment yoke—1 diax4long—416 or 440 S.S.

A B,C

1 3

⁄2 in. grips 102 2 Chain— ⁄16 dia, 700 pound tensile limit, 10 links long—Carbon Steel

D

9 1

103 4 Chain journal— ⁄16 dia x ⁄2 long—416 or 440 S.S.

104 4 Pin— ⁄16 dia x 1—Std Dowel

D

105 2 Grip attachment yoke—1 dia x 2 ⁄8 long—416 or 440 S.S.

1 1 3

106 2 Pin— ⁄4 shank dia with ⁄2 dia x ⁄4 long knurled head, total length

D

2 ⁄2, taper first half inch at 10°—416 or 440 S.S.

D

1 5

107 2 Grip sleeve—1 ⁄2 diax2 ⁄16 long—416 or 440 S.S.

D

108 2 Split sleeve—1 diax1long—416 or 440 S.S.

109 1 Specimen—0.510 dia x 4 ⁄4 long—Carbon

110 Not Used

1B . . . 2 Item 101—Crosshead attachment yoke

A

⁄4 in. grips . . . 2 Item 102—Chain

. . . 4 Item 103—Chain journal

. . . 4 Item 104—Pin

. . . 2 Item 105—Grip attachment yoke

. . . 2 Item 106—Pin

D

1 5

111 2 Grip sleeve—1 ⁄2diax2 ⁄16 long—416 or 440 S.S.

D

112 2 Split sleeve—1 diax1long—416 or 440 S.S.

113 1 Specimen—0.760 dia x 4 ⁄4 long—Carbon

114 Not Used

D

1C 115 2 Crosshead attachment yoke—1 ⁄2 diax4long—416 or 440 S.S.

A

1 3

1 ⁄4 in. grips 116 2 Chain— ⁄8 dia, 5100 pound tensile limit, 10 links long—Carbon Steel

D

5 5

117 4 Chain journal— ⁄8 dia x ⁄8 long—416 or 440 S.S.

3 1

118 4 Pin— ⁄8 diax1 ⁄2 long—Std Dowel

1 5 D

119 2 Grip attachment yoke—1 ⁄2 diax2 ⁄8 long—416 or 440 S.S.

1 3 3

120 2 Pin— ⁄2 shank dia with ⁄4 dia x ⁄4 long knurled head, total length

1 D

4 ⁄4, taper first half inch at 10°—416 or 440 S.S.

D

7 5

121 2 Grip sleeve—1 ⁄8diax3 ⁄8 long—416 or 440 S.S.

D

1 1

122 2 Split sleeve—1 ⁄2diax2 ⁄4 long—416 or 440 S.S.

1 3

123 1 Specimen—1 ⁄4 diax9 ⁄4 long—Carbon

124 Not Used

1D . . . 2 Item 115—Crosshead attachment yoke

A

2in. grips . . . 2 Item 116—Chain

. . . 4 Item 117—Chain journal

. . . 4 Item 118—Pin

D

1 5

125 2 Grip attachment yoke—2 ⁄4 diax2 ⁄8 long—416 or 440 S.S.

1 3 3

126 2 Pin— ⁄2 shank dia with ⁄4 dia x ⁄4 long knurled head, total length

D

4 ⁄4, taper first half inch at 10°—416 or 440 S.S.

D

3 1

127 2 Grip sleeve—2 ⁄4diax5 ⁄2 long—416 or 440 S.S.

D

128 2 Split sleeve—2 ⁄4diax4long—416 or 440 S.S.

129 1 Specimen—2.000 dia x 14 ⁄8 long—Carbon

130 Not Used

A

1 in. is equal to 25.4 mm.

B

Preload chain to yield using a load time recording.

C

Commercially available.

D

Or alternative high strength stainless steel.

simply utilizing elevated temperature materials for the load machine shall have a load measurement capacity such that the

train. This test method has been utilized for temperatures as breaking load of the test specimen falls between 10 % and

highas4352 °F(2400 °C).Thedesignofthefixtures(Figs.2-9 90 % of the scale or load cell capacity. This range must be

and Table 1) and description of the procedures are intended to lineartowithin1 %over1 %incrementseitherbydesignorby

bring about, on the average, parasitic stresses of less than 5 %. calibration.

The specimens for the different graphites have been designed

6.2 Strain Measurements:

to ensure fracture within the gauge section commensurate with

6.2.1 The axial strain can be measured at room temperature

experienced variability in machining and testing care at differ-

by the use of strain gauges, mechanical extensometers, Tuck-

ent facilities. The constant gauge diameter permits rigorous

erman gauges, optical systems, or other devices applied dia-

analytical treatment.

metrically opposite in the gauge length portion of the speci-

5.2 Carbon and graphite materials exhibit significant physi- men. Two opposing gauges provide some compensation for

cal property differences within parent materials. Exact sam- bending and some assurance that it was not severe. Different

pling patterns and grain orientations must be specified in order graphites require different attachment procedures and extreme

tomakemeaningfultensilestrengthcomparisons.SeealsoTest

care is necessary. A proven device for mounting the specimen

Methods C565. with minimum damage and for enabling the specimen to

receive different extensometers is shown in Fig. 9. When

6. Apparatus

attaching strain gauges, the modification of the surface may

6.1 Testing Machine—The machine used for tensile testing result in a glue-graphite composite at the skin and thus the

shall conform to the requirements of Practices E4. The testing resulting strain values may be erroneous and typically low.

C749 − 15 (2020)

A

TABLE 2 Sample Sizes Used in Round-Robin Tests (Suggested Specimen Size)

Recommended

Max Grain Size, Specimen Shank and

B

Material Sample, in.

in. Size, in. Maximum Gauge,

in.

1 C 1 3

AXM-50 0.001 5 by 5 by 5, molded ⁄2 by 0.200 ⁄2 by ⁄16

3 1

⁄4 by ⁄4

1 1

9326 0.001 20 by 10 by 2, molded ⁄2 by ⁄4

⁄4 by 0.3

C

1 3

⁄2 by ⁄16

1 3

⁄2 by ⁄16

3 1

⁄4 by ⁄4

1 1 1 3

9326A 0.001 20 by 10 by 2, molded ⁄2 by ⁄4 ⁄2 by ⁄16

3 3

⁄4 by ⁄8

3 3

⁄4 by 0.3 ⁄4 by 0.3

3 3

⁄4 by ⁄8

1 1 1 1

ATJ 0.006 13, rounds, molded ⁄2 by ⁄4 ⁄2 by ⁄4

3 3 3 1

⁄4 by ⁄8 ⁄4 by ⁄4

3 3 3 1

⁄4 by ⁄8 ⁄4 by ⁄4

3 3

⁄4 by ⁄8

1 1 3 3

HLM 0.033 molded, 10 by 18 by 25 ⁄2 by ⁄4 ⁄4 by ⁄8

3 3

⁄4 by ⁄8

3 3

⁄4 by ⁄8

3 3

⁄4 by ⁄8

CS 0.030 10, rounds, extruded 2 by 1

3 3 3 3

⁄4 by ⁄8 ⁄4 by ⁄8

1 1

⁄2 by ⁄4

1 1

⁄2 by ⁄4

AGR 0.250 25, rounds, extruded 2 by 1 2 by 1

1 5

2by1 1 ⁄4 by ⁄8

2by1

1 5

1 ⁄4 by ⁄8

CGE 0.265 14, rounds, extruded 2 by 1 ⁄4

3 1

⁄4 by ⁄2 2by1

3 1 3 1

Graphitar . . . carbon-graphite, resin impregnated ⁄4 by ⁄4 ⁄4 by ⁄4

C

1 1 1

Grade 86 ⁄2 by ⁄4 ⁄2 by 0.2

1 1

⁄2 by ⁄4

3 1 3 1

Purebon P-59 . . . carbon-graphite, copper treated ⁄4 by ⁄4 ⁄4 by ⁄4

C

1 1 1 3

⁄2 by ⁄4 ⁄2 by ⁄16

1 1

⁄2 by ⁄4

A

Based on Research Report RR:C05-1000 (see Section 11).

B

Identity of suppliers available from ASTM International Headquarters.

C

Gas-bearings.

When using clip-on extensometers, the knife edges can initiate Theparasiticstressshallbecalculatedelasticallybytranslating

fracture. Record, but do not include the fractures at the the moment and assuming that the specimen is a free-end

attachments in the averages. If more than 20 % of the failures beam.

occur at the attachment location, change the strain monitoring

6.4 Gripping Devices—Gripping devices that conform to

system or attachment device.

those shown in Fig. 2 shall be used. The centerlines of all

6.2.2 The circumferential strain can be measured at room

connectionsmustaligntowithinthetolerancesshownthrough-

temperature by use of strain gauges applied circumferentially.

out the test.

Knowledge of the anisotropy in the billet and orientation of the

6.5 General TestArrangement—Thegeneralarrangementof

specimen is necessary in order to properly place the strain-

the specimen, flexible linkages, and crossheads shall be as

measuring device. Generally, one can expect three values of

shown in the schematic of Fig. 3.

Poisson’s ratio for a nonisotropic material. Hence, the strain

sensing devices must be sized and positioned carefully. Note

7. Test Specimens

the limitations on strain gauges mentioned in 6.2.1.

6.2.3 The diametral strains can be measured by most of the

7.1 Test specimens shall be produced to the general con-

devices with limitations mentioned in 6.2.1 and 6.2.2.

figurations shown in Fig. 1.The selection of the proper ratio of

6.3 Parasitic Stress Monitor—An optional parasitic stress shank to gauge diameter is important to prevent excessive

monitor can be inserted as an extension of one of the grips. It head-pops or fracture of the specimen at the groove in the

shall be a steel rod about 4 in. long with strain gauges mounted shanks.The ratios shown in Table 2 have generally been found

at 90° angles to monitor axial bending moments on the rod and satisfactory for this use. For some grades of graphite (see Note

thusonthespecimen.Therodshallbesizedsothatthebending 3), the gauge size ratios of Table 2 still may not be satisfactory

moment applied to the specimen being used can be detected to to eliminate excessive head-pops. In this case, a reduction of

within a 5 % parasitic stress in the outer fiber of the specimen. gaugedimension“KK”byupto8 %oftheTable2valuewhile

C749 − 15 (2020)

Dimensions, Item

in. (mm)

109 113 123 129

0.510 + 0.000 − 0.002 0.760 + 0.000 − 0.002 1.250 + 0.000 − 0.002 2.000 + 0.000− 0.002

HH

(12.95 + 0.00 − 0.05) (19.30 + 0.00 − 0.05) (31.75 + 0.00 − 0.05) (50.80 + 0.00 − 0.05)

JJ 0.390 (9.91) 0.640 (16.26) 0.990 (25.15) 1.490 (37.85)

KK 0.250 ± 0.002 (6.35 ± 0.05) 0.375 ± 0.002 (9.52 ± 0.05) 0.625 ± 0.002 (15.88 ± 0.05) 1.000 ± 0.002 (25.40 ± 0.05)

LL 1 (25.4) 1 (25.4) 2 (50.8) 2 (50.8)

MM 0.635 (16.13) 0.635 (16.13) 1.250 (31.75) 1.500 (38.10)

NN 0.125 (31.75) 0.125 (31.75) 0.255 (6.48) 0.505 (12.83)

3 3 7 3

OO 2 ⁄8 (60.32) 2 ⁄8 (60.32) 4 ⁄8 (123.82) 7 ⁄16 (182.56)

7 7 1

PP ⁄8 (22.22) ⁄8 (22.22) 1 ⁄4 (31.75) 2 (50.8)

3 3 3 3

RR 4 ⁄4 (120.65) 4 ⁄4 (120.65) 9 ⁄4 (247.65) 14 ⁄8 (365.12)

0.030 + 0.000 – 0.005 0.030 + 0.000 – 0.005 0.060 + 0.000 – 0.005 0.120 + 0.000 – 0.005

SS

(0.76 + 0.00 – 0.13) (0.76 + 0.00 – 0.13) (1.52 + 0.00 – 0.13) (3.05 + 0.00 – 0.13)

NOTE 1—Refer to Fig. 2, Items 109, 113, 123, and 129.

FIG. 1 Specimen

maintaining the same radius “LL” is allowable. An acceptable 7.3 The gauge length of the specimen will be measured

alternative method is to double reduce gauge diameters as

from the axial center of the specimen. Gauge marks can be

necessary (see Fig. 10) to eliminate head pops (or out-of-gauge

applied with ink or layout dope but no scratching, punching, or

fractures) or reduce them to an acceptable 20 % maximum

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.