ASTM D5652-95(2000)

(Test Method)Standard Test Methods for Bolted Connections in Wood and Wood-Base Products

Standard Test Methods for Bolted Connections in Wood and Wood-Base Products

SCOPE

1.1 These test methods cover procedures for evaluating the strength and stiffness of single-bolted connections in wood or wood-base products when subjected to static loading. These test methods serve as a basis for determining the effects of various factors on the strength and stiffness of the connection.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5652 – 95 (Reapproved 2000)

Standard Test Methods for

Bolted Connections in Wood and Wood-Based Products

This standard is issued under the fixed designation D 5652; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope compressive or tensile forces applied at a constant rate of

deformation with a suitable testing machine. The deformation

1.1 These test methods cover procedures for evaluating the

of the connection at various intervals of loading is measured.

strength and stiffness of single-bolted connections in wood or

Supplementary physical properties of the wood or wood-based

wood-based products when subjected to static loading. These

members are also determined.

test methods serve as a basis for determining the effects of

various factors on the strength and stiffness of the connection.

4. Significance and Use

1.2 The values stated in inch-pound units are to be regarded

4.1 Connections are one of the weakest links in wood

as the standard. The SI units in parentheses are for information

construction. While the strength of metal bolts and of wood or

only.

wood-based products are ascertainable, a full evaluation of the

1.3 This standard does not purport to address all of the

performance of the combination is only possible through the

safety concerns, if any, associated with its use. It is the

testing of a complete connection. Such variables as member

responsibility of the user of this standard to establish appro-

thickness, member width, end and edge distances, type of bolt,

priate safety and health practices and determine the applica-

fabrication tolerances, moisture content of the wood or wood-

bility of regulatory limitations prior to use.

based product, preservative or fire-retardant treatment of the

2. Referenced Documents wood or wood-based product, and species of wood may affect

connection behavior. In order to develop design criteria for

2.1 ASTM Standards:

established bolt types as well as those under development, the

D 2395 Test Methods for Specific Gravity of Wood and

effect of these variables on connection strength and stiffness

Wood-Base Materials

must be known. The tests described herein permit the obser-

D 2915 Method for Evaluating Allowable Properties for

vation of data on the strength and stiffness of wood or

Grades of Structural Lumber

wood-based connections, or both, under the influence of any or

D 4442 TestMethodsforDirectMoistureContentMeasure-

all of these factors.

ment of Wood and Wood-Base Materials

E 4 Practice for Force Verification of Testing Machines

5. Apparatus

F 606 Test Methods for Determining the Mechanical Prop-

5.1 Testing Machine—Any suitable testing machine capable

erties of Externally and Internally Threaded Fasteners,

4 of operation at a constant rate of motion of its movable head

Washers, and Rivets

and having an accuracy of 61 % when calibrated in accor-

2.2 Federal Specification:

5 dance with Practices E 4.

Fed. Spec. FF-W-92 for Washers, Metal, Flat (Plain)

5.2 Spherical Bearing Block, for compressive loading of

3. Summary of Test Methods specimens.

5.3 Grips—Gripping devices capable of attaching the speci-

3.1 Specimens consisting of at least one wood or wood-

men to the stationary and moving heads of the testing machine

based member fastened with one bolt to at least one other

in such a way as to ensure true axial tensile loads.

member of any material are evaluated for capacity to resist

5.4 Deformation Gages—At least two dial gages with a

least reading of 0.001 in. (0.025 mm) or other suitable devices

These test methods are under the jurisdiction of ASTM Committee D07 on for measuring the slip between connection members during

Wood and are the direct responsibility of Subcommittee D07.05 on Wood Assem-

load application.

blies.

Current edition approved Jan 15, 1995. Published March 1995.

6. Sampling

Annual Book of ASTM Standards, Vol 04.10.

Annual Book of ASTM Standards, Vol 03.01.

6.1 Sampling shall provide for selection of representative

Annual Book of ASTM Standards, Vol 15.08.

test specimens that are appropriate to the objectives of the

Available from Superintendent of Documents, U.S. Government Printing

testing program.

Office, Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

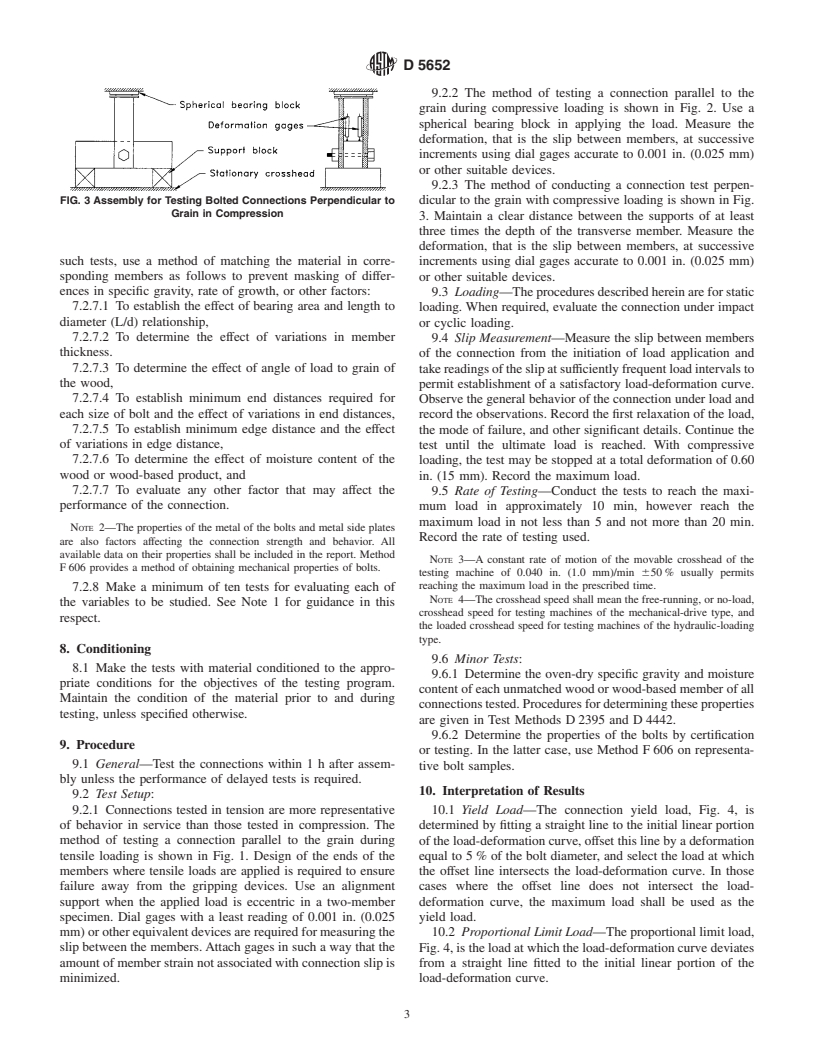

D 5652

6.2 Estimate sample size in accordance with the procedures

of Method D 2915.

NOTE 1—The precision required, and thus, the manner of sampling and

the number of tests, depend upon the specific test objectives. No specific

criteria can therefore be established. General experience indicates that the

coefficients of variation from tests on connections range from approxi-

mately 15 to 30 %.

7. Sampling: Test Specimens and Test Units

7.1 Select wood members, and position the bolt in them in

such a way that the results are not affected by knots, cross

grain, or other natural or manufacturing characteristics unless

thepurposeofthetestmethodsistoevaluatetheeffectsofsuch

growth characteristics. When the affects of growth character-

istics are not being evaluated, wood members shall be essen-

tially clear and straight-grained. For wood-based products,

select specimens with regard to manufactured characteristics.

7.2 Connections Containing One Bolt:

7.2.1 Make tests on three-member connections as shown in

Figs. 1-3 except where specific data on two- or multiple-

memberconnectionsarebeingsought.Selectthewidth,length,

and thickness of the members with consideration of required

edge and end distances. Member dimensions shall be represen-

tative of the intended use of the connection.

7.2.2 For connections involving metal or other side mem-

bers (such as panel materials), the side member thickness shall

be that anticipated in service. For all-wood joints, the thickness

of each side member shall be at least one half of the thickness

of the center member and width and length of all members

shall be selected with consideration of required edge and end

distances for a specific application. Minimum end distance

shall be four bolt diameters for compression loading and seven

bolt diameters for tension loading, unless the effect of various

end distances is to be studied.

7.2.3 The excess of bolt-hole diameter over bolt diameter

1 1

shall be ⁄32 in. (0.8 mm) for bolts ⁄2 in. (13 mm) or less in

diameter, and ⁄16 in. (1.6 mm) for bolts of larger diameter,

unless other bolt-hole diameters are specified.

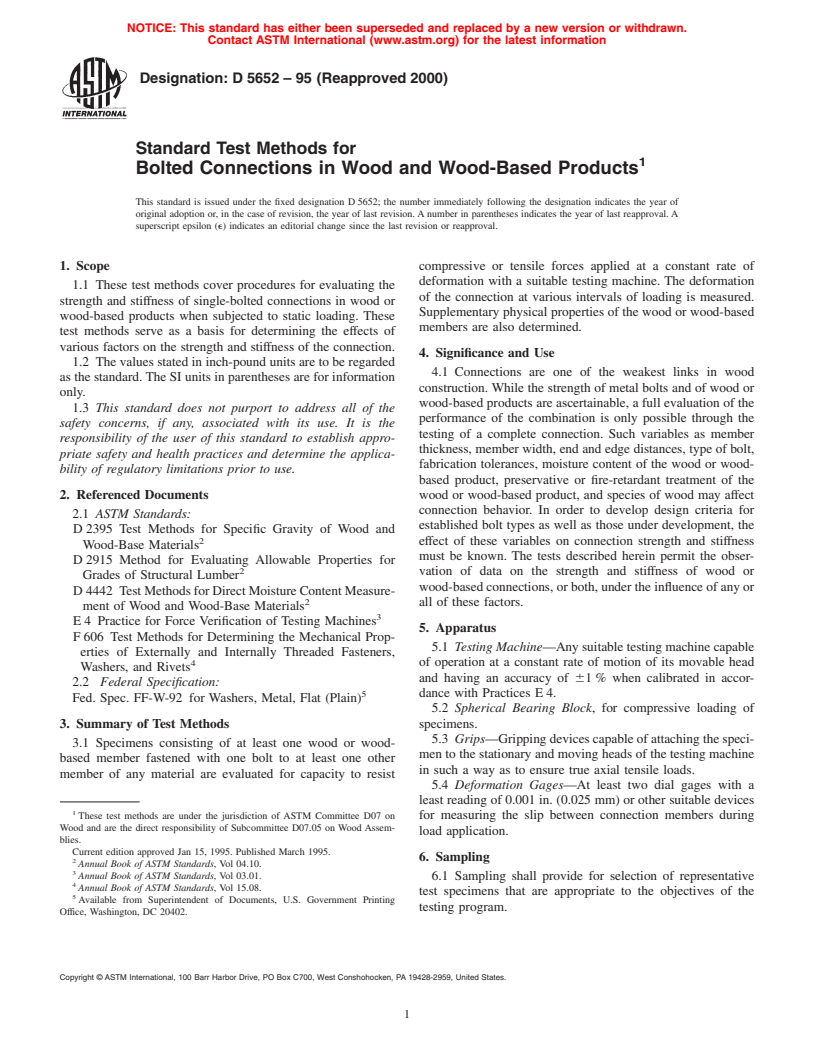

FIG. 1 Assembly for Testing Bolted Connections Parallel to Grain

7.2.3.1 Bolt-holes shall be precisely bored perpendicular to

in Tension

the surface, so that the surface of the hole is smooth and

uniform to ensure good bearing of the bolt. Holes shall be

drilled after members are conditioned unless the purpose of the

test is to study the effect of shrinkage on the performance of

bolted connections.

7.2.4 Bolts shall be of sufficient length to penetrate all

members without having any member bear on the bolt threads.

7.2.5 Place heavy round washers conforming to Fed. Spec.

FF-W-92 for washers, metal, flat (plain), and hereafter referred

to as a standard washer, between wood or wood-based side

members and bolt head and nut. Bring abutting faces of

connection members into normally installed contact; then back

off the nut and retighten to “finger tightness”.

FIG. 2 Assembly for Testing Bolted Connections Parallel to Grain

7.2.6 Primary tests shall be made on connections loaded

in Compression

parallel to the grain of wood members and perpendicular to the

grain of wood members. Perpendicular to the grain tests shall

be conducted with the grain of the center member parallel and be made by applying compressive or tensile loads as required;

the side members perpendicular to the direction of the load or however, application of tensile load is preferred.

with the grain of the center member perpendicular and the side

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.