ASTM D6702-01

(Test Method)Standard Test Method for Determining the Dynamic Wiping Efficiency of Nonwoven Fabrics Not Used in Cleanrooms (Withdrawn 2008)

Standard Test Method for Determining the Dynamic Wiping Efficiency of Nonwoven Fabrics Not Used in Cleanrooms (Withdrawn 2008)

SIGNIFICANCE AND USE

This test method can be used for acceptance testing of commercial shipments but comparisons should be made with caution because information on estimates of between-laboratory precision is limited as noted in the precision and bias section of this test method.

5.1.1 If there are differences of practical significance between reported test results for two laboratories (or more), comparative tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, samples used for such comparative tests should be as homogeneous as possible, drawn from the same lot of material as the samples that resulted in disparate results during initial testing, and randomly assigned in equal numbers to each laboratory. Other fabrics with established test values may also be used for these comparative tests. The test results from the laboratories involved should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If bias is found, either its cause must be found and corrected, or future test results must be adjusted in consideration of the known bias.

This test method depends on the ability to accurately place a known mass/volume of liquid on the surface, so that an accurate mass of liquid adsorbed may be determined.

This test method is useful to select fabrics with superior cleaning and drying properties that can minimize the costs for spill removal. It can also be used to research fabrics for improved spill removal and for production control.

SCOPE

1.1 This test method covers the quantifying of the dynamic wiping efficiency of nonwoven fabrics.

1.2 This test method applies to all nonwoven fabrics not used in cleanrooms.

Note 1—For dynamic wiping efficiency in cleanrooms, refer to Test Method D 6650 Standard Test Method for Determining the Dynamic Wiping Efficiency, Wet Particle Removal Ability, and Fabric Particle Contribution of Nonwoven Fabrics Used in Cleanrooms.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as the standard. Within the text, the inch-pound units are shown in parentheses. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the quantifying of the dynamic wiping efficiency of nonwoven fabrics.

This test method is being withdrawn with no replacement because D13 no longer has the technical expertise to maintain.

Formerly under the jurisdiction of Committee D13 on Textiles, this test method was withdrawn in October 2008.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6702–01

Standard Test Method for

Determining the Dynamic Wiping Efficiency of Nonwoven

Fabrics Not Used in Cleanrooms

This standard is issued under the fixed designation D 6702; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 cleanroom, n—a room in which the concentration of

airborne particles is controlled, and which is constructed and

1.1 This test method covers the quantifying of the dynamic

used in a manner to minimize the introduction, generation, and

wiping efficiency of nonwoven fabrics.

retention of particles inside the room.

1.2 This test method applies to all nonwoven fabrics not

3.1.1.1 Discussion—In addition to particles, other relevant

used in cleanrooms.

parameters, such as temperature, humidity, and pressure, are

NOTE 1—For dynamic wiping efficiency in cleanrooms, refer to Test

controlled as required. The so-called Class of a cleanroom is

Method D 6650 Standard Test Method for Determining the Dynamic

defined in documents including, but not limited to, Federal

Wiping Efficiency, Wet Particle Removal Ability, and Fabric Particle

Standard209Eastheconcentrationperunitvolumeofparticles

Contribution of Nonwoven Fabrics Used in Cleanrooms.

ofadesignatedsize.Thevarioussystemsforsuchclassification

1.3 The values stated in either SI units or inch-pound units

lie beyond the scope of this document.

are to be regarded separately as the standard. Within the text,

3.1.2 dynamic wiping effıciency, n—in textile fabrics, the

the inch-pound units are shown in parentheses. The values

ability of a fabric to remove water, or other liquids, from a

stated in each system are not exact equivalents; therefore, each

surface, usually for spill removal.

system shall be used independently of the other. Combining

3.1.2.1 Discussion—The ability of a fabric to hold liquid is

values from the two systems may result in nonconformance

largely a function of the composition and consturction of the

with the specification.

fabric. A naturally sorptive fabric made of or with hydrophilic

1.4 This standard does not purport to address all of the

componentswillABSORBliquid(typicallywater),whilethose

safety concerns, if any, associated with its use. It is the

made of hydrophobic materials willADSORB liquid (typically

responsibility of the user of this standard to establish appro-

water) between the interstices of the fibers composing the

priate safety and health practices and determine the applica-

fabric. In many cases, both absorption and adsorption take

bility of regulatory limitations prior to use.

place.

2,3 3.2 For definitions of terms used in this test method refer to

2. Referenced Documents

Terminology D 123.

2.1 ASTM Standards:

D 123 Terminology Relating to Textiles

4. Summary of Test Method

D 6650 Test Method for Determining the Dynamic Wiping

4.1 A quarter-folded fabric swatch is clipped to the under-

Efficiency, Wet Particle Removal Ability, and Fabric Par-

side of a 1-kg sled and pulled through a known challenge of

ticle Contribution of Nonwoven Fabrics Used in Clean-

liquid, usually water, placed on a flat surface directly in front

rooms

of a wiper fabric and sled. The percent of liquid removed from

the surface is determined gravimetrically as the dynamic

3. Terminology

wiping efficiency.

3.1 Definitions:

5. Significance and Use

5.1 This test method can be used for acceptance testing of

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

and is the direct responsibility of Subcommittee D13.90 on Executive.

commercial shipments but comparisons should be made with

Current edition approved August 10, 2001. Published November 2001.

caution because information on estimates of between-

Oathout, J. M., “Determining the Dynamic Efficiency of Cleanroom Wipers for

laboratory precision is limited as noted in the precision and

Removal of Liquids and Particles from Surfaces,” Journal of the IEST, 62 (3),

bias section of this test method.

17–26, May/June 1999.

“Evaluating Wiping Materials Used in Cleanrooms and Other Controlled

5.1.1 If there are differences of practical significance be-

Environments,” IEST-RP-CC004.2, Institute of Environmental Science and Tech-

tween reported test results for two laboratories (or more),

nology, 940 East Northeast Highway, Mount Prospect, IL 60056 (1992).

4 comparative tests should be performed to determine if there is

Annual Book of ASTM Standards, Vol 07.01.

Annual Book of ASTM Standards, Vol 07.02. a statistical bias between them, using competent statistical

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6702–01

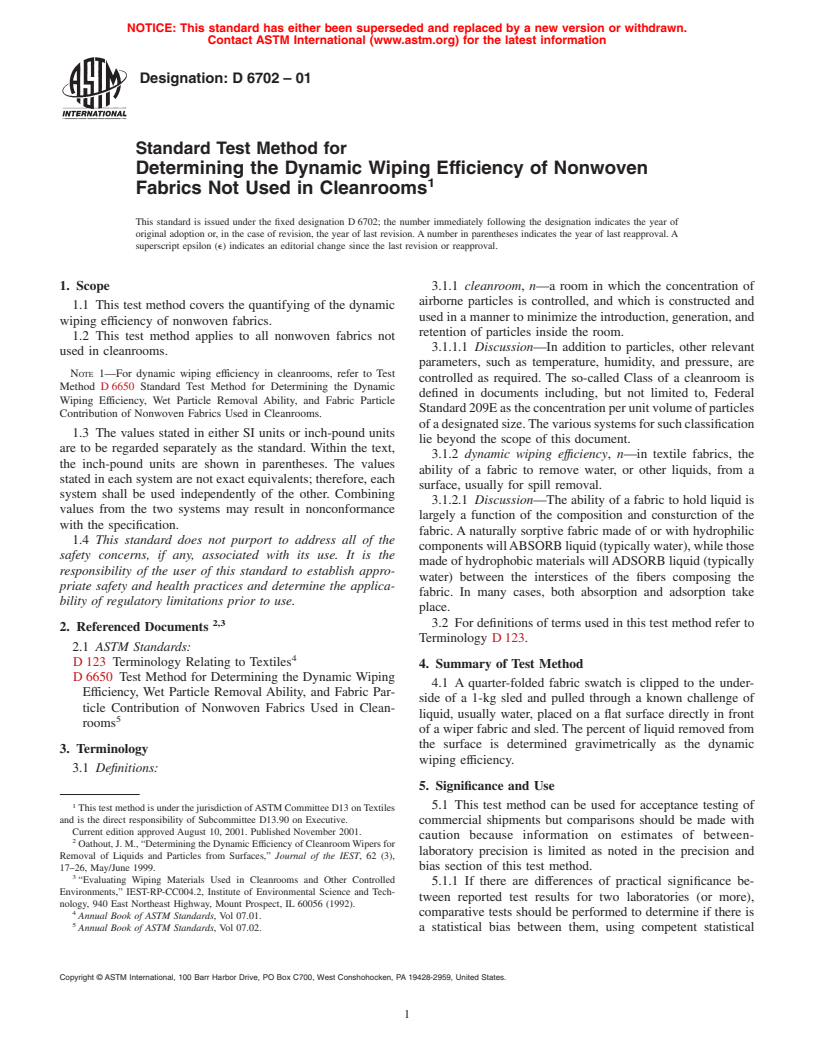

FIG. 1 Illustration of Dynamic Wiping Efficiency Apparatus

assistance. As a minimum, samples used for such comparative end of attached at the midpoint of the yoke and the other end

tests should be as homogeneous as possible, drawn from the attached to a motor (6.1.2) that provides a sled pull rate of 25

same lot of material as the samples that resulted in disparate cm/s (10 in./s). (See Fig. 1).

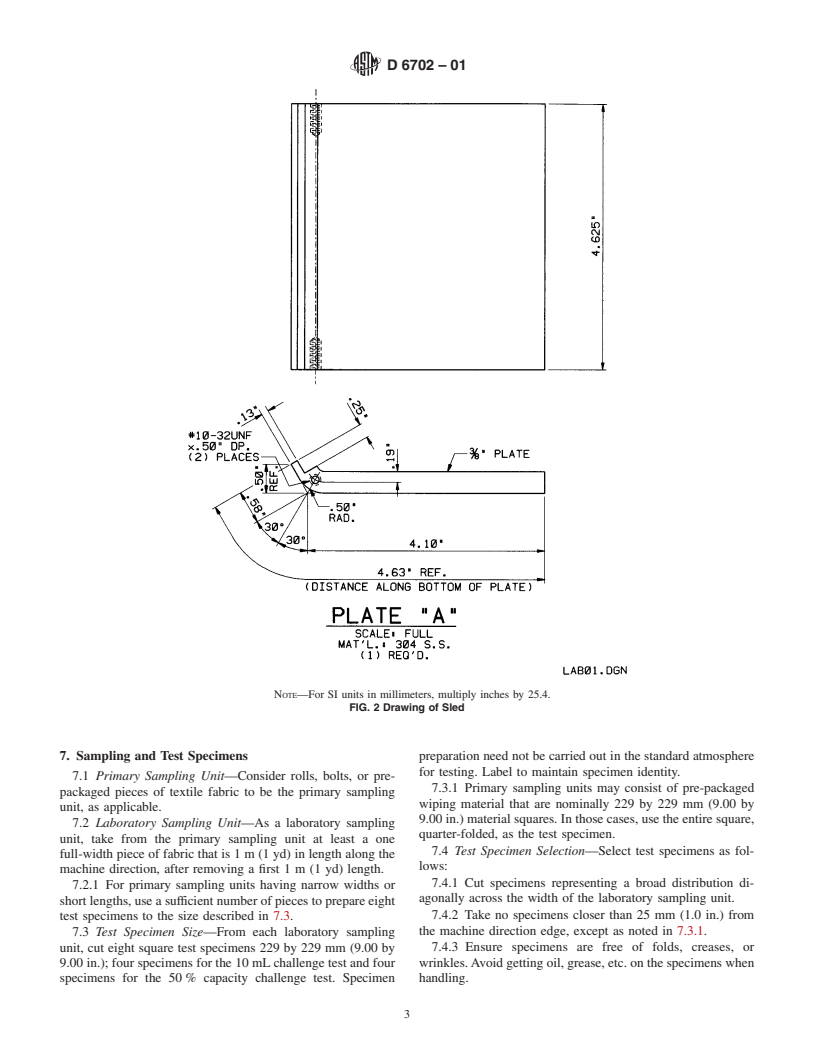

results during initial testing, and randomly assigned in equal 6.1.1 Sled, # 304 stainless steel, 1 kg 6 10g, 117 3 117 mm

numbers to each laboratory. Other fabrics with established test

base, 9.53 mm thick (4.63 by 4.63 in. base, 0.375 in. thick); a

values may also be used for these comparative tests. The test curvedleadingedge,13mm(0.50in.)radius,onthebaseofthe

results from the laboratories involved should be compared

sled forms a lip to which the quarter-folded sample is attached

using a statistical test for unpaired data, at a probability level using a spring-loaded clip. Two stainless steel screws are

chosen prior to the testing series. If bias is found, either its affixed to either outboard edge of the sled in the leading curved

cause must be found and corrected, or future test results must edge. (See Fig. 2).

be adjusted in consideration of the known bias.

6.1.2 Motor, 60 Hz. equipped with a 25 cm (9.84 in.)

5.2 This test method depends on the ability to accurately circumference sheave used as a capstan device to pull the sled

place a known mass/volume of liquid on the surface, so that an

at a constant and uniform speed of 25 cm/s (10 in./s).

accurate mass of liquid adsorbed may be determined. 6.2 Balance, top loading, shielded, 0.01 g readability.

5.3 This test method is useful to select fabrics with superior

6.3 Metal Plate, No. 304, 18 gauge stainless steel, Polish #3

cleaning and drying properties that can minimize the costs for (Brush finish), 61 cm (2 ft) 3 122 cm (4 ft).

spill removal. It can also be used to research fabrics for

6.4 Dispenser,digitalbottletopburette,forreproducibleand

improved spill removal and for production control.

accurate delivery of liquid volumes, Brinkmann Bottletop

Buret, Model 25, or equivalent.

6. Apparatus and Materials

6.5 Liquid, usually water at least distilled grade, or other

liquid when specified.

6.1 Dynamic Wiping Effıciency Test Apparatus, consisting

of a polyester string attached to two stainless steel screws on a 6.6 Tray, or other container, suitable for wetting out a 229

stainless steel sled (6.1.1), forming a yoke, and with a second mm (9.00 in.) square specimen to determine intrinsic soptive

polyester string, approximately 1.5-m (5 ft) long having one capacity (See Annex A1).

D6702–01

NOTE—For SI units in millimeters, multiply inches by 25.4.

FIG. 2 Drawing of Sled

7. Sampling and Test Specimens preparation need not be carried out in the standard atmosphere

for testing. Label to maintain specimen identity.

7.1 Primary Sampling Unit—Consider rolls, bolts, or pre-

7.3.1 Primary sampling units may consist of pre-packaged

packaged pieces of textile fabric to be the primary sampling

wiping material that are nominally 229 by 229 mm (9.00 by

unit, as applicable.

9.00 in.) material squares. In those cases, use the entire square,

7.2 Laboratory Sampling Unit—As a laboratory sampling

quarter-folded, as the test specimen.

unit, take from the primary sampling unit at least a one

7.4 Test Specimen Selection—Select test specimens as fol-

full-width piece of fabric that is1m(1yd)in length along the

lows:

machine direction, after removing a first1m(1yd) length.

7.4.1 Cut specimens representing a broad distribution di-

7.2.1 For primary sampling units having narrow widths or

agonally across the width of the laboratory sampling unit.

short lengths, use a sufficient number of pieces to prepare eight

test specimens to the size described in 7.3. 7.4.2 Take no specimens closer than 25 mm (1.0 in.) from

the machine direction edge, except as noted in 7.3.1.

7.3 Test Specimen Size—From each laboratory sampling

unit, cut eight square test specimens 229 by 229 mm (9.00 by 7.4.3 Ensure specimens are free of folds, creases, or

9.00 in.); four specimens for the 10 mLchallenge test and four wrinkles.Avoid getting oil, grease, etc. on the specimens when

specimens for the 50 % capacity challenge test. Specimen handling.

D6702–01

8. Conditioning of speed of 25 cm/s (10 in./s) along the long axis of the steel

plate for a distance of 1 m (40 in.). Release the tension on the

8.1 No conditioning is required unless otherwise specified

string around the sheave to stop the sled motion.

in a material specification or contract order.

10.7 At the end of 1 m (40 in.) travel, with the sled turned

9. Preparation of Test Apparatus and Calibration fabric-side-up, remove the folded test specimen from the sled,

place on the balance and record its wetted mass, m ,tothe

w

9.1 Ensure the sled pulling speed is as specified.

nearest 0.01 g.

9.2 Verify that the balance is within calibration.

10.8 Continue as directed in 10.1-10.7 until four specimens

9.3 Separate challenges of 10 mLand the volume represent-

have been tested using a 10 mL challenge for each laboratory

ing 50 % of the ply’s capacity are required.

sampling unit.

9.3.1 If the intrinsic sorptive capaci-ty,A[mL/g], of a fabric

i

10.9 Using the remaining four test specimens, test each as

is not already known, determine it on a separate ply of the

directed in 10.1-10.7 using a 50 % capacity challenge for each

material as directed in Annex A1. From the calculated A and

i

laboratory sampling unit.

the measured mass of each fabric, calculate the per-ply

capacity A [mL] for each fabric. This quantity is needed in

ip

11. Calculations

order to calculate to volume representing a 50 % capacity

challenge [0.5A ].

11.1 Calculate the volume of liquid sorbed for individual

ip

9.4 Verify calibration of the burette dispenser. For example:

specimens to the nearest 0.01 mL using Eq 1.

For a burette delivery of 10.00 mL of water, the water at 25°C

~m –

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.