ASTM D7042-04

(Test Method)Standard Test Method for Dynamic Viscosity and Density of Liquids by Stabinger Viscometer (and the Calculation of Kinematic Viscosity)

Standard Test Method for Dynamic Viscosity and Density of Liquids by Stabinger Viscometer (and the Calculation of Kinematic Viscosity)

SIGNIFICANCE AND USE

Many petroleum products, and some non-petroleum materials, are used as lubricants and the correct operation of the equipment depends upon the appropriate viscosity of the liquid being used. In addition, the viscosity of many petroleum fuels is important for the estimation of optimum storage, handling, and operational conditions. Thus, the accurate determination of viscosity is essential to many product specifications.

Density is a fundamental physical property that can be used in conjunction with other properties to characterize both the light and heavy fractions of petroleum and petroleum products.

Determination of the density or relative density of petroleum and its products is necessary for the conversion of measured volumes to volumes at the standard temperature of 15°C.

SCOPE

1.1 This test method specifies a procedure for the concurrent measurement of both the dynamic viscosity, η, and the density, ρ, of liquid petroleum products and crude oils, both transparent and opaque. The kinematic viscosity, ny, can be obtained by dividing the dynamic viscosity, η, by the density, ρ, obtained at the same test temperature.

1.2 The result obtained from this test method is dependent upon the behavior of the sample and is intended for application to liquids for which primarily the shear stress and shear rate are proportional (Newtonian flow behavior).

1.3 While the precision has only been determined for base oils in the viscosity range from 2.05 to 456 mPas at 40°C and from 0.83 to 31.6 mPas at 100°C and in the density range from 0.82 to 0.92 g/mL at 15°C (see 15.4), the test method can be applied to a wider range of materials, viscosity, density, and temperature. For materials not listed in Precision and Bias (Section 15), the precision and bias may not be applicable.

1.4 The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard. The accepted units of measure for density are grams per millilitre (g/mL) or kilograms per cubic metre (kg/m3).

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7042–04

Standard Test Method for

Dynamic Viscosity and Density of Liquids by Stabinger

Viscometer (and the Calculation of Kinematic Viscosity)

This standard is issued under the fixed designation D7042; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope and Viscosity Oil Standards

D2270 Practice for Calculating Viscosity Index from Kine-

1.1 Thistestmethodspecifiesaprocedurefortheconcurrent

matic Viscosity at 40 and 100°C

measurement of both the dynamic viscosity, h, and the density,

D4052 Test Method for Density, Relative Density, and API

r, of liquid petroleum products and crude oils, both transparent

Gravity of Liquids by Digital Density Meter

and opaque. The kinematic viscosity, n, can be obtained by

D6299 Practice for Applying Statistical Quality Assurance

dividingthedynamicviscosity, h,bythedensity, r,obtainedat

and Control Charting Techniques to Evaluate Analytical

the same test temperature.

Measurement System Performance

1.2 The result obtained from this test method is dependent

D6300 Practice for Determination of Precision and Bias

upon the behavior of the sample and is intended for application

Data for Use in Test Methods for Petroleum Products and

toliquidsforwhichprimarilytheshearstressandshearrateare

Lubricants

proportional (Newtonian flow behavior).

D6617 Practice for Laboratory Bias Detection Using Single

1.3 While the precision has only been determined for base

Test Result from Standard Material

oils in the viscosity range from 2.05 to 456 mPa·s at 40°C and

D6708 PracticeforStatisticalAssessmentandImprovement

from0.83to31.6mPa·sat100°Candinthedensityrangefrom

of Expected Agreement Between Two Test Methods that

0.82 to 0.92 g/mL at 15°C (see 15.4), the test method can be

Purport to Measure the Same Property of a Material

applied to a wider range of materials, viscosity, density, and

2.2 ISO Standards:

temperature. For materials not listed in Precision and Bias

ISO 5725 Accuracy (trueness and precision) of measure-

(Section 15), the precision and bias may not be applicable.

ment methods and results

1.4 The values stated in SI units are to be regarded as the

ISO/IEC 17025 General Requirements for the Competence

standard. No other units of measurement are included in this

of Testing and Calibration Laboratories

standard. The accepted units of measure for density are grams

2.3 Other Documents:

per millilitre (g/mL) or kilograms per cubic metre (kg/m ).

NIST Technical Note 1297 Guideline for Evaluating and

1.5 This standard does not purport to address all of the

Expressing the Uncertainty of NISTMeasurement Results

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety and health practices and to determine the

3.1 Definitions:

applicability of regulatory limitations prior to use.

3.1.1 dynamic viscosity (h), n—the ratio between the ap-

2. Referenced Documents plied shear stress and rate of shear of a liquid.

2 3.1.1.1 Discussion—It is sometimes called the coefficient of

2.1 ASTM Standards:

dynamic viscosity or, simply, viscosity. Thus, dynamic viscos-

D445 Test Method for Kinematic Viscosity of Transparent

ity is a measure of the resistance to flow or to deformation of

and Opaque Liquids (and Calculation of Dynamic Viscos-

a liquid under external shear forces.

ity)

3.1.1.2 Discussion—The term dynamic viscosity can also

D2162 PracticeforBasicCalibrationofMasterViscometers

be used in a different context to denote a frequency-dependent

quantity in which shear stress and shear rate have a sinusoidal

time dependence.

This test method is under the jurisdiction of ASTM Committee D02 on

3.1.2 kinematic viscosity (n), n—the ratio of the dynamic

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.07 on Flow Properties.

viscosity (h) to the density (r) of a liquid.

Current edition approved July 1, 2004. Published July 2004. DOI: 10.1520/

D7042-04.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036.

Standards volume information, refer to the standard’s Document Summary page on Available from National Institute of Standards and Technology (NIST), 100

the ASTM website. Bureau Dr., Stop 3460, Gaithersburg, MD 20899-3460.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7042–04

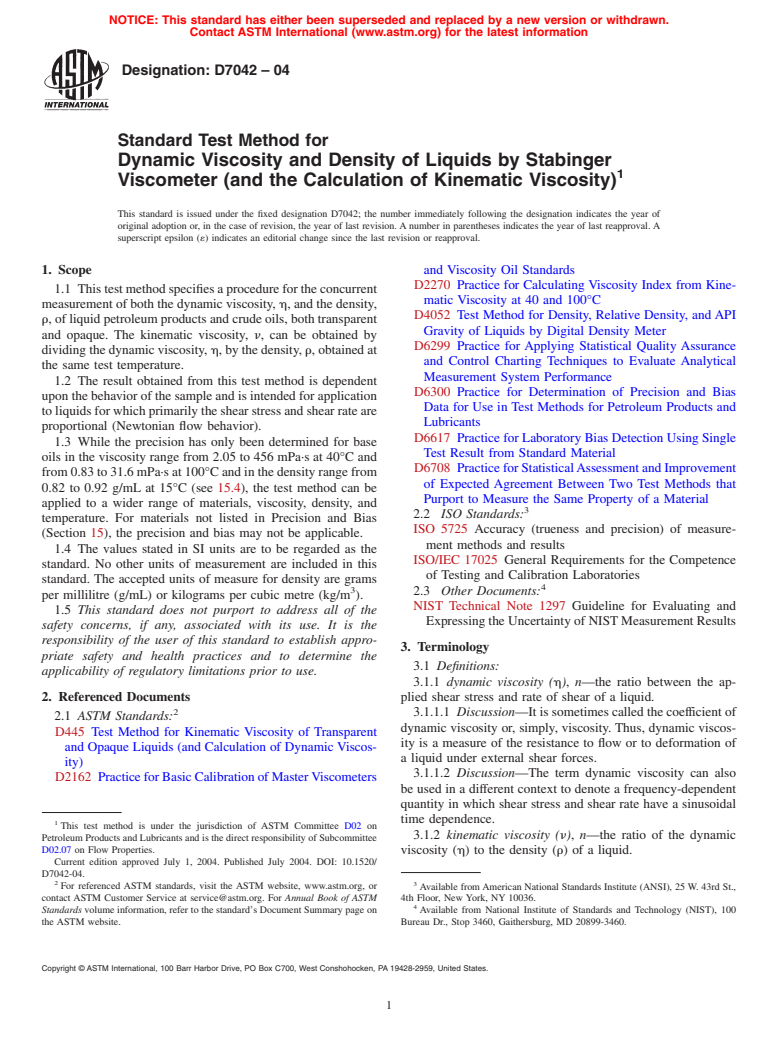

3.1.2.1 Discussion—For gravity flow under a given hydro- and the soft iron ring. Consequently, the system works free of

static head, the pressure head of a liquid is proportional to its bearing friction as found in rotational viscometers. A perma-

density (r). Therefore the kinematic viscosity (n) is a measure nent magnet in the inner cylinder induces eddy currents in the

of the resistance to flow of a liquid under gravity. surrounding copper casing. The rotational speed of the inner

3.1.3 density (r), n—mass per unit volume. cylinder establishes itself as the result of the equilibrium

3.1.4 Relative density (also called specific gravity (SG)), between the driving torque of the viscous forces and the

n—the ratio of the density of a material at a stated temperature retarding eddy current torque. This rotational speed is mea-

to the density of a reference material (usually water) at a stated sured by an electronic system (Hall effect sensor) by counting

temperature. thefrequencyoftherotatingmagneticfield(seeFig.1andFig.

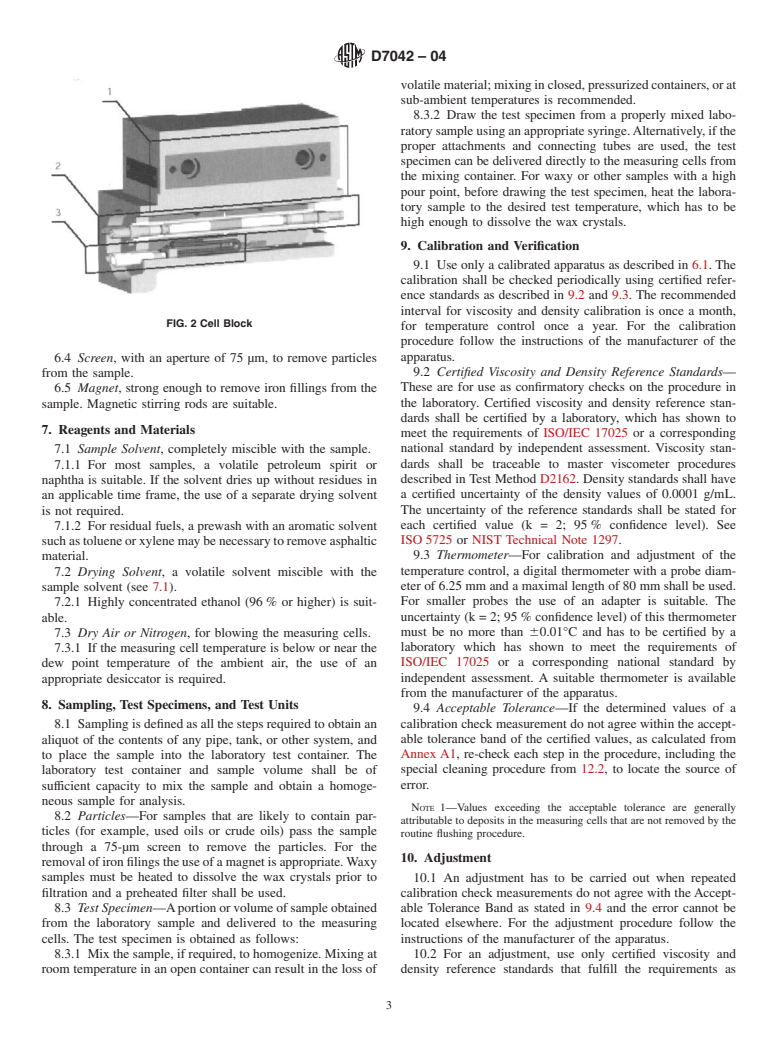

2, No. 2).

4. Summary of Test Method

6.1.2 Density Measurement—The digital density analyzer

4.1 Thetestspecimenisintroducedintothemeasuringcells, uses a U-shaped oscillating sample tube and a system for

which are at a closely controlled and known temperature. The electronic excitation and frequency counting (see Fig. 2, No.

measuring cells consist of a pair of rotating concentric cylin- 3).

ders and an oscillating U-tube. The dynamic viscosity is 6.1.3 Temperature Control—The copper block surrounds

both the viscosity and the density measuring cell in a way that

determined from the equilibrium rotational speed of the inner

cylinder under the influence of the shear stress of the test both cells are held at the same temperature. A thermoelectric

heating and cooling system (see Fig. 2, No. 1) ensures the

specimen and an eddy current brake in conjunction with

adjustment data. The density is determined by the oscillation temperature stability of the copper block within 60.005°C

from the set temperature at the position of the viscosity cell

frequency of the U-tube in conjunction with adjustment data.

The kinematic viscosity is calculated by dividing the dynamic overthewholetemperaturerange.Theuncertainty(k=2;95 %

confidence level) of the temperature calibration shall be no

viscosity by the density.

more than 60.03°C over the range from 15 to 100°C. Outside

5. Significance and Use

this range the calibration uncertainty shall be no more than

5.1 Many petroleum products, and some non-petroleum 60.05°C.

6.1.4 The thermal equilibration time depends on the heat

materials, are used as lubricants and the correct operation of

the equipment depends upon the appropriate viscosity of the capacity and conductivity of the liquid and on the difference

between injection temperature and test temperature. Adequate

liquid being used. In addition, the viscosity of many petroleum

fuels is important for the estimation of optimum storage, temperature equilibration of the test specimen is automatically

determined when successive viscosity values are constant

handling, and operational conditions. Thus, the accurate deter-

mination of viscosity is essential to many product specifica- within 60.07 % over 1 min and successive density values are

constant within 60.00003 g/mL over 1 min.

tions.

5.2 Density is a fundamental physical property that can be 6.2 Syringes, commercially available, at least 5 mL in

used in conjunction with other properties to characterize both volume, with a Luer tip.All construction materials for syringes

shall be fully compatible with all sample liquids and cleaning

the light and heavy fractions of petroleum and petroleum

products. agents, which contact them.

6.3 Flow-Through or Pressure Adapter, for use as an

5.3 Determination of the density or relative density of

petroleum and its products is necessary for the conversion of alternative means of introducing the test specimen into the

measuring cells either by pressure or by suction, provided that

measured volumes to volumes at the standard temperature of

15°C. sufficient care and control is used to avoid any bubble

formation in the test specimen. All construction materials for

6. Apparatus

adaptors shall be fully compatible with all sample liquids and

5,6

cleaning agents, which contact them.

6.1 Stabinger Viscometer

6.1.1 Viscosity measurement—The Stabinger viscometer

uses a rotational coaxial cylinder measuring system. The outer

cylinder (tube) is driven by a motor at a constant and known

rotational speed. The low-density inner cylinder (rotor) is held

in the axis of rotation by the centrifugal forces of the higher

density sample and in its longitudinal position by the magnet

The Stabinger viscometer is covered by a patent. Interested parties are invited

to submit information regarding the identification of an alternative to this patented

item to the ASTM International headquarters. Your comments will receive careful

consideration at a meeting of the responsible technical committee, which you may

attend.

The sole source of supply of the apparatus known to the committee at this time

isAnton Paar GmbH,Anton-Paar-Str. 20,A-8054 Graz,Austria. If you are aware of

alternative suppliers, please provide this information to ASTM International

headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. FIG. 1 Viscosity Cell

D7042–04

volatilematerial;mixinginclosed,pressurizedcontainers,orat

sub-ambient temperatures is recommended.

8.3.2 Draw the test specimen from a properly mixed labo-

ratorysampleusinganappropriatesyringe.Alternatively,ifthe

proper attachments and connecting tubes are used, the test

specimen can be delivered directly to the measuring cells from

the mixing container. For waxy or other samples with a high

pour point, before drawing the test specimen, heat the labora-

tory sample to the desired test temperature, which has to be

high enough to dissolve the wax crystals.

9. Calibration and Verification

9.1 Use only a calibrated apparatus as described in 6.1. The

calibration shall be checked periodically using certified refer-

ence standards as described in 9.2 and 9.3. The recommended

interval for viscosity and density calibration is once a month,

FIG. 2 Cell Block

for temperature control once a year. For the calibration

procedure follow the instructions of the manufacturer of the

apparatus.

6.4 Screen, with an aperture of 75 µm, to remove particles

9.2 Certified Viscosity and Density Reference Standards—

from the sample.

These are for use as confirmatory checks on the procedure in

6.5 Magnet, strong enough to remove iron fillings from the

the laboratory. Certified viscosity and density reference stan-

sample. Magnetic stirring rods are suitable.

dards shall be certified by a laboratory, which has shown to

7. Reagents and Materials

meet the requirements of ISO/IEC 17025 or a corresponding

national standard by independent assessment. Viscosity stan-

7.1 Sample Solvent, completely miscible with the sample.

7.1.1 For most samples, a volatile petroleum spirit or dards shall be traceable to master viscometer procedures

described in Test Method D2162. Density standards shall have

naphtha is suitable. If the solvent dries up without residues in

an applicable time frame, the use of a separate drying solvent a certified uncertainty of the density values of 0.0001 g/mL.

The uncertainty of the reference standards shall be stated for

is not required.

7.1.2 For residual fuels, a prewash with an aromatic solvent each certified value (k = 2; 95 % confidence level). See

ISO 5725 or NIST Technical Note 1297.

suchastolueneorxylenemaybenecessarytoremoveasphaltic

material. 9.3 Thermometer—For calibration and adjustment of the

temperature control, a digital thermometer with a probe diam-

7.2 Drying Solvent, a volatile solvent miscible with the

sample solvent (see 7.1). eter of 6.25 mm and a maximal length of 80 mm shall be used.

For smaller probes the use of an adapter is suitable. The

7.2.1 Highly concentrated ethanol (96 % or higher) is suit-

uncertainty (k = 2; 95 % confidence level) of this thermometer

able.

must be no more than 60.01°C and has to be certified by a

7.3 Dry Air or Nitrogen, for blowing the measuring cells.

laboratory which has shown to meet the requirements of

7.3.1 If the measuring cell temperature is below or near the

ISO/IEC 17025 or a corresponding national standard by

dew point temperature of the ambient air, the use of an

independent assessment. A suitable thermometer is available

appropriate desiccator is required.

from the manufacturer of the apparatus.

8. Sampling, Test Specimens, and Test Units

9.4 Acceptable Tolerance—If the determined values of a

8.1 Sampling is defined as all the steps required to obtain an calibration check measurement do not agree within the accept-

able tolerance band of the certified values, as calculated from

aliquot of the contents of any pipe, tank, or other system, and

to place the sample into the laboratory test container. The Annex A1, re-check each step in the procedure, including the

special cleaning procedure from 12.2, to locate the source of

laboratory test container and sample volume shall be of

sufficient capacity to mix the sample and obtain a homoge- error.

neous sample for analysis.

NOTE 1—Values exceeding the acceptable tolerance are generally

8.2 Particles—For samples that are likely to contain par-

attributable to deposits in the measuring cells that are not removed by the

ticles (for example, used oils or crude oils) pass the sample

routine flushing procedure.

through a 75-µm screen to remove the particles. For the

10. Adjustment

removalofironfilingstheuseofamagnetisappropriate.Waxy

samples must be heated to dissolve the wax crystals prior to 10.1 An adjustment has to be carried out when repeated

filtration and a preheated fi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.