ASTM D2847-22

(Practice)Standard Practice for Testing Engine Coolants in Car and Light Truck Service

Standard Practice for Testing Engine Coolants in Car and Light Truck Service

SIGNIFICANCE AND USE

5.1 The data obtained from the use of this practice will provide a basis for the evaluation of coolant performance in passenger car, and light-duty truck service (according to the test chosen). The data obtained may also be used to provide added significance to the data obtained from simulated service and engine dynamometer tests.

SCOPE

1.1 This practice covers an updated procedure for evaluating corrosion protection and performance of an engine coolant in passenger car, light truck service that closely imitates current vehicle and engine manufacturers’ practices.

Note 1: Coolant evaluation in vehicle service may require considerable time and expense; therefore, the product should be pretested in the laboratory for general acceptability. Typical tests vary from small, closely controlled tests, to large tests where close control is not always practical. The most often referenced protocols for laboratory testing are defined in Specifications D3306, D7714, and D7715.

1.2 The units quoted in this practice are to be regarded as standard. The values given in parentheses are approximate equivalents for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 7.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2847 − 22

Standard Practice for

1

Testing Engine Coolants in Car and Light Truck Service

This standard is issued under the fixed designation D2847; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Corrosion Characteristics of Aluminum Pumps With En-

gine Coolants

1.1 This practice covers an updated procedure for evaluat-

D3306 Specification for Glycol Base Engine Coolant for

ing corrosion protection and performance of an engine coolant

Automobile and Light-Duty Service

inpassengercar,lighttruckservicethatcloselyimitatescurrent

D3321 Test Method for Use of the Refractometer for Field

vehicle and engine manufacturers’ practices.

Test Determination of the Freezing Point of Aqueous

NOTE 1—Coolant evaluation in vehicle service may require consider-

Engine Coolants

able time and expense; therefore, the product should be pretested in the

D4725 Terminology for Engine Coolants and Related Fluids

laboratory for general acceptability. Typical tests vary from small, closely

D5827 Test Method for Analysis of Engine Coolant for

controlled tests, to large tests where close control is not always practical.

The most often referenced protocols for laboratory testing are defined in Chloride and Other Anions by Ion Chromatography

Specifications D3306, D7714, and D7715.

D6130 Test Method for Determination of Silicon and Other

Elements in Engine Coolant by Inductively Coupled

1.2 The units quoted in this practice are to be regarded as

standard. The values given in parentheses are approximate Plasma-Atomic Emission Spectroscopy

equivalents for information only. D7714 Specification for Glycerin Base Engine Coolant for

Automobile and Light-Duty Service

1.3 This standard does not purport to address all of the

D7715 Specification for Fully-Formulated Glycerin Base

safety concerns, if any, associated with its use. It is the

Engine Coolant for Heavy-Duty Engines

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

3. Terminology

mine the applicability of regulatory limitations prior to use.

Specific precautionary statements are given in Section 7.

3.1 Definitions—Refer to Terminology D4725.

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4. Summary of Practice

ization established in the Decision on Principles for the

4.1 Testcoolantshallbeanewcoolant.Thecoolantistested

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical attherecommendedconcentrationinanaqueoussolutionmade

Barriers to Trade (TBT) Committee. with water that complies with the water recommendation

published in Specification D3306. A minimum of five test

2. Referenced Documents vehicles/engines per coolant are required, ten are

2

recommended, but this number may be adjusted by agreement

2.1 ASTM Standards:

between customer and supplier. The test vehicles/engines shall

D1121 Test Method for Reserve Alkalinity of Engine Cool-

have been in service less than 3 months, 3000 miles, 5000 km,

ants and Antirusts

or 500 operating hours. The Original Equipment Manufacturer

D1287 TestMethodforpHofEngineCoolantsandAntirusts

(OEM) may require the replacement of the radiator, heater

D2809 Test Method for Cavitation Corrosion and Erosion-

core, cooling system hoses, and water pump prior to starting

the test depending on vehicle mileage or prior coolant in the

system, or both. Customer and supplier may also choose to

1

This practice is under the jurisdiction of ASTM Committee D15 on Engine

follow requirements published in OEM specifications. The

Coolants and Related Fluids and is the direct responsibility of Subcommittee

cooling system components and coolant are inspected accord-

D15.10 on Dynamometer and Road Tests.

Current edition approved June 1, 2022. Published June 2022. Originally

ing to a prescribed schedule to provide the basis for coolant

approved in 1969. Last previous edition approved in 2015 as D2847 – 15. DOI:

performance evaluation.

10.1520/D2847-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.2 A detailed cleaning and conditioning procedure is es-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

sential to obtain statistically significant and reproducible re-

Standards volume information, refer to the standard’s Document Summary page on

the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2847 − 15 D2847 − 22

Standard Practice for

1

Testing Engine Coolants in Car and Light Truck Service

This standard is issued under the fixed designation D2847; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

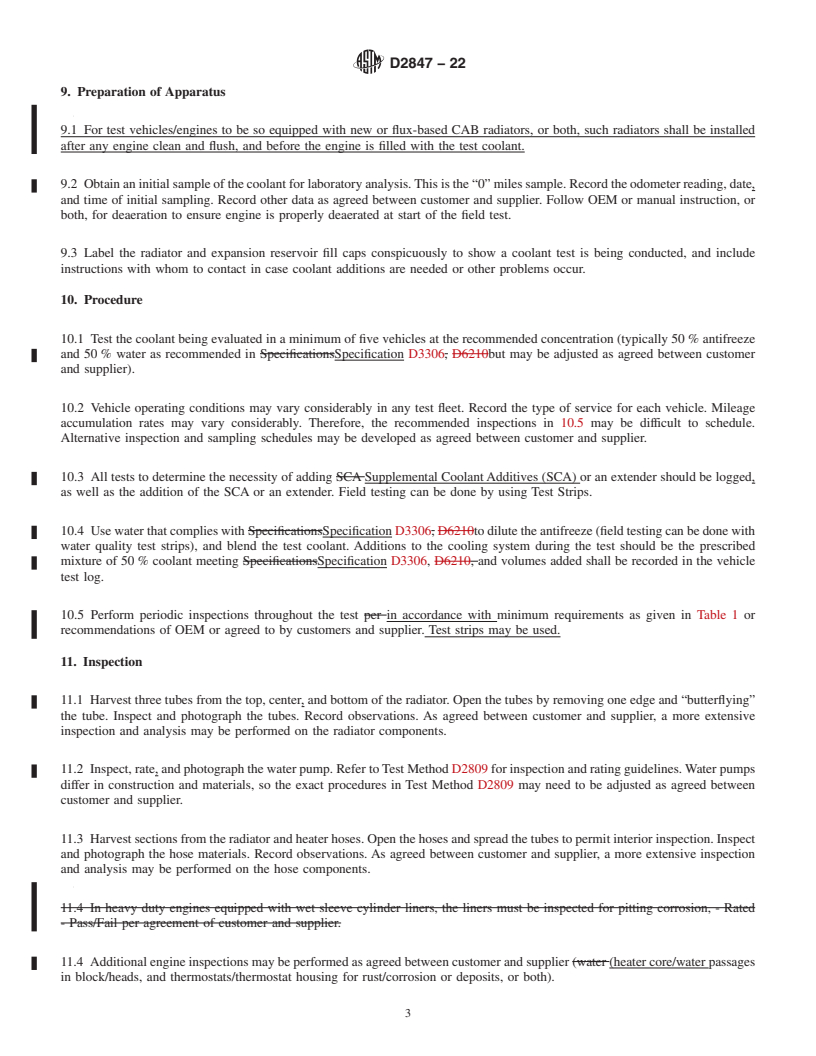

1.1 This practice covers an updated procedure for evaluating corrosion protection and performance of an engine coolant in

passenger car, light and heavy duty truck service that closely imitates current vehicle and engine manufacturersmanufacturers’

practices.

NOTE 1—Coolant evaluation in vehicle service may require considerable time and expense; therefore, the product should be pretested in the laboratory

for general acceptability. Typical tests vary from small, closely controlled tests, to large tests where close control is not always practical. The most often

referenced protocols for laboratory testing are defined in Specifications D3306, D6210, D7517, D7518, D7714, and D7715.

1.2 The units quoted in this practice are to be regarded as standard. The values given in parentheses are approximate equivalents

for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 7.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1121 Test Method for Reserve Alkalinity of Engine Coolants and Antirusts

D1287 Test Method for pH of Engine Coolants and Antirusts

D2809 Test Method for Cavitation Corrosion and Erosion-Corrosion Characteristics of Aluminum Pumps With Engine Coolants

D3306 Specification for Glycol Base Engine Coolant for Automobile and Light-Duty Service

D3321 Test Method for Use of the Refractometer for Field Test Determination of the Freezing Point of Aqueous Engine Coolants

D4725 Terminology for Engine Coolants and Related Fluids

D5827 Test Method for Analysis of Engine Coolant for Chloride and Other Anions by Ion Chromatography

D6130 Test Method for Determination of Silicon and Other Elements in Engine Coolant by Inductively Coupled Plasma-Atomic

Emission Spectroscopy

D6210 Specification for Fully-Formulated Glycol Base Engine Coolant for Heavy-Duty Engines

D7517 Specification for Fully-Formulated 1,3 Propanediol (PDO) Base Engine Coolant for Heavy-Duty Engines

1

This practice is under the jurisdiction of ASTM Committee D15 on Engine Coolants and Related Fluids and is the direct responsibility of Subcommittee D15.10 on

Dynamometer and Road Tests.

Current edition approved May 1, 2015June 1, 2022. Published June 2015June 2022. Originally approved in 1969. Last previous edition approved in 20142015 as

D2847 – 14.D2847 – 15. DOI: 10.1520/D2847-15.10.1520/D2847-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2847 − 22

D7518 Specification for 1,3 Propanediol (PDO) Base Engine Coolant for Automobile and Light-Duty Service

D7714 Specification for Glycerin Base Engine Coolant for Automobile and Light-Duty Service

D7715 Specification for Fully-Formulated Glycerin Base Engine Coolant for Heavy-Duty Engines

3. Terminology

3.1 Definitions—Refer to Terminology D4725.

4. Summary of Practice

4.1 Test coolant shall be a new coolant. The coolant is tested at the recommended concentration in an aqueous solution made with

water that complies with the water recommendation published in SpecificationsSpecification D3306 and D6210. A minimum of

five test vehiclesvehicles/engines per coolant are required, ten are re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.