ASTM D3374-99

(Specification)Standard Specification for Vinyl-Coated Glass Yarns

Standard Specification for Vinyl-Coated Glass Yarns

SCOPE

1.1 This specification covers vinyl-coated glass yarns. These yarns are manufactured in two basic classes. These classes have been established that when properly woven into screening, satisfactory strength, durability, and insect protection are obtained. The two classes are as follows:

1.1.1 Class 1 -Nominal thickness 0.292 mm (0.0115 in.).

1.1.2 Class 2 -Nominal thickness 0.330 mm (0.0130 in.).

1.2 This specification shows the values in both SI units and inch-pound units. "SI units" is the technically correct name for a system of metric units known as the International System of Units. "Inch-pound units" is the technically correct name for the customary units used in the United States. The values stated in inch-pound units are to be regarded as the standard. The values in SI units are provided for information only.

1.3 The following precautionary statement pertains only to the test method portions, Sections 12 through 21, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3374 – 99

Standard Specification for

Vinyl-Coated Glass Yarns

This standard is issued under the fixed designation D 3374; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* D 4329 Practice for Fluorescent UV Exposure of Plastics

D 4909 Test Method for Color Stability of Vinyl-Coated

1.1 This specification covers vinyl-coated glass yarns.

Glass Textiles to Accelerated Weathering

These yarns are manufactured in two basic classes. These

D 4963 Test Method for Ignition Loss of Glass Strands and

classes have been established that when properly woven into

Fabrics

screening, satisfactory strength, durability, and insect protec-

2.2 ANSI/ASQC Standards:

tion are obtained. The two classes are as follows:

ANSI/ASQC Z1.4 Sampling Procedures for Inspection by

1.1.1 Class 1—Nominal thickness 0.292 mm (0.0115 in.).

Attributes

1.1.2 Class 2—Nominal thickness 0.330 mm (0.0130 in.).

ANSI/ASQC Z1.9 Sampling Procedures and Tables for

1.2 The values stated in either SI or inch-pound units are to

Inspection by Variables for Percent Nonconforming

be regarded separately as standard. The values stated in each

2.3 Federal Standard:

system may not be exact equivalents; therefore, each system

CCC-D-950 Specification, Dyeing and After Treating Pro-

shall be used independently of the other. Combining values

cesses for Cotton Cloths

from the two systems may result in nonconformance with this

2.4 AATCC Standard:

specification.

Evaluation Procedure 1, Gray Scale for Color Change

1.3 The following precautionary statement pertains only to

the test method portions, Sections 12–21, of this specification.

3. Terminology

This standard does not purport to address all of the safety

3.1 Definitions:

concerns, if any, associated with its use. It is the responsibility

3.1.1 moisture equilibrium, n—the condition reached by a

of the user of this standard to establish appropriate safety and

material when it no longer takes up moisture from, or gives up

health practices and determine the applicability of regulatory

moisture to, the surrounding atmosphere.

limitations prior to use.

3.1.2 vinyl-coated glass yarn, n—glass continuous filament

2. Referenced Documents yarn, coated with a pigment and plasticized vinyl chloride

2 resin.

2.1 ASTM Standards:

3.1.3 For terminology of other textile terms used in this

D 123 Terminology Relating to Textiles

specification, refer to Terminology D 123.

D 578 Specification for Glass Fiber Strands

D 885 Test Methods for Tire Cords, Tire Cord Fabrics, and

4. Sampling and Number of Specimens

IndustrialFilamentYarnsMadeFromMan-MadeOrganic-

4.1 Lot Sample—As a lot sample for acceptance testing,

Base Fibers

take at random the number of yarn packages directed in an

D 1776 Practice for Conditioning and Testing Textiles

applicable material specification or other agreement between

D 1907 Test Method forYarn Number by the Skein Method

the purchaser and the supplier. Consider yarn packages to be

D 2256 Test Method for Tensile Properties of Yarns by the

the primary sampling unit. In the absence of such agreement,

Single-Strand Method

proceed as follows:

This specification is under the jurisdiction of ASTM Committee D-13 on

Textiles and is the direct responsibility of Subcommittee D13.18 on Glass Fiber and

Its Products. Available from American National Standards Institute, 11 W. 42nd St., 13th

Current edition approved Sept. 10, 1999. Published January 2000. Originally Floor, New York, NY 10036.

published as D 3374 – 75. Last previous edition D 3374 – 94. Available from General Services Administration, Specification and Consumer

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Information Distribution Section (WFSIS), Washington Navy Yard, Bldg. 197,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Washington, DC 20407.

Standards volume information, refer to the standard’s Document Summary page on Available from American Association of Textile Chemists and Colorists, P.O.

the ASTM website. Box 12215, Research Triangle Park, NC 27709.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3374–99

4.1.1 Yarn Number, Ignition Loss, and Strength—Take the 6. Put-Up

number of yarn packages specified inANSI/ASQZ Z1.9 using

6.1 The vinyl-coated glass yarn shall be put up on packages

the count of yarn packages in the lot as a measure of the lot

or tubes, and in containers whose dimensions shall be agreed

size.

upon between the purchaser and the supplier.

4.1.2 Color and Workmanship—Take the number of yarn

7. Yarn Number, Ignition Loss, and Breaking Strength

packages specified in ANSI/ASQZ Z1.4 using the count of

yarn packages in the lot as a measure of the lot size.

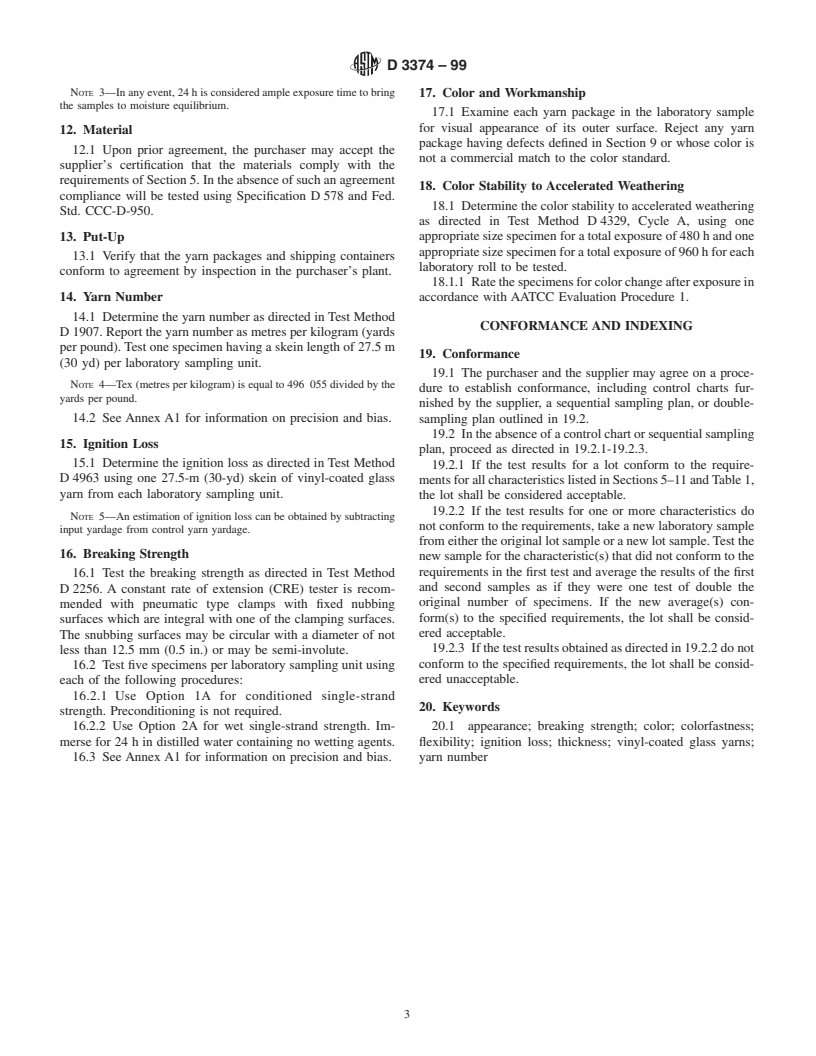

7.1 The requirements of yarn number, ignition loss, and

4.1.3 Color Stability to Accelerated Weathering—Use the breaking strength are specified in Table 1.

yarn packages taken as a lot sample for strength, and yarn

8. Color

number as the lot sample for color stability to accelerated

weathering.

8.1 Samples shall be a commercial match to color standards

agreed upon between the purchaser and the supplier.

NOTE 1—An adequate specification or other agreement between the

purchaser and the supplier requires taking into account the variability NOTE 2—Gray and charcoal are considered standard colors.They are in

between shipping cartons, yarn packages, yarn within a shipping carton, general use and demand and are the most readily available. Other colors

and test specimens from a yarn package to produce a sampling plan with are usually available on a made-to-order basis.

meaningful producer’s risk, consumer’s risk, acceptable quality level, and

9. Workmanship

limiting quality level.

9.1 As agreed upon between the purchaser and the supplier,

4.2 Laboratory Sample—As a laboratory sample for accep-

the following defects shall be considered cause for rejection of

tance testing, proceed as follows:

the yarn package in which they occur:

4.2.1 Yarn Number, Ignition Loss, Strength, Color, and

9.1.1 Uncoated or partially coated sections of yarn.

Workmanship—Use the lot sampling units as laboratory sam-

9.1.2 Slubs, large lumps, or coating irregularities of such

pling units.

degree as to adversely affect weaveability of the yarn or cause

4.2.2 Color Stability to Accelerated Weathering and Low-

excessive rejects of the final product. Small irregularities that

Temperature Flexibility—Use every fifth yarn package in the

represent inherent characteristics of the coating are permitted.

lot sample for strength, and yarn number as the laboratory

9.1.3 Yarns that have been bruised, cut, or mashed.

samplingunits.Forsmalllots,takeatleastoneyarnpackageas

9.1.4 Splices exceeding 25 mm (1 in.) in length or having

a laboratory sampling unit.

unbonded or fused ends.

4.3 Test Specimens—Proceed as follows:

9.1.5 Any defect affecting the free unhampered unwinding

4.3.1 Yarn Number, Ignition Loss, and Strength—Take the of yarn or affecting the secure holding of yarn winds on the

number of specimens per laboratory sampling unit specified in package.

the applicable test method. Evaluate the results of testing using

10. Color Stability toAccelerated Weathering

ANSI/ASQ Z1.9, Inspection Level IV, normal inspection, and

an acceptable quality level of 1.5 %.

10.1 When tested as specified in Section 18, the observed

color change after 480 h shall be no greater than Step 3 on the

4.3.2 Color and Workmanship—Use the yarn packages in

the lot sample as the specimens. Evaluate the results of grayscaleandafter960hshallbenogreaterthanStep2onthe

gray scale.

inspecting the specimens using ANSI/ASQZ Z1.4, Inspection

Level II, normal inspection, and an acceptable quality level of 10.2 When agreed upon between the purchaser and the

supplier, other exposure periods and other gray scale ratings

1.5 %.

may be acceptable.

4.3.3 Color Stability to Accelerated Weathering—Take the

number of specimens per laboratory sampling unit specified in

TEST METHODS

the test methods.

11. Conditioning

REQUIREMENTS

11.1 Condition the laboratory samples without precondi-

tioning for a period of at least 5 h in the atmosphere for testing

5. Material

glass textiles as directed in Practice D 1776, unless otherwise

5.1 Input Yarn—The yarn shall be glass continuous filament

specified.

glass yarn which meets the requirements of Specification

D 578 for the applicable yarn construction.

A

TABLE 1 Physical Property Requirements

5.2 Plastic Coating—The material used to coat or impreg-

Ignition Breaking Strength,

nate the glass continuous filament yarn shall be a compound of

Classi- Yarn Number, text (yd/lb)

Loss, min, N (lbf)

fication

polymerized or copolymerized vinyl chloride resin, plasticized

min nominal max min,% Conditioned Wet

with phosphate or phthalate ester plasticizers exclusively,

Class 1 99 (5000) 91 (5450) 84 (5900) 58 17.8 (4.0) 15.6

(3.5)

pigmented and stabilized to meet the requirements herein.

5.2.1 Optional Plasticizer—As agreed upon between the

Class 2 160 (3100) 136 (3650) 118 (4200) 53 28.9 (6.5) 24.5

(5.5)

purchaser and the supplier, pasticizers other than phosphates

A

and phthalates may be used. Nominal values are supplied for information only.

D3374–99

NOTE 3—In any event, 24 h is considered ample exposure time to bring

17. Color and Workmanship

the samples to moisture equilibrium.

17.1 Examine each yarn package in the laboratory sample

for visual appearance of its outer surface. Reject any yarn

12. Material

package havi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.